External rust-proof paint of mechanical equipment and preparation method of external rust-proof paint

A technology for anti-rust coatings and mechanical equipment, applied in anti-corrosion coatings, fire-retardant coatings, coatings, etc., can solve the problems of poor corrosion resistance and poor heat resistance of anti-rust coatings, and achieve low cost, improved heat resistance, and heat dissipation. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

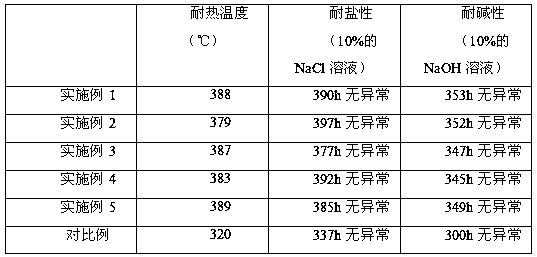

Examples

Embodiment 1

[0027] This embodiment relates to an antirust coating for external use on mechanical equipment, including the following raw materials in parts by weight: 20 parts of styrene-acrylic emulsion, 15 parts of acrylic emulsion, 8 parts of styrene, 3 parts of chlorinated paraffin, 6 parts of tributyl phosphate, bis 5 parts of pentaerythritol, 3 parts of composite filler, 2 parts of barium sulfate, 1 part of defoamer, 2 parts of thickener, 2 parts of curing agent, 2 parts of nano-zinc oxide and 20 parts of deionized water, the composite filler is nano gas phase A mixture of silicon dioxide, titanium dioxide, modified talc powder and montmorillonite, wherein the mass ratio of nano fumed silicon dioxide, titanium dioxide, talc powder and montmorillonite is 1:2:2:1.

[0028] Wherein, the curing agent is an aromatic diamine.

[0029] Wherein, the defoamer is a silicone defoamer.

[0030] Wherein, the thickener is BYK420.

[0031] A method for preparing the anti-rust coating for external...

Embodiment 2

[0039] This embodiment relates to an antirust coating for external use on mechanical equipment, including the following raw materials in parts by weight: 30 parts of styrene-acrylic emulsion, 25 parts of acrylic emulsion, 14 parts of styrene, 7 parts of chlorinated paraffin, 11 parts of tributyl phosphate, bis 9 parts of pentaerythritol, 6 parts of composite filler, 4 parts of barium sulfate, 3 parts of defoamer, 4 parts of thickener, 5 parts of curing agent, 3 parts of nano-zinc oxide and 30 parts of deionized water, the composite filler is nano gas phase A mixture of silicon dioxide, titanium dioxide, modified talc powder and montmorillonite, wherein the mass ratio of nano fumed silicon dioxide, titanium dioxide, talc powder and montmorillonite is 1:5:4:1.

[0040] Wherein, the curing agent is an aromatic diamine.

[0041] Wherein, the defoamer is a silicone defoamer.

[0042] Wherein, the thickener is BYK420.

[0043] A method for preparing the anti-rust coating for exter...

Embodiment 3

[0051] This embodiment relates to an antirust coating for external use on mechanical equipment, including the following raw materials in parts by weight: 23 parts of styrene-acrylic emulsion, 17 parts of acrylic emulsion, 10 parts of styrene, 4 parts of chlorinated paraffin, 7 parts of tributyl phosphate, bis 6 parts of pentaerythritol, 4 parts of composite filler, 2.5 parts of sulfuric acid, 1.3 parts of defoamer, 2.4 parts of thickener, 3 parts of curing agent, 2.2 parts of nano zinc oxide and 23 parts of deionized water.

[0052] Wherein, the composite filler is a mixture of nano fumed silica, titanium dioxide, modified talcum powder and montmorillonite, and the mass ratio of the nano fumed silica, titanium dioxide, talcum powder and montmorillonite is 1: 4:3:1.

[0053] Wherein, the curing agent is an aromatic diamine.

[0054] Wherein, the defoamer is a silicone defoamer.

[0055] Wherein, the thickener is BYK420.

[0056] A method for preparing the anti-rust coating f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com