Production method and production apparatus for insoluble sulfur

A production method and technology of sulfur, applied in the field of insoluble sulfur production methods and production equipment, can solve the problems of impurities brought in, environmental dust cannot be completely avoided, and technical difficulty is large, so as to achieve good crushing effect, no dust pollution, and eliminate dust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

[0020] In order to facilitate specific description in conjunction with the accompanying drawings, the structure of the insoluble sulfur production equipment of the present invention will be described in detail below.

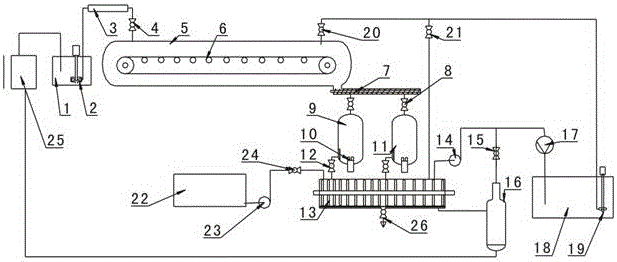

[0021] like figure 1 As shown, the production equipment of the insoluble sulfur of the present invention comprises a sulfur melting tank 1, a liquid sulfur pump 2, an electric heater 3, a reaction tank 5, a conveyor belt 6, a screw conveyor 7, an aging tank 9, a colloid mill 10, a sieve Net 11, rake dryer 13, vacuum pump 14, distillation tower 16, condenser 17, naphthenic oil storage tank 22, submerged pump 19, carbon disulfide storage tank 18, metering pump 23, sulfur purifier 25, liquid sulfur pump 2 Placed in the sulfur melting tank 1, the outlet of the liquid sulfur pump 2 is connected to the inlet of the electric heater 3, the outlet of the electric hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com