Large journey low-temperature extension hydraulic cylinder manufacture method

A technology for a telescopic hydraulic cylinder and a manufacturing method, which is applied in the field of hydraulic cylinder manufacturing, can solve the problems of reduced working capacity of seals, leakage of hydraulic cylinders, time-consuming and labor-intensive replacement of hydraulic cylinder seals, etc., and achieves good low temperature toughness, good sealing effect, Safe and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

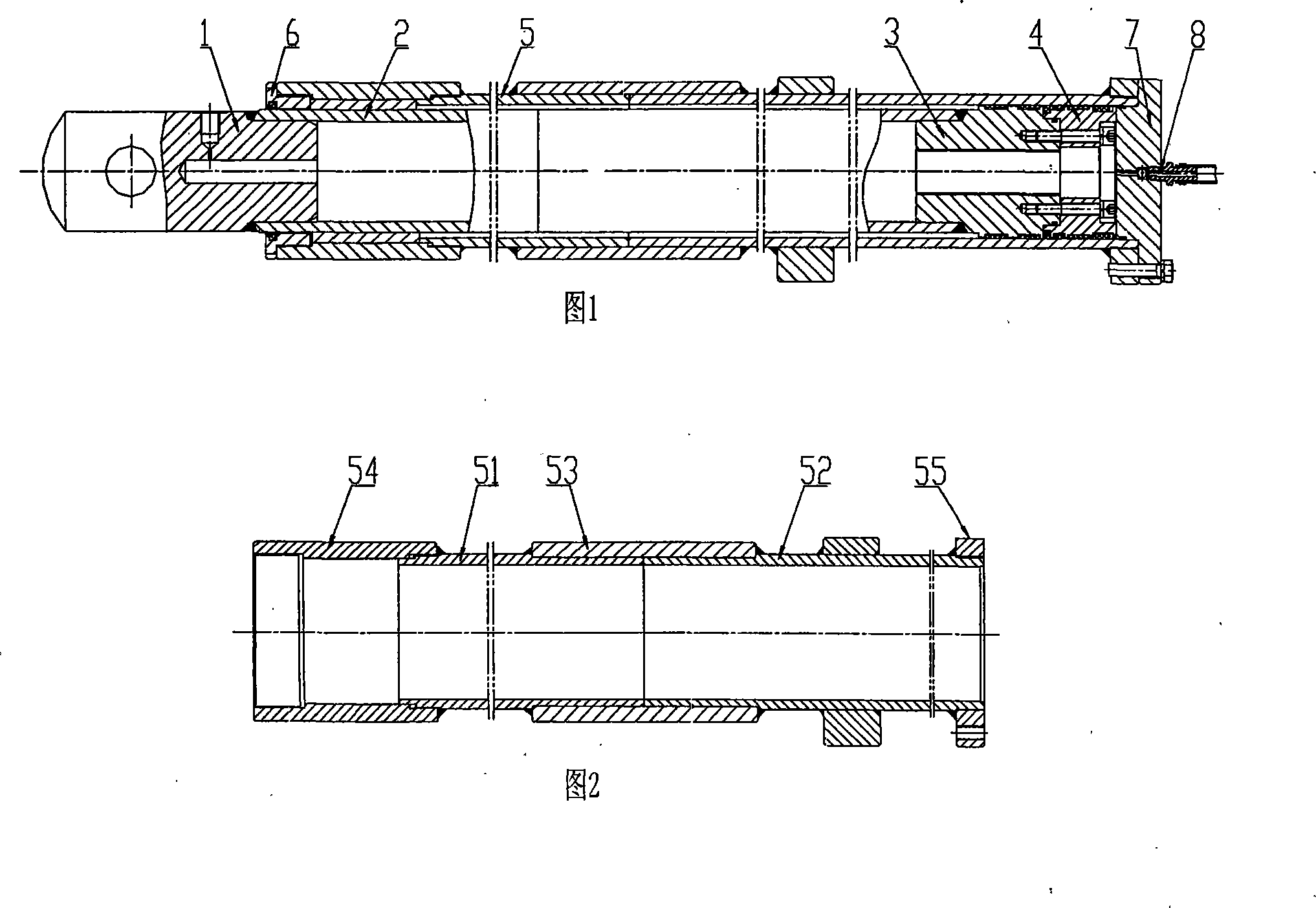

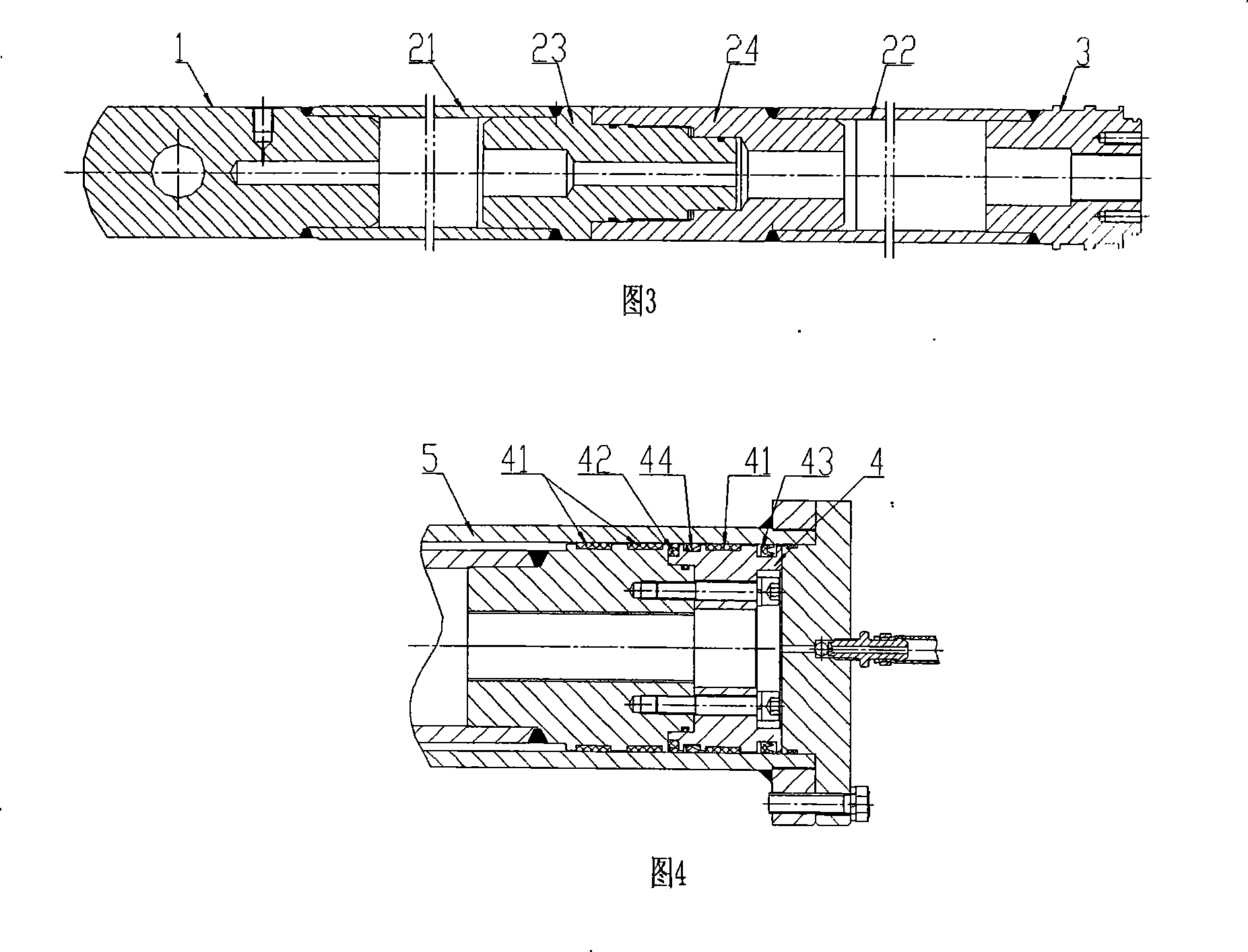

[0018] Figure 1 is a schematic diagram of the structure of the large-stroke low-temperature telescopic hydraulic cylinder for the expansion and contraction of the two-section derrick of the 2000-meter skid-mounted drilling rig. The requirements for it are as follows: when used at low temperature (-45°C), the piston stroke length is required to be 14.8 meters. The large-stroke low-temperature telescopic hydraulic cylinder is composed of piston rod head 1, piston rod 2, piston rod bottom 3, piston 4, cylinder barrel 5, gland 6, cylinder bottom 7, and air release plug 8. The piston rod head 1 and the piston rod bottom 3 are respectively inserted into the holes of the piston rod 2 made of steel pipe butt joints and welded together. The piston rod bottom 3 and the piston 4 are connected by screws, and the piston rod head 1 has an oil inlet and outlet port. . The cylinder barrel 5 is made by butt jointing of low-temperature resistant cold-drawn precision seamless steel pipes. The g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com