Prepn process of pseudoboehmite for luminescent material

A pseudo-boehmite, luminescent material technology, applied in luminescent materials, chemical instruments and methods, aluminum compounds, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

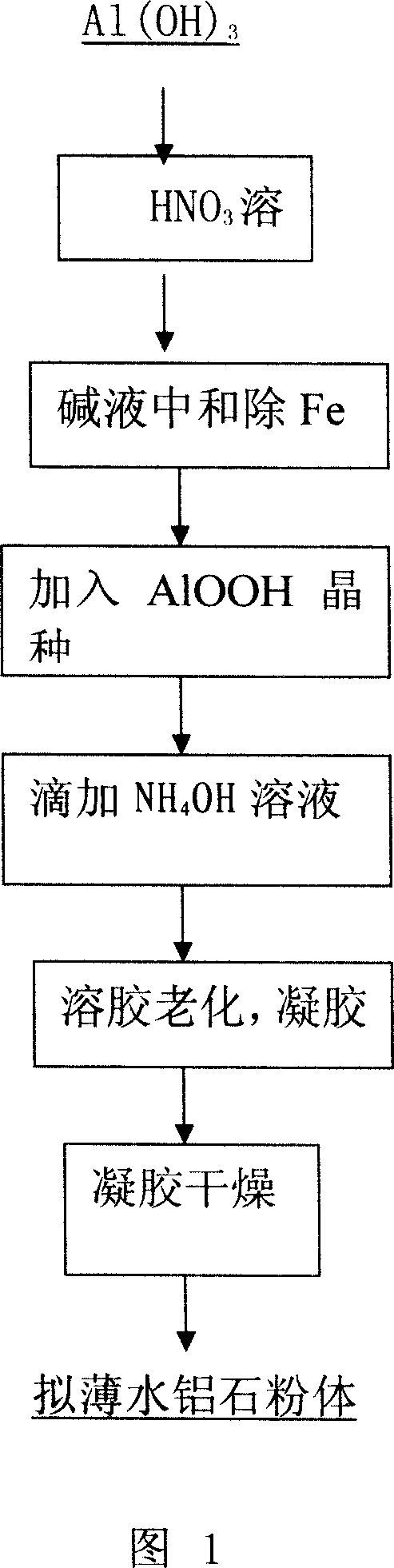

Method used

Image

Examples

preparation example Construction

[0015] The preparation of said aluminum gel is to add dropwise the concentration of NH 0.5mol / L in the Fe solution under the condition of mechanical stirring. 4 OH solution, until the Fe-removing solution turns into a transparent sol, the gel forming temperature is 50-90°C, and it is carried out in a water bath; then the obtained sol is left to age for 6-12 hours, and turns into an aluminum gel.

[0016] Said drying means drying the aluminum gel in an oven at a temperature of 110°C-120°C for 24-72 hours until it reaches a constant weight.

[0017] The following examples are to further illustrate the process characteristics of the present invention without limiting the present invention.

example 1

[0019] Weigh 100 grams of Al(OH) 3 Put it into a beaker and dissolve it with a 50% nitric acid solution to control Al(OH) 3 : HNO 3 Mass ratio=1:2, mechanically stirred at room temperature for 3 hours to obtain an acidic aluminum salt solution; continue to stir, and add dropwise a concentration of 0.5mol / L NH 4 HCO 3 Aqueous solution until pH = 7, to obtain a suspension; the suspension is vacuum filtered, the filter residue is discarded, and the Fe-removing solution is obtained; the Fe-removing solution is transferred to a constant temperature water bath, and the temperature is controlled at 50°C. AlOOH seed crystals with a purity of 99% and a particle size of about 50nm were added to the 2 o 3,氢氧化铝 : Al 2 o 3,拟薄水铝石 : = 1: 0.05 meter; continue to stir, and dropwise add NH with a concentration of 0.5mol / L 4 OH solution until the purified solution turns into a transparent sol; the obtained sol is left to stand for 6 hours, and then turns into an aluminum gel, which is dri...

example 2

[0021] Weigh 100 grams of Al(OH) 3 Put it into a beaker and dissolve it with a 50% nitric acid solution to control Al(OH) 3 : HNO 3 Mass ratio=1:3, mechanically stirred at room temperature for 4 hours to obtain an acidic aluminum salt solution; continue to stir, and add dropwise a concentration of 0.5mol / L NH 4 HCO 3 Aqueous solution, until pH = 8, to obtain a suspension; the suspension is vacuum filtered, the filter residue is discarded, and the Fe-removing liquid is obtained; the Fe-removing liquid is transferred to a constant temperature water bath, and the temperature is controlled at 70 ° C. AlOOH seed crystals with a purity of 99% and a particle size of about 50nm were added to the 2 o 3,氢氧化铝 : Al 2 o 3,拟薄水铝石 : = 1: 0.08 meter; continue to stir, and dropwise add NH with a concentration of 0.5mol / L 4 OH solution until the purified solution turns into a transparent sol; the obtained sol is left to stand for 8 hours, and then turns into an aluminum gel, which is drie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com