Environment-friendly water-base automatic-flowing fettling material and preparation method thereof

A furnace charging and environment-friendly technology, applied in the field of unshaped refractory materials, can solve the problems of health impact of workers, pollution of the on-site workshop environment, intolerant of slag erosion, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

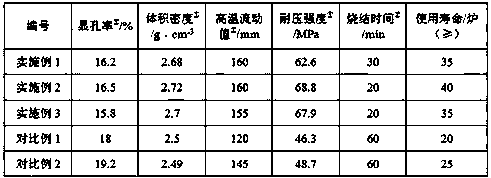

Embodiment 1

[0037] This example is used to illustrate the environment-friendly water-based self-flowing furnace charge and its preparation method of the present invention.

[0038] The environmentally friendly water-based self-flowing furnace charge contains the following components by weight percentage: 30% of mid-grade sintered magnesia, 20% of 97 fused magnesia, 15% of 98 fused magnesia, 6% of silicon micropowder, 5% of white carbon black %, 98 metal silicon 6%, activated alumina micropowder 7%, alumina silica sol 8.5%, SD 80 1%, lignin 1.5%; And the percentage by weight of middle-grade sintered magnesia is: 5-3mm 30%; 3-1mm 35%; The weight percent of 97 fused magnesia is: 5-3mm 20%; 3-1mm 35%; 1-0mm 45%; the particle size of the 98 fused magnesia is: 250 mesh.

[0039] The preparation method comprises the following steps:

[0040] Use a forced concrete mixer to mix the above materials. The order of feeding is to mix the mid-grade sintered magnesia, 97 fused magnesia, 98 fused magnes...

Embodiment 2

[0042] This example is used to illustrate the environment-friendly water-based self-flowing furnace charge and its preparation method of the present invention.

[0043] The environmentally friendly water-based self-flowing furnace charge contains the following components by weight percentage: mid-grade sintered magnesia 15%, 97 fused magnesia 28%, 98 fused magnesia 19%, silicon micropowder 8%, white carbon black 3 %, 98 metal silicon 8%, activated alumina micropowder 6%, alumina silica sol 10%, SD 80 1%, lignin 2%; And the percentage by weight of medium-grade sintered magnesia is: 5-3mm 15%; 3-1mm 45%; The weight percent of 97 fused magnesia is: 5-3mm 15%; 3-1mm 45%; 1-0mm 40%; the particle size of the 98 fused magnesia is: 250 mesh.

[0044] The preparation method comprises the following steps:

[0045]Use a forced concrete mixer to mix the above materials. The order of feeding is to mix the mid-grade sintered magnesia, 97 fused magnesia, 98 fused magnesia, silicon micropow...

Embodiment 3

[0047] This example is used to illustrate the environment-friendly water-based self-flowing furnace charge and its preparation method of the present invention.

[0048] The environmentally friendly water-based self-flowing furnace charge contains the following components by weight percentage: 35% of mid-grade sintered magnesia, 20% of 97 fused magnesia, 15% of 98 fused magnesia, 5% of silicon micropowder, 3% of white carbon black %, 98 metal silicon 6%, activated alumina micropowder 6%, aluminum silica sol 6%, SD 80 1%, lignin 3%; And the percentage by weight of medium-grade sintered magnesia is: 5-3mm 15%; 3-1mm 45%; The weight percent of 97 fused magnesia is: 5-3mm 30%; 3-1mm 35%; 1-0mm 35%; the particle size of the 98 fused magnesia is: 250 mesh.

[0049] The preparation method comprises the following steps:

[0050] Use a forced concrete mixer to mix the above materials. The order of feeding is to mix the mid-grade sintered magnesia, 97 fused magnesia, 98 fused magnesia,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com