Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "To achieve the purpose of rust prevention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

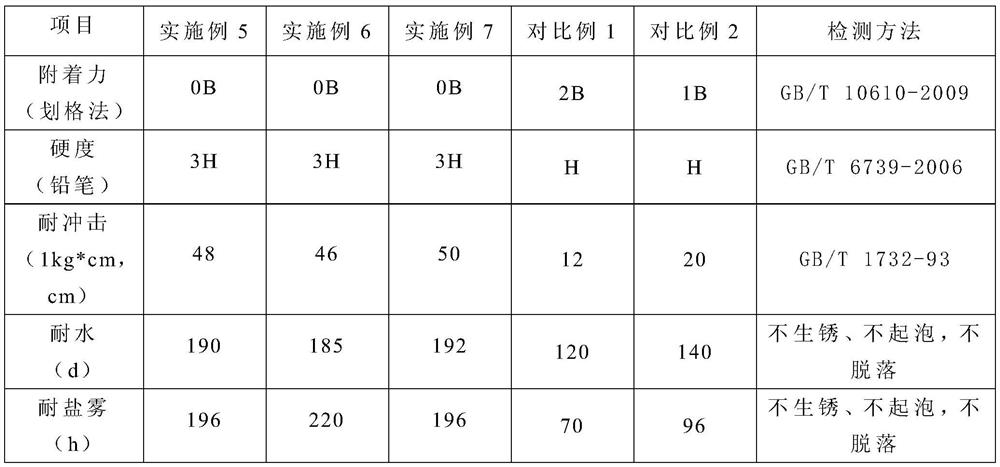

Acrylate copolymer emulsion, and aqueous industrial anticorrosive paint adopting acrylate copolymer emulsion as film forming substance

ActiveCN105859936AReduce the temperatureGuaranteed compactnessAnti-corrosive paintsCross-linkSodium bisulfate

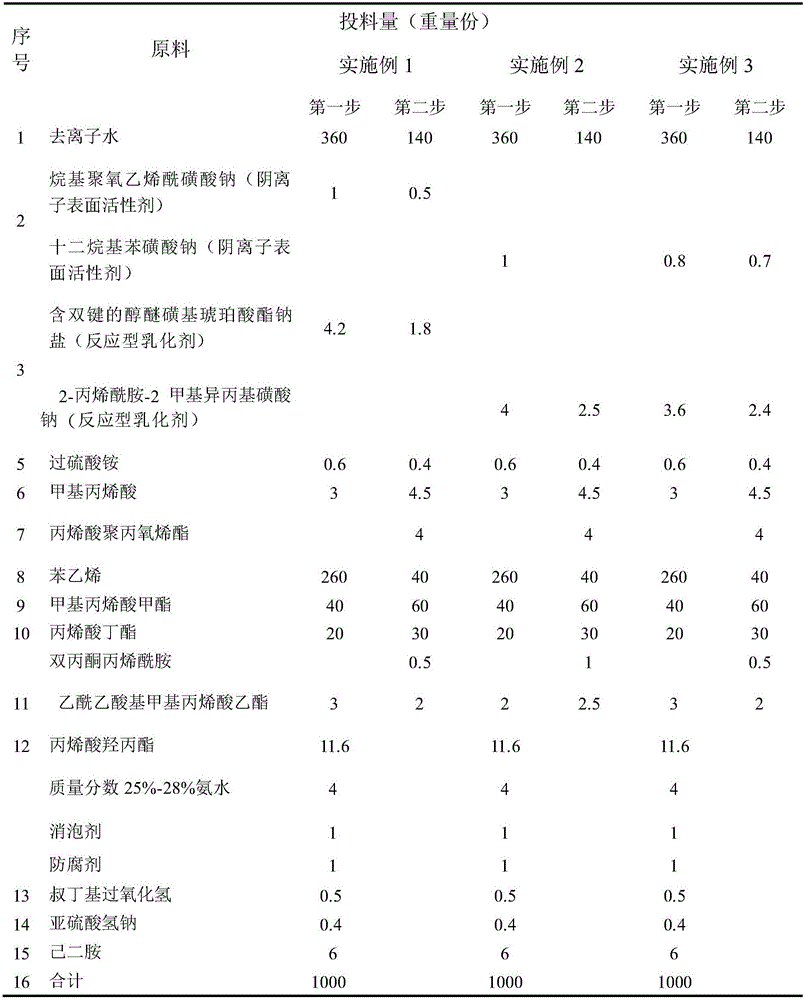

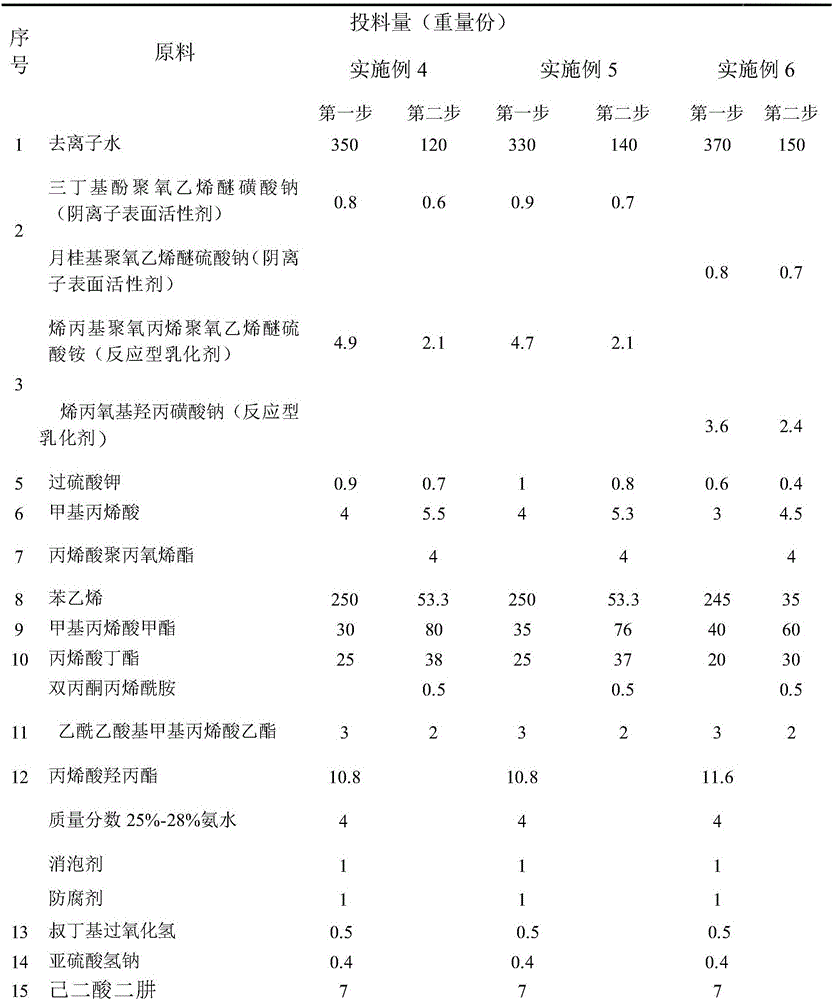

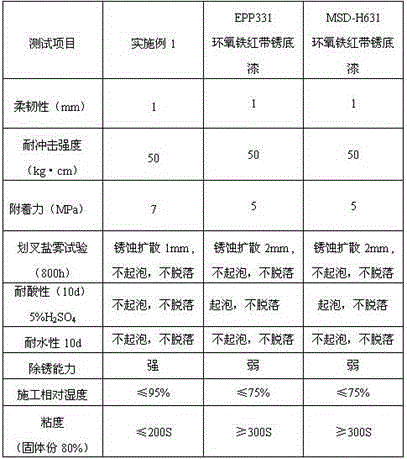

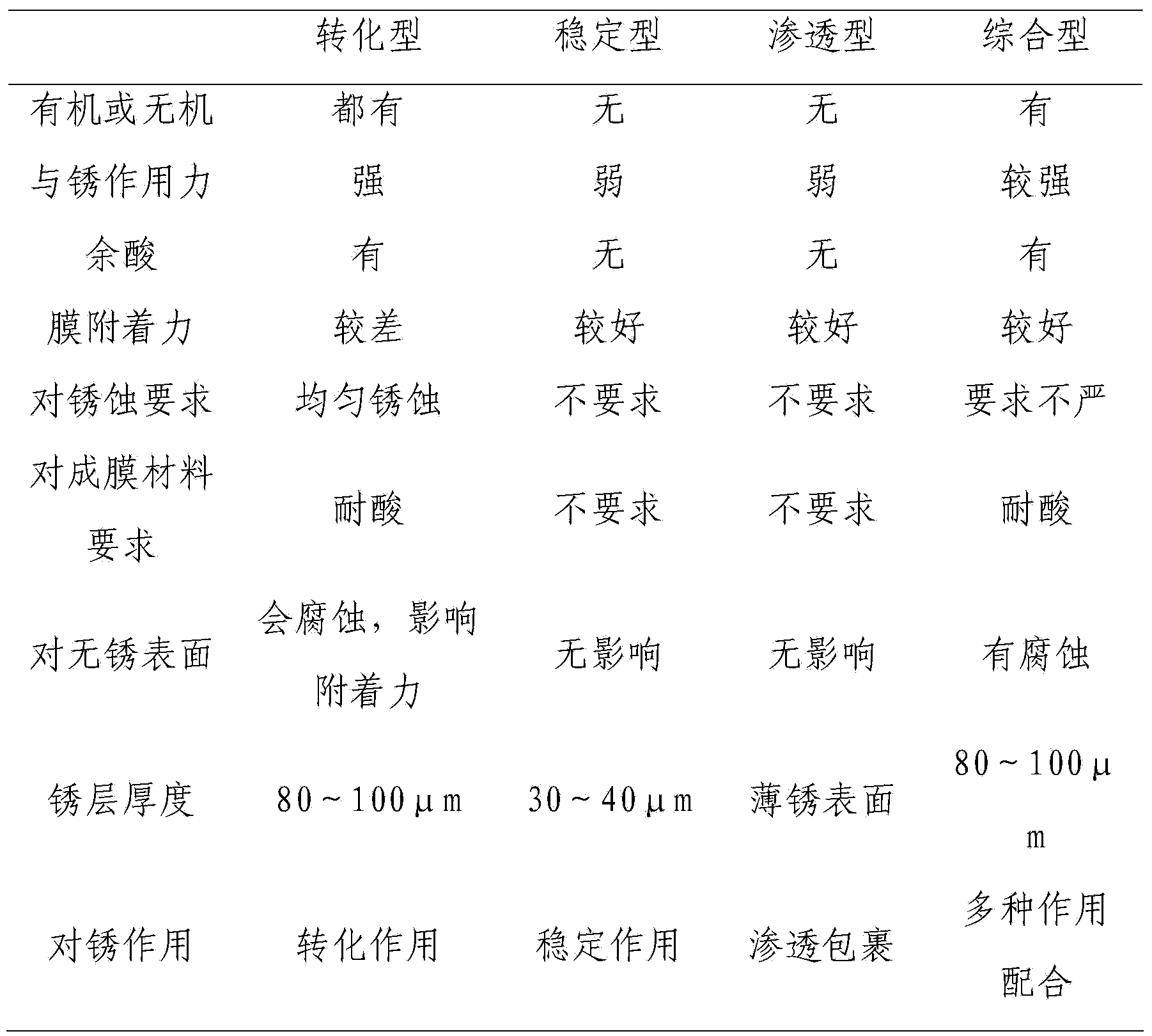

The invention discloses an acrylate copolymer emulsion, and belongs to the technical field of aqueous coatings. The acrylate copolymer emulsion comprises, by weight, 450-550 parts of deionized water, 1-2 parts of an anionic surfactant, 5-8 parts of a reactive emulsifier, 3-15 parts of hydroxypropyl acrylate, 50-160 parts of methyl methacrylate, 20-75 parts of butyl acrylate, 200-410 parts of styrene, 5-10 parts of methacrylic acid, 3-10 parts of an adhesion function monomer, 2-9 parts of a cross-linking monomer, 3-10 parts of a cross-linking agent, 0.1-3 parts of an antifoaming agent, 0.8-2 parts of an initiator, 3-5 parts of ammonia water, 0.8-2 parts of an antiseptic, 0.1-1 part of tert-butyl hydroperoxide and 0.1-0.8 parts of sodium bisulfate. The invention also discloses an aqueous industrial anticorrosive coating adopting the acrylate copolymer emulsion as a film forming substance. The coating has the advantages of high adhesion to a substrate, high water resistance and high salt spray resistance.

Owner:HENGSHUI XINGUANG CHEM

Metal surface rust protection solution

InactiveCN102994995AGood anti-rust functionImprove bindingMetallic material coating processesLiquid wasteSodium phosphates

Owner:杨恒春

Epoxy anticorrosion decoration paint

ActiveCN102911586AEffective isolationLow Molecular TG ValueAnti-corrosive paintsEpoxy resin coatingsEpoxyPolymer science

The invention provides an epoxy anticorrosion decoration paint. The epoxy anticorrosion decoration paint is characterized by being prepared by mixing a component A and a component B according to the weight ratio of 4:1, wherein the component A contains 30-50% of low molecular weight epoxy resin, 5-10% of zinc phosphate, 5-10% of packing, 5-10% of aluminium triphosphate, 20-30% of iron oxide red, 0.2-0.5% of tetra-n-propyl zirconate, 0.1-0.3% of silane coupling agent and 5-20% of butyl cellosolve, and the component B contains 30-50% of amino-terminated epoxy-amine affixture, 0.1-0.5% of penetrant, 0.1-0.5% of phytic acid, 30-48% of ethanol and 30-48% of n-butyl alcohol. The paint has excellent corrosion resistance, strong base material adhesion, good flexibility and shock resistance, high solid content, low viscosity, strong tolerance to environment humidity and strong construction adaptability.

Owner:江苏纽克莱涂料有限公司

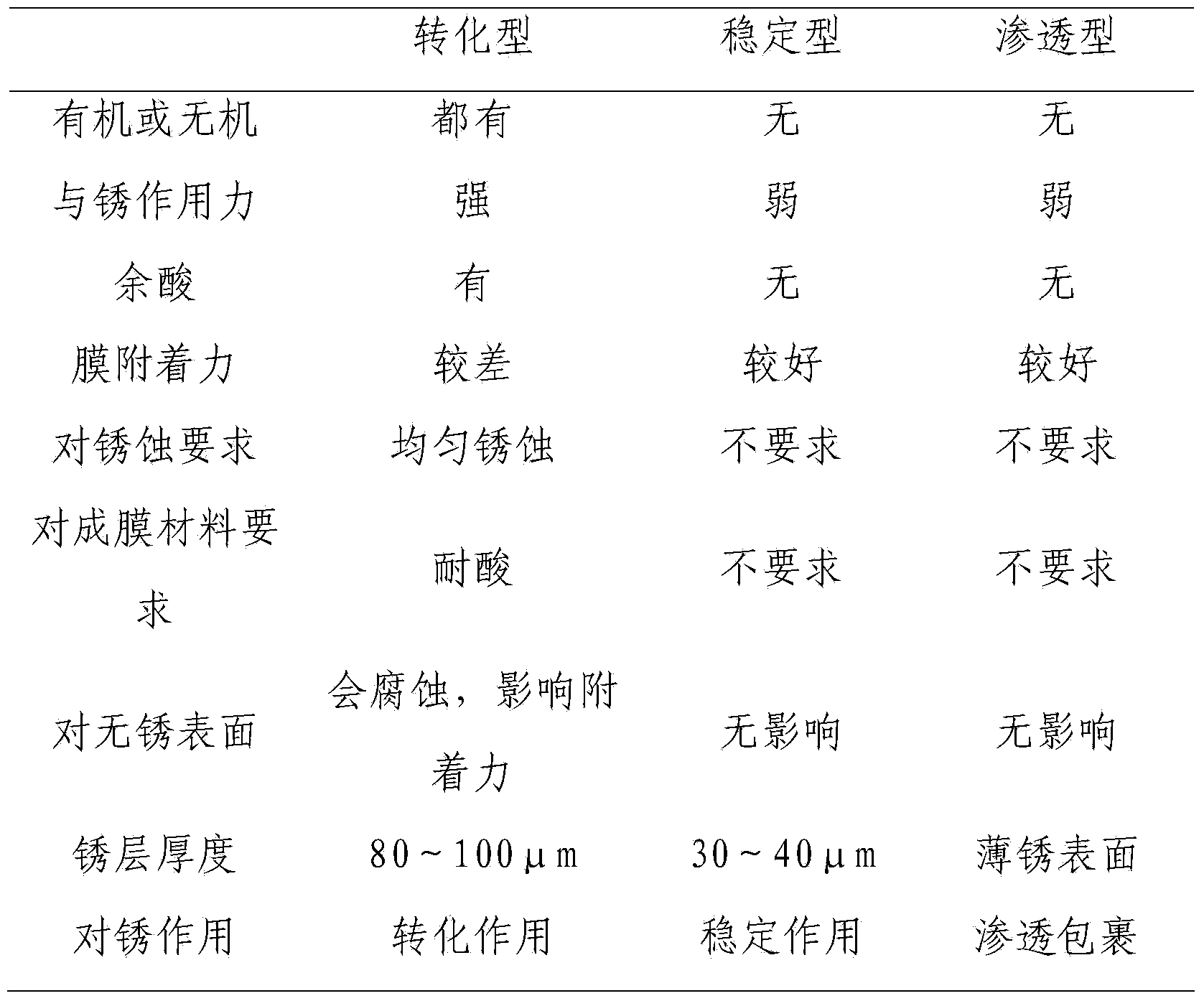

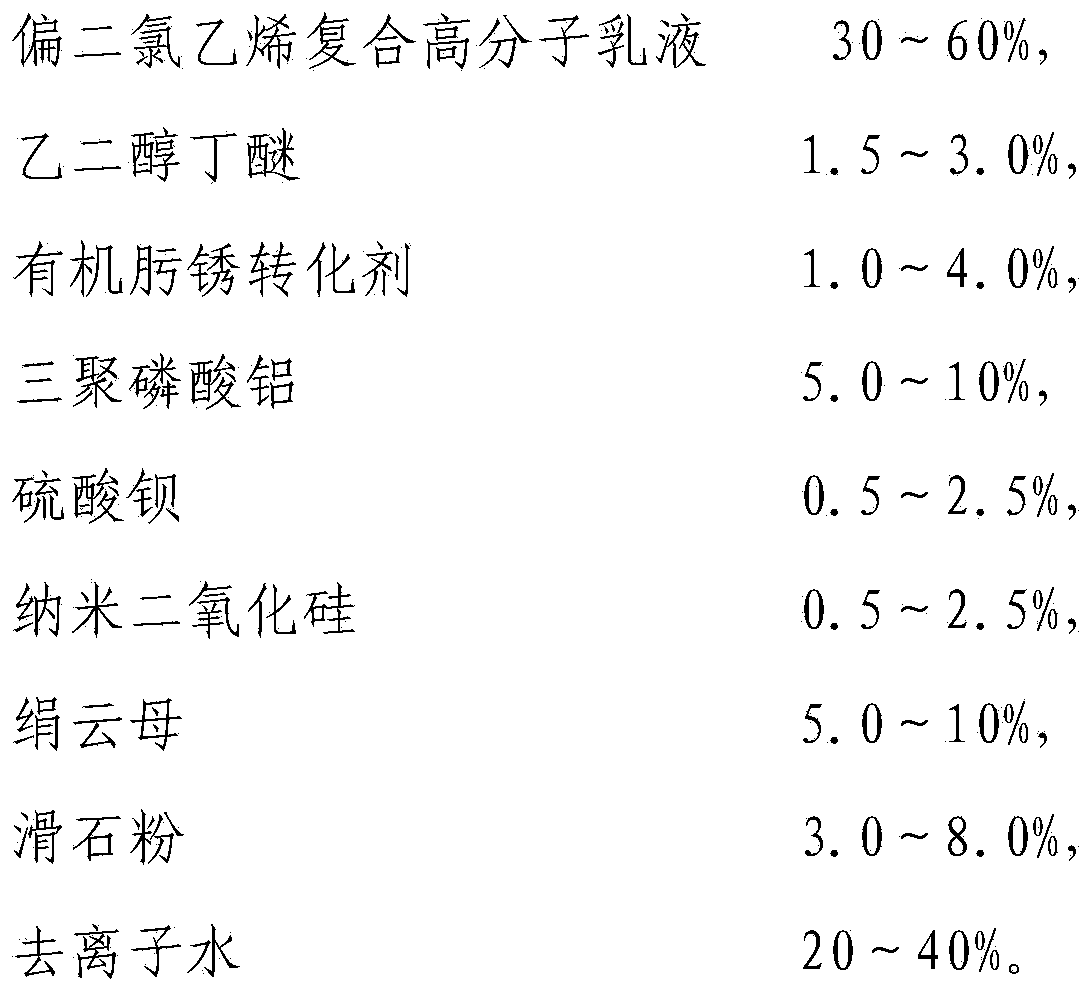

Rust transforming agent and preparation method thereof, water-based iron rust conversion coating and preparation method thereof

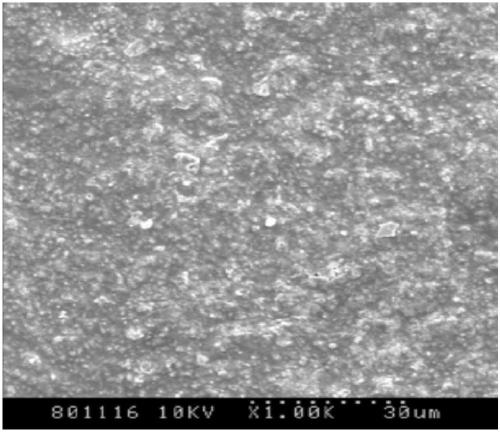

InactiveCN103849862AImprove water resistanceImprove stabilityAnti-corrosive paintsMetallic material coating processesWater basedGallic acid ester

The invention belongs to the technical field of a metal anti-corrosion coating, and particularly relates to a rust transforming agent and a preparation method thereof, a water-based iron rust conversion coating and a preparation method thereof. The rust transforming agent comprises a step of synthesizing 2-hydroxypropyl 3,4,5-trihydroxybenzoic acid by taking a gallic acid, 1,2-propylene glycol and a p-toluenesulfonic acid as initial raw materials, wherein the rust transforming agent contains 18.5-26.7% of gallic acid, 66.6-74% of 1,2-propylene glycol, and 6.6-7.5% of p-toluenesulfonic acid; the water-based iron rust conversion coating is prepared from a vinylidene chloride composite polymer emulsion, ethylene glycol butyl ether, filling slurry prepared in the step (1) and the rust transforming agent. The prepared rust transforming agent disclosed by the invention is good in water tolerance, strong in stability, and good in matching property with a water paint and an oil paint.

Owner:SHANDONG UNIV OF SCI & TECH

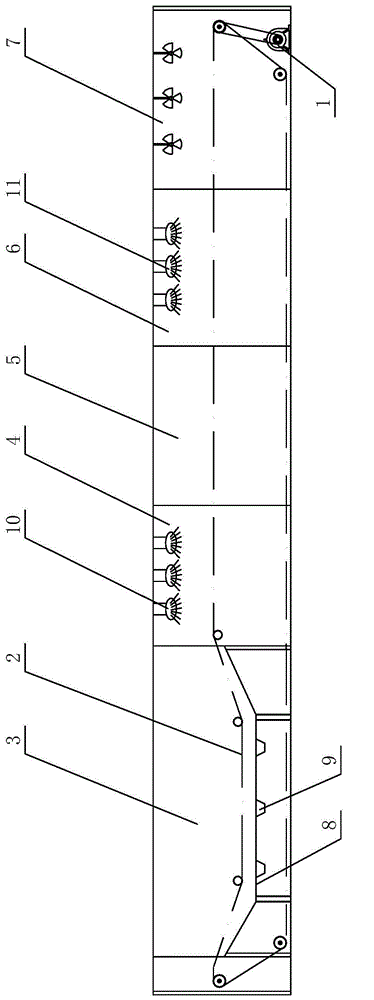

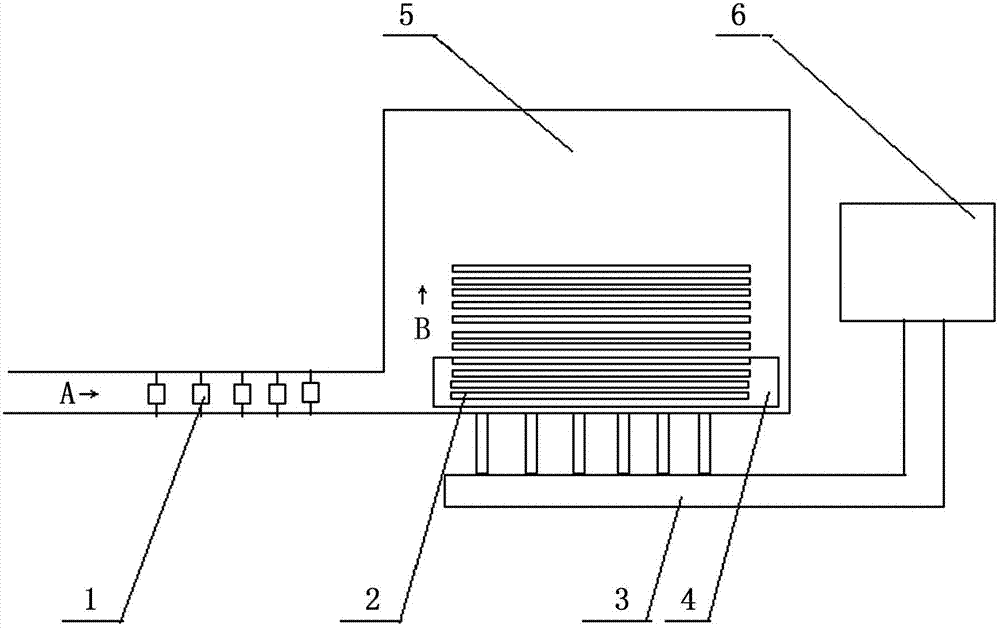

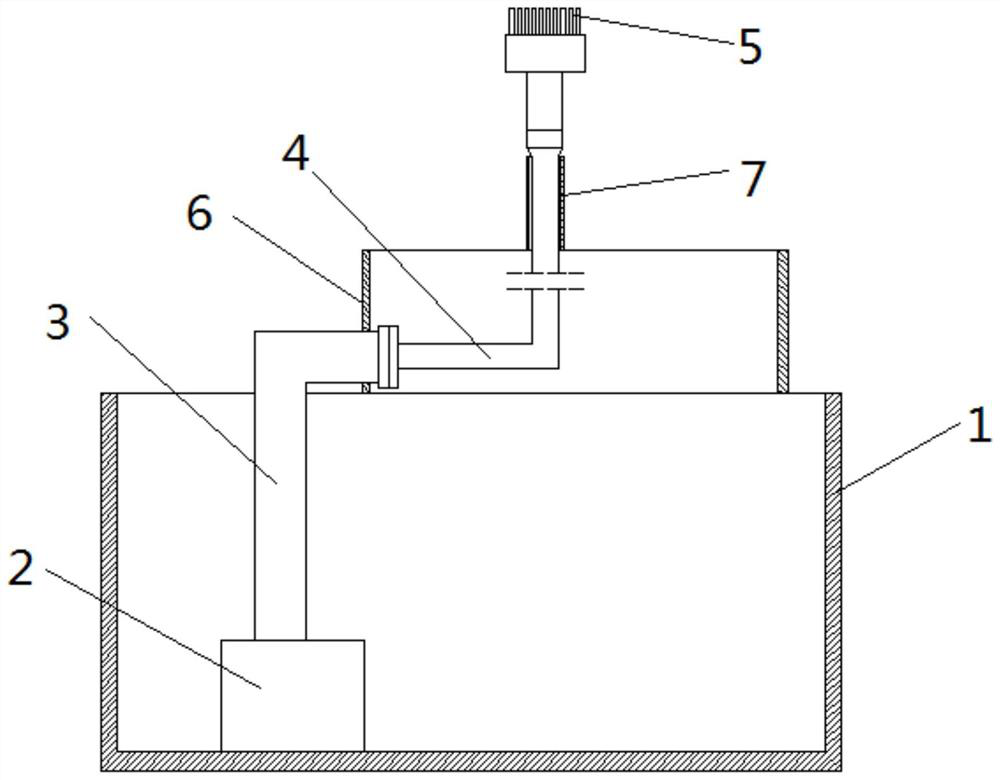

Workpiece cleaning line

InactiveCN105457931AExtended service lifeEasy to cleanCleaning using liquidsMaintainance and safety accessoriesMegasonic cleaningEngineering

The invention discloses a workpiece cleaning line. The workpiece cleaning line comprises a conveying line driven through a conveying motor. An ultrasonic cleaning device, a spraying device, a drying oven, an oiling device and an air drying box are arranged on the conveying line in sequence in the conveying direction. The workpiece cleaning line adopts the ultrasonic cleaning device and the spraying device for cleaning, so that the cleaning effect is good and the dead angle is avoided during cleaning; oiling is conducted through the oiling device after drying through the drying oven; finally, air drying is carried out through the air drying box. Accordingly, the purpose of rust prevention is achieved, and the service life of workpieces is prolonged.

Owner:无锡杨市表面处理科技有限公司

Environment-friendly water-based antirust liquid formula and application thereof

InactiveCN105463469AGood film formingTo achieve the purpose of rust preventionWater basedAntioxidant

The invention discloses an environment-friendly water-based antirust liquid formula. The formula includes, by weight, 10-20 parts of phytic acid, 10-15 parts of konjac glucomannan, 3-12 parts of a-D-glucose pentaacetate, 0.5-5.5 parts of carboxymethyl cellulose, 2-5 parts of sodium alginate, 5-15 parts of sebacic acid, 1-5 parts of triethanolamine, 30-80 parts of deionized water and 1-2 parts of antioxidant. An antirust liquid preparing method is simple, the antirust effect is good, good rust prevention can be achieved at low concentration, no toxin exists, the antirust liquid is harmless to the human body and the environment, and the environment-friendly water-based antirust liquid formula can be applied to rust prevention in high-temperature and high-humidity environments for ethyl HT300 cast iron of hot-rolled steel plates and cold-rolled steel plates.

Owner:SUZHOU GAIDE FINE MATERIALS CO LTD

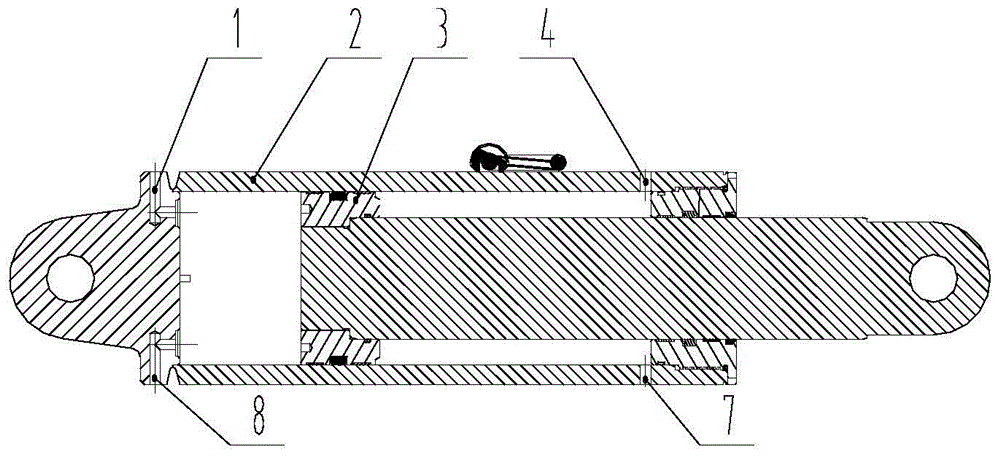

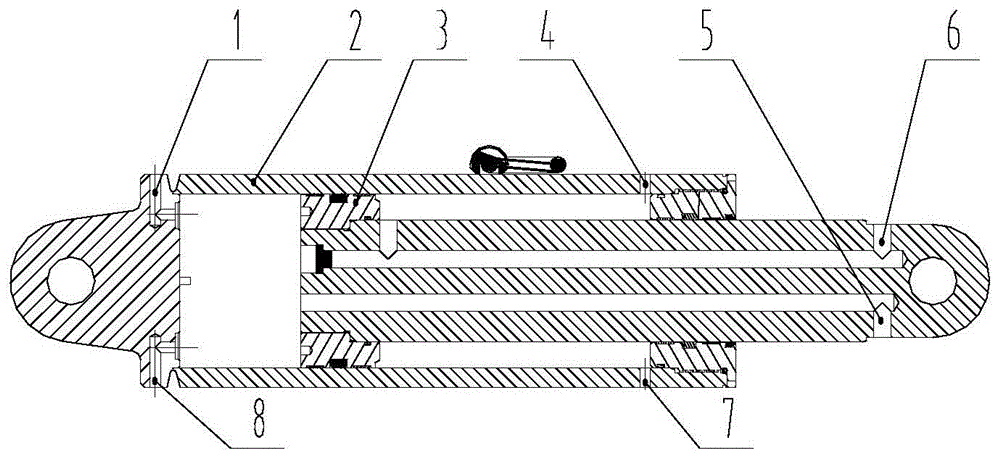

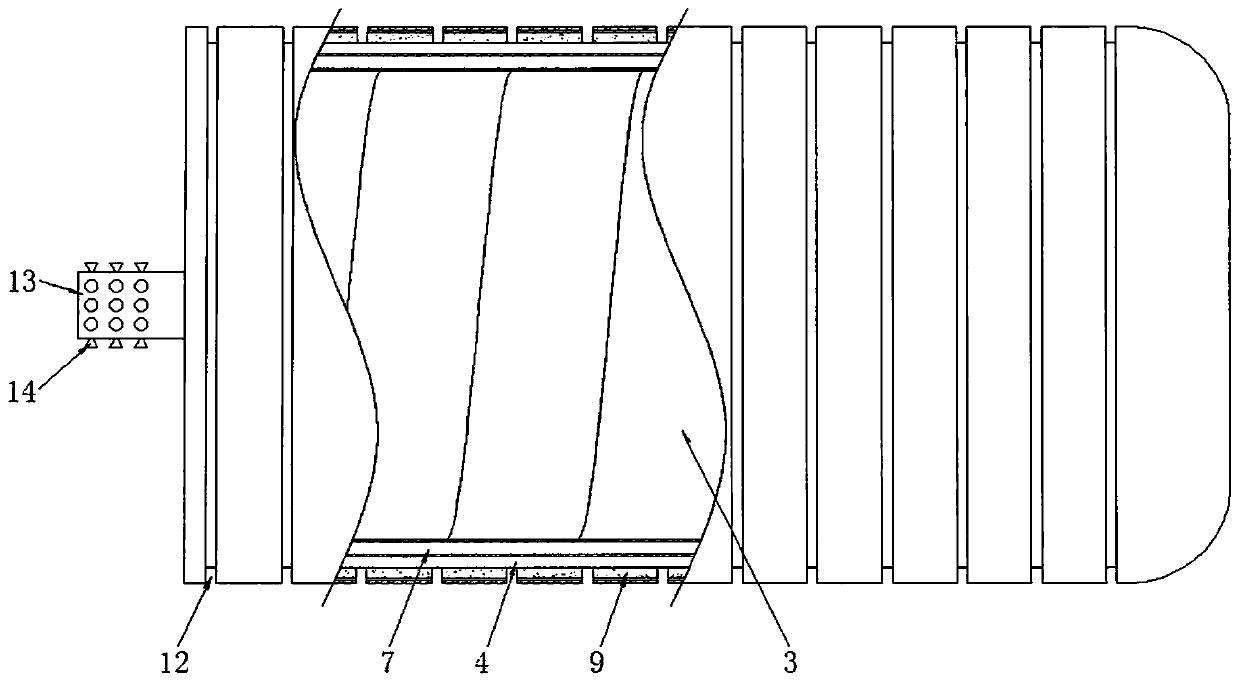

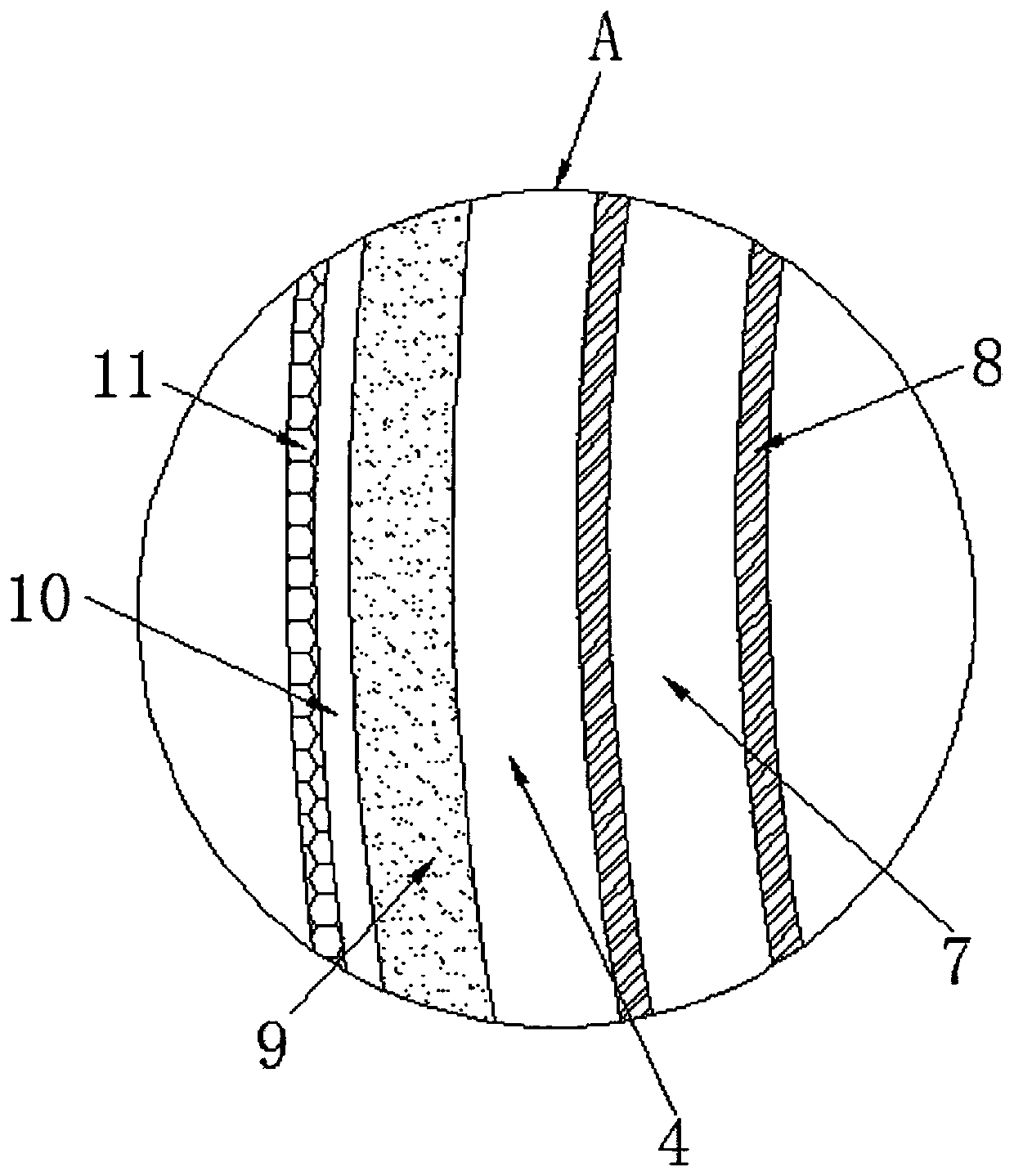

Mine hydraulic cylinder capable of achieving hydraulic medium replacement under pressure

InactiveCN105041768ATo achieve the purpose of rust preventionPrevent or retard corrosionFluid-pressure actuatorsPiston rodsHydraulic cylinderEngineering

The invention relates to a mine hydraulic cylinder capable of achieving hydraulic medium replacement under pressure. The hydraulic cylinder is provided with a cylinder body (2), a piston (3) located in the cylinder body (2) and a piston rod, wherein the piston rod is connected with the piston (3) into a whole and stretches out of the cylinder body (2). The space inside the cylinder body (2) is divided into a rodless cavity part and a rod cavity part. The rodless cavity part is provided with a rodless cavity control liquid connector (8), and the rod cavity part is provided with a rod cavity control liquid connector (7). A liquid supply pipeline is connected with the rod cavity part through the rod cavity control liquid connector. The piston rod is further provided with a rodless cavity liquid discharge port (5) communicated with a rodless cavity, and a rod cavity liquid discharge port (6) communicated with a rod cavity. The invention further provides a replacement method for a hydraulic medium of the hydraulic cylinder. By means of the technical scheme, working media in the rod cavity part and the rodless cavity part can be replaced under pressure, the purpose of replacing stagnant water in the hydraulic cylinder is achieved, and thus corrosion of the hydraulic cylinder is prevented or slowed down.

Owner:SANY HEAVY EQUIP +1

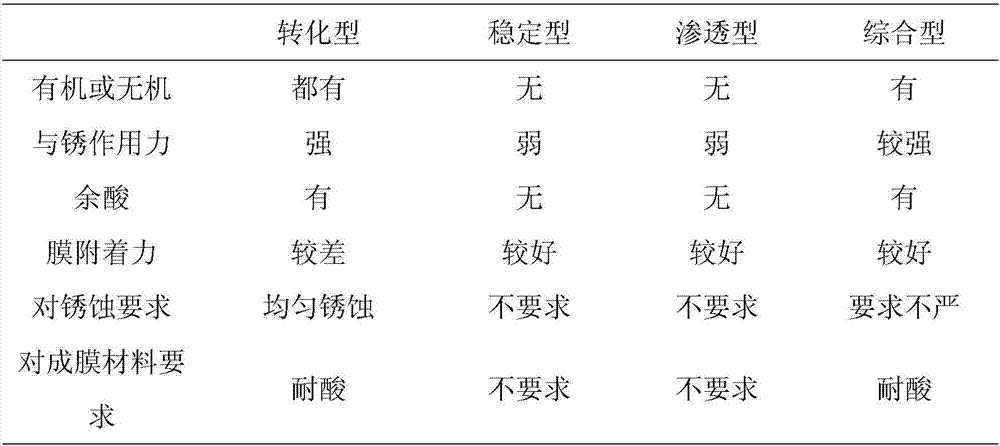

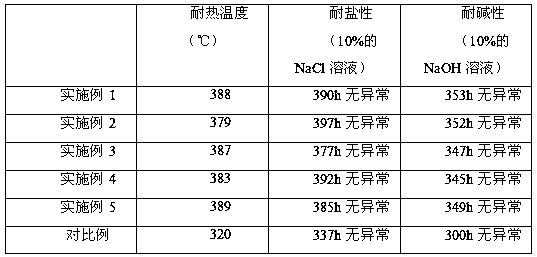

Water-based rust conversion priming paint and preparation method

InactiveCN107033686AImprove water resistanceImprove stabilityAnti-corrosive paintsWater basedEmulsion

The invention belongs to the technical field of metal anticorrosive coatings and relates to a water-based rust conversion priming paint and a preparation method. The water-based rust conversion priming paint comprises the components of, by weight, 30-60 parts of vinylidene chloride compound macromolecule emulsion, 20-40 parts of color filling slurry, 5-15 parts of 2-hydroxyl propyl-3,4,5-trihydroxybenzoic acid rust conversion agent, 0.05-0.1 part of antifoaming agent and 0.1-0.5 part of thickening agent. The rust conversion agent is good in water resistance, high in stability and excellent in matching with water-based and oil-based paints, and the workability, the conversion efficiency and the corrosion resistance are all relatively high.

Owner:SHANDONG UNIV OF SCI & TECH

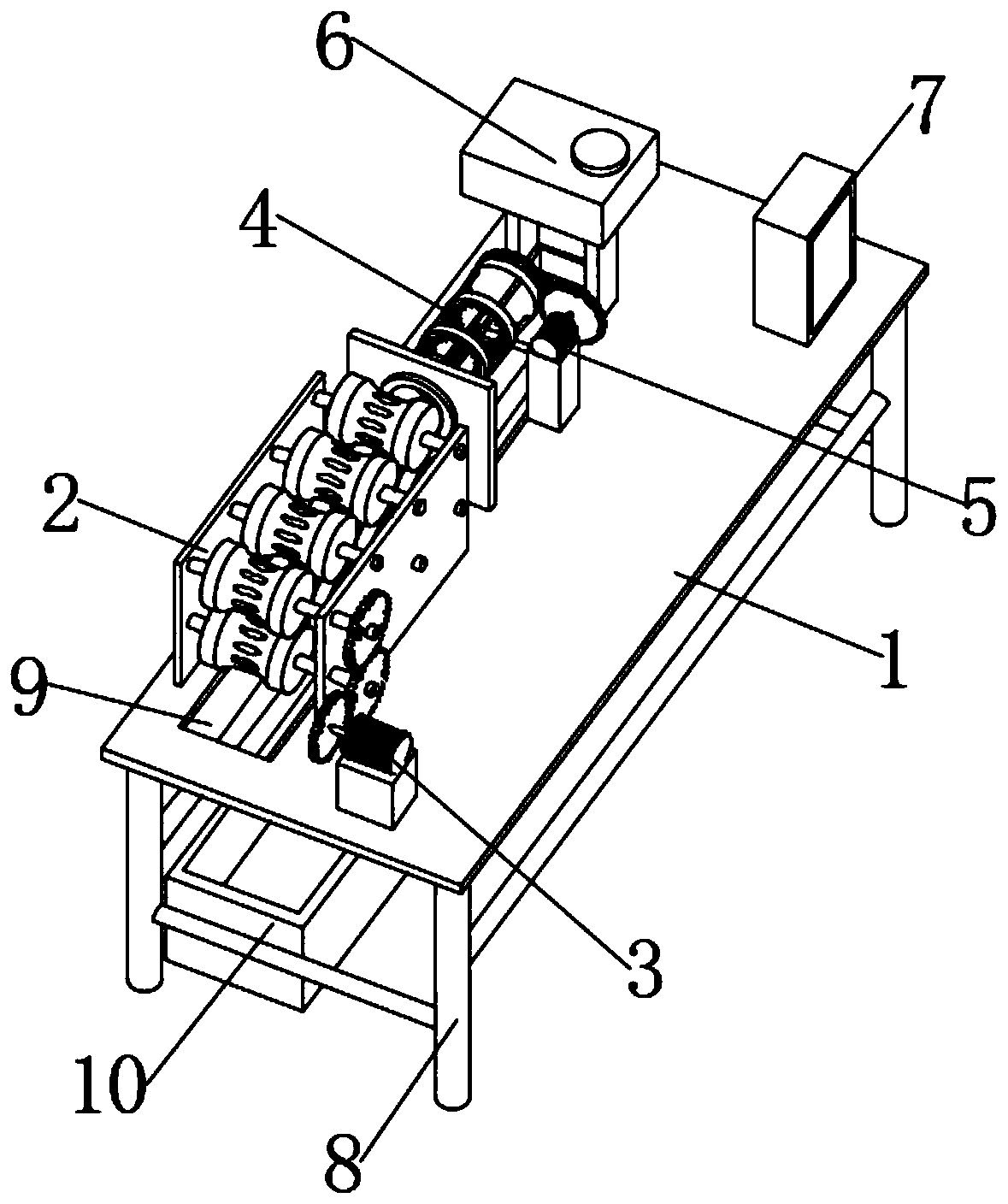

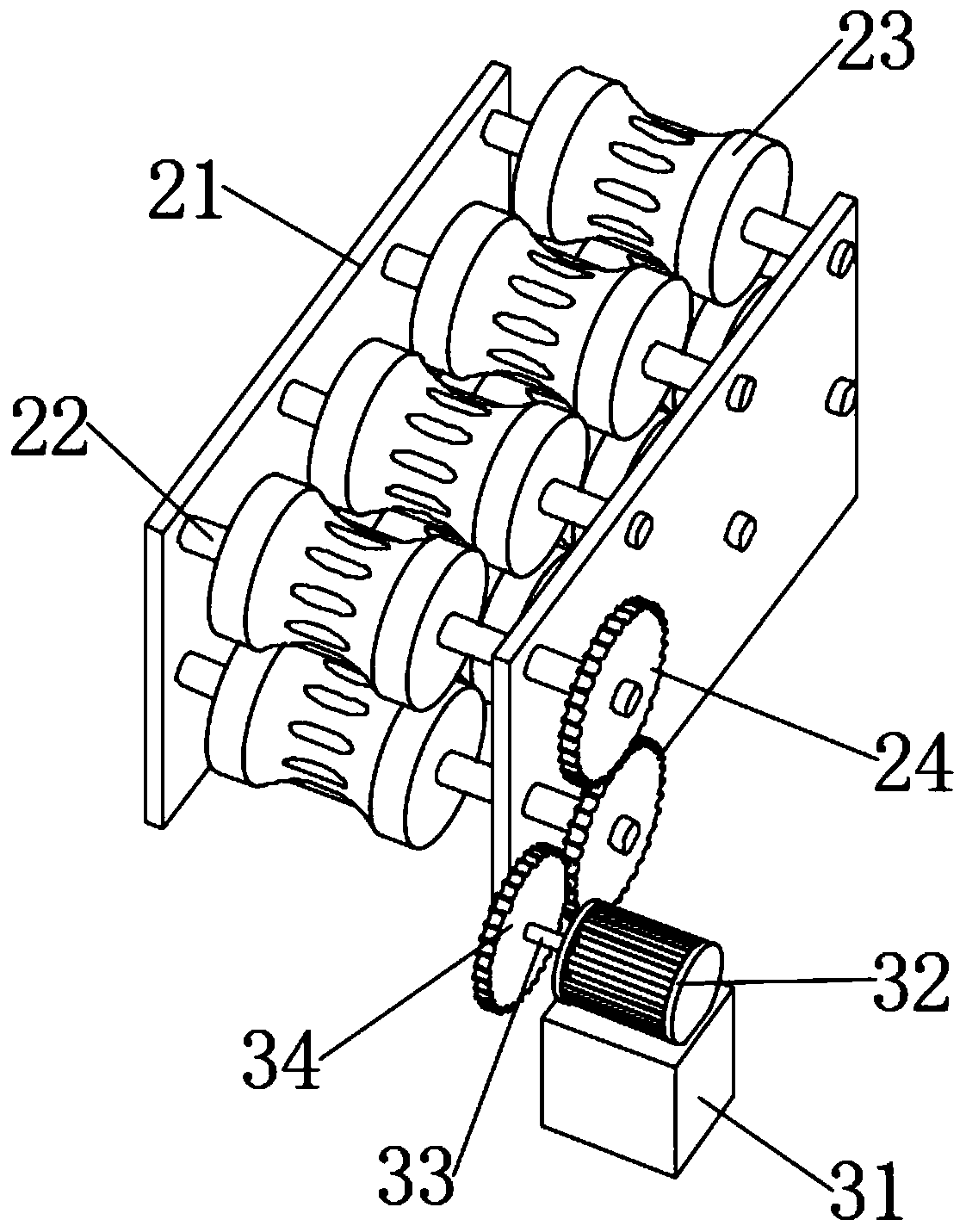

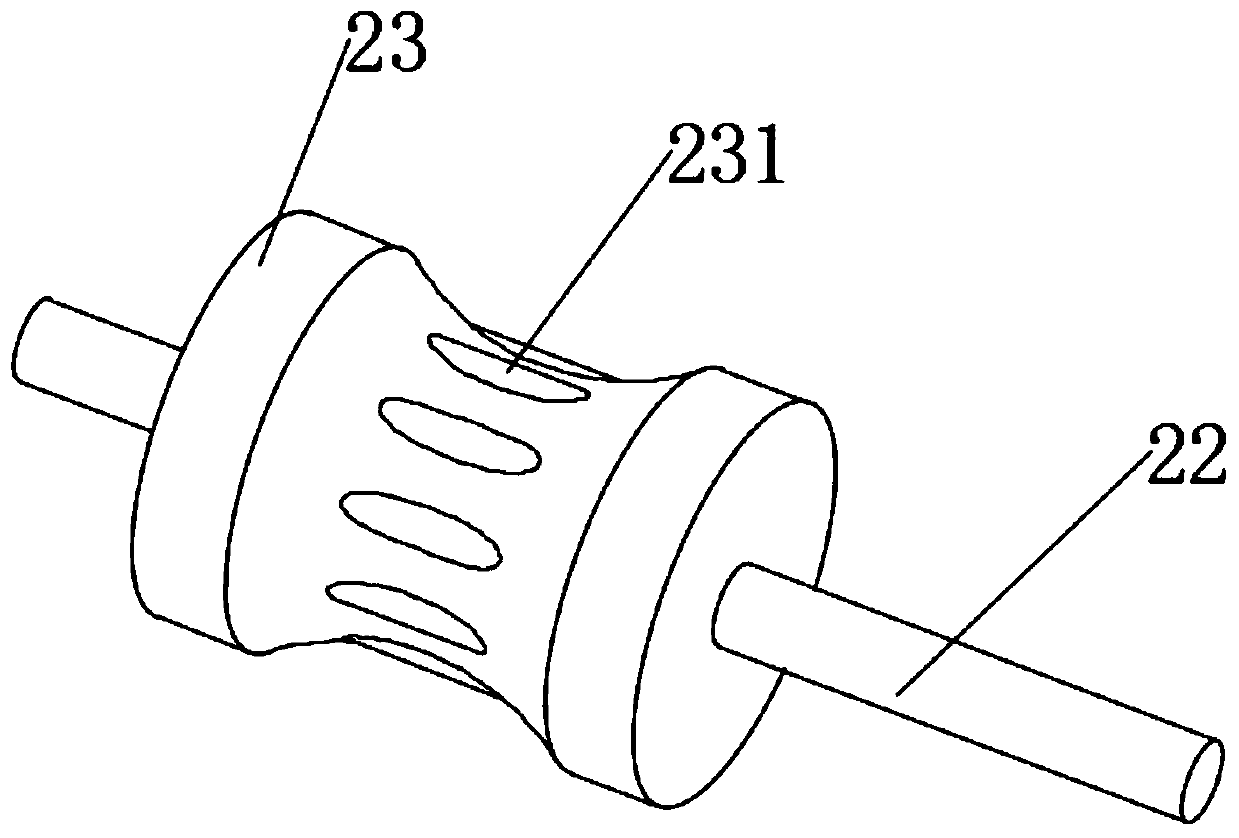

Electric automation reinforcing steel bar straightening machine

InactiveCN111531073AEasy to cleanTo achieve the purpose of rust removalLiquid surface applicatorsGrinding drivesRebarWorkbench

The invention discloses an electric automation reinforcing steel bar straightening machine, which comprises a workbench and a collection box, wherein the front part of the upper end of the workbench is fixedly provided with a straightening device, a rust removal device and an oil coating device; the straightening device, the rust removal device and the oil coating device are arranged in sequence from left to right; a position, which is positioned behind the straightening device, of the upper end of the workbench is provided with a first driving mechanism; a position, which is positioned behindthe rust removal device, of the upper end of the workbench is provided with a second driving mechanism; the right rear corner of the workbench is fixedly provided with an electronic control box; thelower end of the workbench is fixedly provided with a supporting frame; the upper end of the workbench is provided with a blanking groove which is vertically through; and an opening on the upper end of the collection box is positioned just below the blanking groove. The electric automation reinforcing steel bar straightening machine disclosed by the invention combines working procedures, includingreinforcing steel bar straightening, reinforcing steel bar rust removal, reinforcing steel bar straightening rust prevention and the like, into a whole, working efficiency can be greatly improved, better economic benefits can be brought, and the electric automation reinforcing steel bar straightening machine is suitable to be popularized and utilized.

Owner:武汉船舶职业技术学院

Green and environment-friendly water-based antirust agent and preparation method thereof

InactiveCN104312348AGood film formingIsolated contactAnti-corrosive paintsProtein coatingsSodium polyacrylateCitrate sodium

The invention discloses a green and environment-friendly water-based antirust agent. The green and environment-friendly water-based antirust agent is characterized in that the water-based antirust agent is prepared from the following raw materials in parts by weight: 0.5-1 part of chitosan, 0.3-0.5 part of citric acid, 0.1-0.2 part of tea polyphenol, 0.5-1 part of polyaspartic acid, 6-8 parts of gelatin, 1-2 parts of sodium citrate, 0.1-0.2 part of cocoalkanoylamido propyl betaine, 8-10 parts of pure acrylic emulsion, 1-2 parts of sodium dihydrogen phosphate, 0.2-0.4 part of polysorbate-80, 0.5-1 part of sodium polyacrylate, 6-8 parts of a modified additive and 30-40 parts of water. The antirust agent disclosed by the invention is good in the film-forming property on metal surfaces, can isolate the metal surface from being in contact with oxygen and water vapor, and the purpose of rust protection is achieved; moreover, the antirust agent is safe, pollution-free, green and environment-friendly, and has good environmental benefits.

Owner:HEFEI DAAN PRINTING

Automobile water pump hub preparation method

The invention discloses an automobile water pump hub preparation method, comprising the following steps: iron powder is reduced with the material of powder metallurgy, copper powder, nickel powder, molybdenum powder, additives such as sulfur and the like are added, by scientific formulation and reasonable production method, the water pump hub is formed in one step by a high tonnage hydraulic machine and then the obtained product is sintered and after one more mold cover half shaping and high temperature steam nigrescence rust-proof treatment, the finished product is obtained. The invention has the advantages of simple operation, low production cost, time and labor saving, good overall performance and high intensity and precision.

Owner:丁邦顺

Novel acrylic resin bottom face synthetic lacquer

The present invention discloses novel acrylic acid resin undersurface synthetic paint for an automobile chassis, which is prepared from the following materials by weight percentage: 5 to 10 percent of 50 percent hydroxy acrylic acid resin (molecular weight is between 25,000 and 30,000), 37 to 57 percent of 50 percent acrylic acid (molecular weight is between 45,000 and 60,000), 1 to 3 percent of carbon black, 3 to 5 percent of talcum powder, 2 to 3 percent of antirust agent, 20 to 25 percent of solvent, 1 to 4 percent of permanent white and 3 to 7 percent of sodium tripolyphosphate. The paint has the advantages of low film forming temperature, high strength and convenient construction.

Owner:张家港市一达新型建材有限公司

Dead and spare equipment protecting agent and preparation method thereof

The invention relates to a protective agent for reserve equipment and idle equipment, characterized in that the agent is composed of cyclohexylamine carbonate, salvolatile, dicyclohexylamine nitrite, nitrite and methenamine. The compositions are 30% to 60%, 5% to 30%, 5% to 30%, 2% to 10%, 2% to 10% of the total weight respectively. The invention also discloses a preparation of the protective agent. The invention has the characteristics of long rust-proof life, high corrosion inhibition efficiency, low cost and simple process.

Owner:杨逢春

Composite antirust paint

InactiveCN102786849ATo achieve the purpose of rust preventionImprove rust resistanceAnti-corrosive paintsPolyacetal coatingsResin-Based CompositePolyacrylamide

The invention discloses a composite antirust paint. The composite antirust paint comprises components in parts by weight as follows: 30-50 parts of styrene acrylic emulsion, 10-20 parts of formaldehyde resin, 10-20 parts of talcum powder, 3-5 parts of zinc oxide, 3-5 parts of barium sulfate, 10-20 parts of titanium dioxide, 1-3 parts of sodium benzenesulfonate, 5-8 parts of ethylene glycol, 1-3 parts of polyacrylamide and 60-100 parts of water. Compared with a prior art, the composite antirust paint provided by the invention is the composite antirust paint for permeable rust; mainly using composite resin with strong permeability as a main film forming matter and being assisted by other auxiliary agents, the coated composite antirust paint penetrates into a rust layer to isolate the rust from outer media so as to achieve the antirust purpose. The composite antirust paint provided by the invention has the advantages of good antirust effect, simple preparation process and cheap price.

Owner:WUJIANG QINGYI TEXTILE

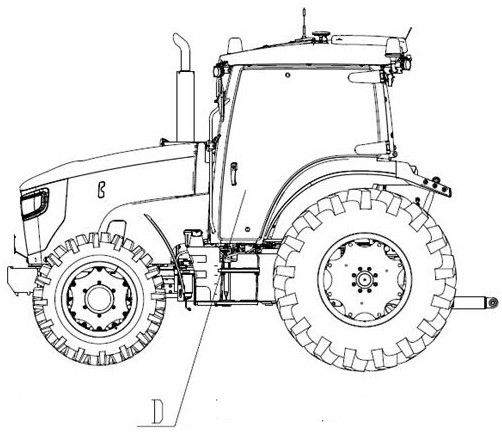

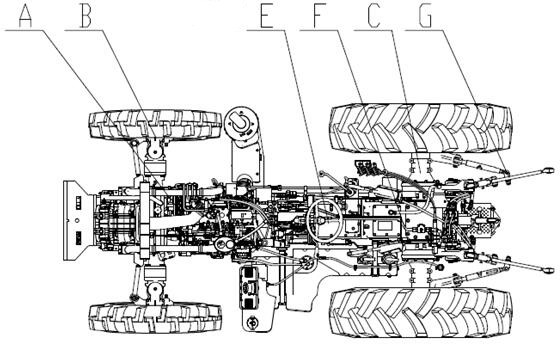

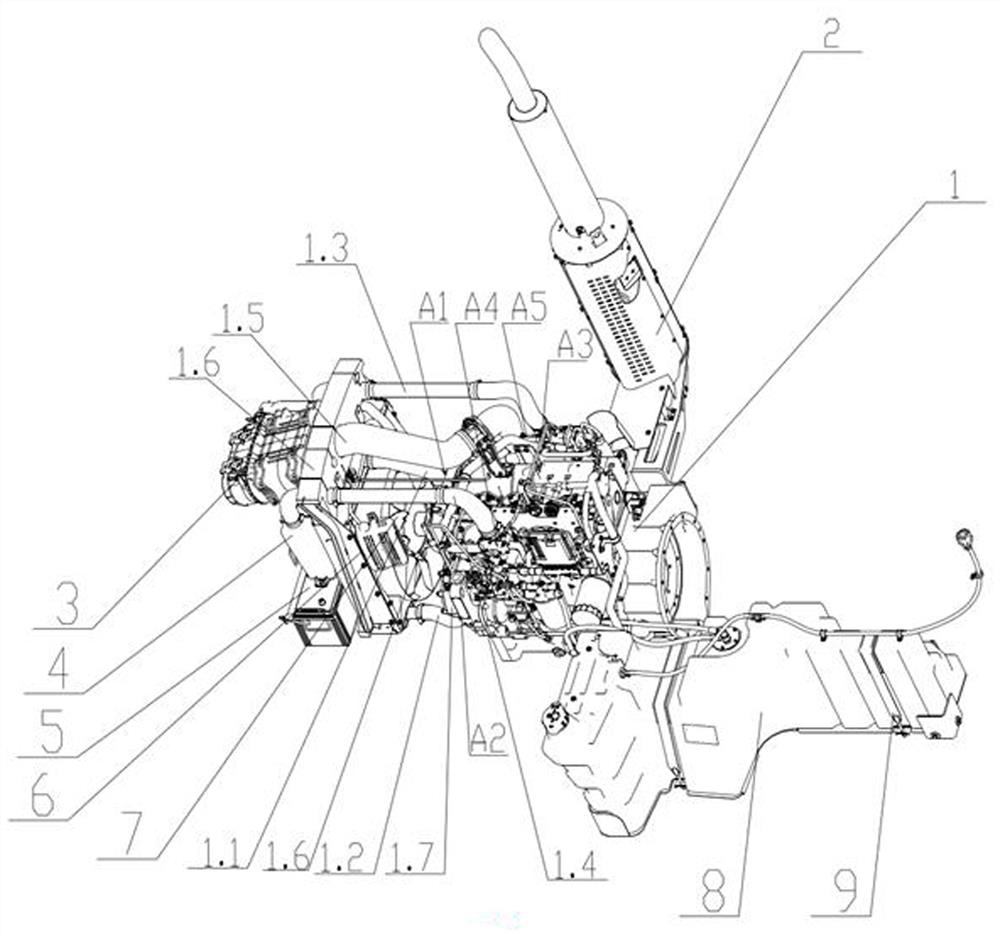

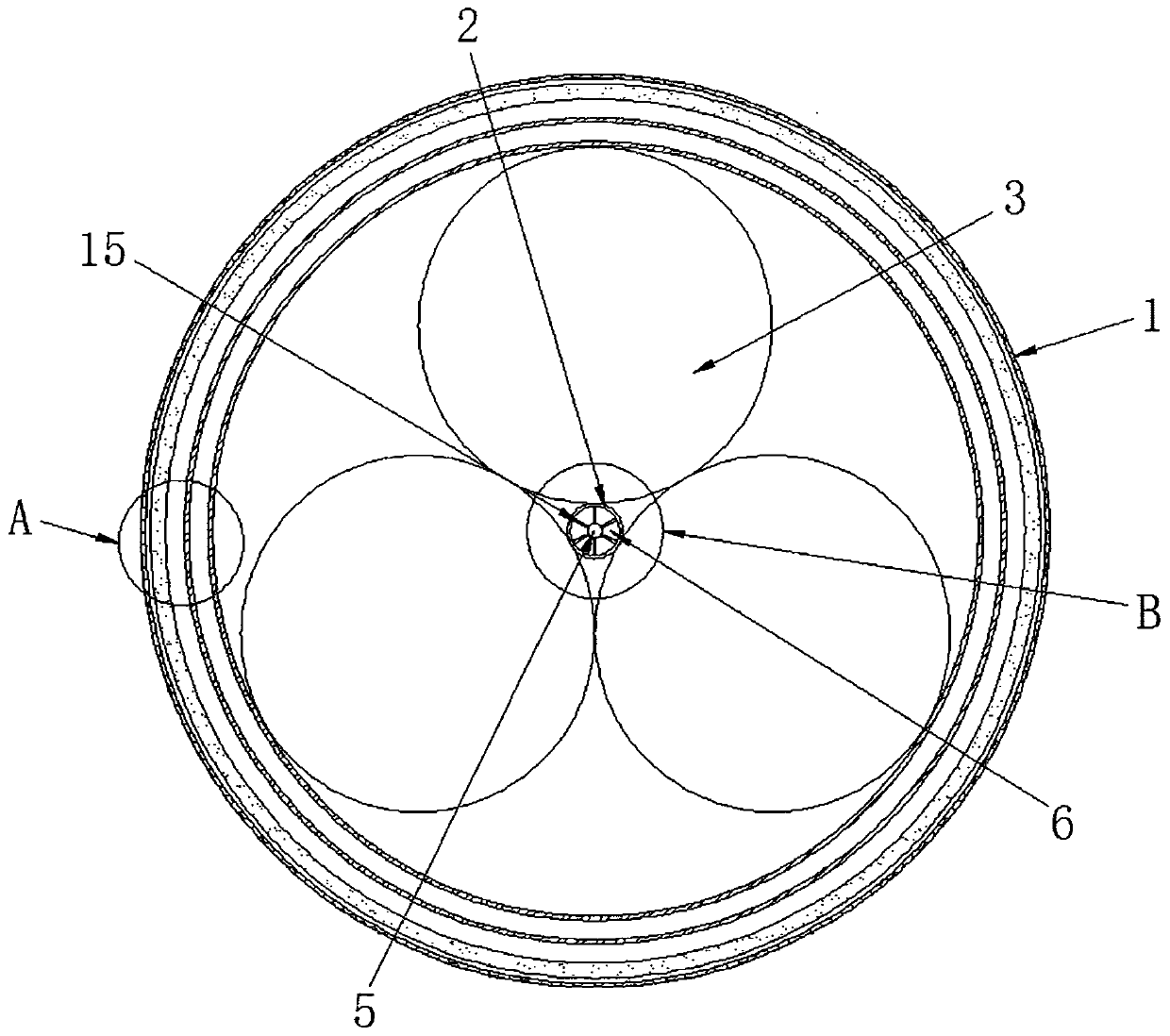

Paddy field wheeled tractor

PendingCN112297813AImprove passabilityImprove adaptabilityHydrostatic brakesTractorsAgricultural scienceSteering angle

The invention relates to a paddy field wheeled tractor which comprises a power system assembly, a walking system assembly, a transmission system assembly, a covering part assembly, a steering system assembly, a hydraulic system assembly and a rear working device. The transmission system assembly serves as the basis of the whole tractor. The power system assembly, the walking system assembly, the covering part assembly, the steering system assembly, the hydraulic system assembly and the rear working device are directly or indirectly connected with the transmission system assembly. By optimizingthe structural layout, the front wheel steering angle is increased, the turning radius of the whole machine is reduced, the ground clearance of the whole machine is increased, and the mass of the whole machine is reduced, so that the tractor has good trafficability in a paddy field, and the requirements of the national IV emission standard are met.

Owner:FIRST TRACTOR

Twisted bar surface rust prevention method

InactiveCN102925850AAvoid contactTo achieve the purpose of rust preventionSolid state diffusion coatingRebarMechanical engineering

The invention provides a twisted bar surface rust prevention method. The twisted bar is subjected to vapor bath treatment to generate a protective layer on the twisted bar surface. The twisted bar on-line rust prevention method can obtain the twisted bar with favorable surface gloss, and can satisfy the requirements for continuous production of twisted bars.

Owner:LAIWU IRON & STEEL GRP

Rust-proof device using bolar energy

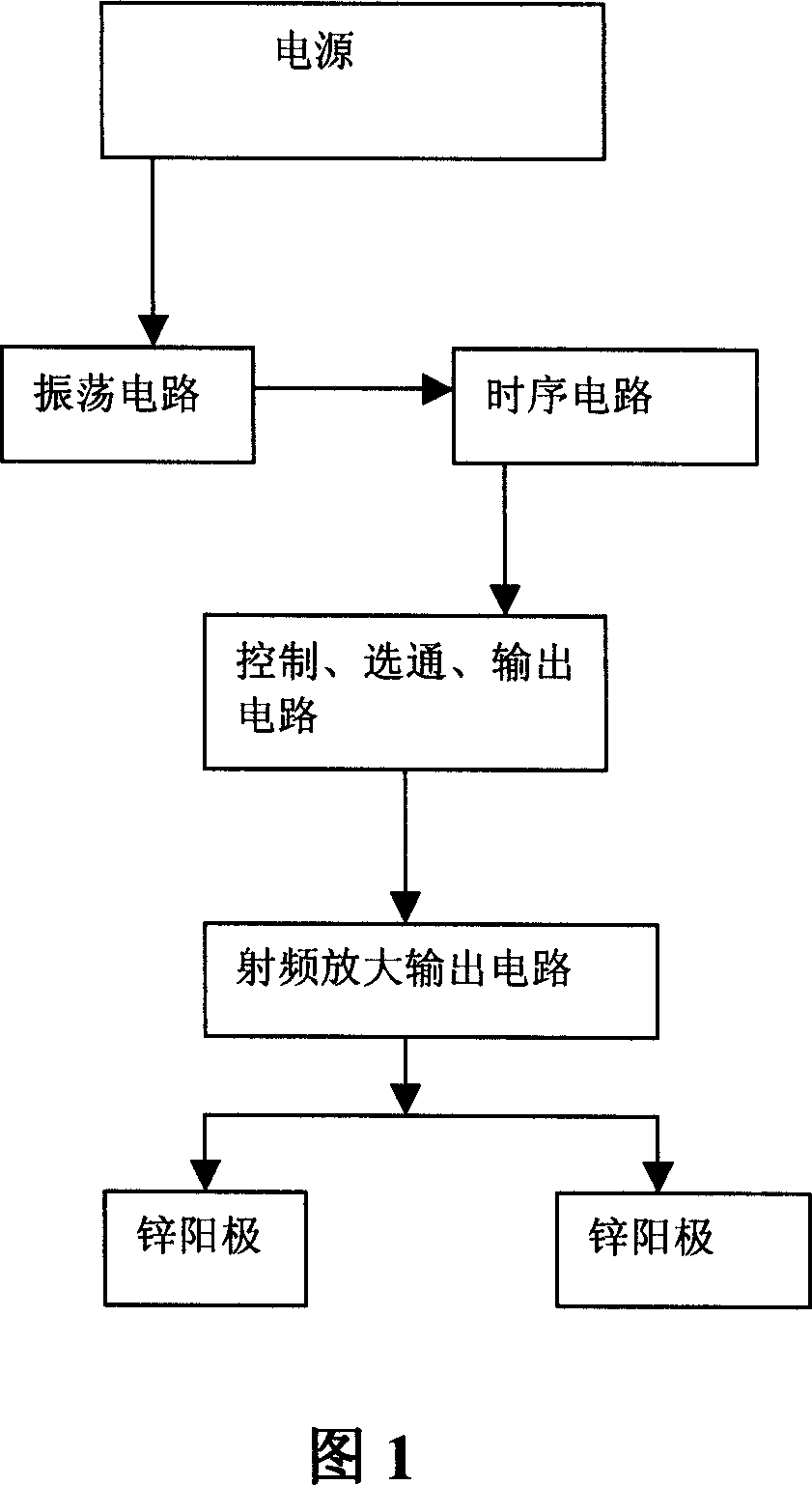

InactiveCN1978706ATo achieve the purpose of rust preventionPhotovoltaic energy generationSemiconductor devicesEngineeringZinc

The invention relate to solar energy non-rusting device. It includes electrical source, oscillating circuit, sequence circuit, control, gate and output circuits, radiofrequency amplification output circuit, and zinc anode. The electrical source includes one solar panel, one solar charging control and storage circuit. The advantage of the invention is that it can use unlimited solar energy as cathode protection electrical source to reach the same non-rusting purpose for the metallic product surface which is more environmental protection and safer.

Owner:TOPRET IND DESIGN(SHANGHAI) CO LTD

Method for prolonging quality guarantee period of tire bead wire

InactiveCN103057359AAvoid air contact with steel wireImprove adhesion performance indicatorsTyre beadsSizingEngineering

The invention discloses a method for prolonging a quality guarantee period of a tire bead wire. The method comprises the following steps: (1), coating a cumar coating film on the surface of a copper plated tire bead wire, wherein the tire bead wire can be in direct contact with air by using the cumar coating film; and (2), coating one or more anti-rust papers outside the tire bead wire coated with the cumar coating film and fixing the anti-rust papers outside the tire bead wire through sizing materials.

Owner:JIANGSU XINGDA STEEL TYPE CORD

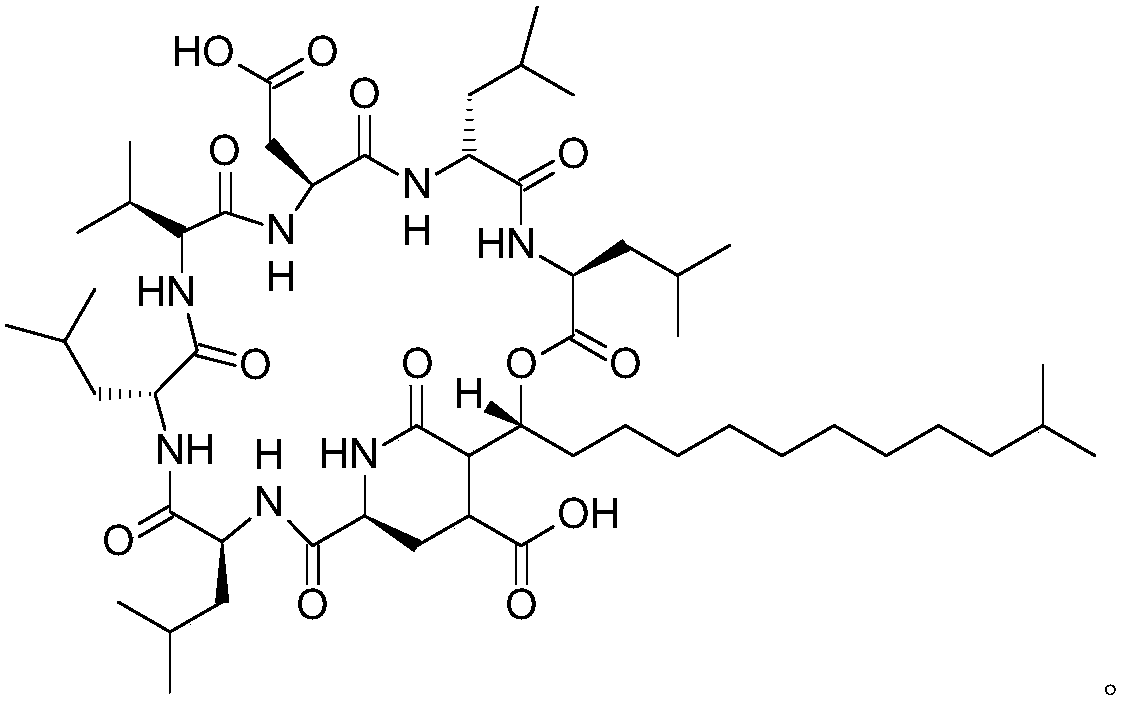

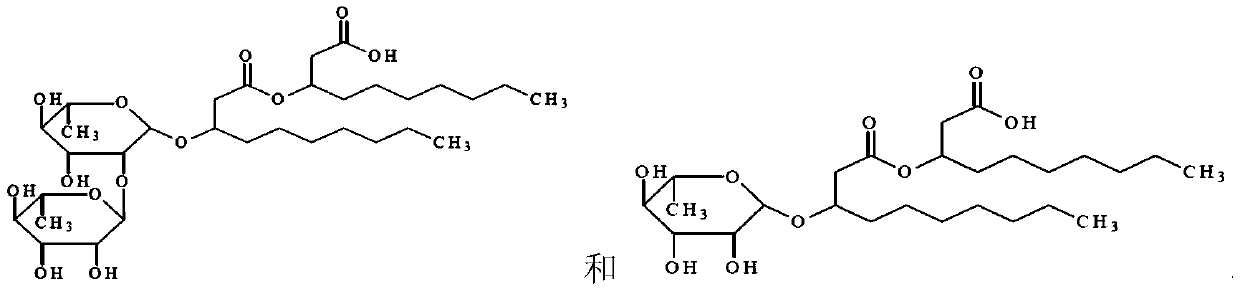

Cleaning agent composition for metal processing product surface as well as preparation method and using method thereof

ActiveCN109536972APromote degradationExcellent low temperature washing performanceCleansing AgentsMonosodium Aspartate

The invention discloses a cleaning agent composition of a metal processing product surface as well as a preparation method and a using method thereof. The cleaning agent composition comprises 1%-5% ofsurface active peptide, 2%-5% of rhamnolipid biological surfactant, 1%-3% of sodium polyaspartate, 1%-5% of lysine, 3%-6% of sodium oxalate, 0.1%-1% of a defoaming agent and the balance water. The metal product cleaning agent is mainly composed of the biodegradable biological surfactant, does not contain carcinogenic substances such as phosphorus and nitrite, and does not contain APED surfactant,the cleaning effect is excellent, the cleaning time is short, and automatic cleaning is facilitated; the cleaning agent is alkaline, the corrosion of the surface of the stainless steel product is negligible, and the cleaning agent can be safely used; and the product is a water-soluble liquid, the cleaned waste liquid is convenient to treat and discharge, the surfactant component is biodegradableand does not pollute the environment.

Owner:新沂肽科生物科技有限公司

Central-wire-free stranded welding wire

InactiveCN110936053ABurn evenlyImprove conductivityWelding/cutting media/materialsSoldering mediaConductive coatingElectrically conductive

Owner:河北联之捷焊业科技有限公司

A kind of flame-retardant gas-phase rust-proof pearl cotton and preparation method thereof

ActiveCN103435886BGood weather resistanceImprove flame retardant performanceMasterbatchMonoglyceride

Owner:东莞市欣辉塑料制品有限公司

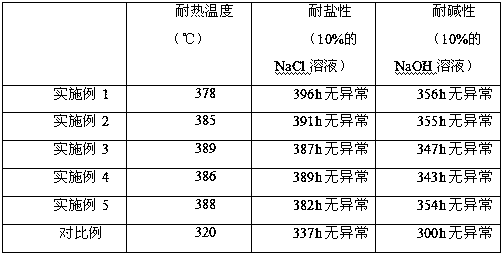

Anti-rust coating layer with high-temperature resistantce for automobile spare and accessory parts and preparation method thereof

InactiveCN109608949AImprove mechanical propertiesImprove scratch resistanceFireproof paintsRosin coatingsIonRosin

The invention discloses an anti-rust coating layer with high-temperature resistance for automobile spare and accessory parts and a preparation method thereof. The anti-rust coating layer is formed through the following steps: coating an anti-rust coating onto the surfaces of automobile spare and accessory parts, and carrying out drying. The anti-rust coating comprises the following raw materials by weight: 50 to 60 parts of a filler emulsion, 10 to 20 parts of modified polyacrylonitrile based carbon fiber, 5 to 10 parts of a toughening lubricant, 5 to 10 parts of a film-forming agent, 8 to 10parts of rosin and 20 to 30 parts of deionized water. The preparation method for the anti-rust coating comprises the following steps: uniformly mixing the filler emulsion with the modified polyacrylonitrile based carbon fiber so as to obtain a component A; dissolving the rosin into the deionized water, and adding the toughening lubricant so as to obtain a component B; mixing the component A with the component B, and adding the film-forming agent so as to obtain the anti-rust coating. According to the invention, when the anti-rust coating is coated onto the surfaces of the automobile spare andaccessory parts, a volatile solvent is slowly dried and volatilized under external conditions, and remaining substances begin aggregation to form a continuous and dense coating layer, so the surfacesof the automobile spare and accessory parts are isolated from the external environment, and the purpose of rust prevention is finally achieved.

Owner:广州市领格汽车零件制造有限公司 +1

External rust-proof paint of mechanical equipment and preparation method of external rust-proof paint

InactiveCN108707353ALow costGood heat dissipationFireproof paintsAnti-corrosive paintsNano zinc oxideDefoaming Agents

The invention discloses external rust-proof paint of mechanical equipment. The external rust-proof paint of the mechanical equipment is prepared from the following raw materials in parts by weight: 20-30 parts of styrene-acrylic emulsion, 15-25 parts of acrylic emulsion, 8-14 parts of styrene, 3-7 parts of chlorinated paraffin, 6-11 parts of tributyl phosphate, 5-9 parts of dipentaerythritol, 3-6parts of compound filler, 2-4 parts of barium sulfate, 1-3 parts of a defoaming agent, 2-4 parts of a thickener, 2-5 parts of a curing agent, 2-3 parts of nano-zinc oxide and 20-30 parts of deionizedwater. According to the external rust-proof paint of the mechanical equipment, by controlling the types and proportion of the raw materials, the prepared rust-proof paint is low in cost, good in heatdissipation and excellent in heat resistance and salt resistant performance, and thus the service life of machinery can be effectively prolonged.

Owner:ANHUI TONGSHENG RING

Oil spray workstation

InactiveCN106111419AIncrease contact areaGood adhesionLiquid surface applicatorsSpraying apparatusMaterial resourcesRust

The invention relates to the field of paint spray, in particular to an oil spray workstation. The oil spray workstation comprises a tank body, a paint holder, an oil spray device, a paint recycling device and an oil mist cleaning device, wherein the oil spray device, the paint recycling device and the oil mist cleaning device are connected with the paint holder. The paint holder is fixed to the exterior of the tank body. One end of the oil spray device is fixed to the exterior of the tank body, and the other end of the oil spray device is fixed to the interior of the tank body. The paint recycling device is fixed to the bottom of the tank body. The oil mist cleaning device is fixed to the exterior of a rear door of the tank body. By means of the oil spray workstation, spraying can be rapidly conducted on the surface of a to-be-machined product, manpower and material resources can be effectively saved, and it can be ensured that anti-rust oil is uniformly attached to the surface of the product so that the rust prevention aim can be achieved; and yet paint spraying is conducted on the product in the closed tank body, and therefore the anti-rust oil can be attached to any part of the surface of the product, and the probability that the product rusts is lowered.

Owner:广州凌云汽车零部件有限公司

Preparation methods of organic oxime rust transforming agent and aqueous iron rust transforming undercoat

InactiveCN103882440AEffectively closedGood conversion effectMetallic material coating processesChemical reactionN dimethylformamide

The invention relates to preparation methods of an organic oxime rust transforming agent and an aqueous iron rust transforming undercoat. The organic oxime rust transforming agent is prepared from the following raw materials in percentage by weight: 27%-35% of methanol, 0.7%-1.0% of Mg, 8.5%-12.7% of methylbenzene, 0.83%-1.75% of gallic acid, 11.3%-15.7% of N,N-dimethylformamide, 12.0%-17.5% of formaldehyde, 3.6%-5.8% of hydroxylamine hydrochloride and 20.1%-25.4% of deionized water. The aqueous iron rust transforming undercoat is prepared from the following raw materials in percentage by weight: 30%-60% of vinylidene chloride composite macromolecular emulsion, 1.5%-3.0% of butyl cellosolve, 1.0%-4.0% of a rust transforming agent and the balance of pigment filling slurry. The organic oxime rust transforming agent and the aqueous iron rust transforming undercoat are good in transforming property and can react chemically with iron rust to generate stable complexes, so that the iron dust is effectively sealed and isolated from external substances, thus achieving a rust prevention purpose.

Owner:山东卡勒新材料有限公司

Anti-corrosion process for iron handrail

PendingCN112827785ATo achieve the purpose of rust preventionEasy to carryPretreated surfacesAnti-corrosive paintsMetallurgyCleansing Agents

The invention provides an anti-corrosion process for an iron handrail. The process is characterized by comprising the following steps: pretreatment and anti-rust paint coating, in the pretreatment, spraying a cleaning agent on the surface of the iron handrail by using a spray cleaning device, and cleaning the iron handrail; and then coating the surface of the handrail with an antirust agent. When the anti-corrosion process is used for carrying out anti-corrosion treatment on the iron handrail, the anti-corrosion process has the advantages of short construction time in the pretreatment process and long anti-corrosion effect.

Owner:日照中意华坤金属制造有限公司

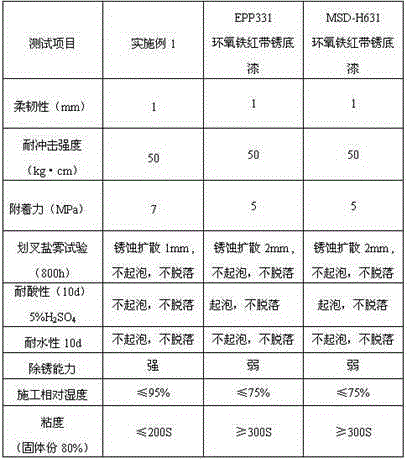

Epoxy anti-corrosion paint with rust

ActiveCN102911586BExcellent anti-rust and anti-corrosion performanceStrong adhesionAnti-corrosive paintsEpoxy resin coatingsPhytic acidPhosphoric acid

The invention provides an epoxy anticorrosion decoration paint. The epoxy anticorrosion decoration paint is characterized by being prepared by mixing a component A and a component B according to the weight ratio of 4:1, wherein the component A contains 30-50% of low molecular weight epoxy resin, 5-10% of zinc phosphate, 5-10% of packing, 5-10% of aluminium triphosphate, 20-30% of iron oxide red, 0.2-0.5% of tetra-n-propyl zirconate, 0.1-0.3% of silane coupling agent and 5-20% of butyl cellosolve, and the component B contains 30-50% of amino-terminated epoxy-amine affixture, 0.1-0.5% of penetrant, 0.1-0.5% of phytic acid, 30-48% of ethanol and 30-48% of n-butyl alcohol. The paint has excellent corrosion resistance, strong base material adhesion, good flexibility and shock resistance, high solid content, low viscosity, strong tolerance to environment humidity and strong construction adaptability.

Owner:江苏纽克莱涂料有限公司

Antirust coating for mechanical device and preparation method of antirust coating

InactiveCN108659666AStrong adhesionImprove heat resistanceAntifouling/underwater paintsPaints with biocidesEpoxyTetrafluoroborate

The invention discloses antirust coating for a mechanical device. The antirust coating is prepared from the following raw materials in parts by weight: 20 to 30 parts of phenolic resin, 15 to 25 partsof epoxy resin, 10 to 20 parts of silicone acrylic emulsion, 4 to 8 parts of tetraethylammonium tetrafluoroborate, 2 to 3 parts of cellulose acetate, 3 to 6 parts of dibutyl phthalate, 2 to 5 parts of strontium chromate, 3 to 9 parts of rosin, 2 to 4 parts of iron oxide, 1 to 3 parts of nano silver, 2 to 7 parts of modified bamboo powder, 1 to 4 parts of dispersing agent, 2 to 4 parts of thickening agent, 3 to 5 parts of stabilizer, and 15 to 25 parts of deionized water. By controlling the original types and proportion, the prepared antirust coating is low in cost, good in heat dissipation performance, excellent in heat resistance and salt resistance, and capable of effectively prolonging the service life of the machinery.

Owner:ANHUI TONGSHENG RING

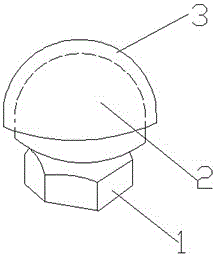

Rust-proof cap nut

InactiveCN105041822AAvoid enteringTo achieve the purpose of rust preventionPinsNutsPulp and paper industryPrism

The invention discloses a rust-proof cap nut. The rust-proof cap nut is creatively characterized in that the cap nut comprises a nut body and a nut cap, wherein the nut body and the nut cap are integrally formed; the nut body is in a prism shape, the direct ration of the nut cap and the nut body is 2 to 1, and the nut body is treated through a nickel plating process; and the nut cap is sleeved with sealing rubber. According to the rust-proof cap nut, the rust-proof cap nut is protected against rust by the nut cap and the sealing rubber; the size of the nut cap is larger than that of the nut body, rain can be thrown off through the radian of the top of the nut cap, and therefore air and moisture in the outside are prevented from entering the cap nut effectively; the nut body is treated through the nickel plating process, a layer of razor-thin passive film can be generated on the surface of the nut quickly, and the stability in the air is very high; and the nut cap is sleeved with the sealing rubber and thus capable of being resistant to corrosion by the atmosphere, alkali and some acids.

Owner:NANTONG DILONG KNITTING GARMENT

A kind of solvent-free railway screw spike with rust anti-corrosion coating and preparation method thereof

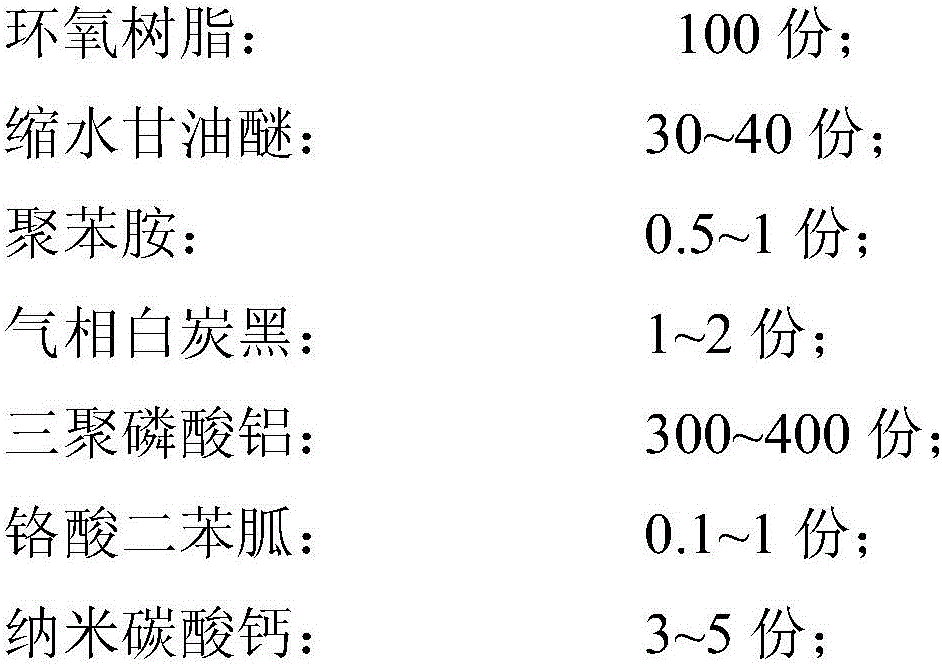

ActiveCN104513586BReduce usageLow viscosityAnti-corrosive paintsEpoxy resin coatingsGas phaseSolvent free

The invention belongs to the technical field of coatings and particularly relates to a solvent-free railway screw spike antirust corrosion-resistant coating and a preparation method thereof. The preparation method includes following steps: (1) successively feeding raw materials into a high-speed dispersing machine for dispersion, wherein the raw materials includes, by mass, 100 parts of epoxy resin, 30-40 parts of glycidyl ether, 0.5-1 part of polyaniline and 1-2 parts of gas-phase white carbon black; (2) successively adding 300-400 parts by mass of aluminium tripolyphosphate, 0.1-1 part by mass of diphenyl guanidine chromate and 3-5 parts by mass of nano calcium carbonate into the dispersed raw materials and performing dispersion continuously to obtain an A component raw mixture; (3) grinding the A component raw mixture on a sand mill and discharging an obtained material; and (4) heating 100 parts by mass of a modified aromatic amine and adding 4-6 parts by mass of salicylic acid, maintaining the temperature and mixing and stirring the mixture for one hour to obtain a B component raw mixture; and (5) mixing the grinded A component raw mixture and the obtained B component raw material mixture with stirring uniformly to obtain a finished product of the coating.

Owner:石家庄利鼎电子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com