A kind of solvent-free railway screw spike with rust anti-corrosion coating and preparation method thereof

A spiral spike, rust and anti-corrosion technology, applied in the field of coatings, can solve the problems of difficult rust removal, flammable and explosive, rust and dust endangering human health, etc., achieve good permeability and wettability, avoid toxic and harmful, widen The effect of using the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

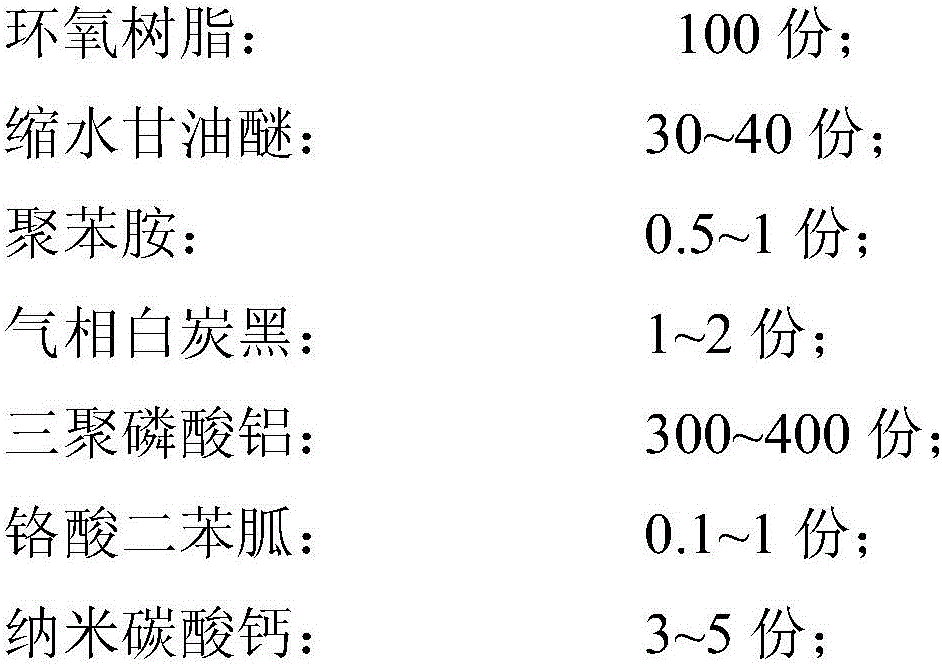

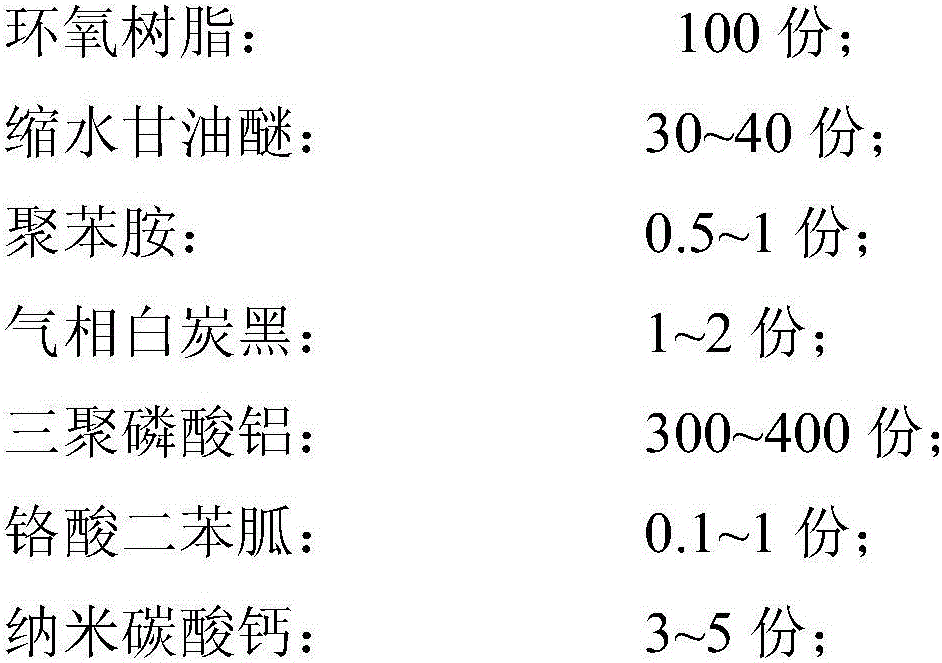

[0045] (1) Put 100 parts of epoxy resin, 30 parts of glycidyl ether, 0.5 parts of polyaniline and 1 part of fumed silica in parts by mass into a high-speed disperser for dispersing. The number of revolutions of the disperser is 1000 rpm , dispersed for 4 minutes;

[0046] (2) By mass parts, 300 parts of aluminum tripolyphosphate, 0.1 part of diphenylguanidine chromate, and 3 parts of nano-calcium carbonate are added successively in step (1) after passing through the raw materials dispersed by the high-speed disperser, continue to disperse by the high-speed disperser, The number of rotations of the disperser is 1000 rpm, and the dispersion is for 2 minutes to obtain the raw material mixture of component A;

[0047] (3) Grinding the component A raw material mixture obtained in step (2) on a sand mill until the particle size is less than 40 microns and then discharging;

[0048] (4) Heat 100 parts by mass of the modified aromatic amine to 80° C., add 4 parts by mass of salicylic...

Embodiment 2

[0053] (1) Add 100 parts of epoxy resin, 40 parts of glycidyl ether, 1 part of polyaniline and 2 parts of fumed silica in parts by mass to a high-speed disperser for dispersing. The number of revolutions of the disperser is 1200 rpm , dispersed for 6 minutes;

[0054](2) 400 parts of aluminum tripolyphosphate, 1 part of diphenylguanidine chromate, and 5 parts of nano-calcium carbonate are added successively in steps (1) in the raw materials dispersed by the high-speed disperser in parts by mass, and continue to be dispersed by the high-speed disperser, The number of rotations of the disperser is 1200 rpm, and the dispersion is for 4 minutes to obtain the raw material mixture of component A;

[0055] (3) Grinding the component A raw material mixture obtained in step (2) on a sand mill until the particle size is less than 40 microns and then discharging;

[0056] (4) Heat 100 parts by mass of the modified aromatic amine to 100° C., add 6 parts by mass of salicylic acid, heat-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com