Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

308results about "Piston rods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

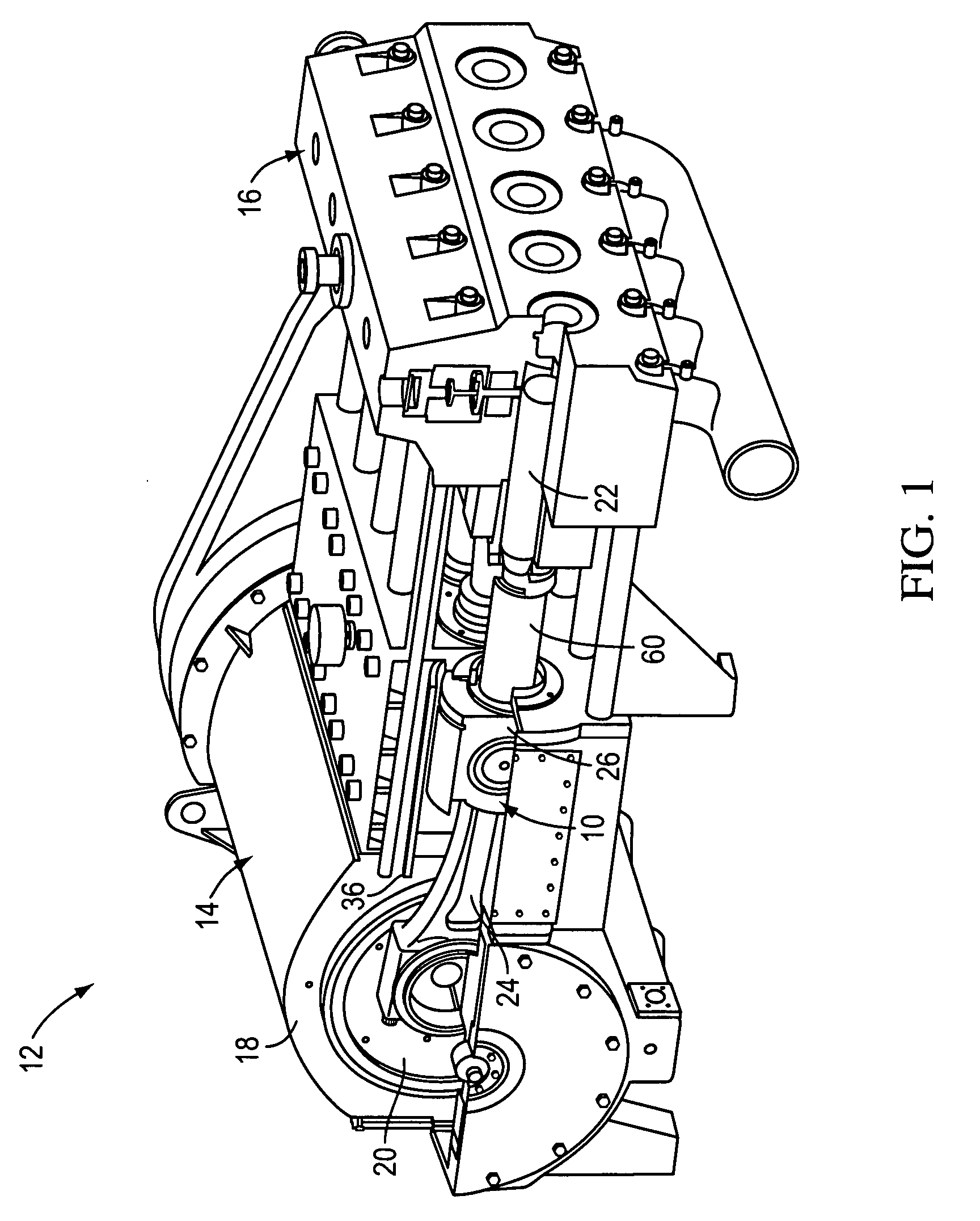

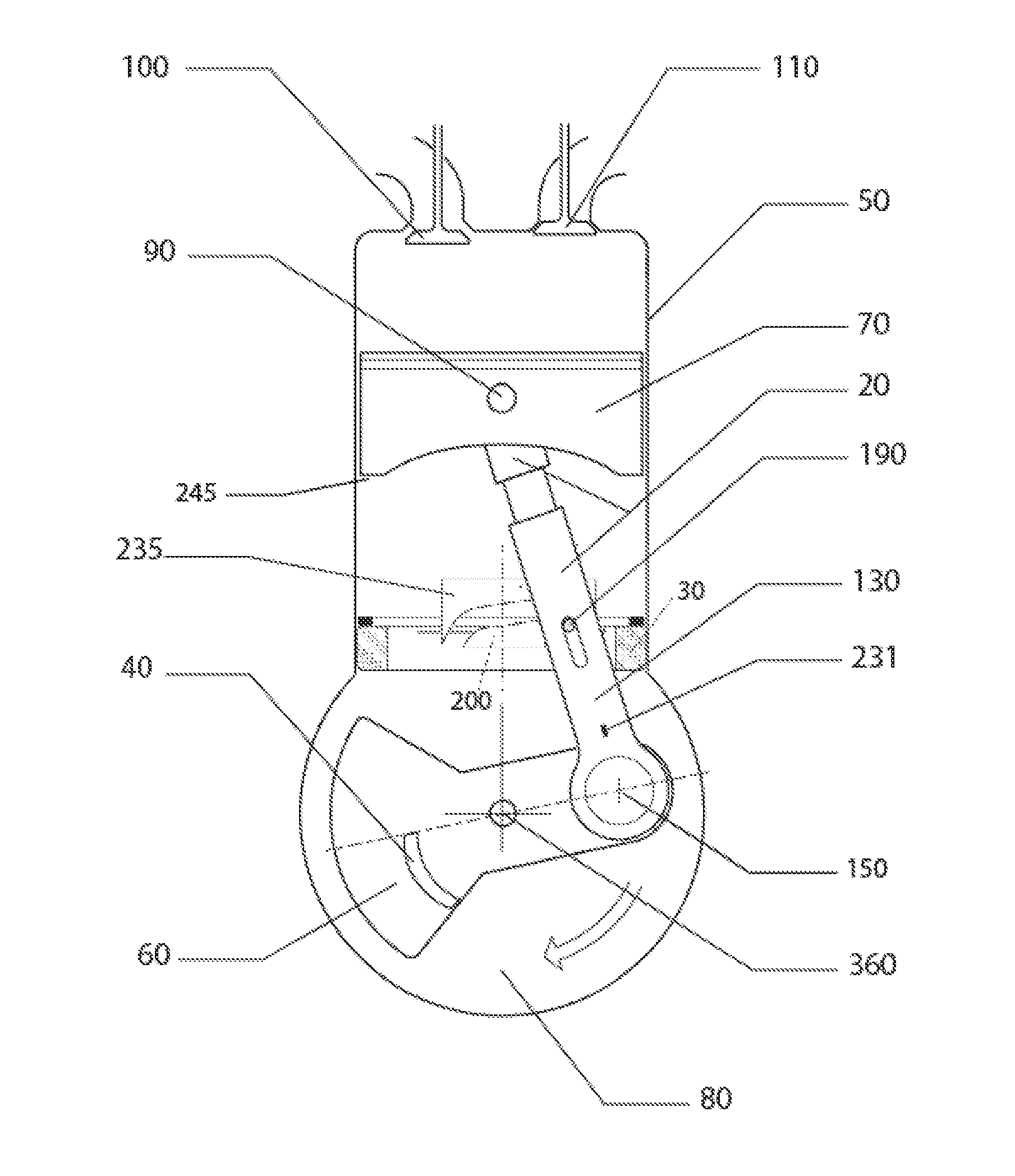

Self-Aspirated Reciprocating Internal Combustion Engine

InactiveUS20110146601A1Eliminating shaft counter weightExcessive vibrationConnecting rodsSealing arrangements for enginesSingle plateInternal combustion engine

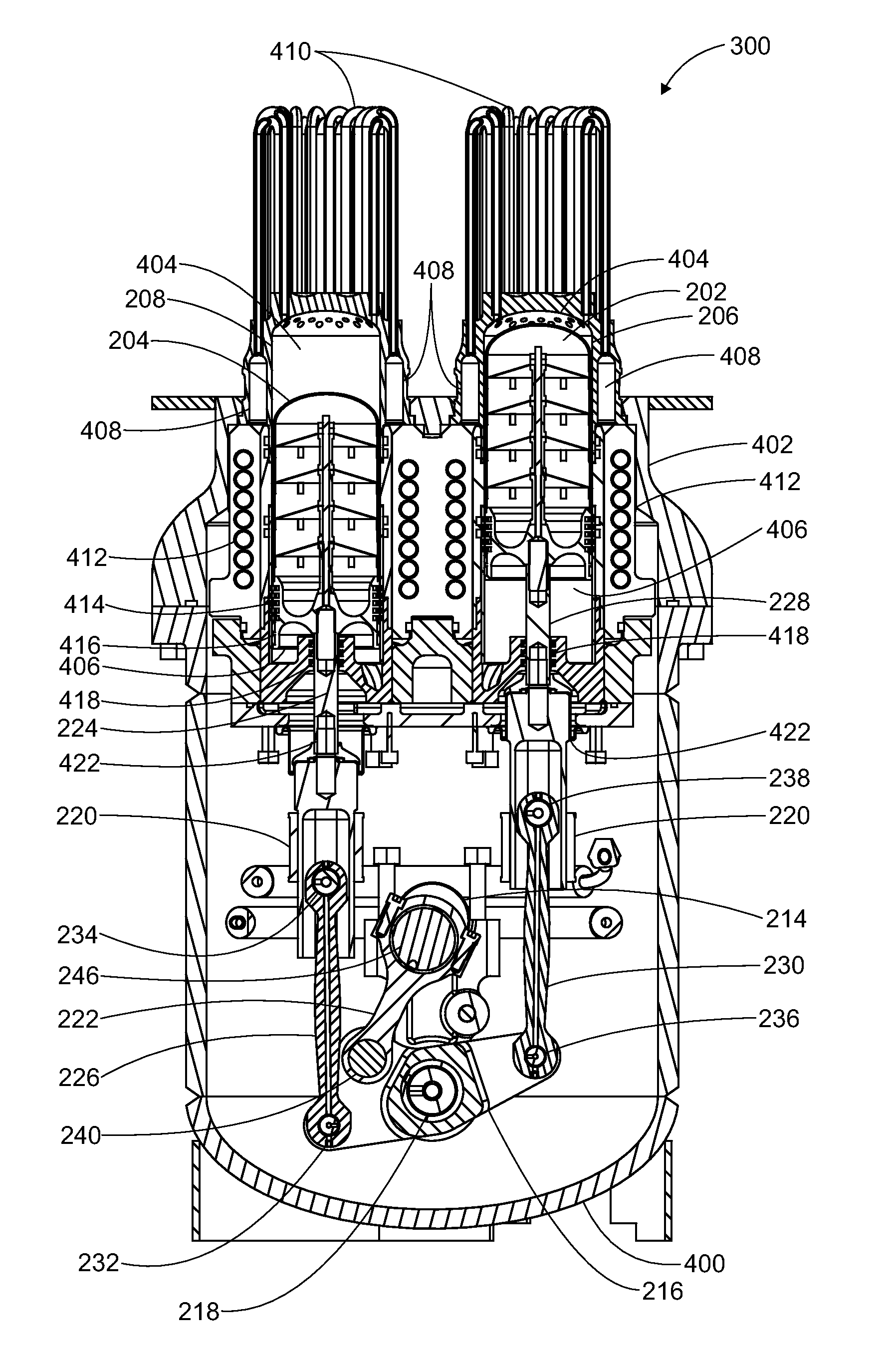

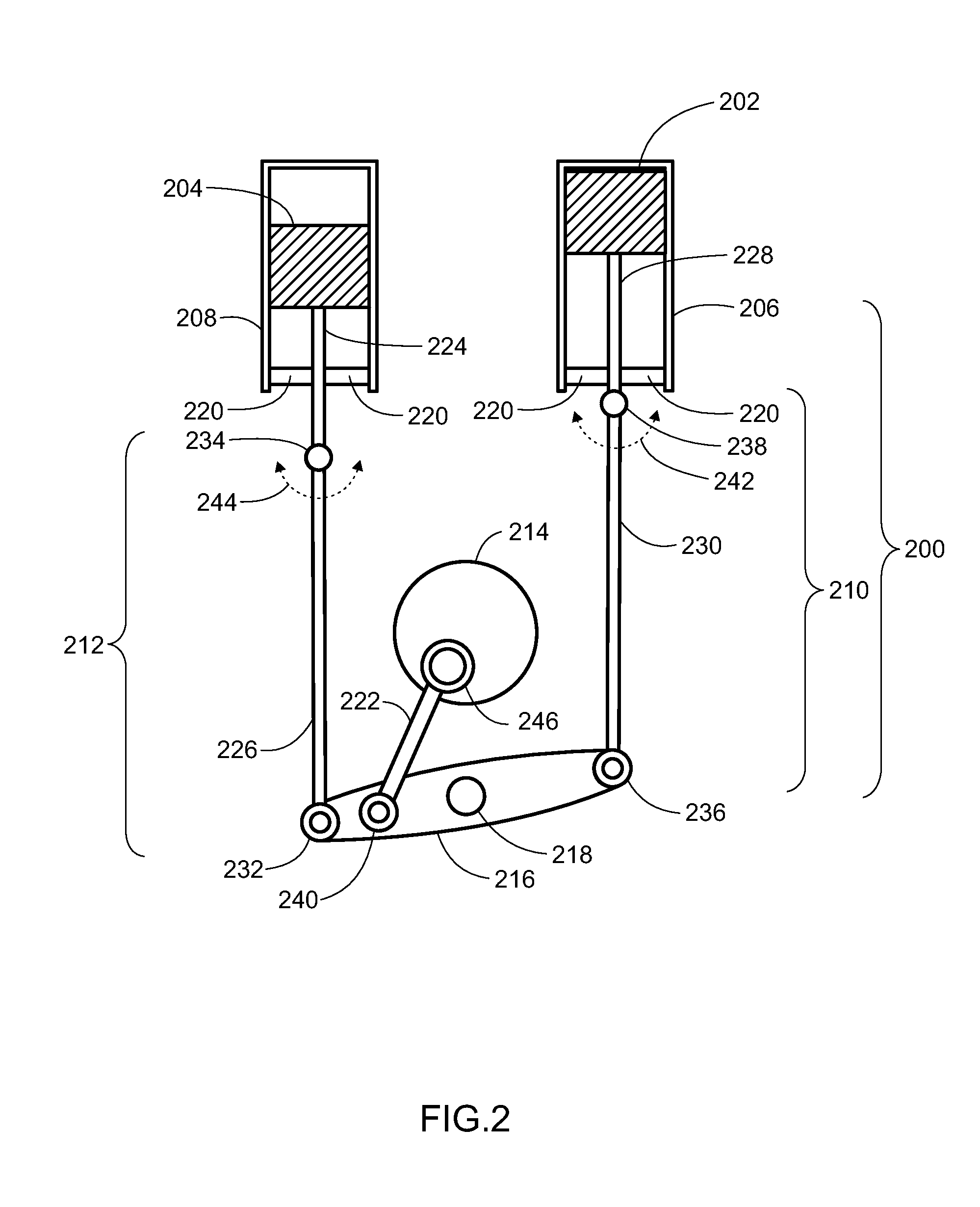

Disclosed are crankshaft, single-plate cam and beam mechanisms that provide significant improvements in performance for 2- & 4-stroke engines, compressors and pumps. These cost effective mechanisms include linkages with the new and improved use of pivoting arms that operate with a variety of cylinder arrangements. One embodiment of the crankshaft mechanism has its crankpin roller positioned within a novel yoke-arm. The cam mechanism uses a pair of centrally positioned parallel links that are connected to roller cam followers and single or diametrically-opposed pistons. A pair of laterally extending follower arms connects to the ends of the links to provide support and alignment for the piston rods. Between the reciprocating links, cam followers and follower arms is a rotating odd-lobe plate cam. A beam mechanism uses opposite-direction extending balancing beams that are connected to links, cam followers and piston rods.

Owner:FISHER PATRICK T

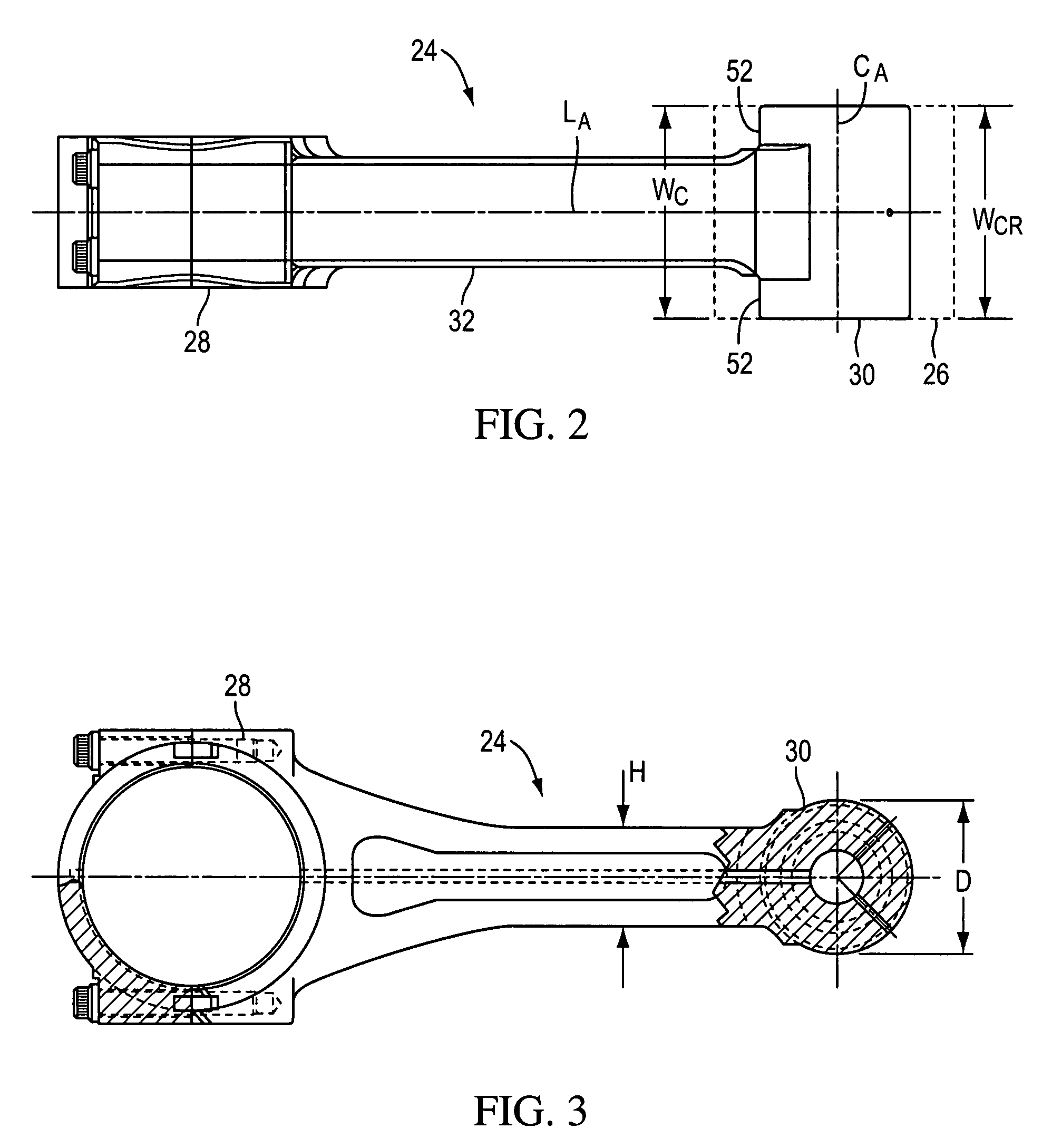

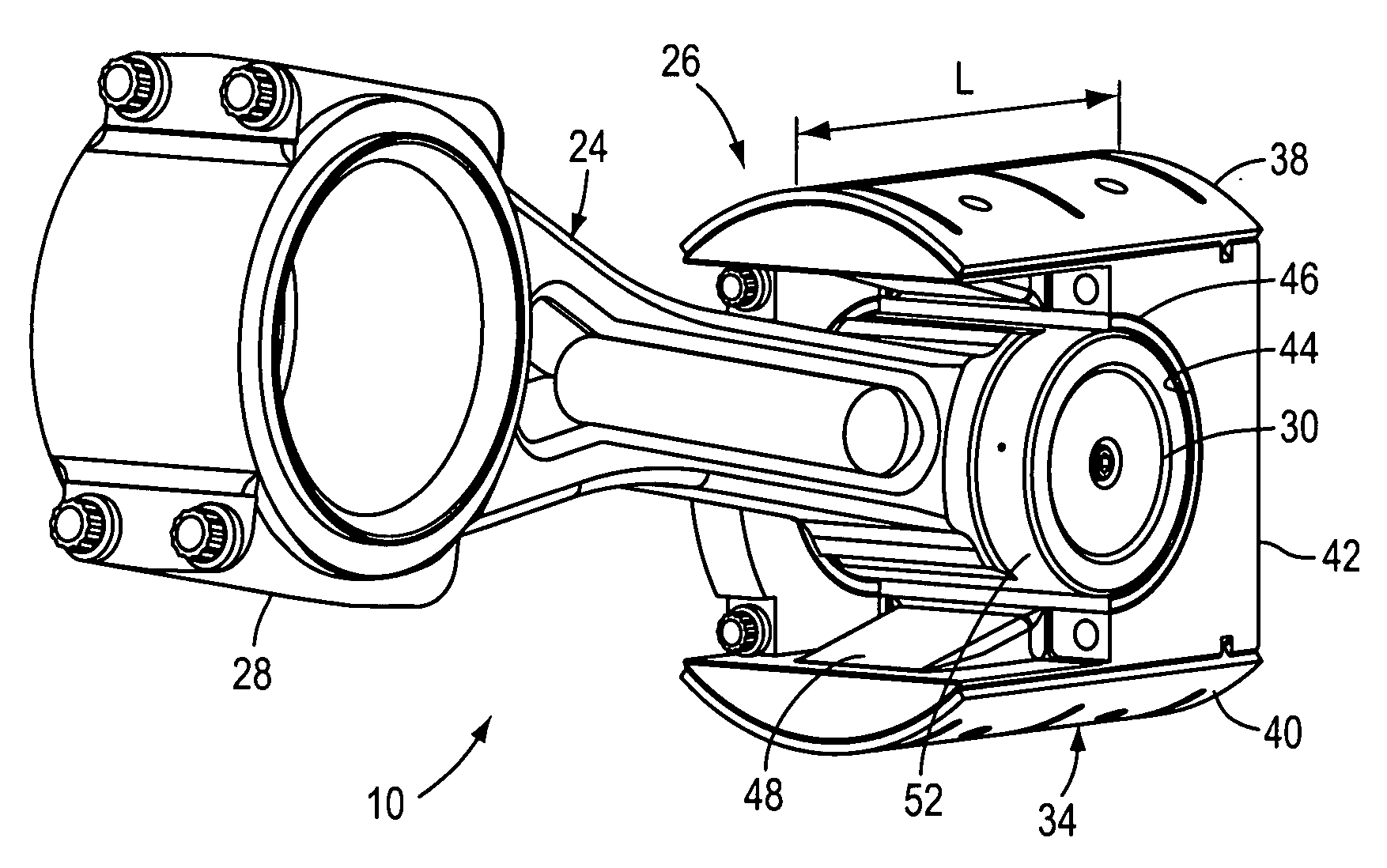

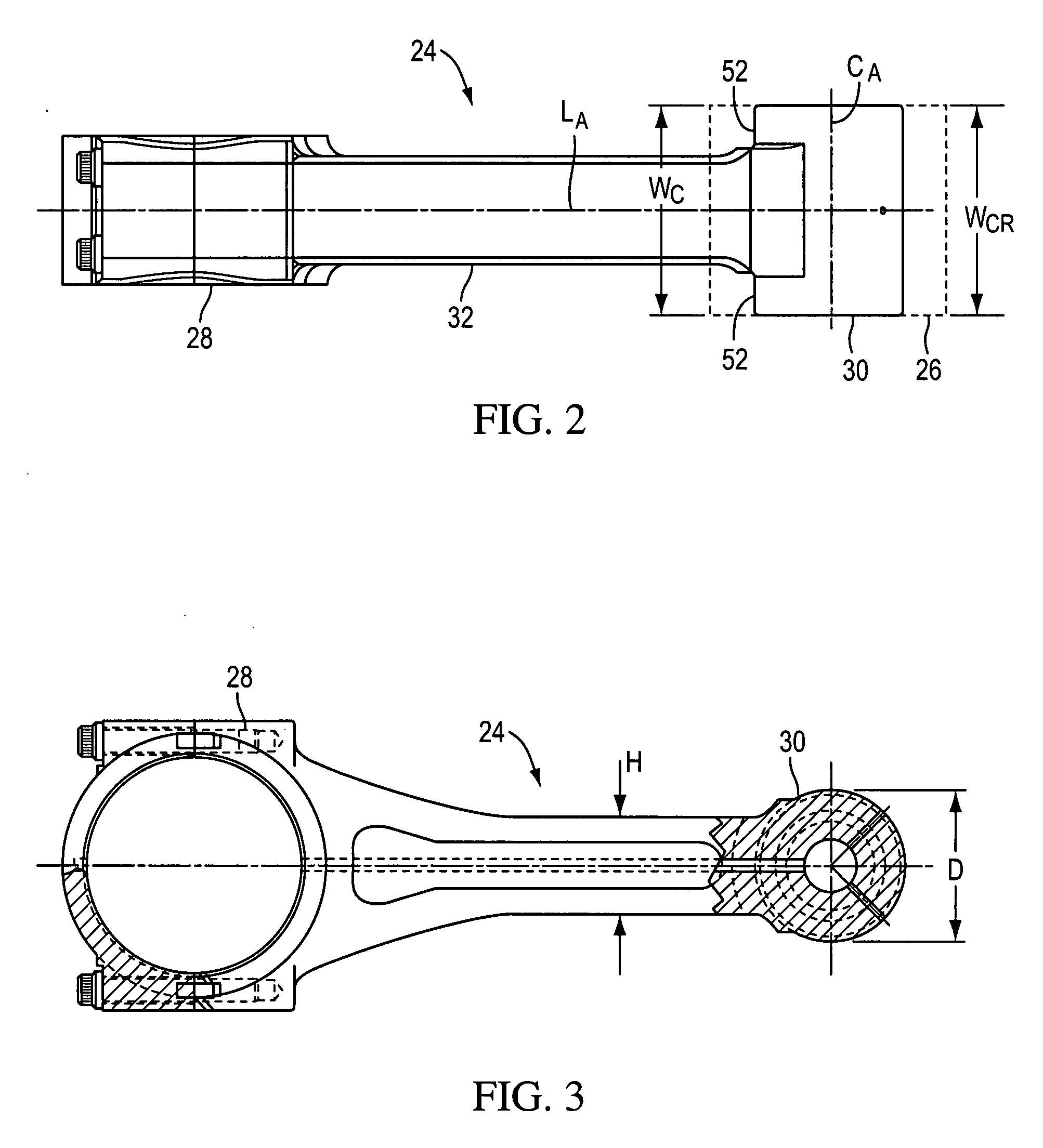

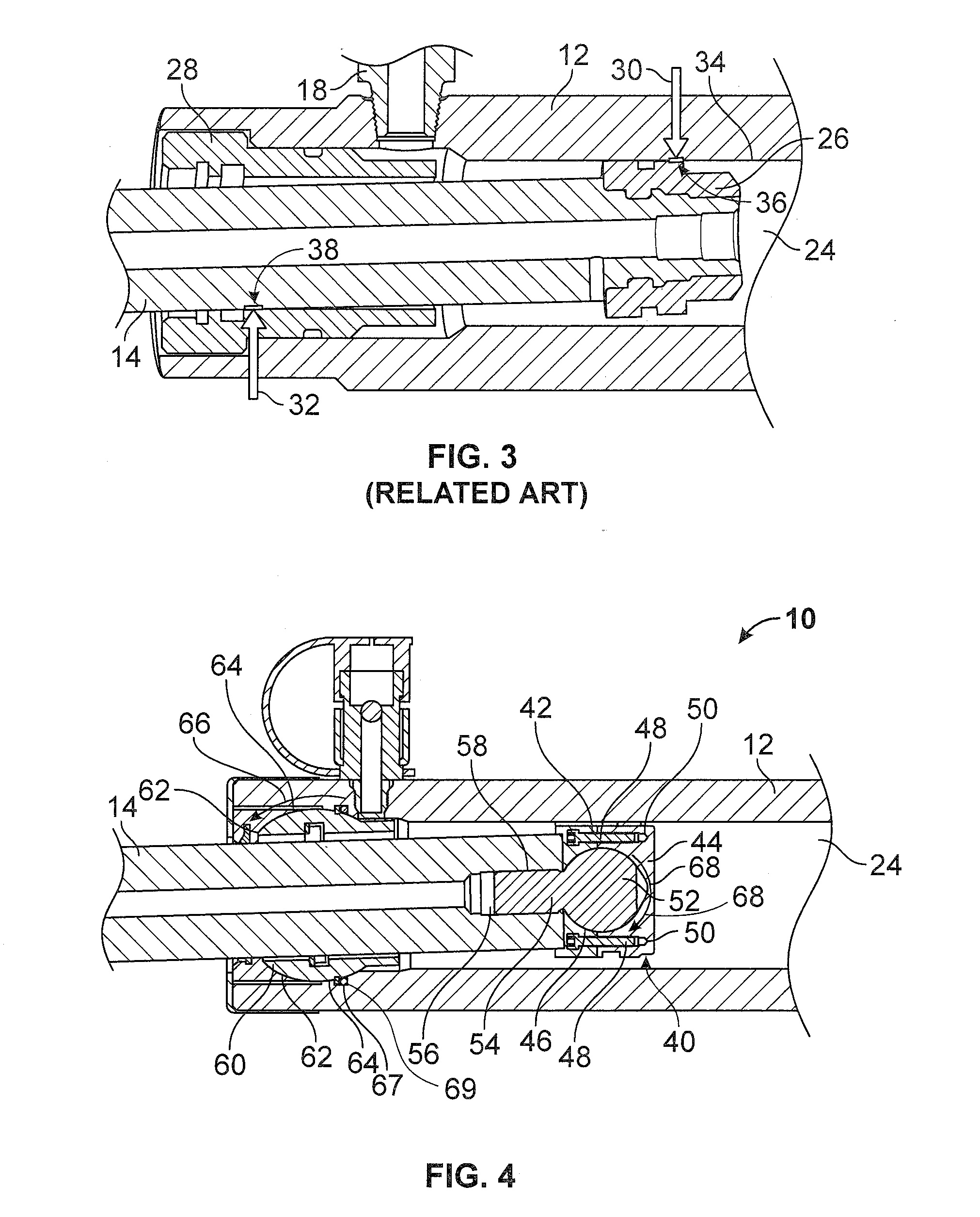

Pump crosshead and connecting rod assembly

ActiveUS7610847B2Increase surface areaBearing stressConnecting rodsPositive displacement pump componentsEngineeringMechanical engineering

A crosshead and connecting rod assembly for a pump comprises a connecting rod which includes a first end that is rotatably connected to the crankshaft of the pump, a second end that comprises a generally cylindrical configuration, and a shaft that extends between the first and second ends. The second end comprises at least one annular shoulder adjacent to the shaft, and the crosshead and connecting rod assembly further comprises a crosshead which includes a body that comprises a generally semi-cylindrical socket within which the second end is rotatably received and at least one trunnion that comprises a generally semi-cylindrical recess which aligns with the socket and within which the shoulder is rotatably received when the trunnion is connected to the body.

Owner:FMC TECH INC

Pump crosshead and connecting rod assembly

ActiveUS20080006148A1Increase surface areaBearing stressConnecting rodsPositive displacement pump componentsEngineeringMechanical engineering

A crosshead and connecting rod assembly for a pump comprises a connecting rod which includes a first end that is rotatably connected to the crankshaft of the pump, a second end that comprises a generally cylindrical configuration, and a shaft that extends between the first and second ends. The second end comprises at least one annular shoulder adjacent to the shaft, and the crosshead and connecting rod assembly further comprises a crosshead which includes a body that comprises a generally semi-cylindrical socket within which the second end is rotatably received and at least one trunnion that comprises a generally semi-cylindrical recess which aligns with the socket and within which the shoulder is rotatably received when the trunnion is connected to the body.

Owner:FMC TECH INC

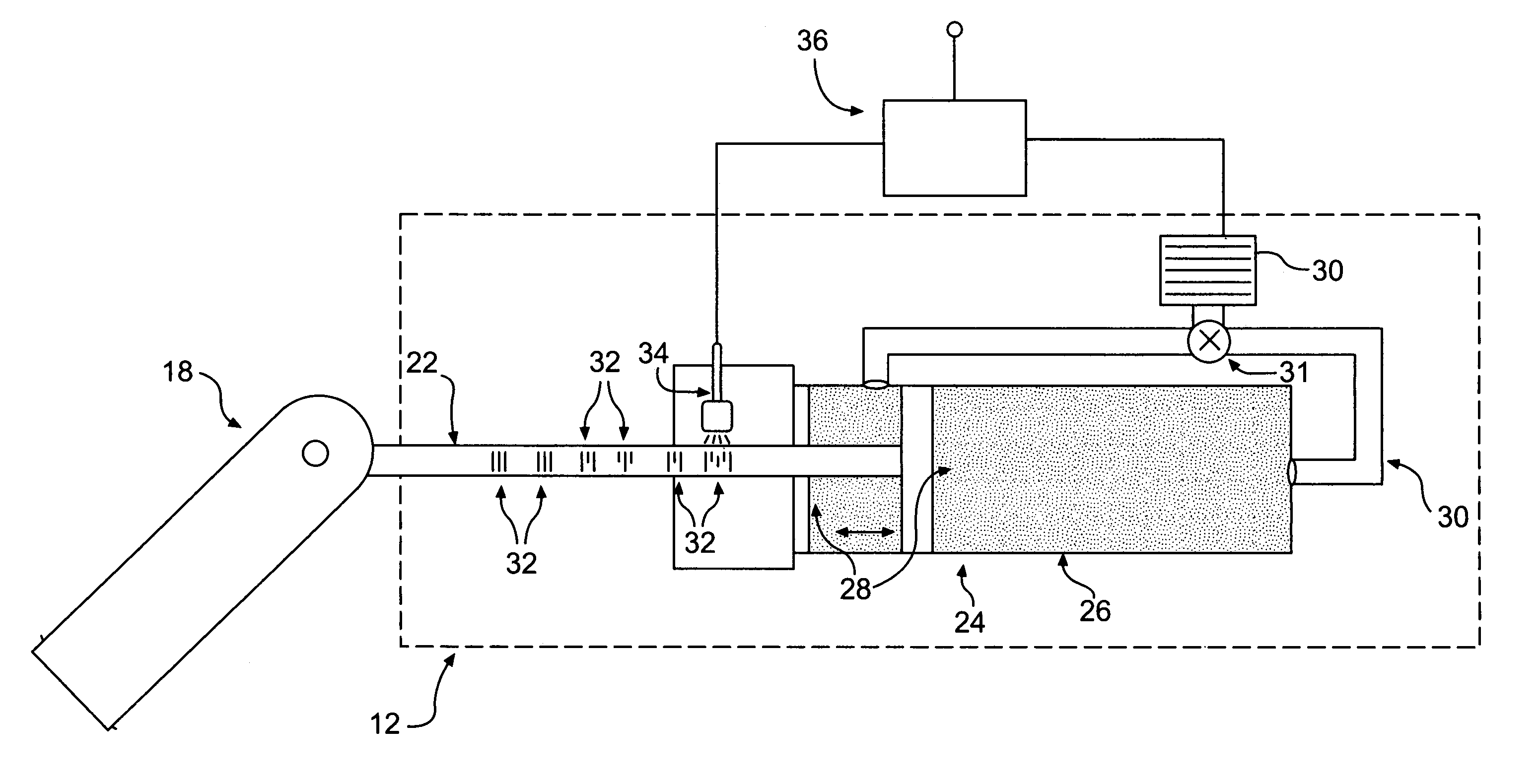

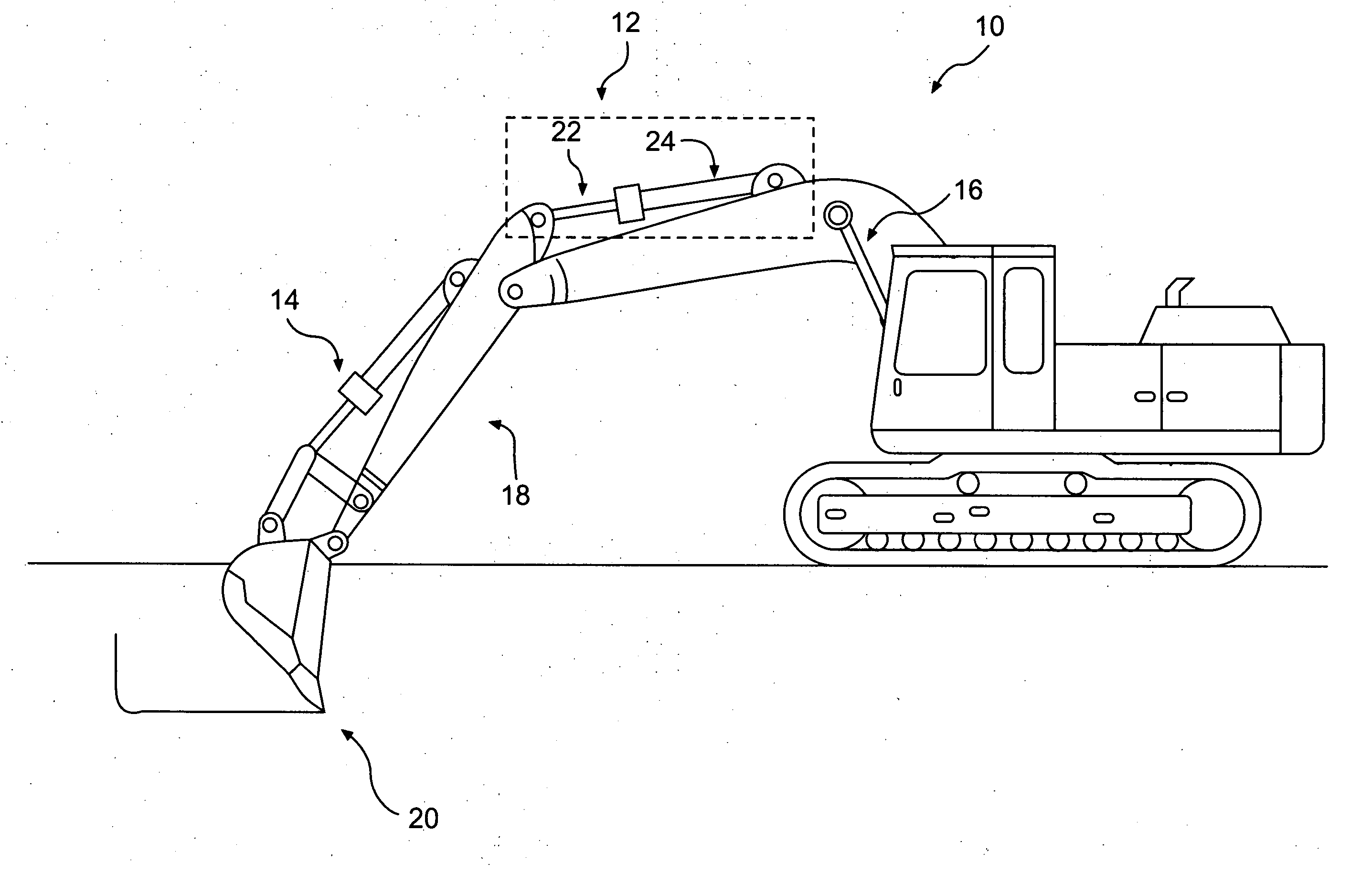

Cylinder rod with position sensor surface markings

A cylinder rod with wear-resistant surface markings is provided. The cylinder rod may include a rod substrate, a thermal-spray coating disposed on a surface of the substrate, and one or more surface markings disposed on the coating at predetermined locations along the length of the cylinder rod.

Owner:CATERPILLAR INC

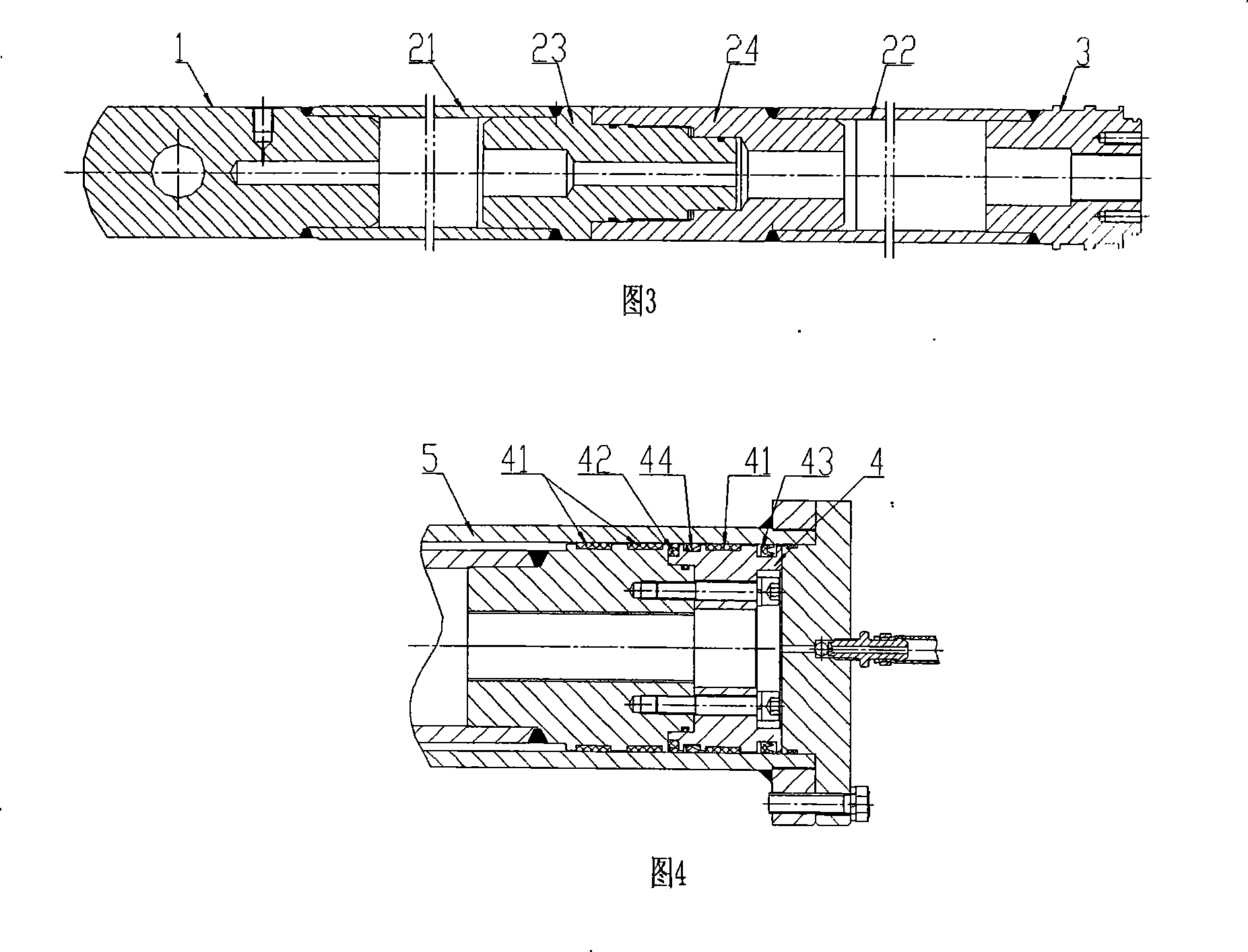

Multifunctional crown block piston rod

InactiveCN102384266AAddressing Early Fatigue FracturesSolve wear and tearSolid state diffusion coatingPiston rodsBiochemical engineeringStress relief

The invention provides a multifunctional crown block piston rod. A piston is arranged on a piston rod, the piston rod and the piston are of an integral structure, the piston rod is made of 38CrMoA1A steel, and the production process of the piston rod is as follows: blank-forging-normalizing-rough turning-tempering-semi finish turning-stress relief annealing-grinding-ion nitriding-polishing. The piston rod provided by the invention has high strength and rigidity and good wear resistance and fatigue resistance, so that the problem that the piston rod is easy to be fatigue to break and easy to wear in the early stage can be solved, and the service life of the piston rod is prolonged greatly and can be longer than 18 months.

Owner:贵阳白云高原紧固件有限公司

Cylinder rod with position sensor surface markings

A cylinder rod with wear-resistant surface markings is provided. The cylinder rod may include a rod substrate, a thermal-spray coating disposed on a surface of the substrate, and one or more surface markings disposed on the coating at predetermined locations along the length of the cylinder rod.

Owner:CATERPILLAR INC

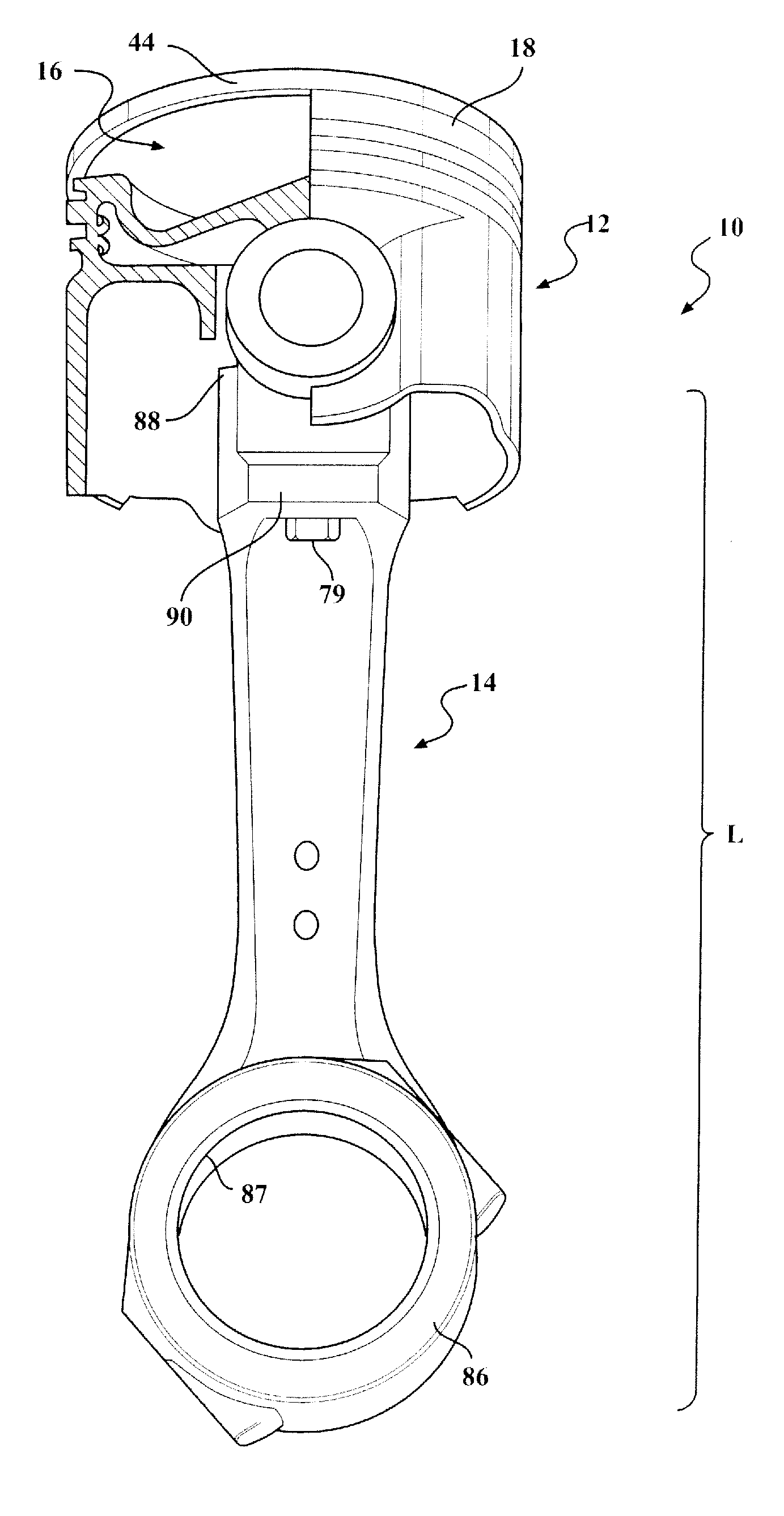

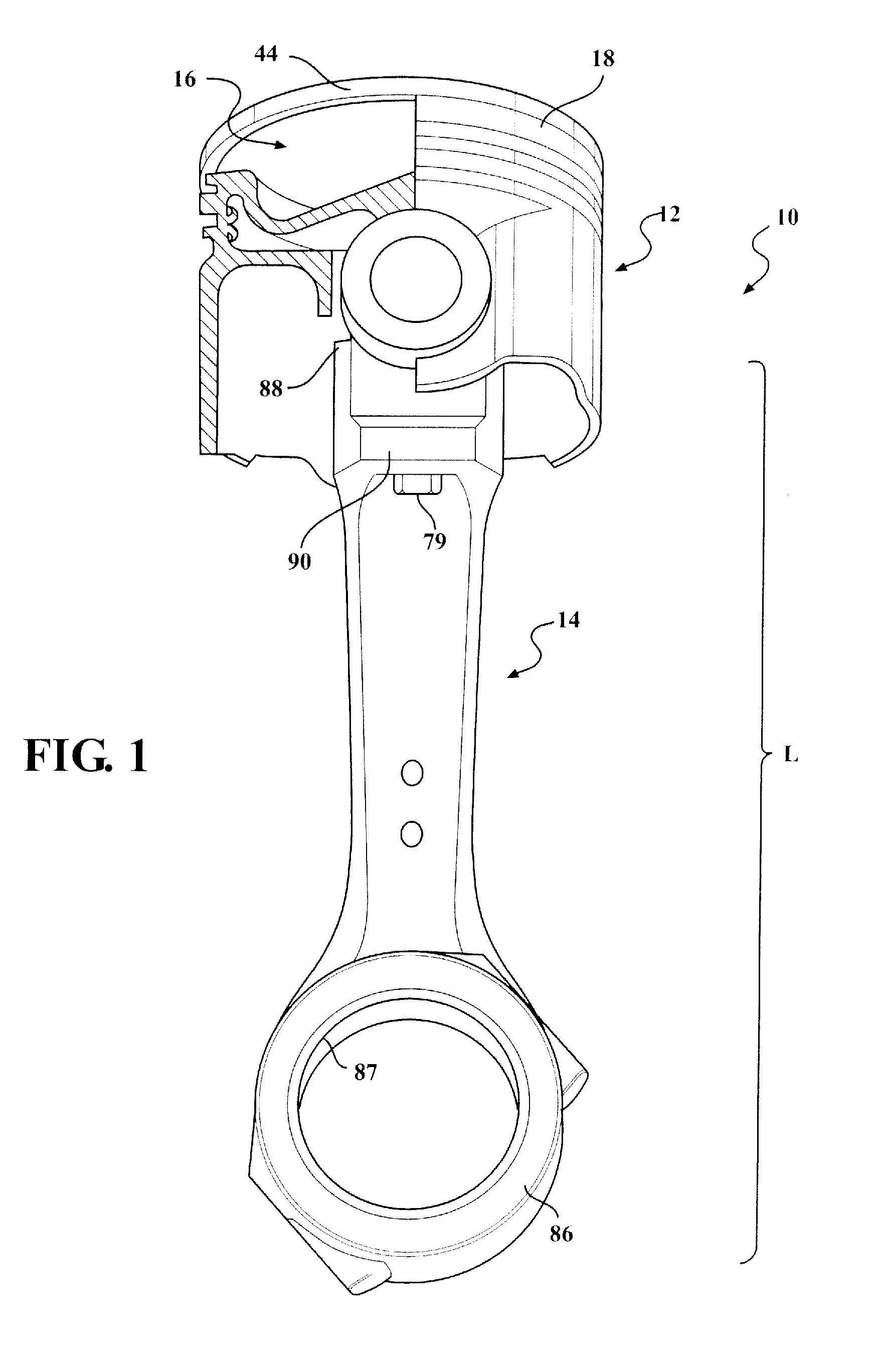

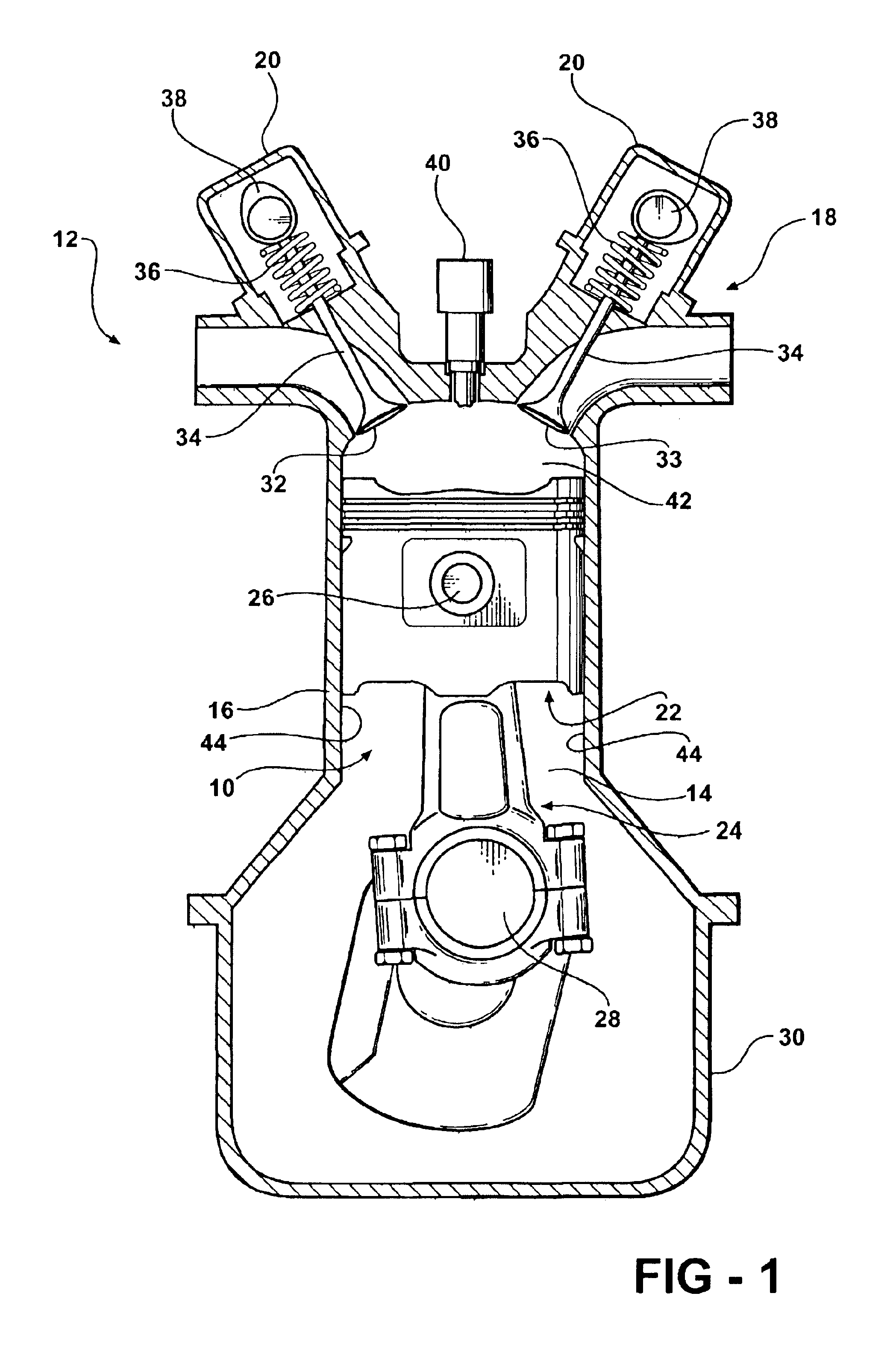

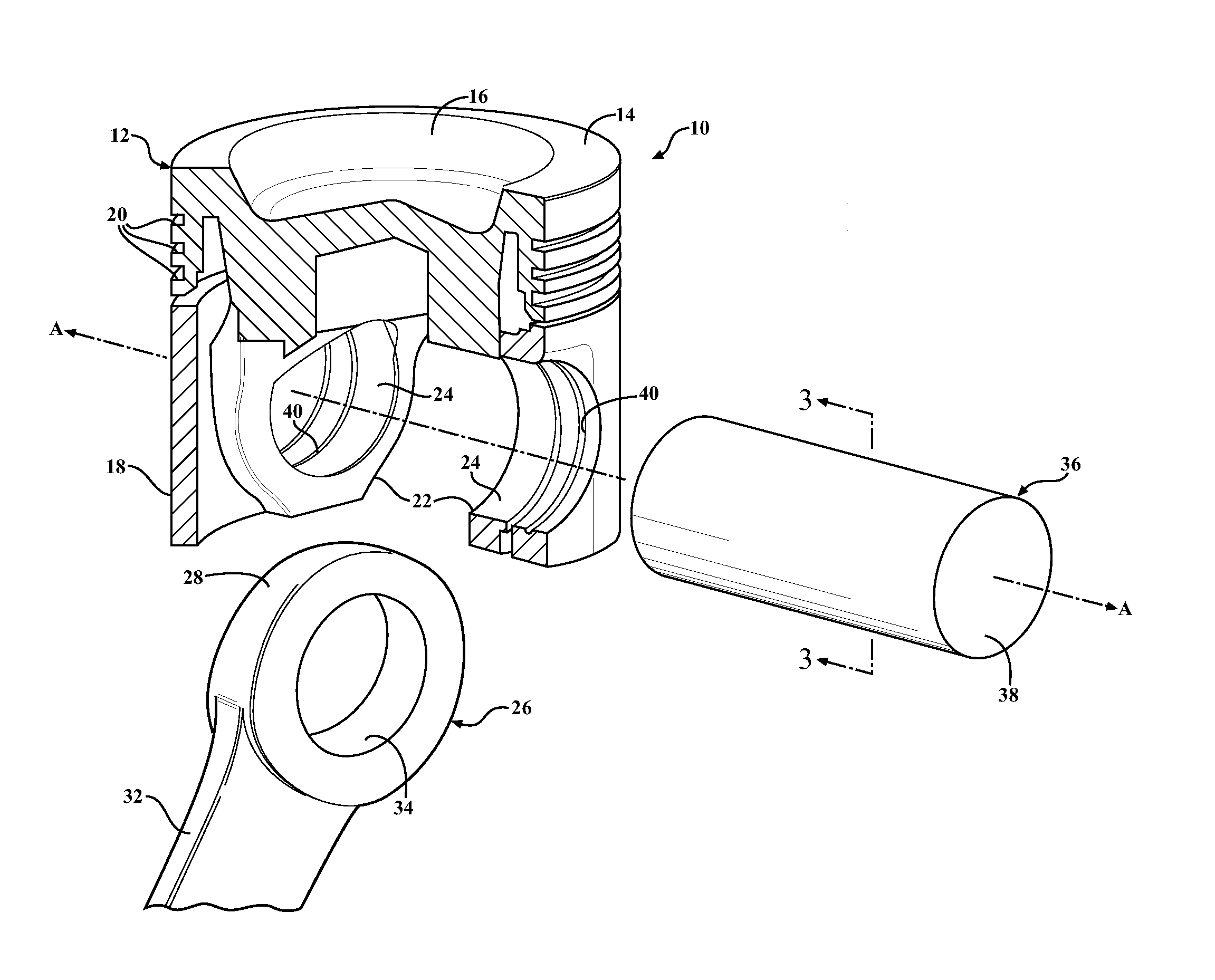

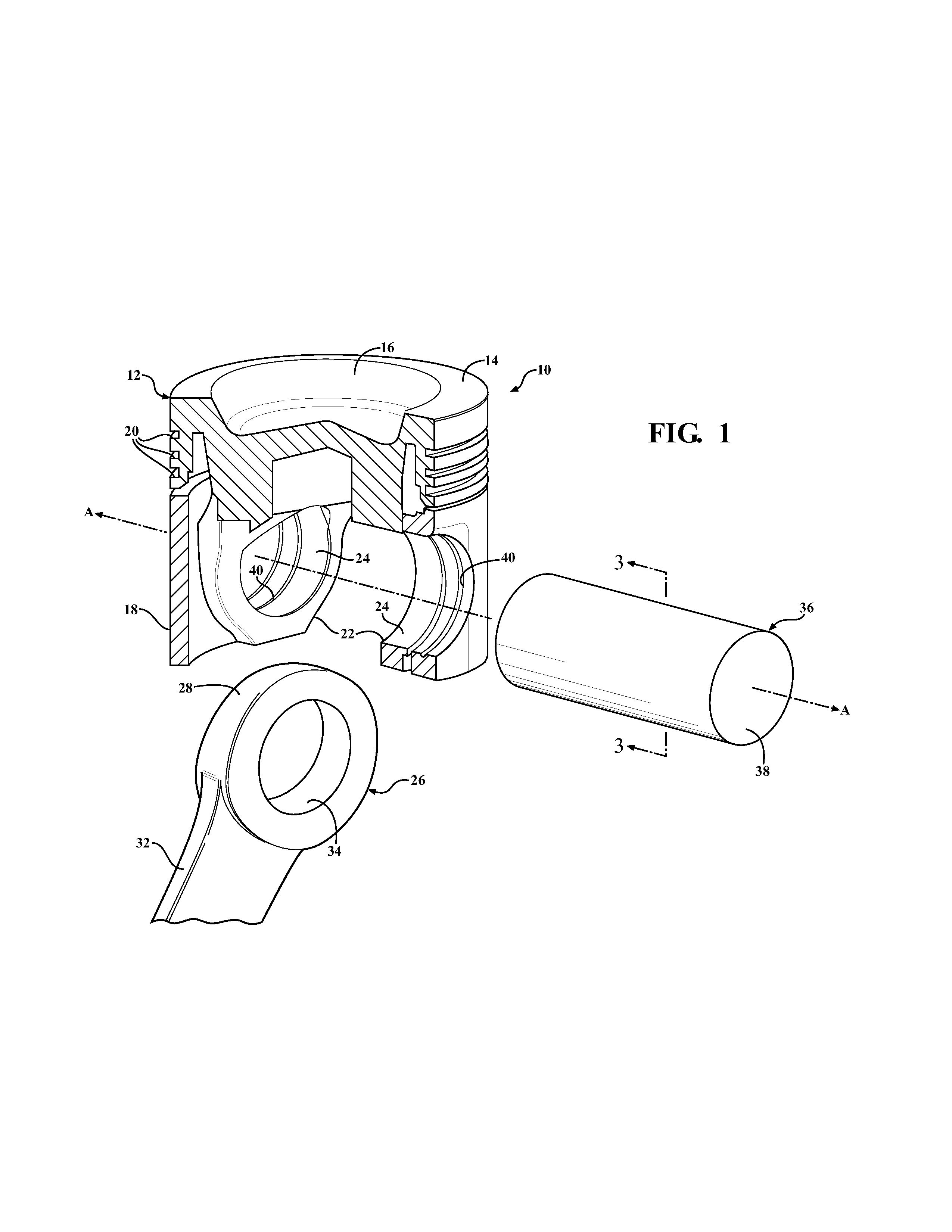

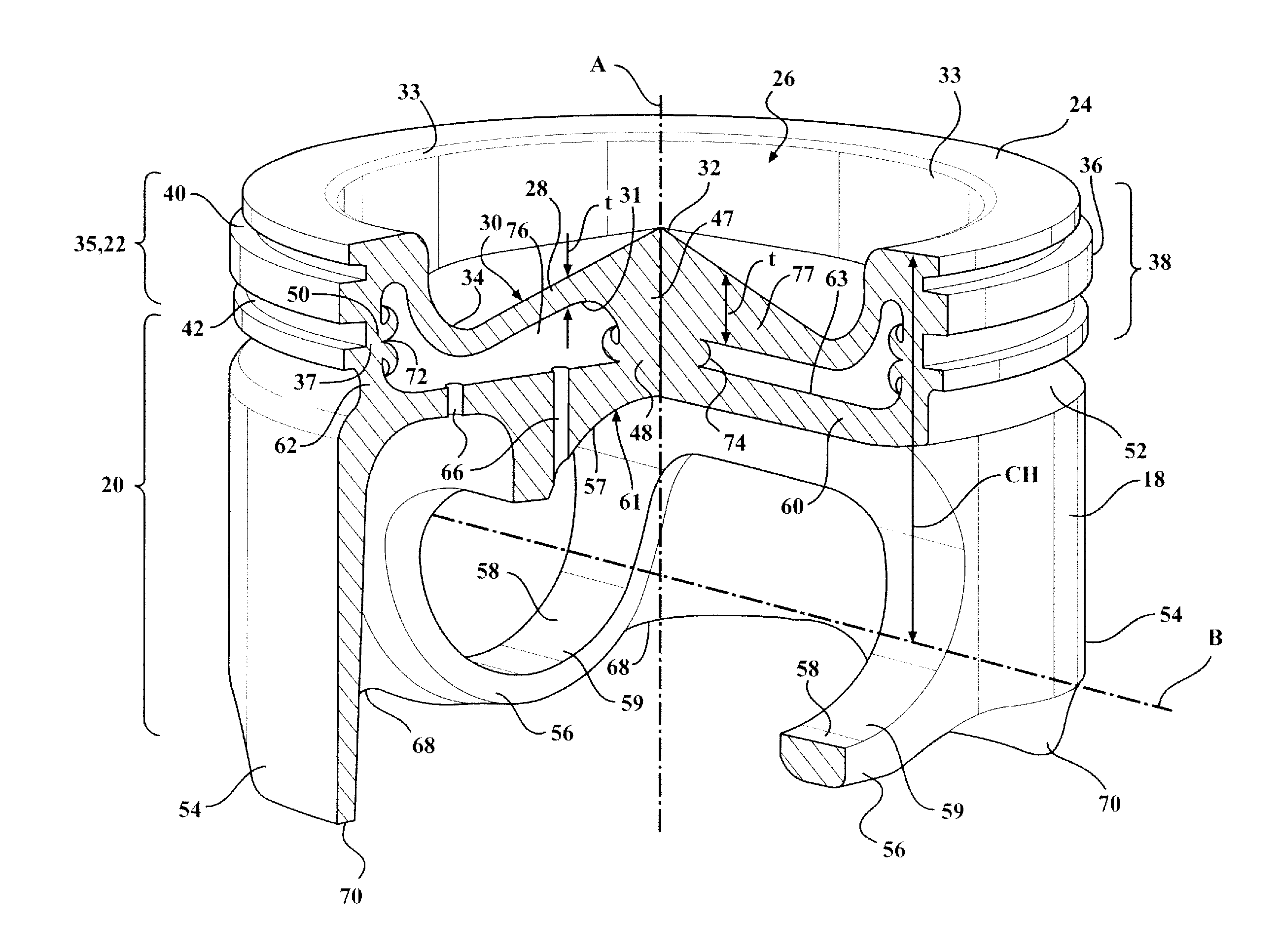

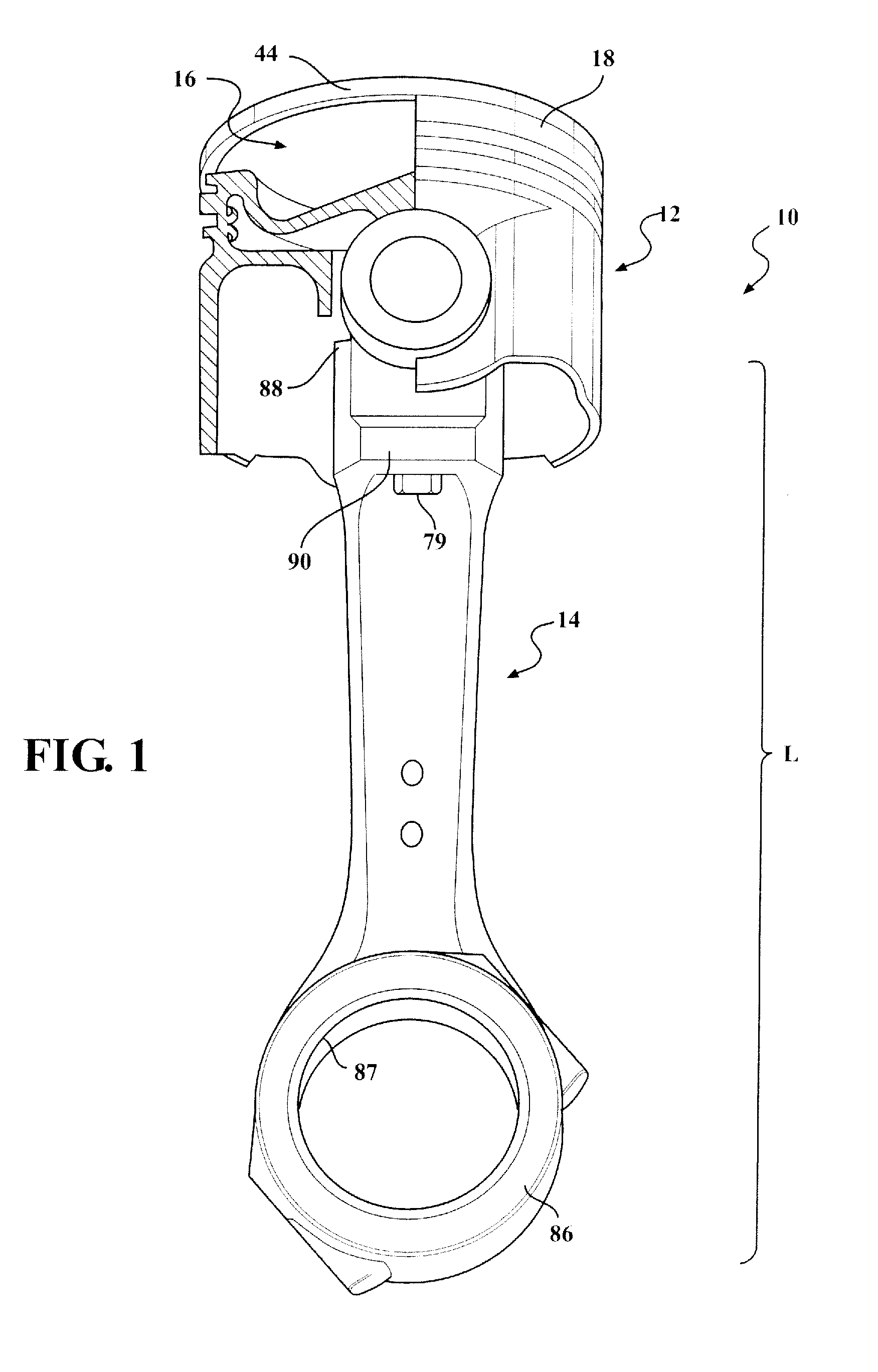

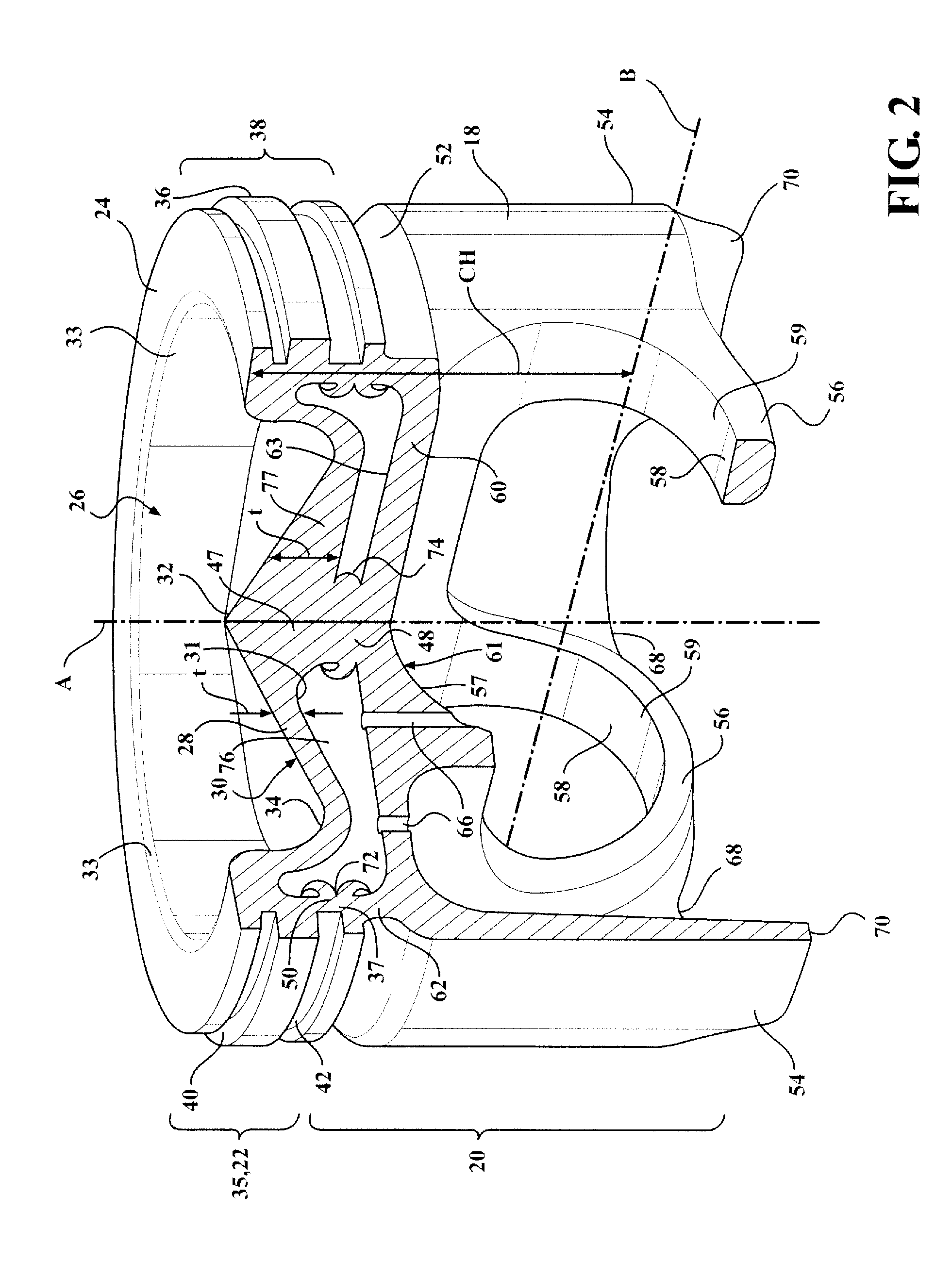

Reduced compression height piston and piston assembly therewith and methods of construction thereof

InactiveUS20140083390A1Enhanced strength and durabilityIncreased compressive loadPlungersMachines/enginesCombustionEngineering

A piston assembly and method of construction thereof for an internal combustion engine are provided. The assembly includes a piston head having an upper combustion wall with an undercrown surface and a ring belt region. The piston head has a floor with an upper surface and a bottom surface. The floor is spaced beneath the upper combustion wall in radial alignment with the ring belt region. A substantially enclosed, annular cooling gallery is bounded by the undercrown surface and the floor. A pair of pin bores depends directly from the floor of the cooling gallery. The assembly further includes a pin having ends configured for oscillating receipt in the pin bores. A pin bearing surface extends within the pin bores and between the pin bores in the lower surface of the floor. The assembly includes a connecting rod with an end fixed to the pin for conjoint oscillation therewith.

Owner:TENNECO INC

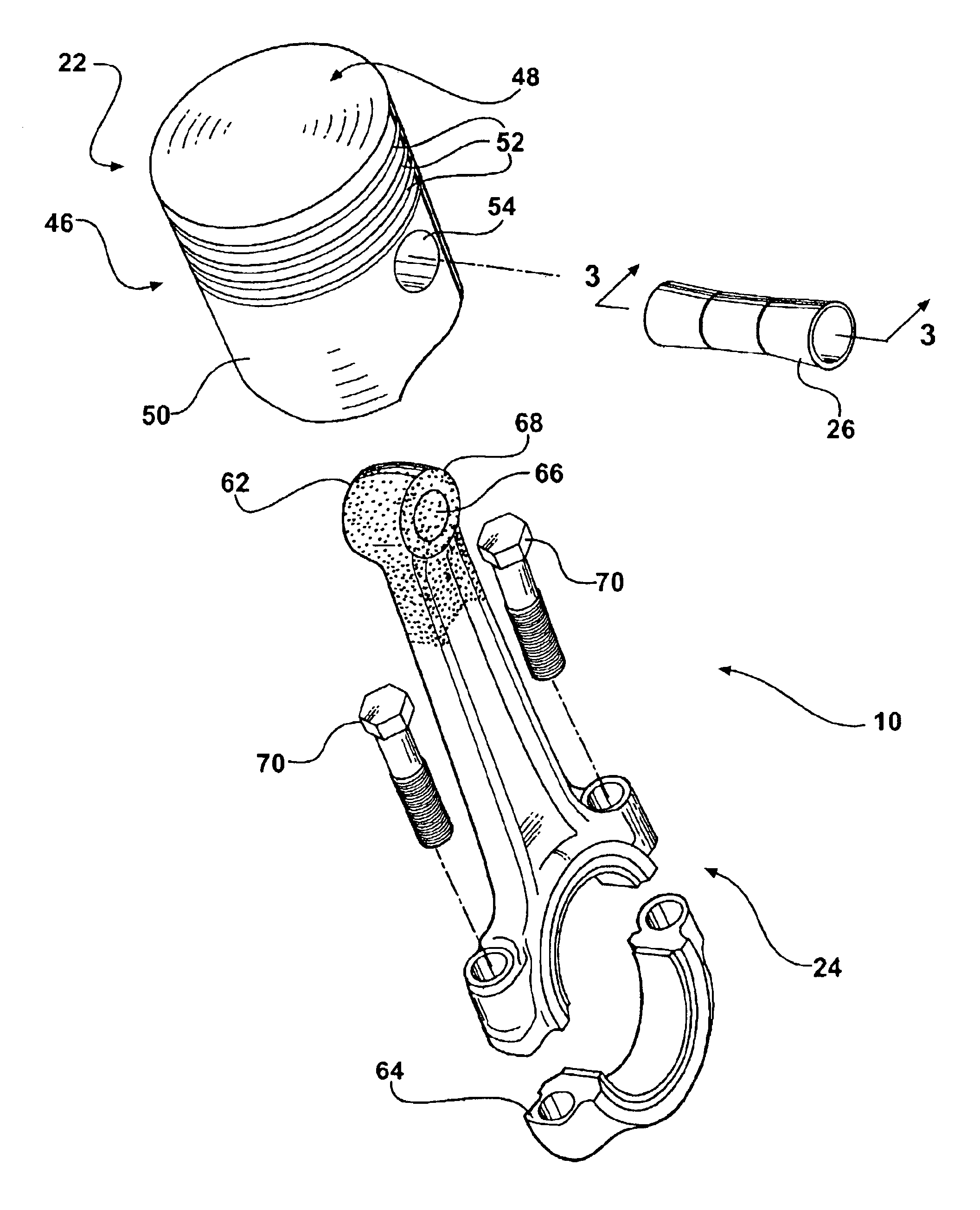

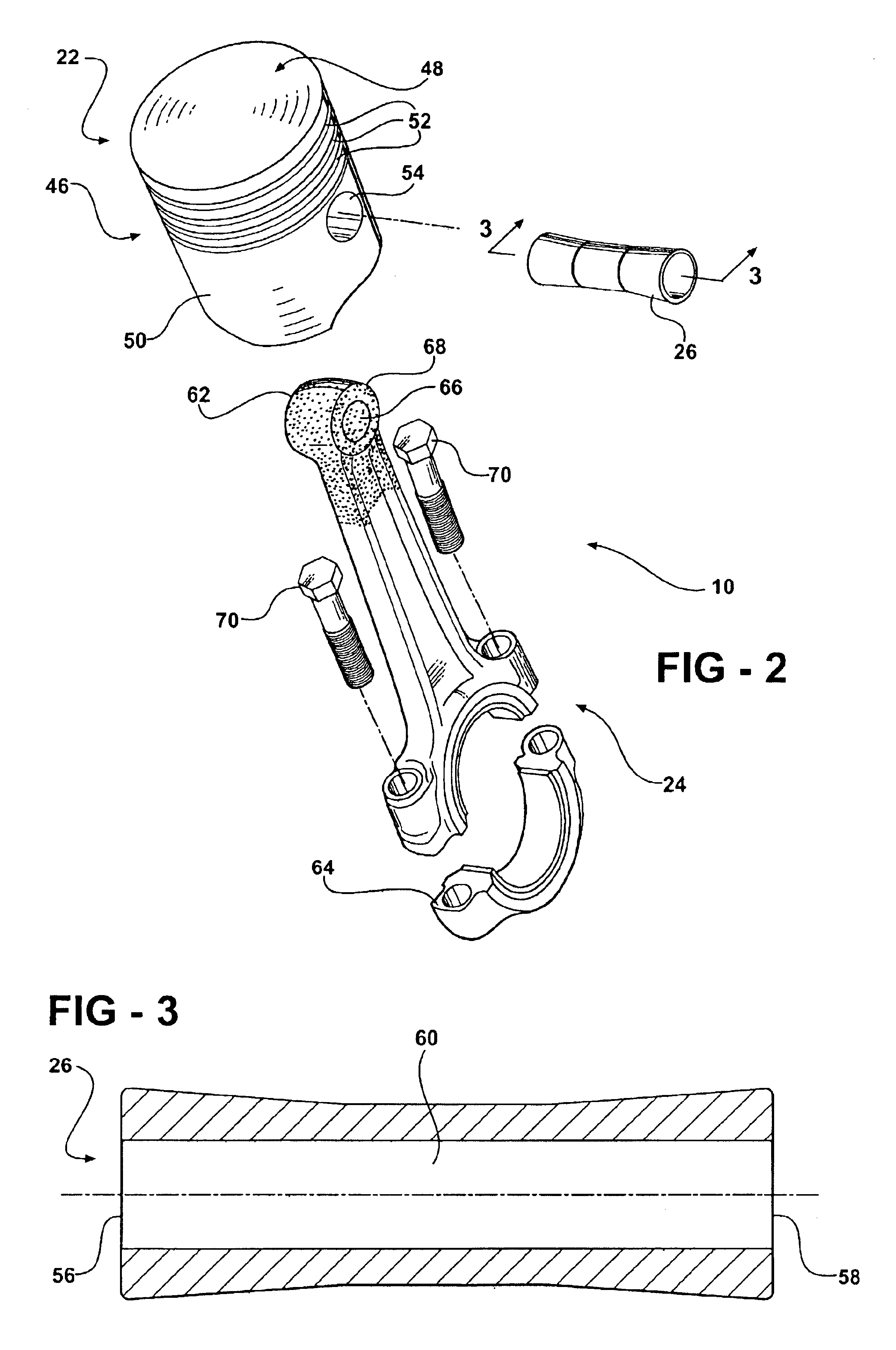

Piston and connecting rod assembly having phosphatized bushingless connecting rod and profiled piston pin

InactiveUS6923153B2Improve wear resistanceAvoid seizuresConnecting rodsPlungersEngineeringInternal combustion engine

The present invention relates to a connecting rod and piston pin assembly for an internal combustion engine to improve wear of the piston / connecting rod pivot point and reduce deformation of the pin bore. To this end, the assembly includes a piston having a pin bore, a connecting rod having a bore adapted to be aligned with the piston pin bore and piston pin interconnecting the piston and the connecting rod through engaging their respective bores. The piston pin has a profiled outer circumference that is substantially circular in cross-section with a larger diameter at the distal ends than at the center portion. One end of the connecting rod includes a phosphatized coating and is adapted to facilitate movement between the connecting rod bore and the profiled piston pin.

Owner:MAHLE TECH

Composite coating piston rod and manufacturing method thereof

ActiveCN103775634AHigh hardnessImprove wear resistanceVacuum evaporation coatingSputtering coatingDiamond-like carbonSurface layer

The invention discloses a composite coating piston rod and a manufacturing method thereof, and relates to the field of air compressor piston rods. The composite coating piston rod has high surface hardness and comprises a piston rod body, a nitriding layer is arranged on the surface of the piston rod body, a composite coating is attached outside the nitriding layer, a metal bottom layer, a hard coating and a solid lubrication surface layer are sequentially arranged on the composite coating from inside to outside, the metal bottom layer is Ti or Cr layer, the hard coating is a metal nitride or metal carbonitride layer, the hardness of the metal nitride or metal carbonitride layer is 20GPa-50GPa, the surface friction coefficient of the metal nitride or metal carbonitride layer is 0.2-0.5, the solid lubrication surface layer is one of a diamond-like carbon coating, a MoS2 layer or WS2 layer, and the hard coating, the solid lubrication surface layer and the metal bottom layer are coated by a vapor deposition method. The manufacturing method can be applied to the air compressor piston rods and other parts with surfaces needing high hardness.

Owner:SICHUAN JINXING CLEAN ENERGY EQUIP CO LTD +3

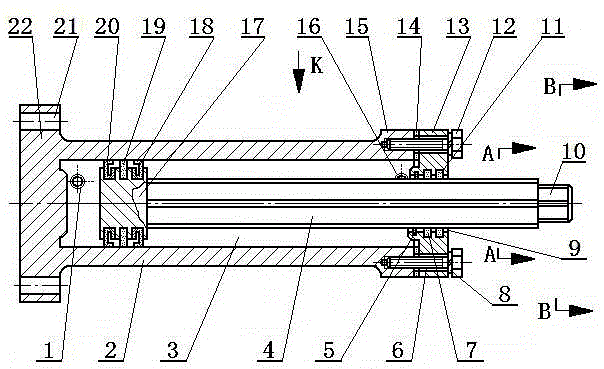

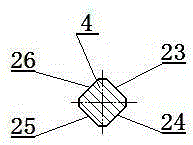

Cylinder with tetragonal prism-shaped piston rod

InactiveCN105402197ALow costHigh precisionEngine sealsFluid-pressure actuatorsEconomic benefitsEngineering

The invention discloses a cylinder with a tetragonal prism-shaped piston rod. The cylinder is mainly characterized in that a piston is arranged in the central circular hole of the cylinder body. The right end of a piston is provided with a tetragonal prism-shaped piston rod integrally formed with the piston. The right end of the tetragonal prism-shaped piston rod respectively passes through a square seal ring A, a square seal ring B and a square seal ring C in a square hole on the center line of a cylinder cover to be exposed out of the right end surface of the cylinder cover. The tail part of the right end of the tetragonal prism-shaped piston rod is provided with a tetragonal prism-shaped joint. The four planes of the tetragonal prism-shaped joint are in the same direction with the four planes of the tetragonal prism-shaped piston rod. The central axis of the tetragonal prism-shaped joint is provided with a threaded hole. The tetragonal prism-shaped joint, the tetragonal prism-shaped piston rod and the piston are on the same central axis. According to the technical scheme of the invention, the accurate orientation is directly realized, while the guiding orientation based on a guiding rod is not required. Therefore, the cost of production equipment is greatly reduced, and the precision of equipment is improved. The occupation space of the equipment is reduced and the weight of the equipment itself is lowered. The economic benefit is significantly improved.

Owner:安徽珂力智能电气有限公司

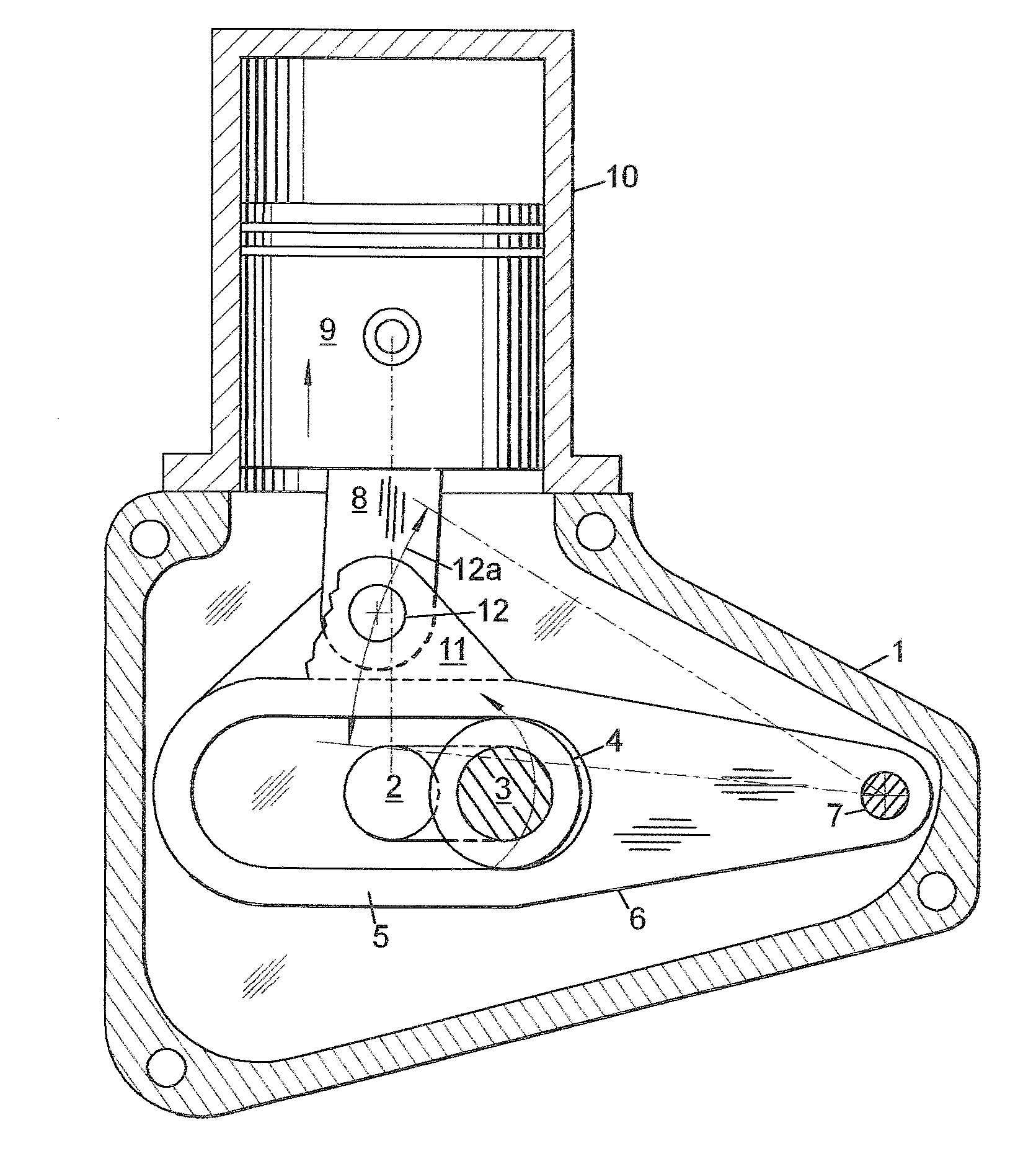

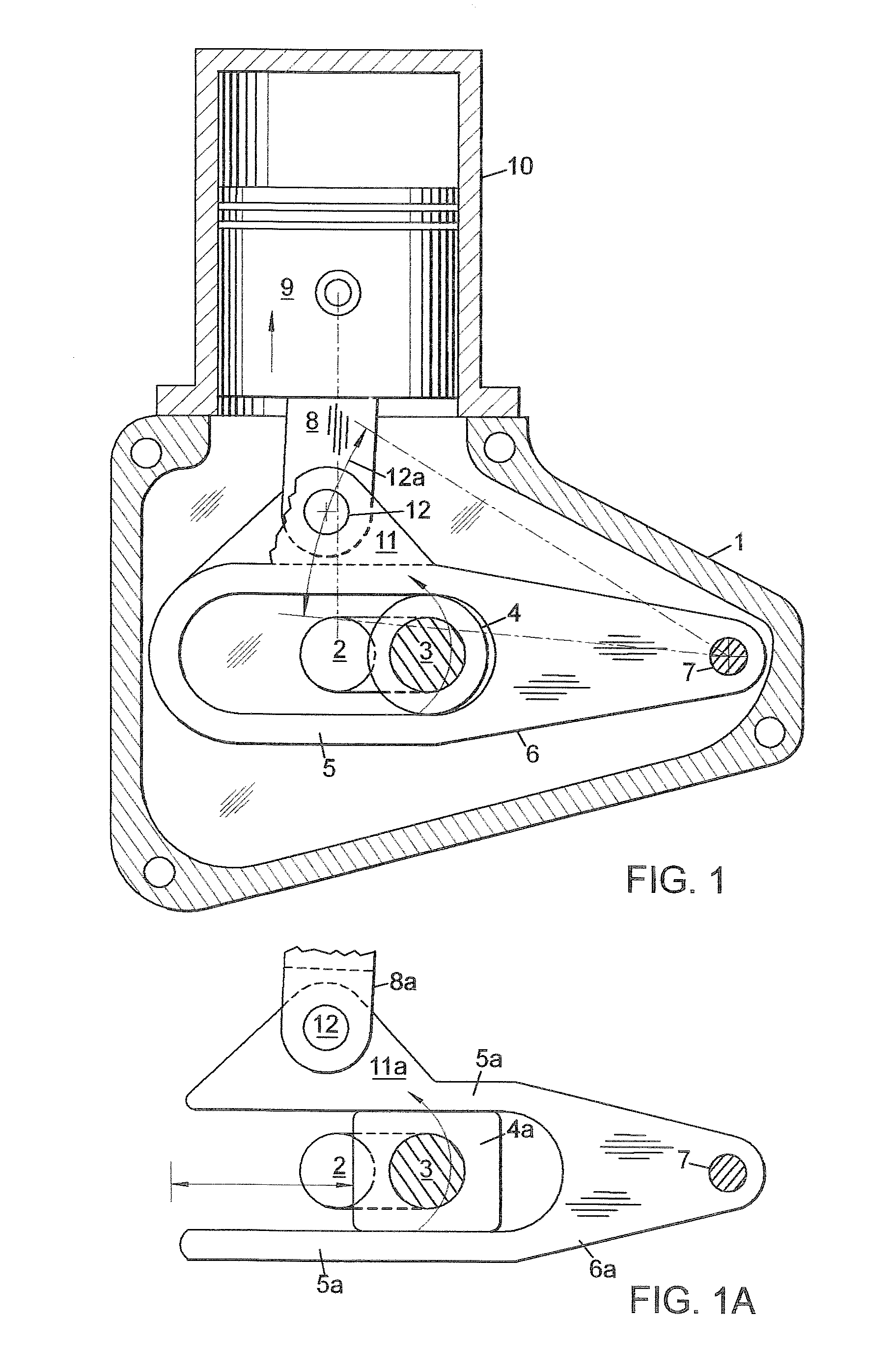

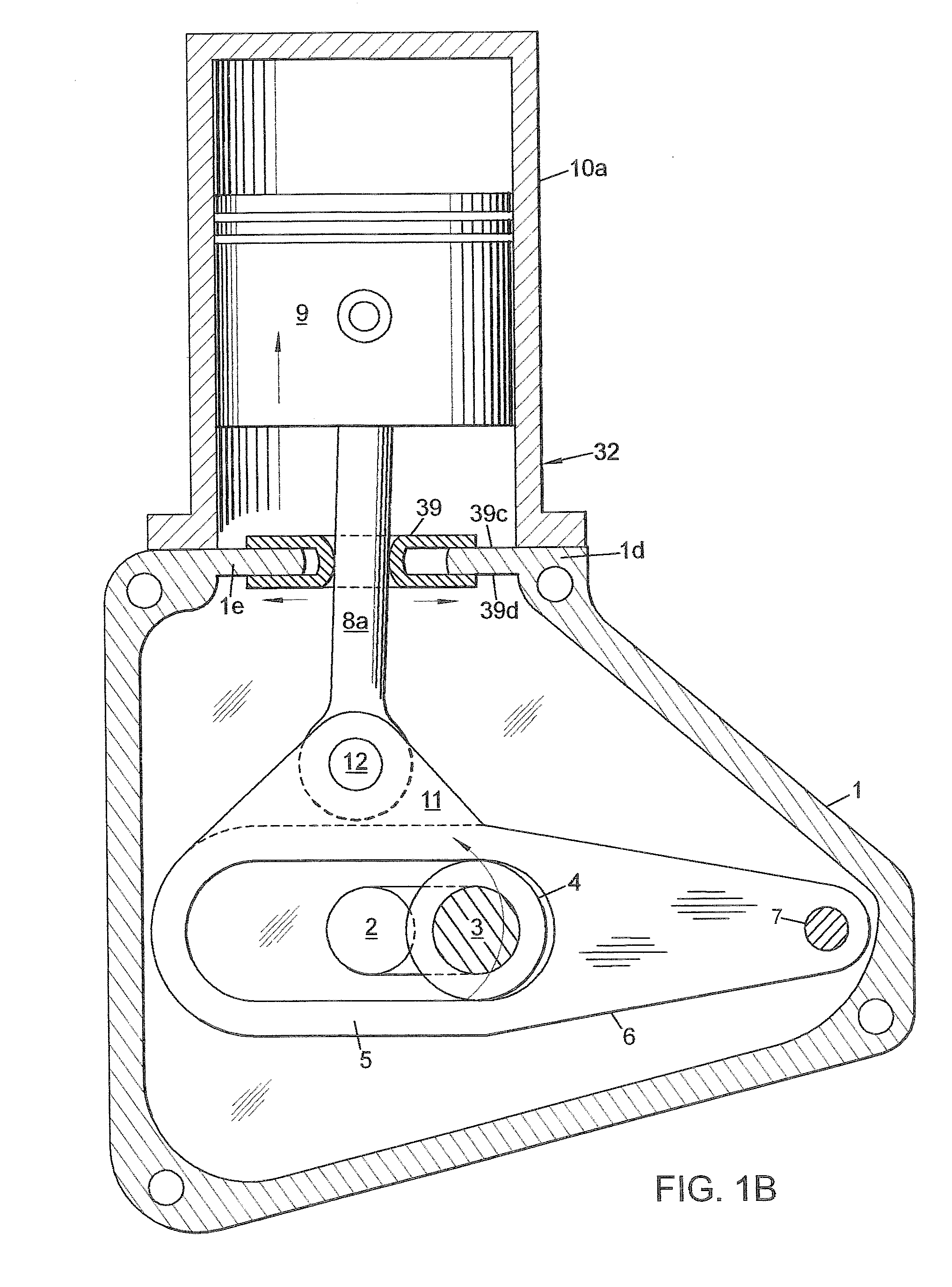

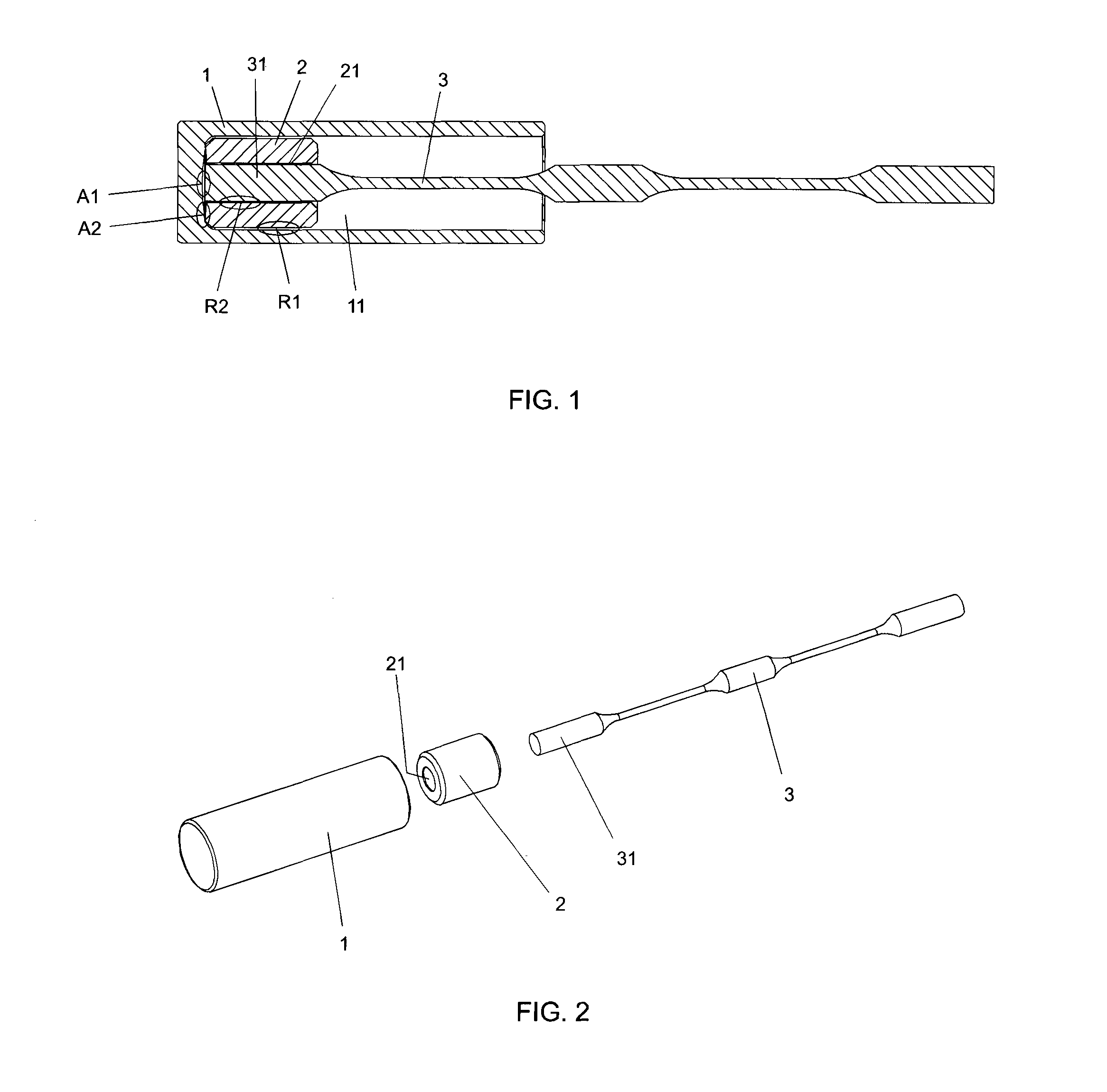

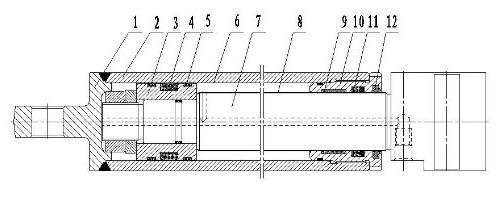

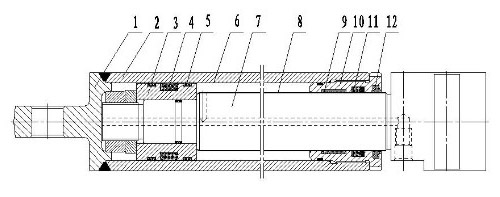

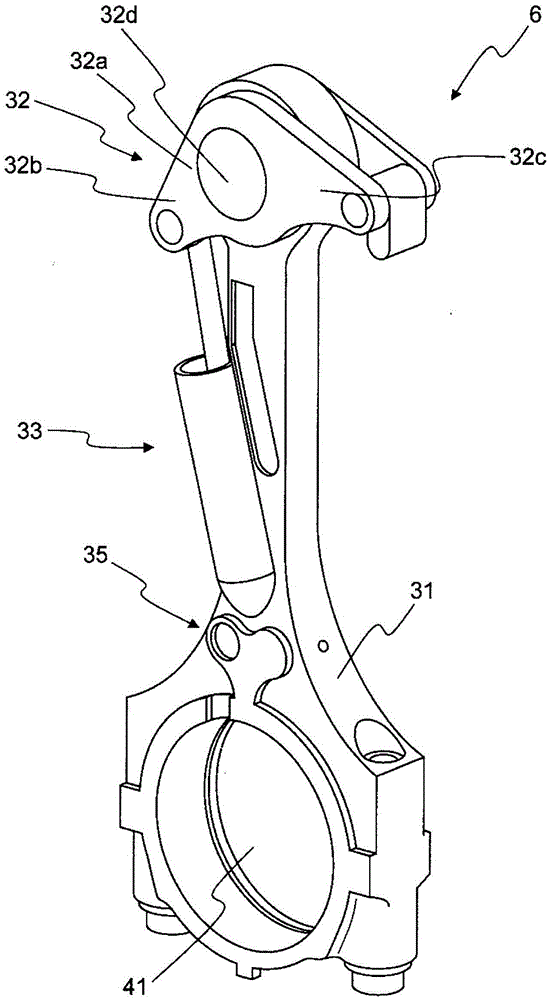

Connecting rod/piston arrangement for alternative compressor and process for assembling connecting rod/piston arrangement for alternative compressor

InactiveUS20150040752A1Control (and reduction) of piston massSimple processPositive displacement pump componentsPlungersEngineeringPiston

The present invention refers to a connecting rod / piston arrangement for alternative compressor, comprising using at least an intermediate element capable of associating said connecting rod with the piston, wherein both do not radially contact with one another. A process for assembling said connecting rod / piston arrangement for alternative compressor is also disclosed. The connecting rod / piston arrangement for alternative compressor comprises at least a piston (1), at least an intermediate element (2) and at least a connecting rod (3), wherein said piston (1) comprises at least a non-through axial channel (11); said intermediate element (2) comprises at least a through axial channel (21); and said connecting rod (3) comprises at least a connection end (31). In this regard, the intermediate element (2) is securely housed inside the non-through axial channel (11) of piston (1); and said connection end (31) of connecting rod (3) is securely housed inside the through axial channel (21) of intermediate element (2).

Owner:EMBRACO IND DE COMPRESSORES E SOLUCOES EM REFRIGERACAO LTDA

Processing, formation and manufacturing method of piston rod using 38CrMoAlA steel as materials

InactiveCN102534392AReduce contentHigh purityProcess efficiency improvementPiston rodsHardnessHigh pressure

The invention discloses a processing, formation and manufacturing method of a piston rod using 38CrMoAlA steel as a material, which belongs to the technical field of powder metallurgy. A gear is realized through the following work procedures of baiting, powder metallurgical blank manufacture, annealing, tongs center emptying, rough turning, tempering, fine turning, center hole accurate grinding, hexagon milling and nitriding treatment. The piston rod manufactured by the manufacture method does not deform at high temperature and high pressure, the surface hardness is high, the abrasion performance is good, the bending resistance capability is high, the fatigue strength is high, in addition, the center roughness is good, the service life is long, the work reliability is high, and because blanks are manufactured by the powder metallurgy, the high-temperature resistance is good.

Owner:无锡市万邦机械制造厂

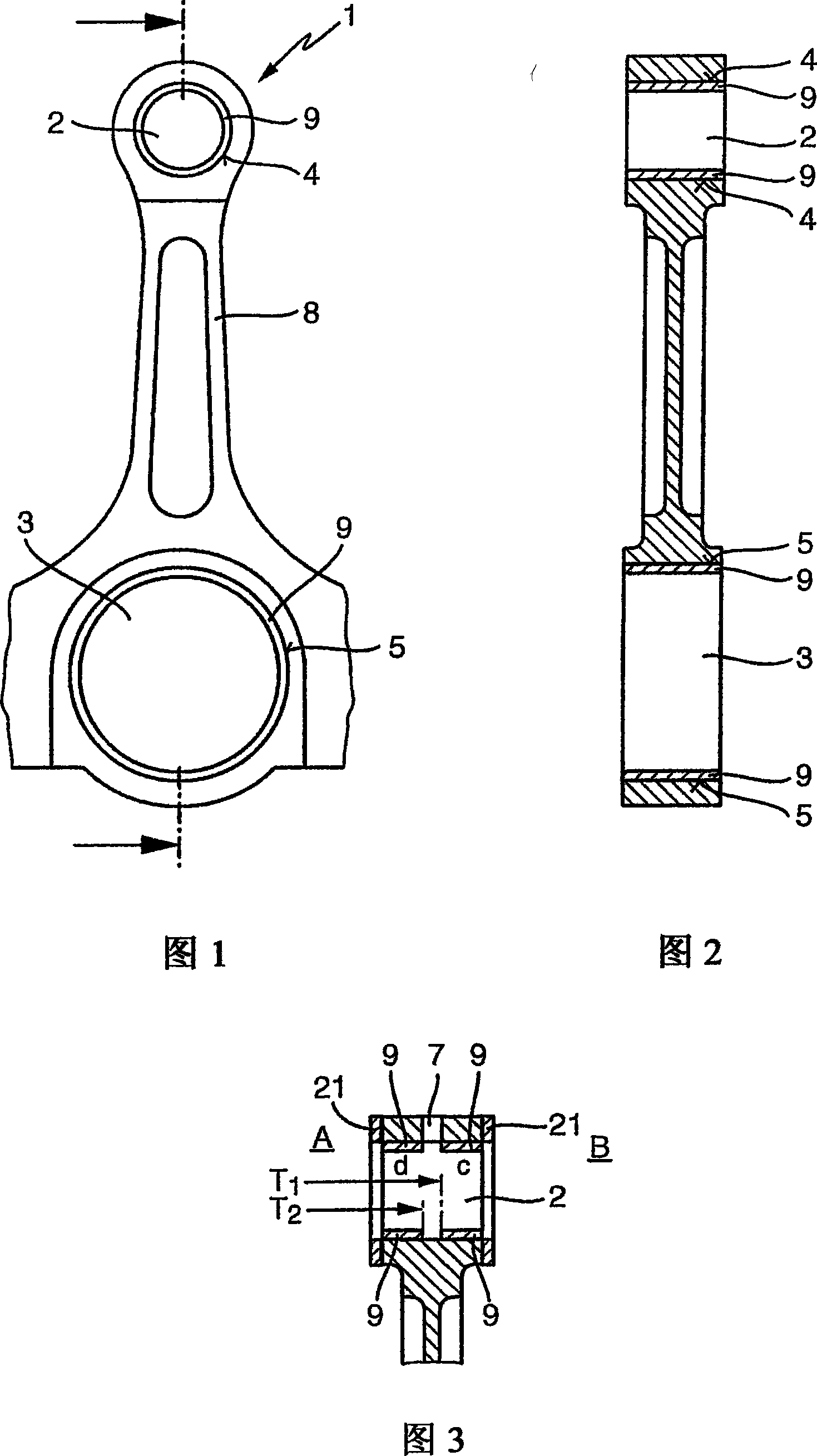

Connecting rod for a combustion engine and method for coating the plain bearing surfaces thereof

ActiveCN101094731AImprove surface qualityLimited depthConnecting rod bearingsShaftsCombustionInternal combustion engine

Disclosed is a connecting rod for a combustion engine, comprising a small connecting-rod eye that is provided with a plain bearing surface and is used for accommodating a piston pin, and a large connecting-rod eye which is provided with a plain bearing surface and embraces a crankshaft journal. In order to very effectively and inexpensively prevent the piston pin and the crankshaft journal of said connecting rod from jamming and wearing off, a self-lubricating coating made of a thermally cured resin which contains embedded solid lubricant particles is applied directly to at least one of the plain bearing surfaces by means of rotary atomization.

Owner:MAHLE INT GMBH

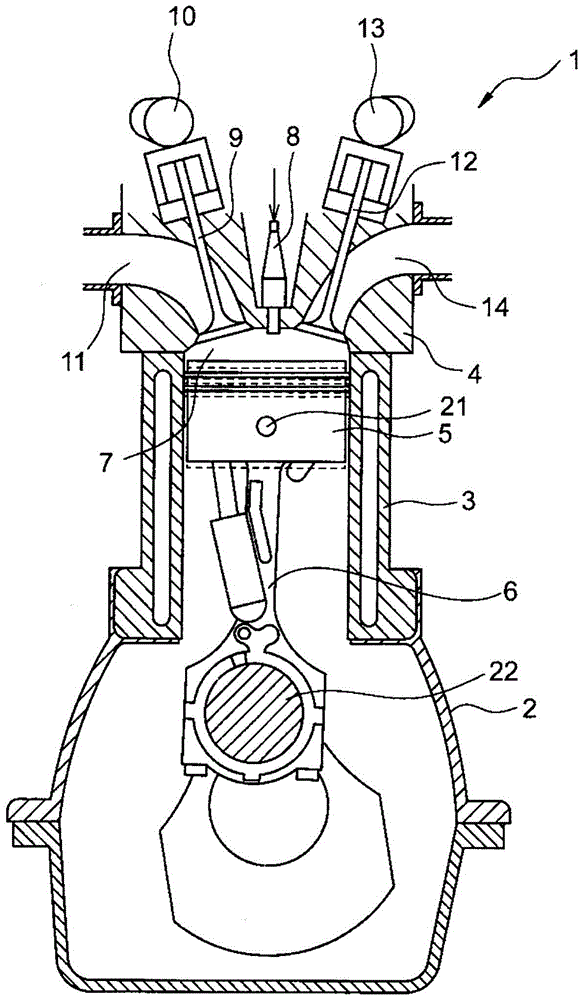

System for a mechanical conversion of an internal combustion engine of 4 strokes into 8 strokes

InactiveUS20160222880A1Connecting rodsInternal combustion piston enginesCombustionInternal combustion engine

A converting mechanical system including a dual connecting rod having a top section adapted to be pivotally connected to a piston on a conventional internal combustion engine and a bottom section adapted to be connected to a crankshaft of a conventional internal combustion engine. A support surrounds each dual connecting rod and includes a retractable device. A decoupling device is adapted to be located on the crankshaft a conventional internal combustion engine. The dual connecting rod has a first working position and in which the dual connecting rod is rigid and connected to the crankshaft when the piston moves. In the second working position, the dual connecting rod disconnects the crankshaft from the piston by action of the decoupling device.

Owner:VELAZQUEZ LUIS ALBERTO

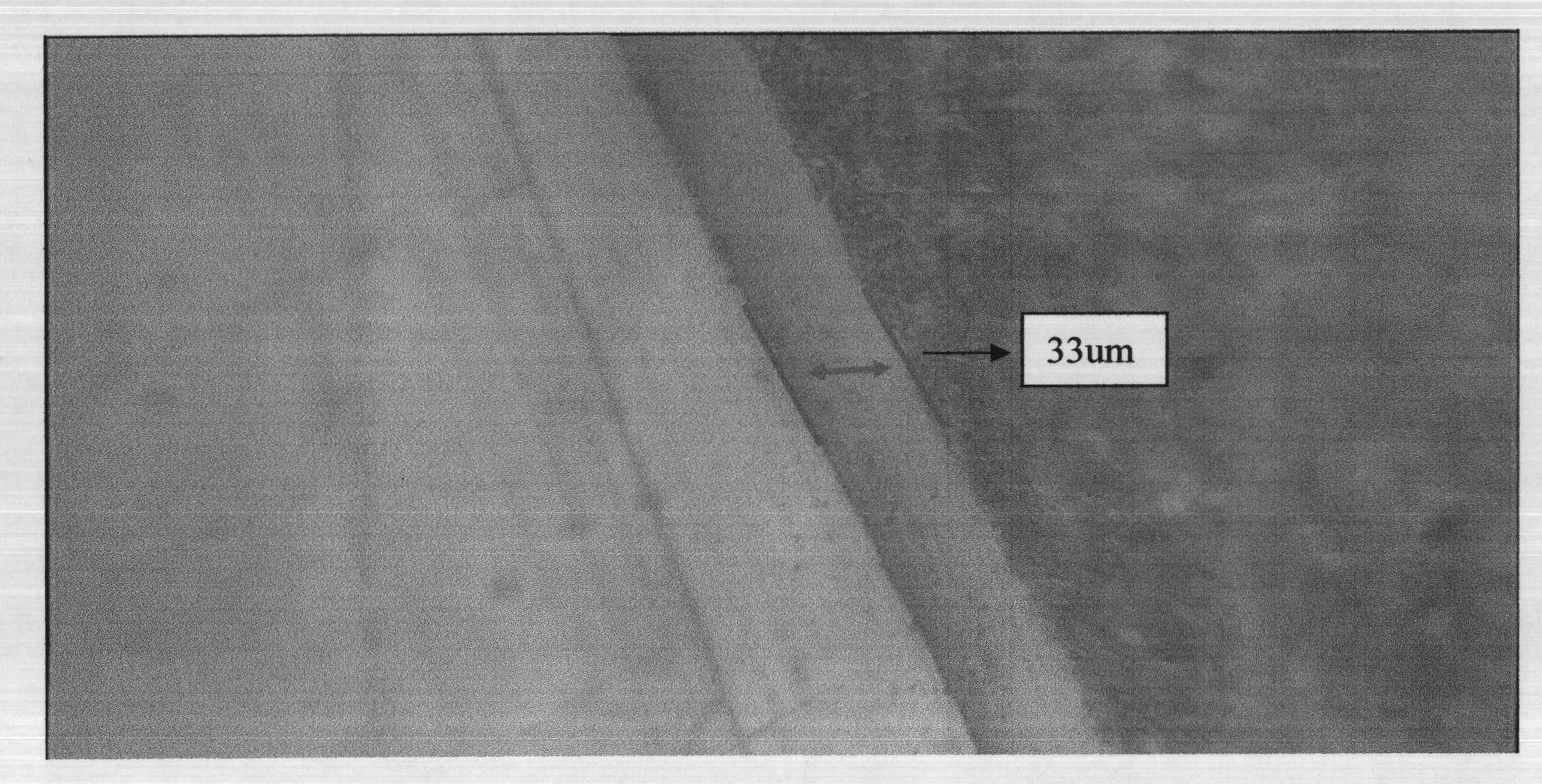

Piston rod and production method thereof as well as carbonitriding agent for piston rod surface treatment

The invention relates to a piston rod and a production method thereof as well as a carbonitriding agent for piston rod surface treatment. The carbonitriding agent comprises the following components by weight percent: 20-24% of urea, 13-15% of thiourea, 10-14% of barium acetate, 24-27% of calcium carbonate, 22-26% of barium carbonate and 4-10% of lithium carbonate. The carbonitriding layer tissue comprises an oxide layer, a tectorium, a compound layer, an Austria layer and a diffusion layer. The carbonitriding agent has the beneficial effects of simple formula and low cost; the piston rod produced by using the carbonitriding agent is smooth in surface, low in roughness and is airproof, the piston rod compound carbonitriding layer is more than 32mu m in thickness and has the characteristics of high corrosion resistance and abrasion resistance, low rejection ratio and long service life; in the piston rod production process, thermal treatment and anti-corrosion treatment are completed once, treatment temperature is between 600 DEG C-700 DEG C, the piston rod production process has the advantage of optimizing the machining process; and nitriding time is shortened to 30-50 minutes, production period is shortened, and production cost is reduced.

Owner:QINGDAO ZHANGSHI MACHINERY

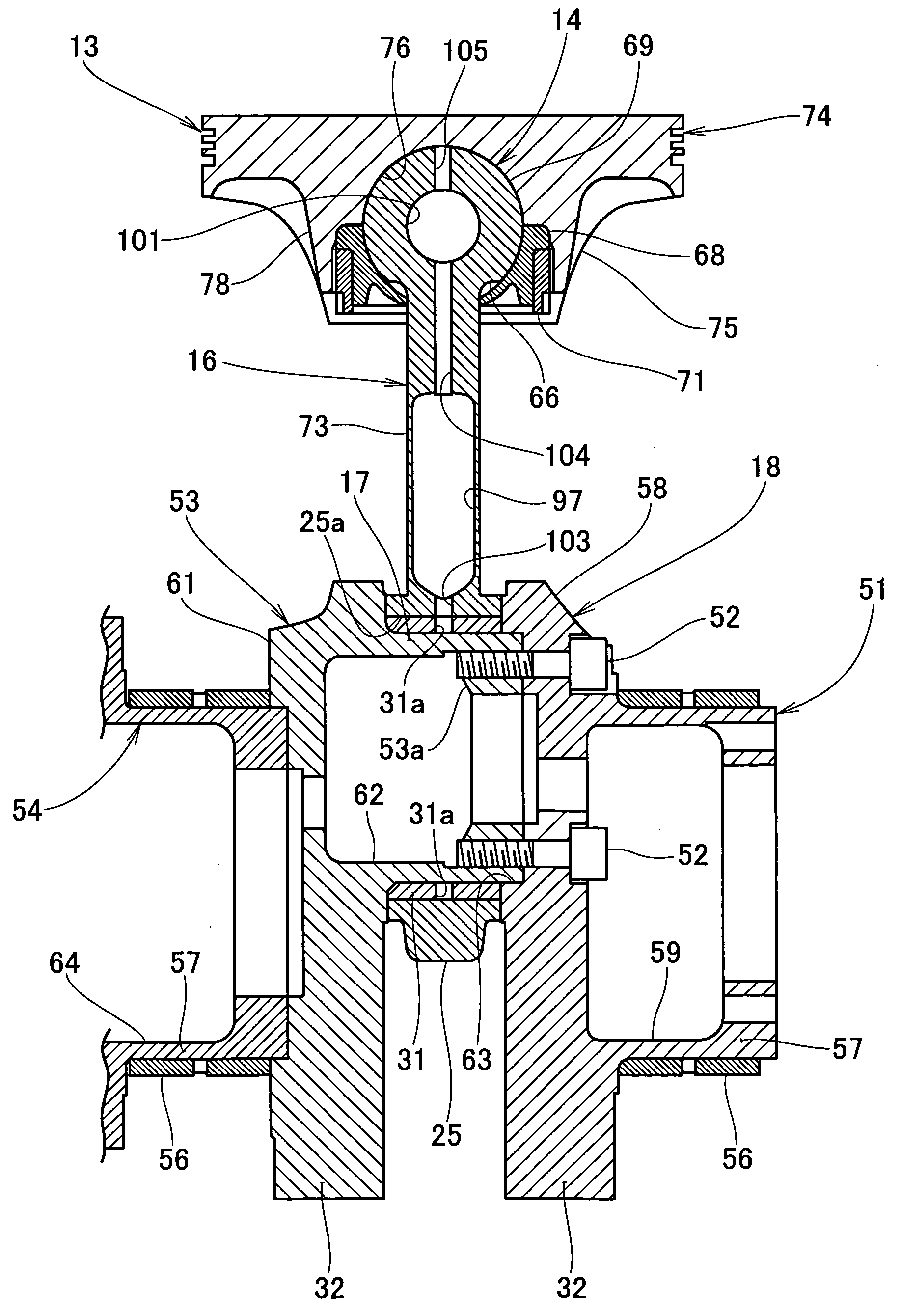

Internal combustion engine and connecting rod therefor

InactiveUS20050098140A1Simple processIncrease speedConnecting rod bearingsCrankshaftsSpherical jointEngineering

A connecting rod of an internal combustion engine, and an internal combustion engine including the connecting rod, a piston, a crankshaft and a float bearing as main moving parts. A piston is connected to a connecting rod by a spherical joint and has radial ribs on a rear face of a crown part; a connecting rod is of an integrated, one-piece type having integrally a spherical small end part to be connected to the piston and an annular big end part; the crankshaft is of an assembly type, and a float bearing is interposed between the big end part and a crank pin.

Owner:HONDA MOTOR CO LTD

High speed fuel gas spraying process for treating piston rod surface

InactiveCN1986886AImprove anti-corrosion and wear-resistant effectShort cycleSuperimposed coating processPiston rodsHot workingWear resistance

The present invention is ceramic hardening treatment process for the surface of piston rod and aims at simplifying piston rod production, lowing the production cost and raising the product quality. The piston rod production process of the present invention includes the steps of: forging, normalizing, coarse machining, tempering, semi-finishing, stress eliminating tempering, coarse grinding, HVOF and finishing. The production process with ceramic treatment has greatly reduced hot working time and raised product quality, and the piston rod with antiwear and anticorrosive ceramic layer has greatly increased service life.

Owner:任希文

Method of producing connecting rod with bearing, and connecting rod with bearing

InactiveCN101065586AConsistent thicknessAvoid jammingConnecting rod bearingsConnecting rodsMetallic materialsMechanical engineering

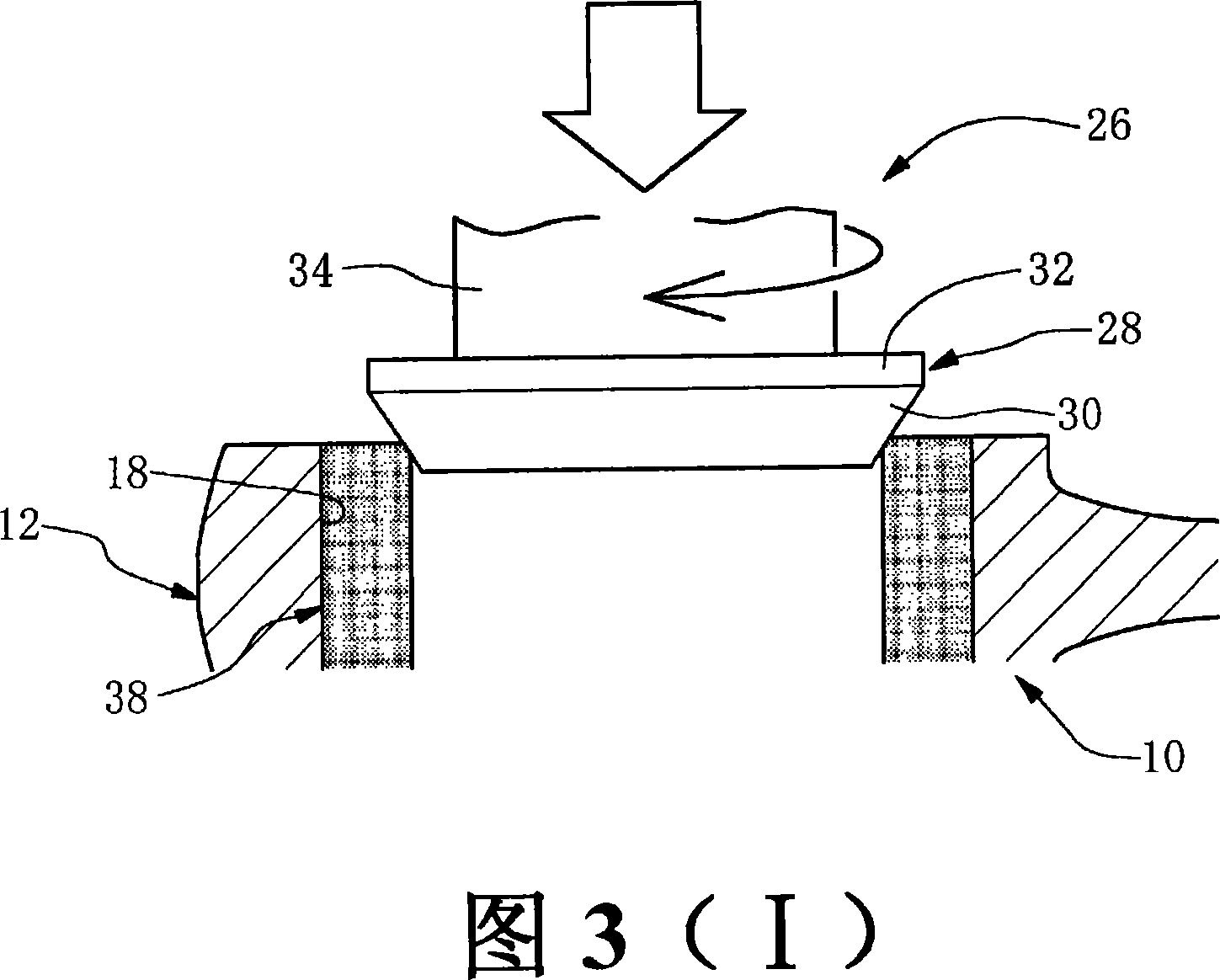

A method of producing a connecting rod with a bearing, in which both a process for producing a bearing separately from a connecting rod and a process for assembling the bearing to the connecting rod can be eliminated to reduce processes, labor, and costs to produce the connecting rod. A hollow cylindrical molding (38) of a bearing metal material is inserted and fitted, as an inner member, inside an inner surface of a circular large end hole (18) of a large end section (12) of a connecting rod (10). A tapered surface (30) of a rotary pressing tool (26) is pressed, while rotating, to the hollow cylindrical molding (38) to heat and soften the hollow cylindrical molding (38), causing the hollow cylindrical molding (38) of the bearing metal material to plastically flow axially and radially outward, whereby a bearing metal layer (22) is directly joined and formed on the inner surface of the large end hole (18).

Owner:JAPAN SCI & TECH CORP +1

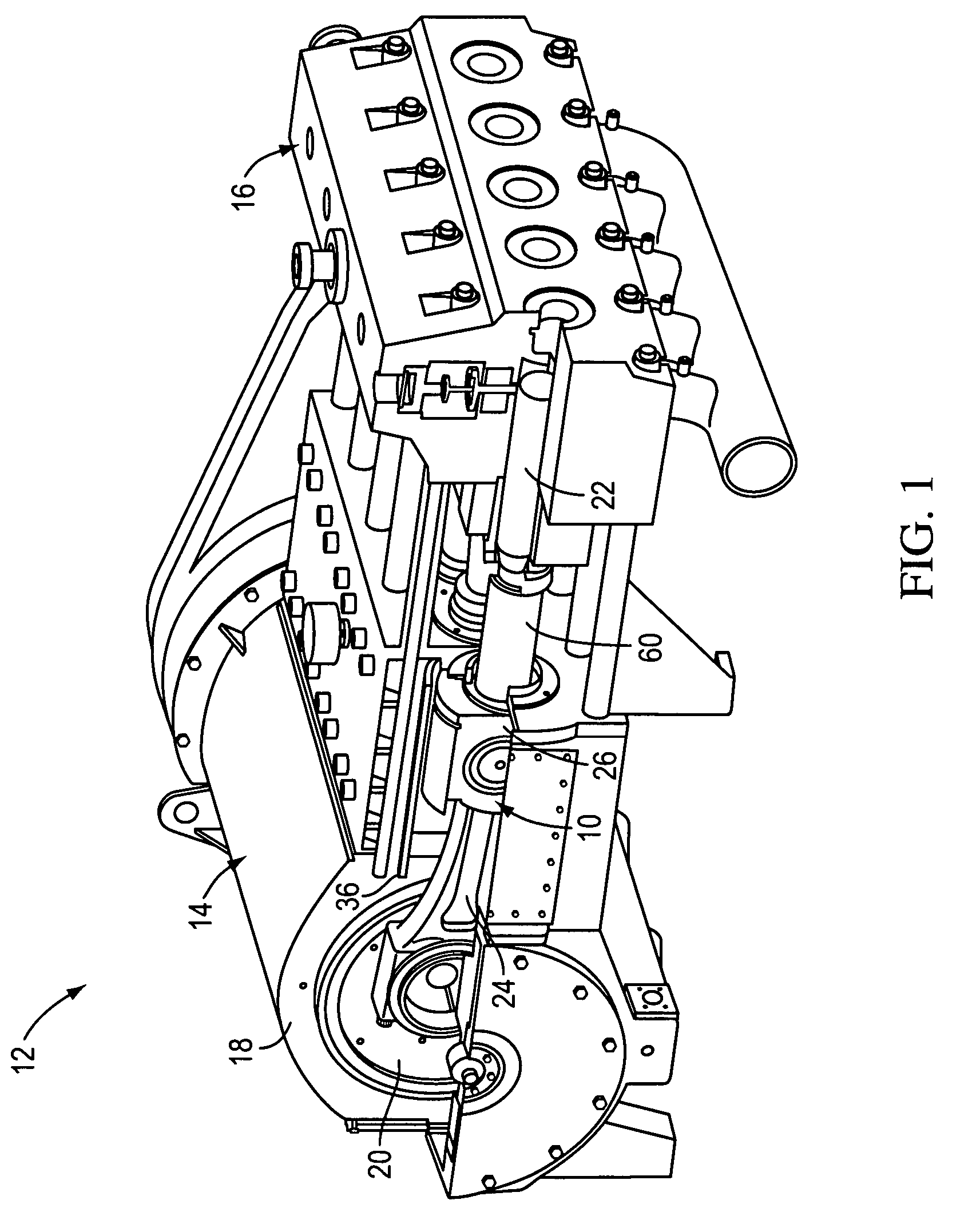

Linear Cross-Head Bearing for Stirling Engine

ActiveUS20150184614A1Heat exchanger casingsStationary tubular conduit assembliesLinear motionCombustor

An external combustion engine including a burner element, a heater head, a piston cylinder containing a piston, a cooler and a crankcase. The crankcase includes a crankshaft, a piston rod connected to the piston, a drive mechanism for converting the linear motion of the piston rod to rotary motion of the crankshaft and a linear cross-head bearing that is connected rigidly to the piston rod at one end and to the drive mechanism at the other end. Also the external combustion engine includes a piston clearance seal and a piston rod seal unit that has floating rod seals. The piston includes a inner dome to reduce axial heat transfer via radiation and convection.

Owner:NEW POWER CONCEPTS

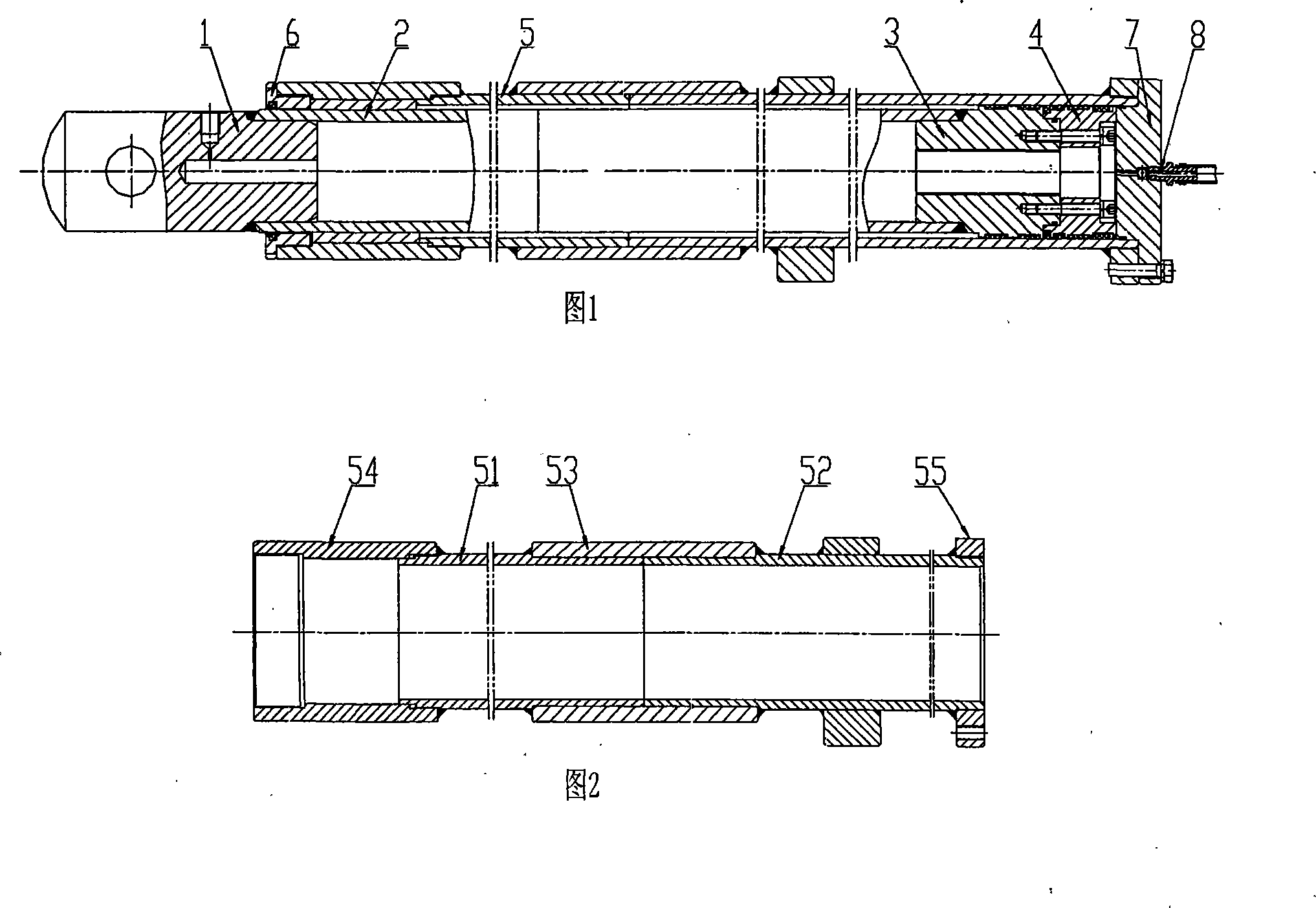

Large journey low-temperature extension hydraulic cylinder manufacture method

InactiveCN101216056AMeet the intensityImprove low temperature toughnessPiston ringsPlungersHeat-affected zoneAlloy

The invention relates to the technology for manufacturing a hydraulic cylinder, in particular to a method for manufacturing a large-stroke low temperature stretching hydraulic cylinder. The large-stroke low temperature stretching hydraulic cylinder is used on an oil well rig or a service machine working in cold areas and is used for stretching of a nesting headframe. In the technological process of the invention, low temperature resistant alloy structural steel is selected to be blanked and machined into components; the components are conventionally heated; a low temperature process is adopted to weld, connect and assemble the components; low temperature resistant sealing elements are arranged in the four sealed grooves of a piston. In this way, the large-stroke low temperature stretching hydraulic cylinder is manufactured. The large-stroke low temperature stretching hydraulic cylinder manufactured through the method has good low temperature property; the performance of the welds and the heat-affected zones of the cylinder tube and a piston rod reaches the following indices: Sigma b is more than or equal to 410MPa; Delta s is more than or equal to 20 percent; Akv (-45 DEG C) is more than or equal to 27J; the large-stroke low temperature stretching hydraulic cylinder can meet the requirements for intensity, toughness, rigidity and elasticity under low temperature (-45 DEG C), and works reliably with high sealing performance.

Owner:NANYANG NANSHI LITIAN PETROLEUM EQUIP CO LTD

Integral seal jack

InactiveCN101941657AImprove securityImprove reliabilityCylindersLifting devicesPiston GuideEngineering

The invention provides an integral seal jack. The jack consists of a cylinder body, a piston rod, a piston component and a cylinder port component, wherein the cylinder body consists of a base and a cylinder tube, and the base and the cylinder tube are welded together; the piston rod is a step bar one end of which is provided with a shoulder, and is sleeved in the cylinder tube; and the piston component is sleeved on the piston rod, is positioned by the shoulder of the piston rod, and is fixed on the piston rod through a nut. The integral seal jack is characterized in that the piston component consists of a piston, two piston guide parts and a piston seal component, and is an integral piston; the two piston guide parts are positioned on the front end and the rear end of the piston respectively; the piston seal component is positioned between the two piston guide parts; the piston seal component and the two piston guide parts are integrally cast on the piston; a stainless steel sleeve is welded on the inner wall of the cylinder tube; and a laser cladding layer is arranged on the outer surface of the piston rod. The integral seal jack has the advantages of simple structure, low cost, safety, reliability, good seal performance and low repair rate, and can remarkably improve the corrosion resistance effect of the jack.

Owner:中煤邯郸煤矿机械有限责任公司

Piston rod machining process

InactiveCN104439964AImprove pressure resistanceImprove corrosion resistanceSuperimposed coating processPiston rodsCeramic coatingHardness

The invention discloses a piston rod machining process. The piston rod machining process comprises the working procedures of blank forging, annealing, rough turning, heat treatment quenching and tempering, semi-finish turning, ultrasonic flaw detection, central oil hole boring, key groove milling, pin hole drilling, stable tempering heat treatment, ceramic coating spraying, external grinding, nitriding heat treatment and Sic grinding wheel precision grinding. According to the piston rod machining process, physical characteristics of the surface of a piston rod are changed, and the piston is good in pressure loss resistance and corrosion resistance due to the ceramic coating spraying process added to the piston rod; through the follow-up nitriding heat treatment process, the surface hardness, fatigue resistance and abrasive resistance of the piston rod are improved, and therefore product quality is greatly improved, and production cost is lowered.

Owner:WUZHONG DISTRICT GUANGFU JINYI HARDWARE FITTINGS FACTORY

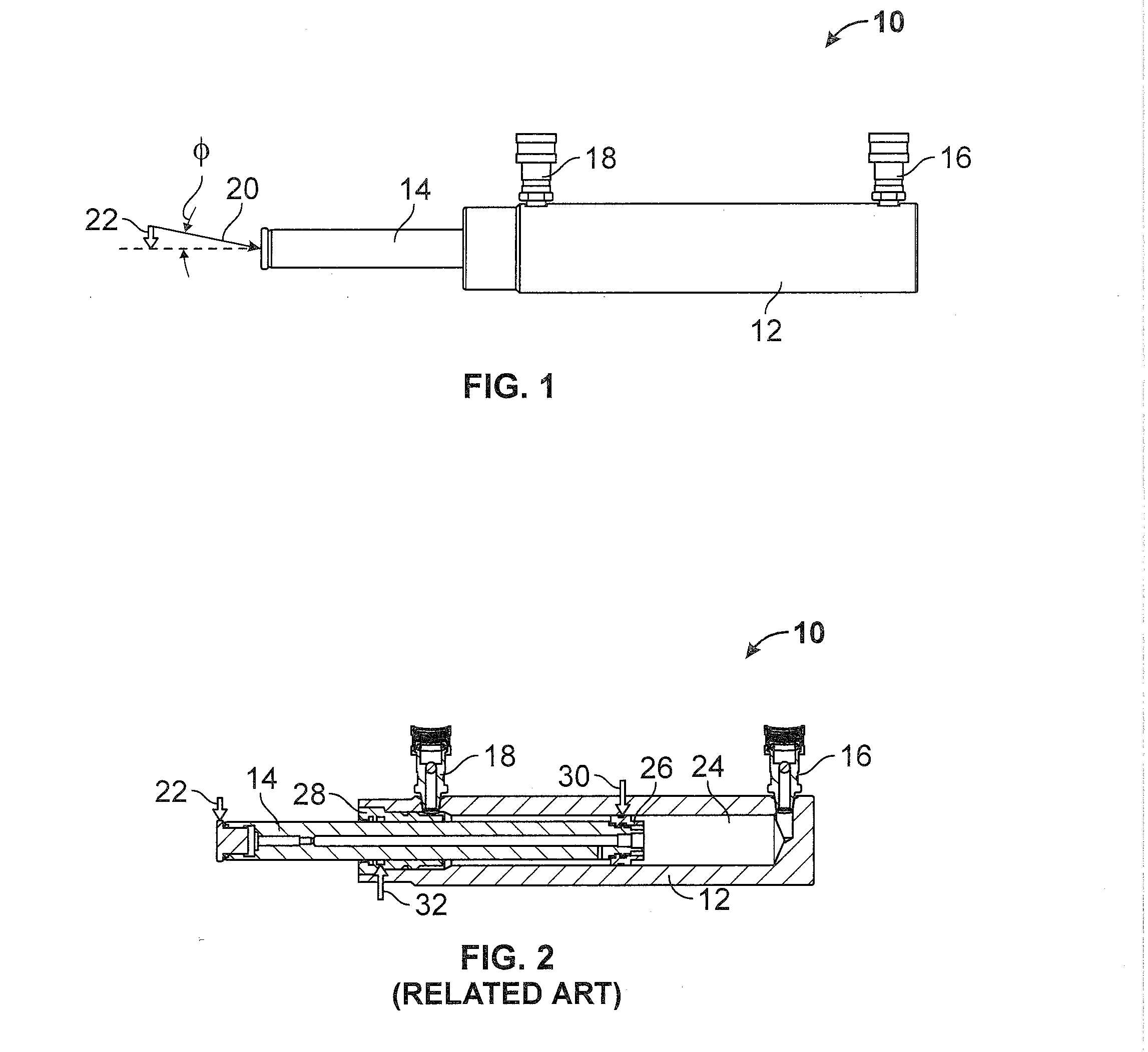

Self aligning cylinder piston and rod bearing and method of manufacture thereof

InactiveUS20140102293A1Concentrated stress loadingPlungersTrunk pistonsEngineeringMechanical engineering

A piston assembly is provided. The piston assembly may include: a piston rod; a piston pivotally connected to the piston rod; and a rotatable rod bearing configured to allow the piston rod to pass therethough and rotate along with the piston rod as the piston rod pivots with respect to the piston. A method of making a piston assembly may be provided. The method may include: attaching a piston rod to a piston in a pivoting connection; providing a rotatable bearing for the piston rod; and supporting the piston rod with the rotatable bearing.

Owner:SPX FLOW INC

Processing technique for piston rod of steering cylinder

InactiveCN104209714ASolution to short lifeFluid-pressure actuatorsPiston rodsHydraulic cylinderHydraulic ram

The invention discloses a processing technique for a piston rod of a steering cylinder and belongs to the field of a hydraulic cylinder. The processing technique comprises the steps: (1) preparing a material; (2) roughly turning an outer circle; (3) drilling a hole on a milling surface; (4) quenching in super-audio frequency; (5) grinding the outer circle; (6) electroplating; (7) polishing; (8) forming semi-finished products. A quenching layer and an electroplating layer are formed on the surface of the piston rod in double surface hardening modes of super-audio frequency quenching and electroplating; the hardness of the quenching layer is HRC45-55 and the thickness of the quenching layer is 1-1.5mm; the hardness of the electroplating layer is HRC65 and the thickness of the electroplating layer is 0.03-0.05mm; the surface of the piston rod is more wear-resisting and the service life is longer.

Owner:ANQING TIANRUN ENG MACHINERY

Piston pin for heat dissipation

A piston assembly including a piston body pivotally connected to a connecting rod by a wrist pin. The wrist pin includes a sealed cavity therein partially filled with a heat transfer medium. The heat transfer medium may be composed of a fusible alloy. The sealed cavity may be comprised of discrete compartments. The wrist pin may be integrated with the connecting rod and share a conjoined sealed cavity therewith so that heat transfer medium can draw heat effectively away from the piston body.

Owner:TENNECO INC

Variable Length Connecting Rod And Variable Compression Ratio Internal Combustion Engine

ActiveCN105715370AReduce weightRotary bearingsConnecting rod bearingsHydraulic cylinderEffective length

The invention provides an variable length connecting rod and variable compression ratio internal combustion engine. A variable length connecting rod which can change the effective length comprises a connecting rod body, an eccentric member which is attached at the small end to the connecting rod body to be able to swivel and which changes the effective length of a variable length connecting rod when swiveled, one piston mechanism which has one hydraulic cylinder which is provided in the connecting rod body and one hydraulic piston which slides in the hydraulic cylinder, a direction switching mechanism which switches between supply and discharge of hydraulic fluid to the hydraulic cylinder, and a hydraulic fluid supply source which supplies the hydraulic cylinder with hydraulic fluid. The piston mechanism is configured so that the eccentric member swivels in one direction if hydraulic fluid is supplied to the hydraulic cylinder and so that the eccentric member swivels in the other direction if hydraulic fluid is discharged from the hydraulic cylinder.

Owner:TOYOTA JIDOSHA KK

Reduced compression height piston and piston assembly therewith and methods of construction thereof

InactiveUS9127618B2Enhanced strength and durabilityIncreased compressive loadPlungersMachines/enginesCombustionEngineering

A piston assembly and method of construction thereof for an internal combustion engine are provided. The assembly includes a piston head having an upper combustion wall with an undercrown surface and a ring belt region. The piston head has a floor with an upper surface and a bottom surface. The floor is spaced beneath the upper combustion wall in radial alignment with the ring belt region. A substantially enclosed, annular cooling gallery is bounded by the undercrown surface and the floor. A pair of pin bores depends directly from the floor of the cooling gallery. The assembly further includes a pin having ends configured for oscillating receipt in the pin bores. A pin bearing surface extends within the pin bores and between the pin bores in the lower surface of the floor. The assembly includes a connecting rod with an end fixed to the pin for conjoint oscillation therewith.

Owner:TENNECO INC

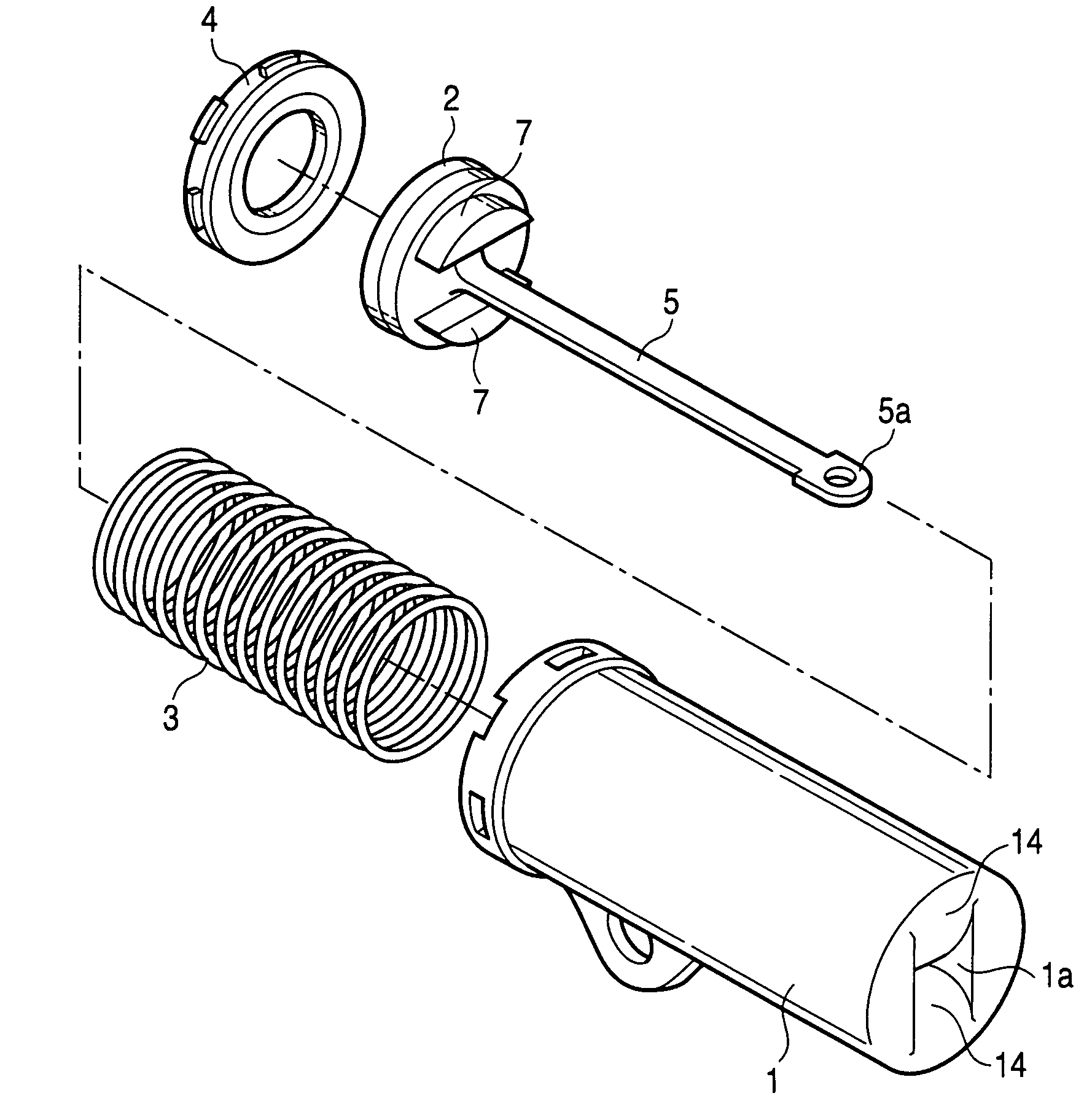

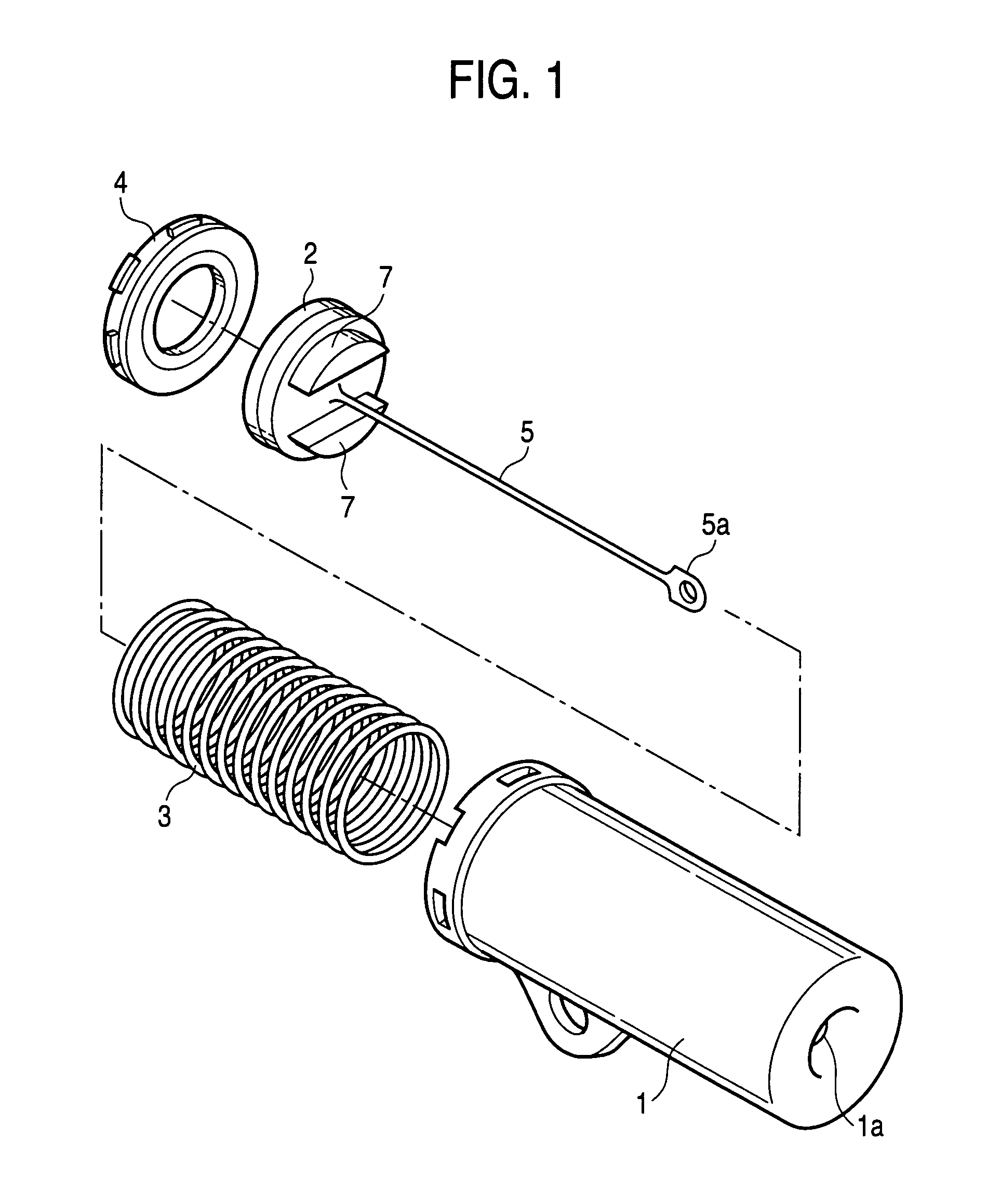

String type air damper

A string type air damper includes a cylinder formed in a tubular shape, defining a guide hole at one end portion thereof, a piston, which moves in the cylinder, a helical spring for biasing the piston toward the other end portion of the cylinder, and a string member guided from inside of the cylinder to outside thereof through the guide hole. The piston and the string member are integrally formed. Since the string member is formed integrally with the piston, unlike a method according to a related art, it becomes unnecessary to form a loop at the base end portion of the string member with a complicated work and form a hook portion at the piston and hook the base end portion of the string member at the hook portion of the piston. Therefore, the string type air damper can be very easily assembled.

Owner:PIOLAX CO LTD

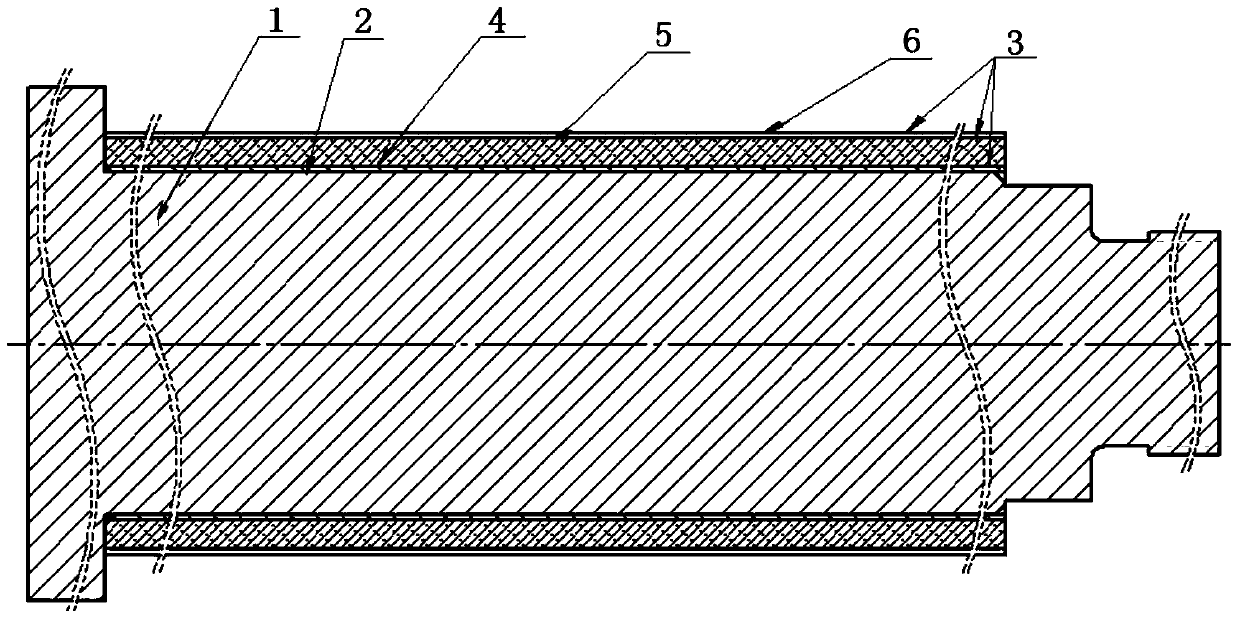

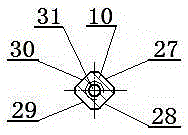

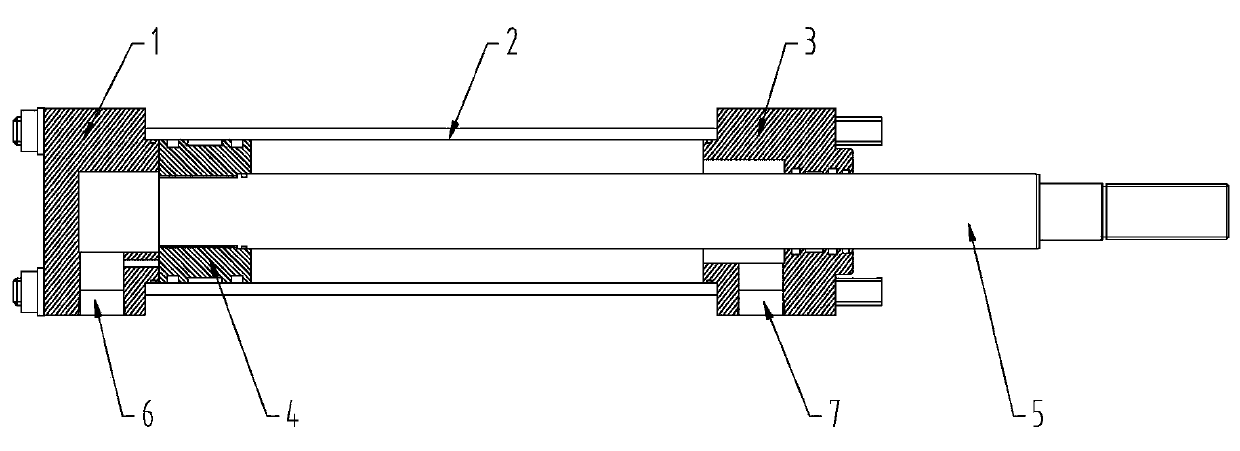

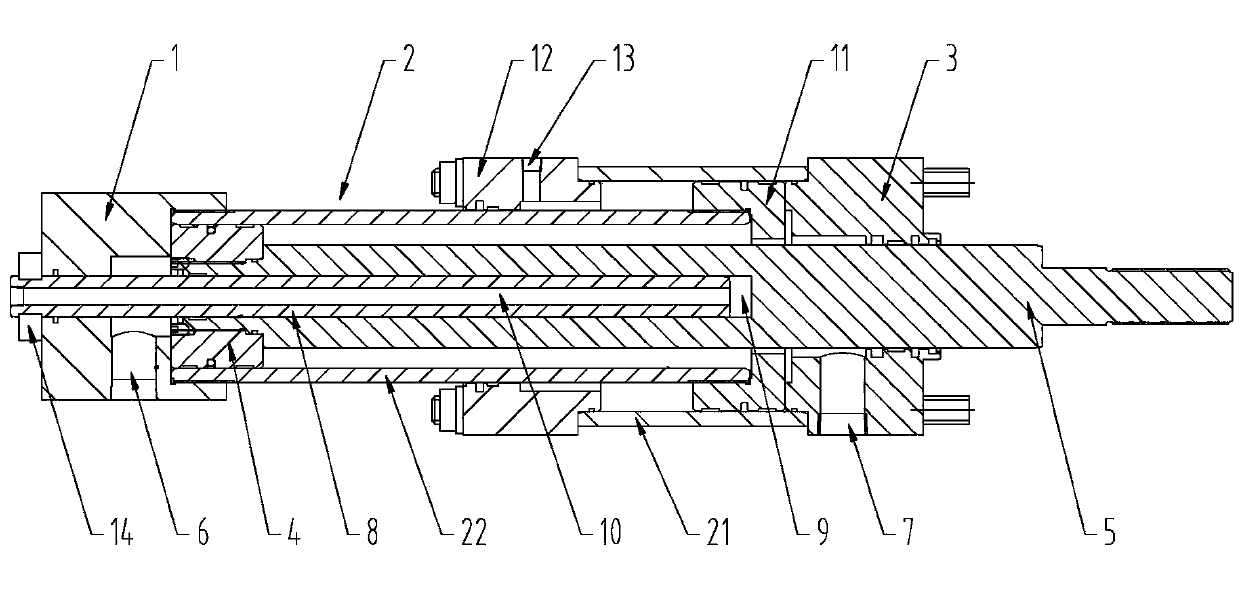

Fast die closingoil cylinder used for high-speed die-casting machine

InactiveCN104196813AFast clamping speedHigh speedFluid-pressure actuatorsPiston rodsDie castingEngineering

The invention discloses a fast die closing oil cylinder used for a high-speed die-casting machine. The fast die closing oil cylinder comprises a die closing cylinder rear cover (1), a die closing cylinder barrel (2), a die closing cylinder front cover (3), a die closing cylinder piston (4), a die closing cylinder piston rod (5), an oil supply hole (6) and an oil return hole (7), wherein the die closing cylinder piston rod (5) is internally provided with a cavity (9) used for a fast piston rod (8) to insert, the fast piston rod (8) is internally provided with a through hole (10) arranged along the axial direction, and the other end of the fast piston rod (8) sequentially penetrates through the die closing cylinder piston (4) and the die closing cylinder rear cover (1) so as to enable the through hole (10) to be communicated with a main oil path of a hydraulic system, so that the hydraulic system can push the die closing cylinder piston rod (5) to move forward by supplying oil into the cavity (9) through the through hole (10). The fast piston rod is arranged in the die closing cylinder piston rod, so that the die closing speed is improved by more than 60 percent, and meanwhile, the die opening speed is improved by increasing the diameter of the die closing cylinder piston rod.

Owner:江苏佳晨华科机械技术研究院有限公司

Connecting structure and installation method for piston and piston rod

InactiveCN102128261ATightly sealed stateTightly locked statePiston ringsPlungersInterference fitWear resistant

The invention discloses a connecting structure for a piston and a piston rod. The connecting structure mainly comprises the piston rod and the piston sleeved on the piston rod, wherein the piston is in interference fit with the piston rod; the outer wall of the piston is provided with a wear-resistant pad clamping groove and a sealing ring clamping groove; and the piston is provided with a tapered pin hole which passes through the piston rod from one side to the other side and is positioned in the wear-resistant pad clamping groove. The piston is in interference fit with the piston rod according to an expansion and contraction principle of metal, so that the piston and the piston rod are tightly sealed and locked; the tapered pin hole is drilled in the middle of the piston, so that the locking fixing force of the piston is increased, and the piston does not move or drain oil on the piston rod during work; and production benefit is improved, and production cost is reduced.

Owner:CHENGDU SANHUAN METAL PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com