Antirust coating for mechanical device and preparation method of antirust coating

A technology for anti-rust coatings and mechanical equipment, applied in the direction of anti-corrosion coatings, anti-fouling/underwater coatings, epoxy resin coatings, etc., can solve the problems of poor heat resistance and poor corrosion resistance of anti-rust coatings, and achieve stable performance, Strong adhesion and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

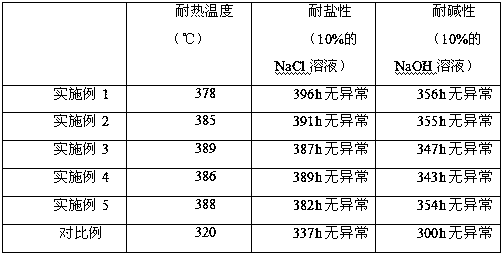

Examples

Embodiment 1

[0028] This embodiment relates to a kind of antirust paint for mechanical equipment, including the following raw materials in parts by weight: 20 parts of phenolic resin, 15 parts of epoxy resin, 10 parts of silicon acrylic emulsion, 4 parts of tetraethylamine tetrafluoroborate, cellulose acetate 2 parts of prime, 3 parts of dibutyl phthalate, 2 parts of strontium chromate, 3 parts of rosin, 2 parts of iron oxide, 1 part of nano-silver, 2 parts of modified bamboo powder, 1 part of dispersant, 2 parts of thickener , 3 parts of stabilizer and 15 parts of deionized water.

[0029] Wherein, the preparation method of described modified bamboo powder is as follows:

[0030] First soak the bamboo powder in a dilute nitric acid solution with a mass fraction concentration of 4% for 4 hours, then ultrasonically treat it at an ultrasonic frequency of 22kHz and a power of 758W for 20min, then add an equivalent amount of sodium polyacrylate under stirring, heat up to 80°C for 45min, and re...

Embodiment 2

[0042] This embodiment relates to a kind of antirust paint for mechanical equipment, including the following raw materials in parts by weight: 30 parts of phenolic resin, 25 parts of epoxy resin, 20 parts of silicon acrylic emulsion, 8 parts of tetraethylamine tetrafluoroborate, cellulose acetate 3 parts of prime, 6 parts of dibutyl phthalate, 5 parts of strontium chromate, 9 parts of rosin, 4 parts of iron oxide, 3 parts of nano-silver, 7 parts of modified bamboo powder, 4 parts of dispersant, 4 parts of thickener , 5 parts of stabilizer and 25 parts of deionized water.

[0043] Wherein, the preparation method of described modified bamboo powder is as follows:

[0044] First soak the bamboo powder in a dilute nitric acid solution with a mass fraction concentration of 4% for 4 hours, then ultrasonically treat it at an ultrasonic frequency of 22kHz and a power of 758W for 20min, then add an equivalent amount of sodium polyacrylate under stirring, heat up to 80°C for 45min, and ...

Embodiment 3

[0056] This embodiment relates to a kind of antirust paint for mechanical equipment, including the following raw materials in parts by weight: 22 parts of phenolic resin, 17 parts of epoxy resin, 13 parts of silicon acrylic emulsion, 5 parts of tetraethylamine tetrafluoroborate, cellulose acetate 2.1 parts of prime, 4 parts of dibutyl phthalate, 3 parts of strontium chromate, 4 parts of rosin, 2.4 parts of iron oxide, 1.5 parts of nano-silver, 3 parts of modified bamboo powder, 2 parts of dispersant, 2.6 parts of thickener parts, 3.4 parts of stabilizer and 18 parts of deionized water.

[0057] Wherein, the preparation method of described modified bamboo powder is as follows:

[0058] First soak the bamboo powder in a dilute nitric acid solution with a mass fraction concentration of 4% for 4 hours, then ultrasonically treat it at an ultrasonic frequency of 22kHz and a power of 758W for 20min, then add an equivalent amount of sodium polyacrylate under stirring, heat up to 80°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com