Anti-rust coating layer with high-temperature resistantce for automobile spare and accessory parts and preparation method thereof

A technology of anti-rust coating and spare parts, applied in the direction of coating, anti-corrosion coating, fire-proof coating, etc., to achieve high surface strength and smoothness, improve overall stability and reduce roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

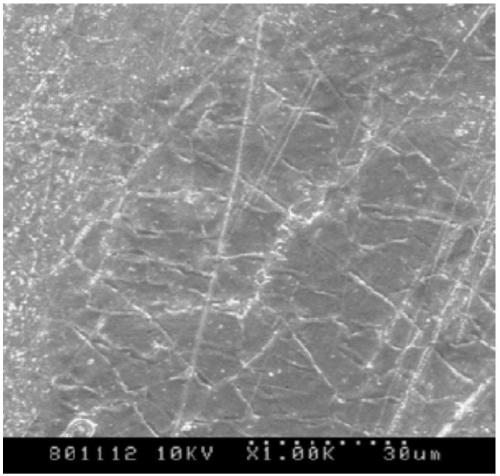

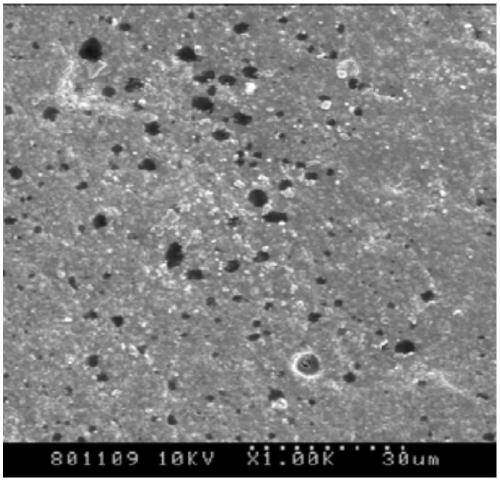

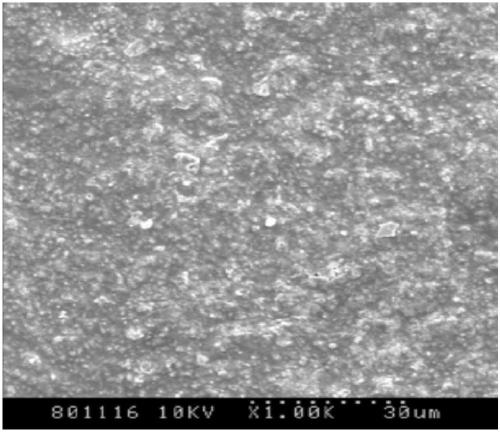

[0040] see Figure 1~3 Shown, a kind of antirust coating for high temperature resistant auto parts is formed after being covered with antirust paint by auto parts surface and is dried, and described antirust paint comprises following raw material composition and parts by weight: 50 parts of filler emulsion, 10 parts of modified polyacrylonitrile-based carbon fiber, 5 parts of toughening lubricant, 5 parts of film former, 8 parts of rosin, 20 parts of deionized water;

[0041] The antirust coating preparation method comprises the steps:

[0042] Step S1: Add 50 parts of filler emulsion to the stirring disperser, after heating up to 60-70°C, add 10 parts of modified polyacrylonitrile-based carbon fiber, first stir at 100-120r / min at high speed for 0.2-0.5h, then reduce the stirring Speed up to 30-40r / min, after stirring for 0.5-1h, stop stirring, put it into an ultrasonic disperser and ultrasonicate for 2-3h, and obtain component A in a hyperdispersed state;

[0043] Step S2...

Embodiment 2

[0055] see Figure 1~3 Shown, a kind of anti-rust coating for high-temperature-resistant auto parts is formed after being covered with anti-rust coating on the surface of auto parts after being dried, and described anti-rust coating comprises following raw material composition and parts by weight: 60 parts of filler emulsion, 20 parts of modified polyacrylonitrile-based carbon fiber, 10 parts of toughening lubricant, 10 parts of film former, 10 parts of rosin, 30 parts of deionized water;

[0056] The antirust coating preparation method comprises the steps:

[0057] Step S1: Add 60 parts of filler emulsion to the stirring disperser, heat up to 60-70°C, add 20 parts of modified polyacrylonitrile-based carbon fiber, first stir at 100-120r / min for 0.2-0.5h at high speed, then reduce the stirring Speed up to 30-40r / min, after stirring for 0.5-1h, stop stirring, put it into an ultrasonic disperser and ultrasonicate for 2-3h, and obtain component A in a hyperdispersed state;

[...

Embodiment 3

[0070] see Figure 1~3Shown, a kind of anti-rust coating for high-temperature-resistant auto parts is formed after being covered with anti-rust coating on the surface of auto parts after being dried, and described anti-rust coating comprises following raw material composition and parts by weight: 60 parts of filler emulsion, 20 parts of modified polyacrylonitrile-based carbon fiber, 10 parts of toughening lubricant, 10 parts of film former, 10 parts of rosin, 30 parts of deionized water;

[0071] The antirust coating preparation method comprises the steps:

[0072] Step S1: Add 60 parts of filler emulsion prepared by montmorillonite that has not been treated with dilute hydrochloric acid into the stirring disperser, after heating up to 60-70°C, add 20 parts of modified polyacrylonitrile-based carbon fiber, first 100-120r / min high-speed stirring for 0.2~0.5h, then reduce the stirring speed to 30~40r / min, after stirring for 0.5~1h, stop stirring, put it into an ultrasonic disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com