Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Strong plating ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ni-Cu-P ternary alloy coating serving as welding spot reaction barrier layer and electroplating preparation technology thereof

InactiveCN102560576AReduce energy consumptionHigh bath stabilitySoldering apparatusInterconnectionAlloy coating

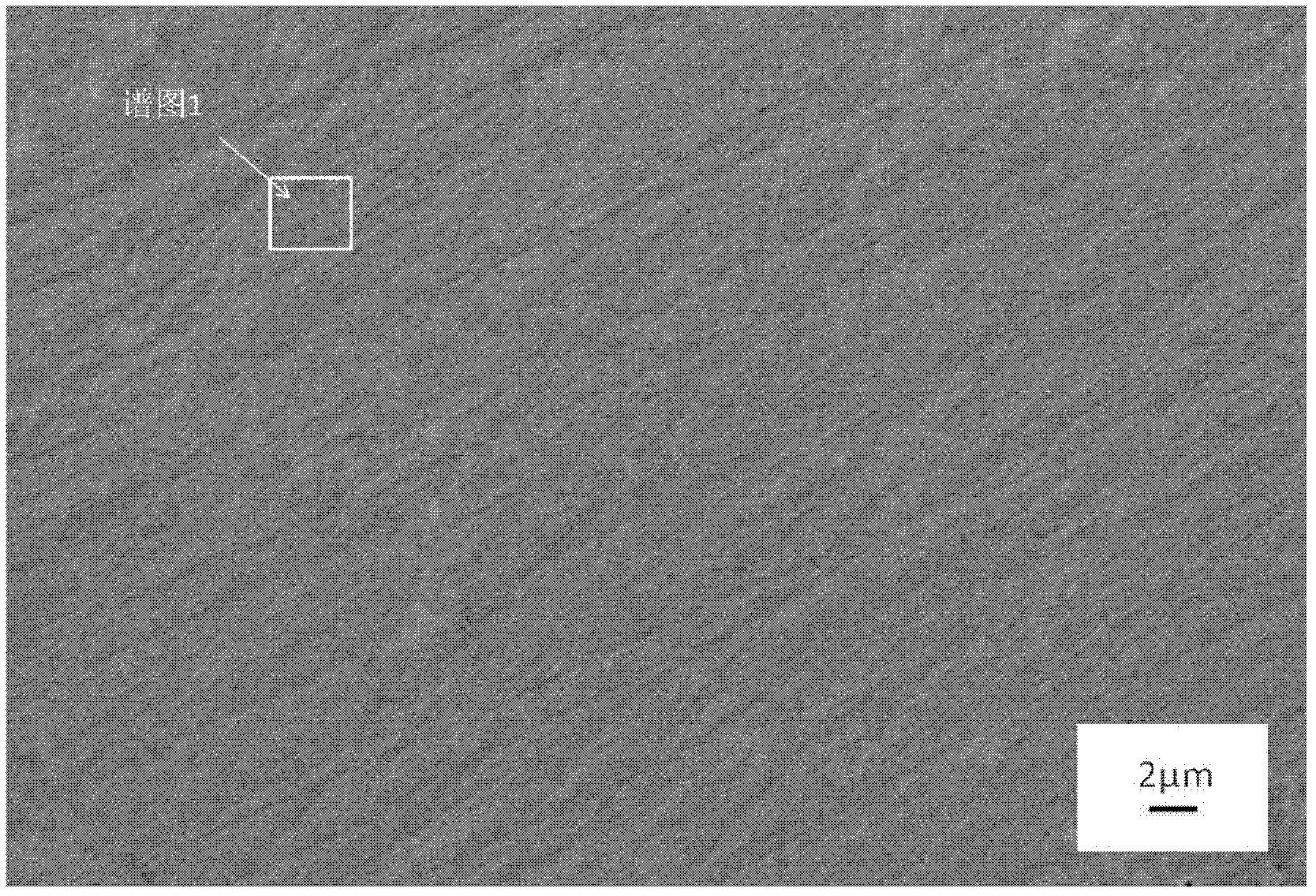

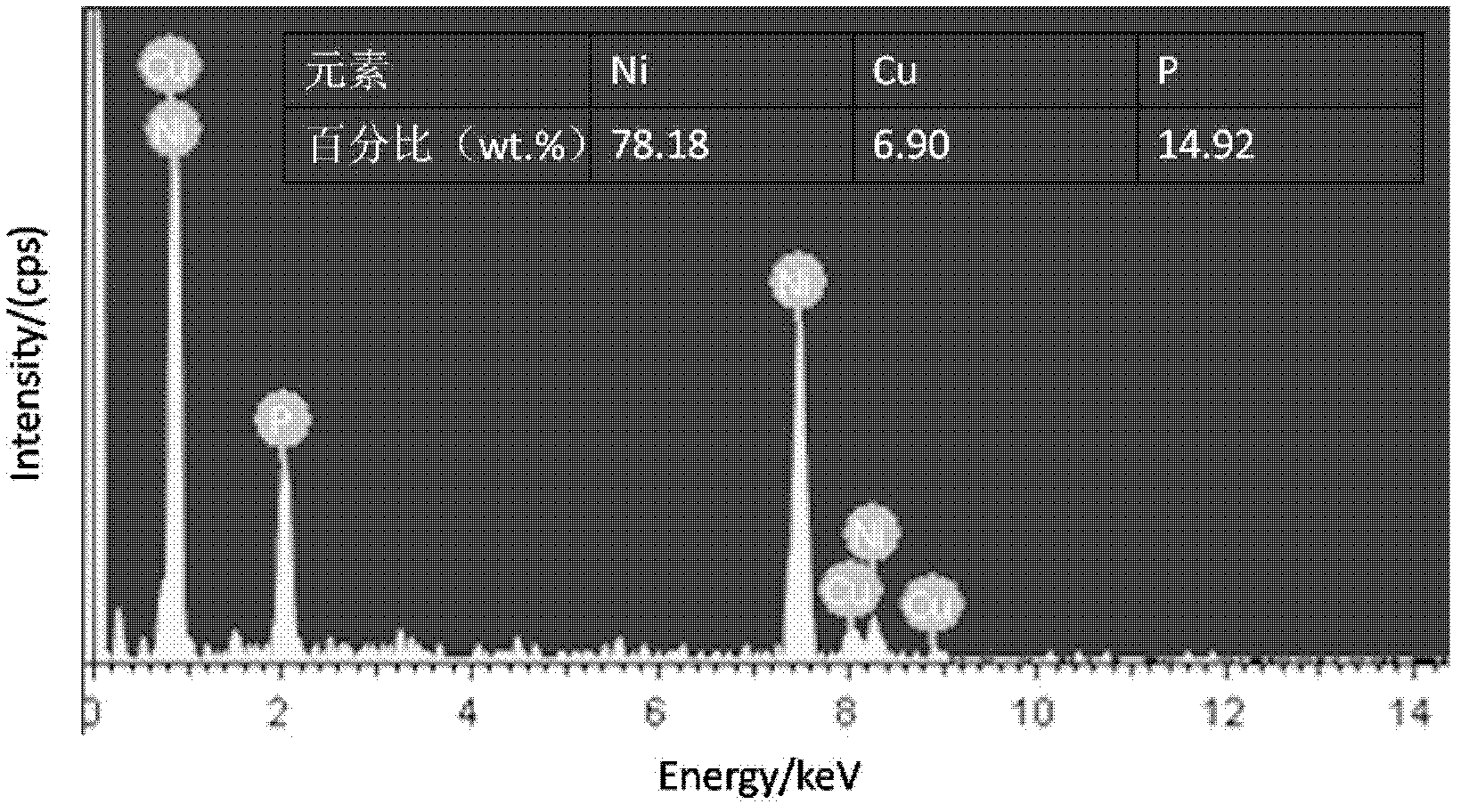

The invention discloses a Ni-Cu-P ternary alloy coating serving as a welding spot reaction barrier layer and an electroplating preparation technology thereof. The Ni-Cu-P ternary alloy coating serving as the welding spot reaction barrier layer comprises the following components in percentage by weight: 70-90% of Ni, 3-10% of Cu and 7-20% of P. The thickness of the coating is 2-15mu m. The preparation method comprises the following steps of: putting an electroplated cathode piece (metallized Si chip or Cu piece) and an electroplated anode sheet (Pt piece) into electroplate liquid; introducing dipulse current for dipulse electroplating; and forming an Ni-Cu-P alloy coating on the surface of the cathode piece. The components of the Ni-Cu-P alloy coating prepared by using the electroplating preparation technology conform to the use requirement of a welding spot reaction barrier layer for electronic packaging and interconnection, the coating and the cathode piece substrate (metallized Si chip or Cu piece) are tightly combined, a plating layer is flat, and the Ni-Cu-P ternary alloy coating is fine in cellular tissue, even in thickness, and compact in structure and is basically free from holes.

Owner:HEFEI UNIV OF TECH

Reinforced Resin Composition For Plating Base, Molded Article, And Electroplated Component

ActiveUS20100276289A1Good moldabilityHigh mechanical strengthDuplicating/marking methodsActive material electrodesPolymer scienceShell molding

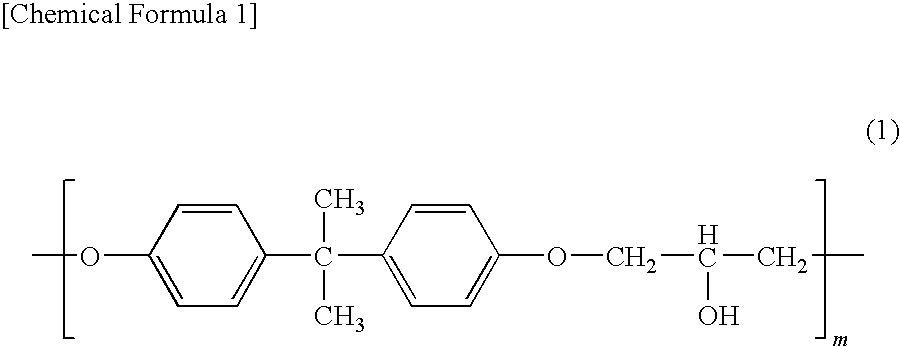

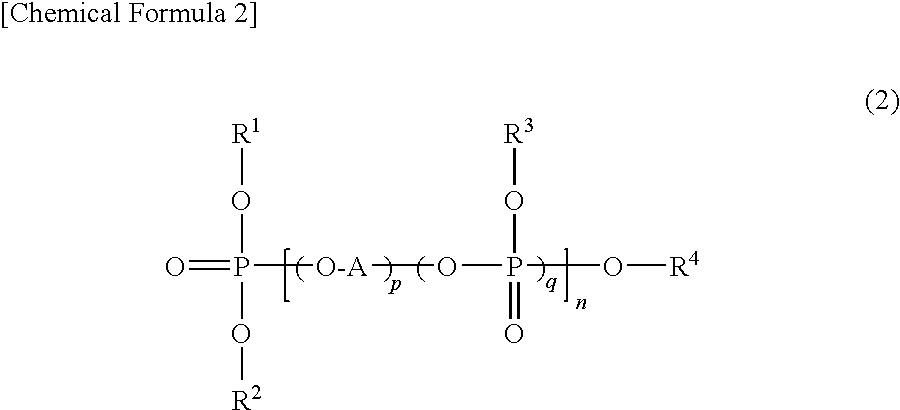

The present invention relates to a reinforced resin composition for plating bases having excellent moldability, mechanical strengths, and plating ability, as well as being capable of improving the surface appearance of the molded article after plating. The reinforced resin composition for plating bases of the present invention includes: graft copolymer (A) in which a graft chain (A2) is grafted to a rubber polymer (A1) a matrix polymer (B) which includes one or more types of polymers selected from the group consisting of a vinyl-based copolymer (B-1), a polycarbonate resin (B-2), and a polyester resin (B-3); an inorganic filler (D); and a glycidyl ether unit-containing polymer (E). The content of the rubber polymer (A1) is from 5 to 25% by mass, relative to 100% by mass of the total amount of the component of (A) and the component of the matrix polymer (B).

Owner:TECHNO UMG CO LTD

Repairing method of scrapped continuous casting crystallizer copper plate

ActiveCN105780063AImprove performanceExtended service lifeElectroforming processesSand blastingPre treatment

The invention discloses a repairing method of a scrapped continuous casting crystallizer copper plate. The repairing method comprises the steps of (1) pretreatment: carrying out degreasing treatment, mechanical sand blasting scuffing treatment, electrolytic degreasing treatment, ultrasonic degreasing treatment and acid spraying activating treatment on a copper plate base material subjected to machining, so as to obtain a to-be-cast copper plate base material; (2) electroforming solution injection: injecting an electroforming solution into an electroforming tank, adjusting the pH, and heating the electroforming solution till the temperature reaches a set value; and (3) electroforming: putting the to-be-cast copper plate base material adopted as a cathode into the electroforming tank, putting an anode into the electroforming tank, switching on the power, and stopping electroforming till the thickness of a silver-copper alloy plating reaches a set value. According to the repairing method, the crystallizer copper plate base material at the scrapping limit is repaired and reutilized through adopting an easy and feasible preparation method, the obtained crystallizer copper plate is excellent in performance, the service life of the crystallizer copper plate is prolonged through the silver-copper alloy plating, the production cost is improved, and the sustainable development property is high.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

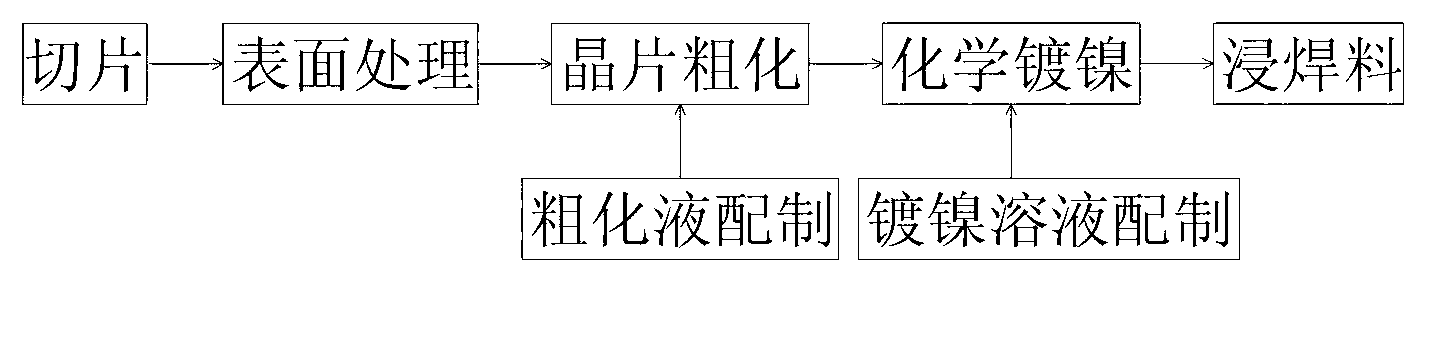

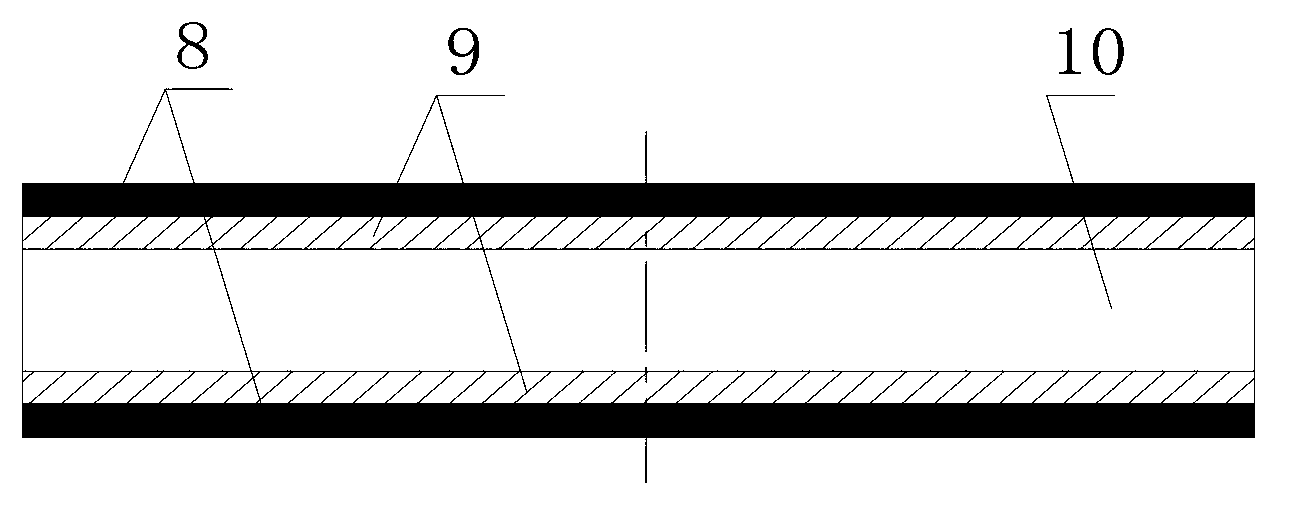

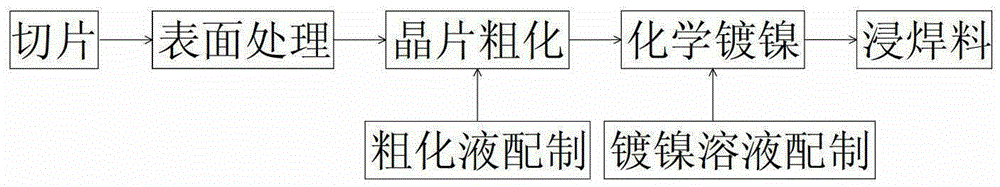

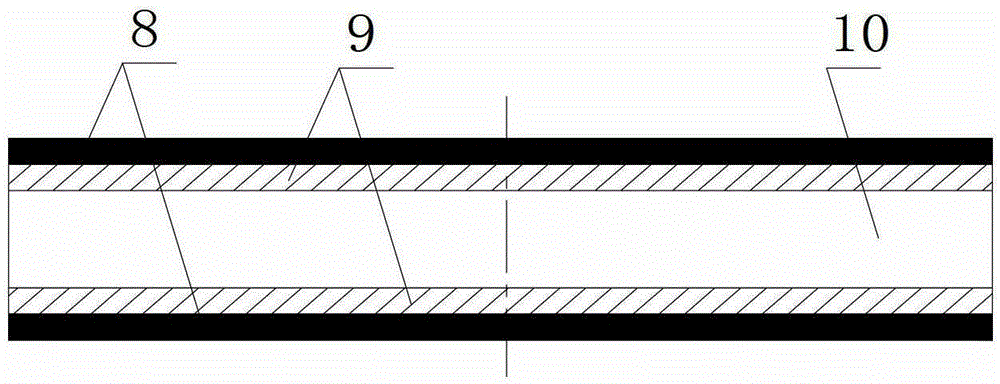

Treatment method of thermoelectric materials before welding

ActiveCN103056470AConsistent thicknessImprove bindingSoldering apparatusLiquid/solution decomposition chemical coatingThermoelectric materialsFailure rate

The invention relates to a treatment method of thermoelectric materials before welding. The treatment method is characterized by including steps of alkali wash and acid wash of a thermoelectric material sheet, coarsening of the thermoelectric material sheet, chemical nickel plating and soldering flux immersing. According to the treatment method, sodium hypophosphite is added into a solution which is subjected to chemical nickel plating, the temperatures are kept to be 85-95 DEG C, and a P-Ni alloy nickel layer which is high in binding forces, excellent in weldability and uniform in thickness is formed on the surface of the thermoelectric material sheet and used as a transition layer. When a thermoelectric refrigeration assembly manufactured by the thermoelectric material sheet and formed by welding thermoelectric elements works in the temperature environment of (-55) DEG C-115 DEG C, the thermoelectric elements can not fall off, space resistant radiation is 300 Krad (Si), and the failure rate is 200 fit. The service life of the thermoelectric refrigeration assembly can reach 15 years in the working environment, and the thermoelectric refrigeration assembly can be widely applied to electrical devices with high reliability and long service life.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Copper electroplate liquid and preparation method thereof

The invention relates to a copper electroplate liquid and a preparation method thereof. The formula of the electroplate liquid comprises the following raw materials: 80-150g / L of copper sulfate, 50-90g / L of copper chloride, 40-70g / L of sodium sulfate, 60-120g / L of potassium sulphate, 5-30g / L of a brightener, 5-20g / L of a wetting agent, 25-55g / L of a buffer agent and deionized water added to 1,000ml. The method comprises the following steps: putting the deionized water into a container; weighing a proper amount of brightener and a proper amount of wetting agent, stirring and dissolving; weighing a proper amount of copper sulfate and a proper amount of sulfur copper chloride to a solution, stirring and dissolving at room temperature; adding sodium sulfate and potassium sulphate to the solution; and heating the solution to 55-65 DEG C, heating and stirring, and then adjusting the pH value of the solution by adopting the buffer agent. A clad layer formed by the method is good in ductility, free of brittleness, bright in surface, high in flatness, strong in throwing power and covering power, and high in current efficiency; the electroplate liquid is non-toxic; and a high-density zone of the clad layer is not scorched.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

Cobalt-tungsten-nickel alloy electroplating solution and preparation method thereof

The invention relates to a cobalt-tungsten-nickel alloy electroplating solution and a preparation method thereof. The electroplating solution is prepared as follows: adding 30-70g / L sodium tungstate, 10-20g / L cobalt sulfate, 40-75g / L nickel sulfate, 50-120g / L sodium chloride, 40-70g / L potassium sulfate, 20-40g / L a buffer, 20-50g / L a stabilizer and 1-5g / L an antioxidant into deionized water to 1000ml, weighing an appropriate amount of a wetting agent, adding the deionized water and stirring till dissolution; and further weighing an appropriate amount of sodium tungstate, cobalt sulfate and nickel sulfate into a solution, and stirring at normal temperature till dissolution; further adding sodium chloride and potassium sulfate into the solution, heating the solution to 55-65 DEG C, stirring while heating and regulating the pH value of the solution with the buffer. A plated layer formed by the electroplating solution provided by the invention has strong throwing power and covering power, strong corrosion resistance, high current efficiency and little environmental pollution, and a high-density area of the plated layer can not be burned.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

Zinc-impregnating layer anodic oxidation method colouring process and its treatment solution formula

InactiveCN1477229ANo pollution in the processSolve pollutionSuperimposed coating processPotassium hydroxideAniline

Firstly, pretreating metal base body as anode, i.e. degreasing, acid cleaning, alkali washing, activating, zinc-soaking and preparing treatment solution, applying electric current in the treatment solution to produce electric energy so as to make the surface of metal base body have a layer of compact colour film. The composition of said treatment solution includes (wt%) 20%-45% of potassium hydroxide, 30%-40% of aniline and 20%-45% of potassium oxalate.

Owner:SHANGHAI AIERSI LIGHT ALLOY

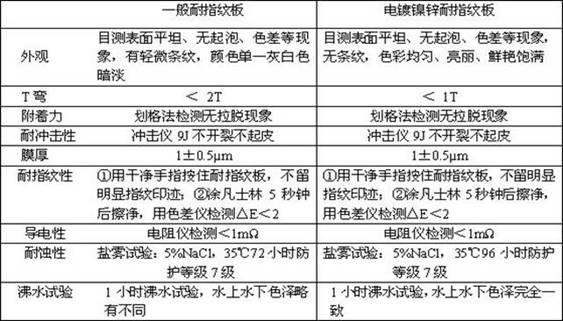

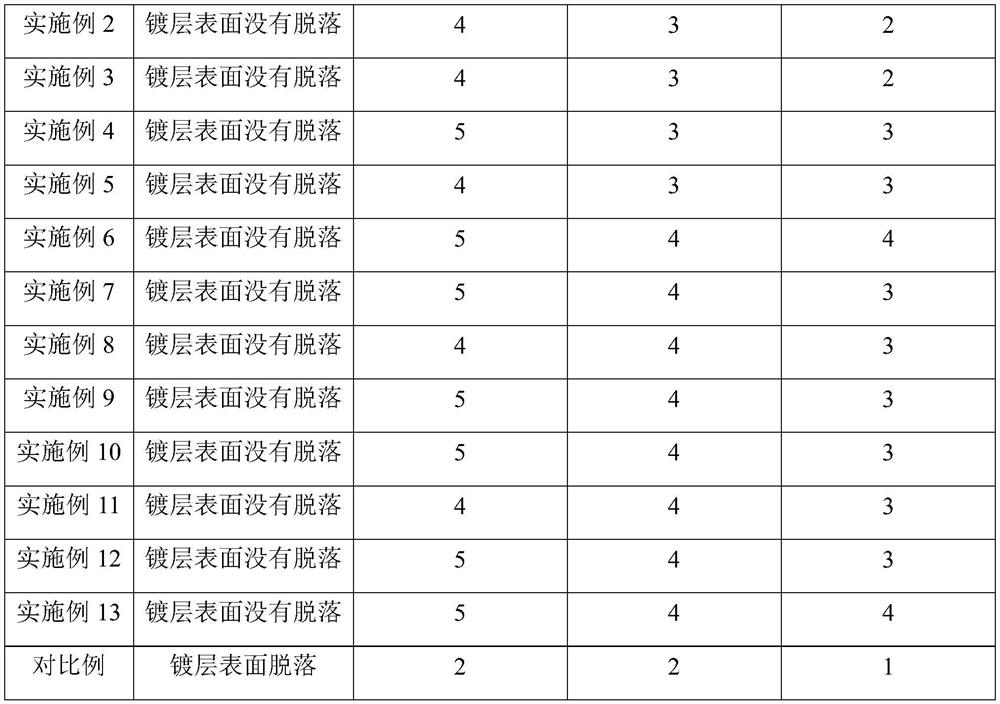

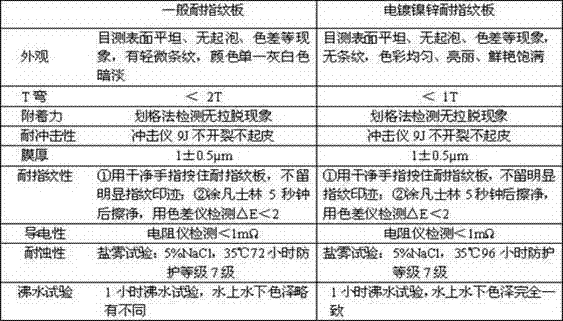

Technique for continuously producing nickel-zinc electroplated anti-fingerprint plate

The invention discloses a technique for continuously producing a nickel-zinc electroplated anti-fingerprint plate, which comprises the following steps: carrying out alkaline nickel electroplating on a substrate steel plate, and carrying out acidic zinc electroplating. The electroplating section technique is organically added into the production line to continuously produce the nickel-zinc electroplated anti-fingerprint plate. The product obtained by using the technique has the advantages of smooth surface, uniform and fine plating crystal, high bonding strength, high adhesive force, high corrosion resistance and excellent mechanical properties, and is especially applicable to harsh environments, such as high heat, high coldness, high humidity, strong heat and the like.

Owner:山东恒达精密薄板科技有限公司

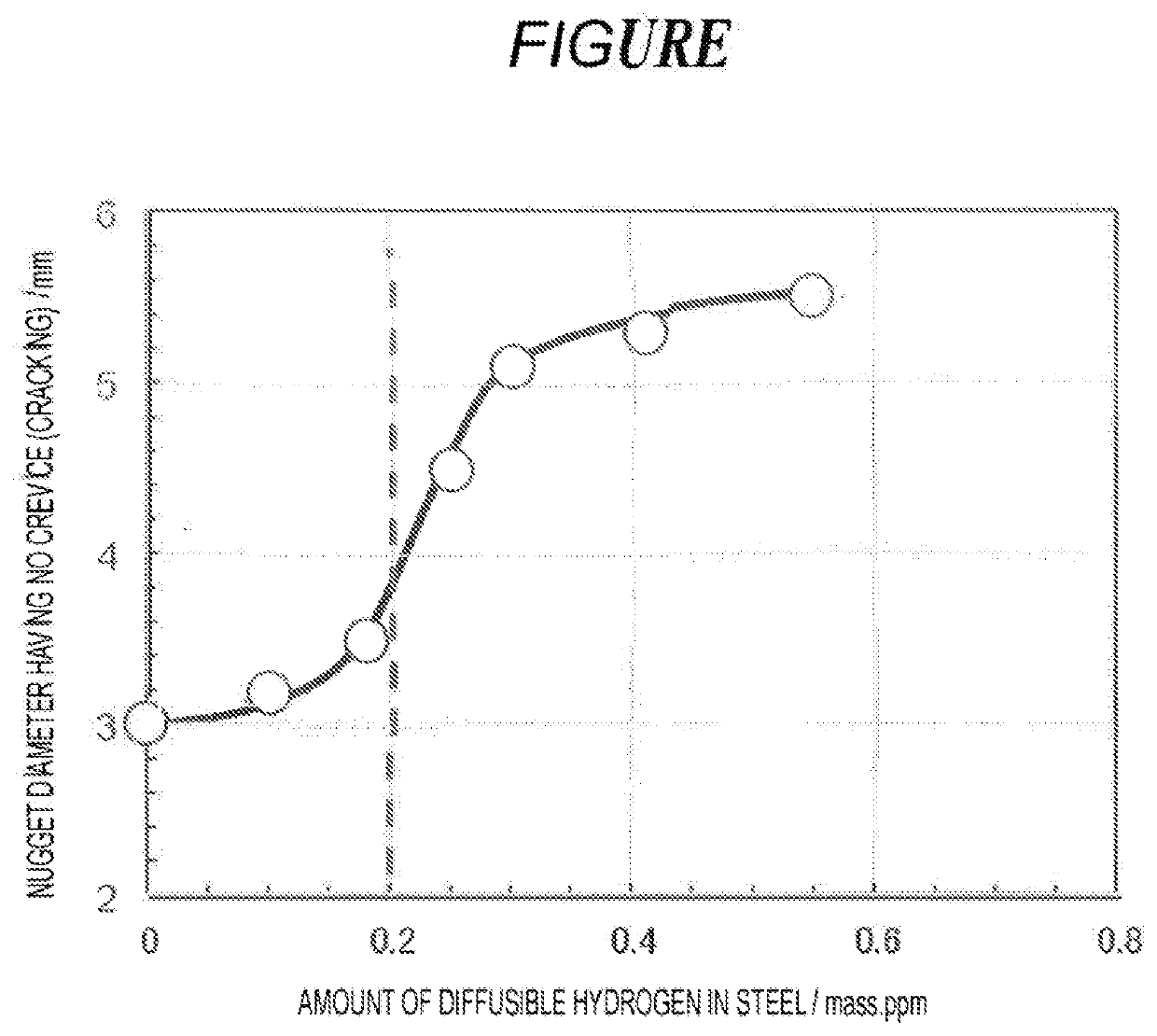

High-strength galvanized steel sheet and method for manufacturing same

ActiveUS20200291499A1Strong plating abilityExcellent in surface external appearanceHot-dipping/immersion processesFurnace typesUltimate tensile strengthMn oxide

There is provided a high-strength galvanized steel sheet excellent in the external appearance of plating and the hydrogen brittleness resistance, and has a high yield ratio suitable for building materials and automotive collision-resistant parts, and a method for manufacturing the same.Provided is a high-strength galvanized steel sheet including a specific component composition and a specific steel structure, the amount of diffusible hydrogen in the steel being 0.20 mass ppm or less; and a galvanizing layer provided on a surface of the steel sheet, having a content amount of Fe of 8 to 15% in mass %, and an attachment amount of plating per one surface of 20 to 120 g / m2, wherein the amount of Mn oxides contained in the galvanizing layer is 0.050 g / m2 or less, and a yield strength is 700 MPa or more and a yield strength ratio is 65% or more and less than 85%.

Owner:JFE STEEL CORP

Brush plating technology for restoring rolling-mill gear shaft by using pulse electric brush plating

A related brush plating technology for restoring a rolling-mill gear shaft by using pulse electric brush plating comprises (1) cleaning the gear shaft; (2) performing electric purifying; (3) activating; (4) performing brush plating on a bottom layer; and (5) performing brush plating on a working layer. A plating repaired by the technology is uniform in surface, free of cracks, free of burrs, and free of cracking and stripping phenomena. The pulse electric brush plating technology is capable of effectively reducing the tensile stress of the plating and even obtaining pressure stress, thereby substantially improving the thickly plating capacity of brush plating, the single-side plating thickness reaches 1 mm or more, and the combination strength is high. The restored gear shaft well runs, the cost is reduced and the economic benefit is improved.

Owner:无锡市森信精密机械厂

Copper plating additive suitable for printed circuit board and copper electroplating solution

The invention relates to the field of copper plating additives, and particularly discloses a copper plating additive suitable for a printed circuit board and a copper electroplating solution. The copper plating additive comprises the following components according to the concentration ratio: 1-50 mg / L of brightening agent, 1-100 mg / L of leveling agent, 0.5-50 g / L of wetting agent and the balance pure water. The copper electroplating solution comprises the following components according to the concentration ratio: 180-250g / L of sulfuric acid, 50-80g / L of copper sulfate pentahydrate, 40-120ppm of chloride ions, 10-50ml / L of coppering additive and the balance pure water. According to the copper plating additive, the uniformity of a plating layer and the deep plating capacity of a plating solution can be effectively improved, the deep plating capacity TP of a through hole with the aspect ratio being 8 can reach 92.4%, the deep plating capacity TP of a through hole with the aspect ratio being 12 can reach 83.3%, and the electroplating uniformity COV of the printed circuit board can reach 9.5%.

Owner:珠海松柏科技有限公司 +2

Surface treating agent for enhancing binding force of engineering plastic coating and application

The invention discloses a surface treating agent for enhancing binding force of engineering plastic coating and application. According to the defects existing in the existing engineering plastic plating process, the plastic passes through chemical surface treating agents of a specific formula in sequence and is treated according to a certain method, the plastic is modified, and the hydrophilic performance and the binding force of the plastic and the plating layers are improved. The surface treating agent for enhancing the binding force of the engineering plastic and the plating layers is easy to prepare and high in industrial feasibility, the hydrophilic performance of the modified plastic is remarkably improved, good stability is achieved, the absorption and plating capacity is greatly improved, the binding force with the coating is greatly improved, and the service life is long. The defects of traditional plastic are overcome, and high practical value is achieved.

Owner:SUZHOU RONGCHANG COMPOUND MATERIAL

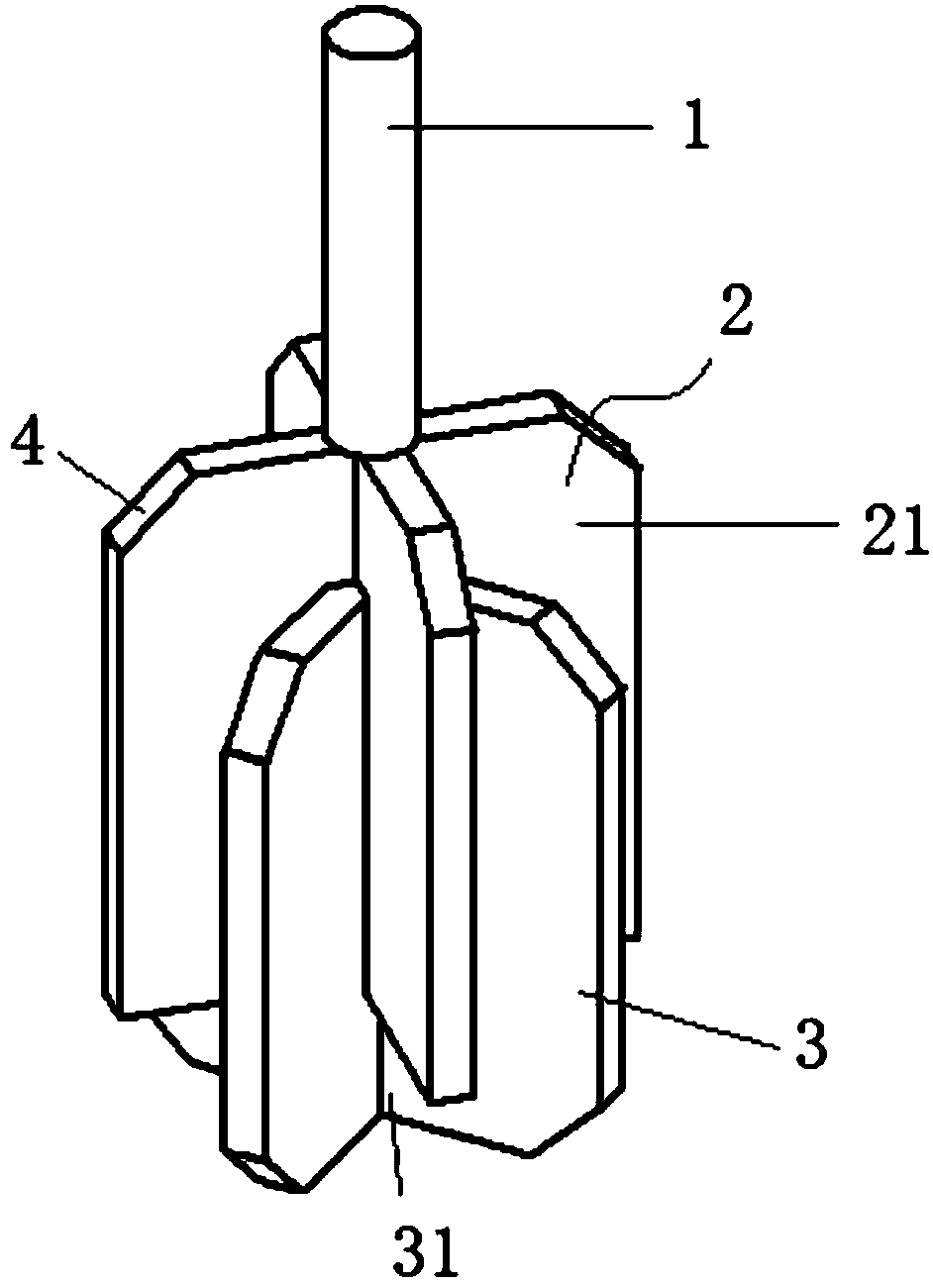

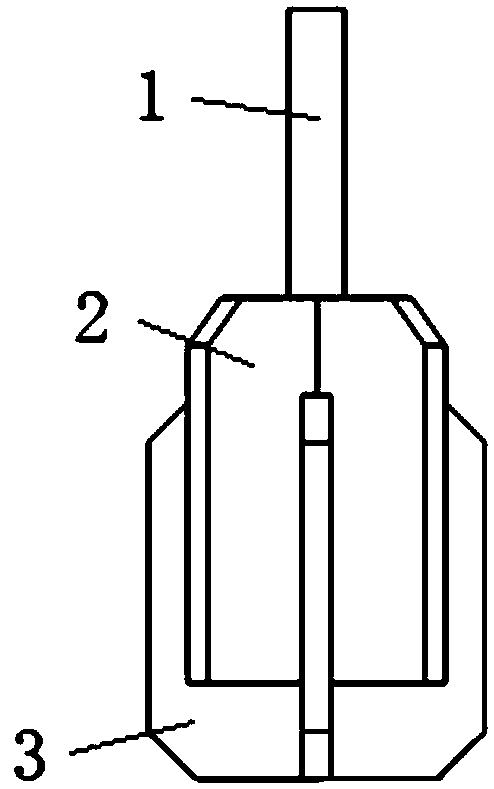

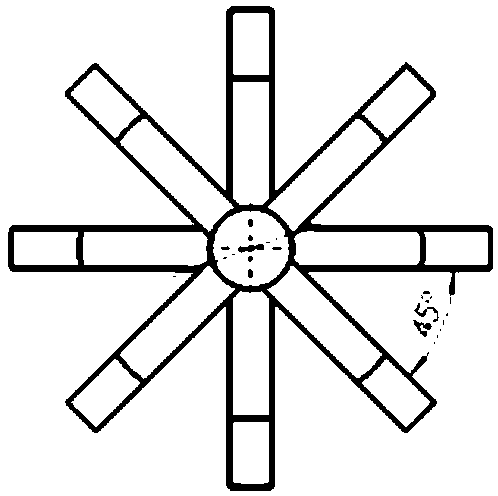

Anode structure for large-size inner-hole iron plating repair and application

ActiveCN109183136AEmission reductionReduce industrial water pollutionCellsElectrodesSteel columnsTitanium

The invention discloses an anode structure for large-size inner-hole iron plating repair and an application. The anode structure for large-size inner-hole iron plating repair comprises a steel columnand a cross-shaped connection titanium plate positioned at the lower end of the steel column, the axis of the steel column and the axis of the cross-shaped connection titanium plate are positioned onthe same straight line, a lower titanium plate is arranged between every two adjacent supporting plates of the cross-shaped connection titanium plate, and the four lower titanium plates are uniformlydistributed by taking the straight line where the axis of the steel column is located as the axis. According to the anode structure, the anode structure for large-size inner-hole iron plating repair is used for performing large-size cylinder sleeve inner-hole iron plating repair, compared with a traditional cylindrical anode, the anode structure for large-size inner-hole iron plating repair is characterized in that the surface is extremely large, then the contact area between the anode structure and a plating solution is increased, and the concentration difference of the plating solution is relatively small.

Owner:DALIAN MARITIME UNIVERSITY

Alloy electrolyte solution replacing chromium and preparation method thereof

The invention discloses an alloy electrolyte solution replacing chromium, wherein the alloy electrolyte solution includes nickel sulfate, sodium tungstate, sodium citrate, potassium sodium tartrate, saccharin, coumarin, 1,4-butynediol, and lauryl sodium sulfate; the pH value is 7.3-8.5, the low temperature is 18-30 DEG C, the low electric current is 0.8-1 A / dm<2>, an anode is graphite or a nickelplate, a softening agent is cobalt sulfate and ethylenediamine tetraacetic acid tetrasodium salt. The alloy electrolyte solution replacing chromium has the advantages that under conditions of normal temperature and low electric current, a product with high hardness and good wear resistance, ductility, corrosion resistance and binding force can be plated.

Owner:AOJIE SPECIAL AUTOCAR MFG YINGKOU

Surface treating agent for increasing coating binding force of engineering plastic

The invention discloses a surface treating agent for enhancing coating binding force of an engineering plastic and application thereof, and aims at overcoming the defects existing in the electroplating of existing engineering plastics, the plastic is subjected to treatment by a chemical surface treating agent of a specific formula in sequence according to a certain method, so that the plastic is modified, and the hydrophilicity and the coating binding force are improved; the surface treating agent used for enhancing the coating bonding force of the engineering plastic has the advantages that the preparation is simple and the industrial feasibility is high, the plastic subjected to modification treatment has greatly improved hydrophilicity and relatively good stability, the plating-absorption capability is greatly enhanced, the coating binding force is greatly improved, the service life is long, the defects of the traditional plastics are broken through, and the surface treating agent has very strong practical value.

Owner:宁波铁锚电器有限公司

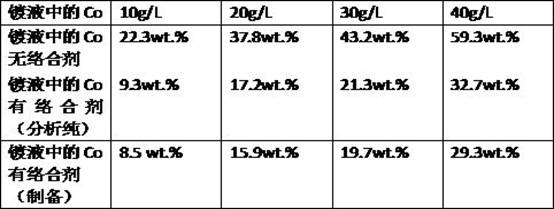

Additive of Co-Ni alloy electroplating solution for electroplating

ActiveCN112267134ARich in channelsNon-uniform pore structureProcess efficiency improvementSulfonateSodium acetate

The invention provides an additive of a Co-Ni alloy electroplating solution for electroplating. The additive comprises chlorobenzaldehyde, 1, 3-propanedithiol, butyne alcohol ether propane sodium sulfonate and sodium diethylenetriamine pentaacetate. The additive can effectively inhibit abnormal deposition of CoNi, a coating is small in grain, the surface is smooth, internal stress is low, deep plating capacity is high, and the electroplating effect is better than that of similar electroplating solutions.

Owner:中山市康迪斯威科技有限公司

Preparation method of Co-Ni alloy electroplating solution

The invention provides a preparation method of a Co-Ni alloy electroplating solution, wherein the electroplating solution can effectively inhibit abnormal deposition of CoNi, an obtained plating layeris small in grain, smooth in surface, low in internal stress and high in deep plating capacity, and electroplating effect is superior to that of similar plating solutions.

Owner:峨山金峰金属制品有限责任公司

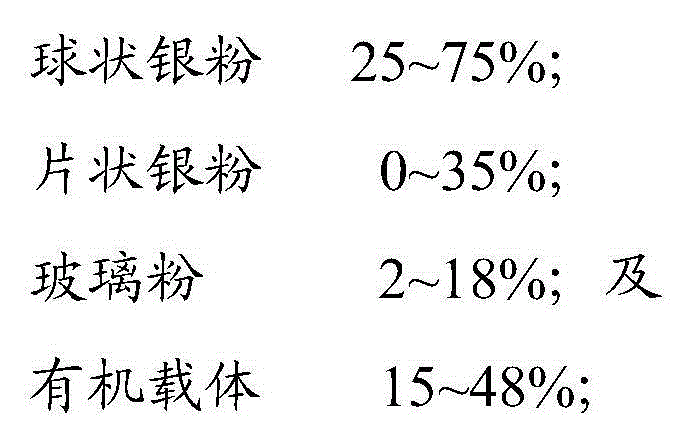

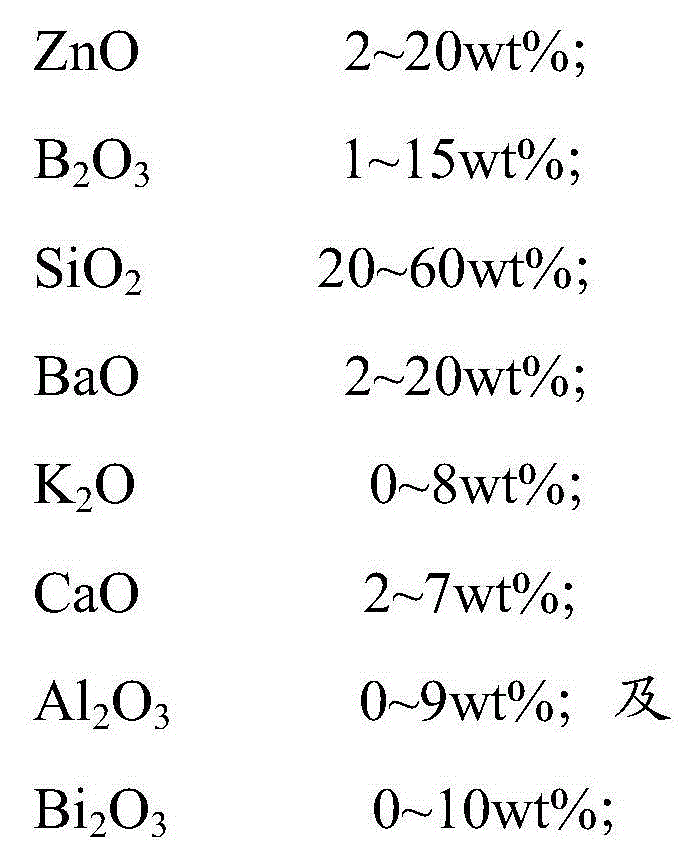

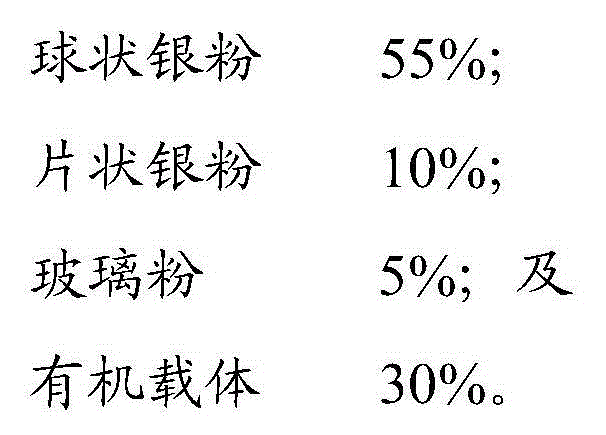

Silver Electrode Paste

ActiveCN103440899BGood and stable physical propertiesUse low volatilityTransformers/inductances coils/windings/connectionsNon-conductive material with dispersed conductive materialSilver electrodeMaterials science

The invention relates to a silver electrode paste. The silver electrode paste comprises, by mass, 25%-75% of spherical silver powder, 0%-35% of flaky silver powder, 2%-18% of glass powder and 15%-48% of organic carriers. The silver electrode paste is obtained through proper matching of the components. Experiments show that the silver electrode paste is good and stable in physical performance, low in volatility, wide in silver content range, strong in platability, wide in sintering temperature range, large in after-plating adhesive force, and stable in quality.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

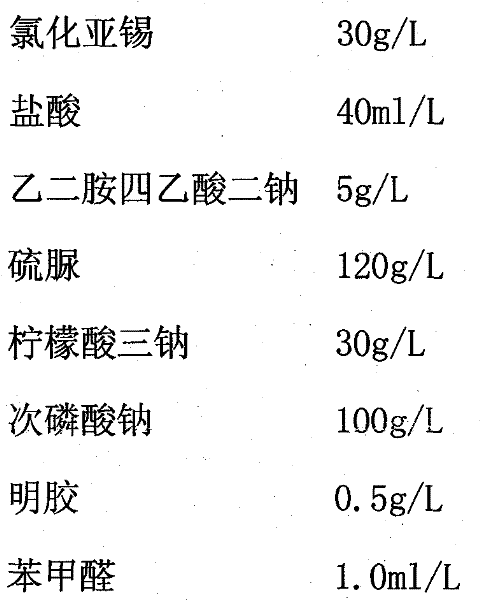

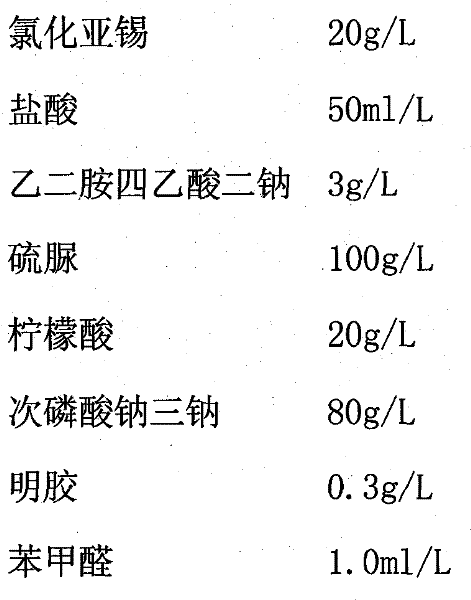

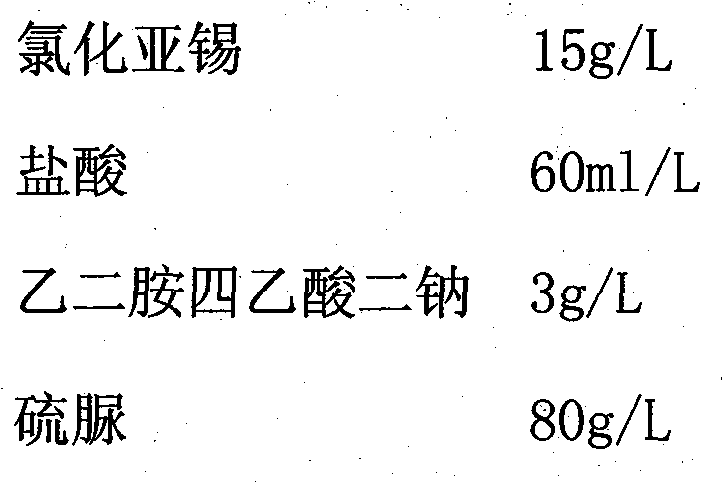

Semi-bright lead-free chemical tinning liquid and using method thereof

InactiveCN101717929BEnables continuous autocatalytic depositionFast depositionLiquid/solution decomposition chemical coatingThioureaBenzaldehyde

The invention discloses new semi-bright lead-free chemical tinning liquid and a using method thereof. A semi-bright silver tin-copper alloy chemical plating layer is obtained on copper and copper alloy matrix. In the chemical plating liquid, tin sulfate is used as a main salt, thiourea is used as a main complexing agent, citric acid is used as an auxiliary complexing agent, sodium hypophosphite is used as a reducing agent, ethylene diamine tetraacetic acid is used as an antioxidant, sulfuric acid is used as a stabilizing agent, gelatin is used as a leveling agent, and benzaldehyde is used as an auxiliary brightening agent. The pH value of the plating liquid is 0.8 to 2.0, the temperature of the plating liquid is between 80 and 90 DEG C, the carrying capacity of the plating liquid is 0.8 to 1.5dm2 / L, and the mechanical stirring speed is 50 to 100 rpm. The continuous self-catalytic deposition of tin is implemented on the copper and copper alloy matrix, plating layers of different thicknesses can be obtained by controlling the chemical plating time, and the deposition speed is high; crystalline grains are obviously refined, the surface flatness of the plating layer is improved, and the plating surface area is large; the plating layer and the matrix are combined firmly; and after passivating treatment, the change resistance of the plating layer is high. The technology has broad application prospect in products such as deep hole pieces, blind hole pieces, small-sized electronic parts and components which are difficult to process, printed circuit boards (PCB) and the like.

Owner:KUNMING UNIV OF SCI & TECH

Treatment method of thermoelectric material before welding

ActiveCN103056470BConsistent thicknessImprove bindingSoldering apparatusLiquid/solution decomposition chemical coatingThermoelectric materialsSodium Hypophosphite Monohydrate

The invention relates to a treatment method of thermoelectric materials before welding. The treatment method is characterized by including steps of alkali wash and acid wash of a thermoelectric material sheet, coarsening of the thermoelectric material sheet, chemical nickel plating and soldering flux immersing. According to the treatment method, sodium hypophosphite is added into a solution which is subjected to chemical nickel plating, the temperatures are kept to be 85-95 DEG C, and a P-Ni alloy nickel layer which is high in binding forces, excellent in weldability and uniform in thickness is formed on the surface of the thermoelectric material sheet and used as a transition layer. When a thermoelectric refrigeration assembly manufactured by the thermoelectric material sheet and formed by welding thermoelectric elements works in the temperature environment of (-55) DEG C-115 DEG C, the thermoelectric elements can not fall off, space resistant radiation is 300 Krad (Si), and the failure rate is 200 fit. The service life of the thermoelectric refrigeration assembly can reach 15 years in the working environment, and the thermoelectric refrigeration assembly can be widely applied to electrical devices with high reliability and long service life.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

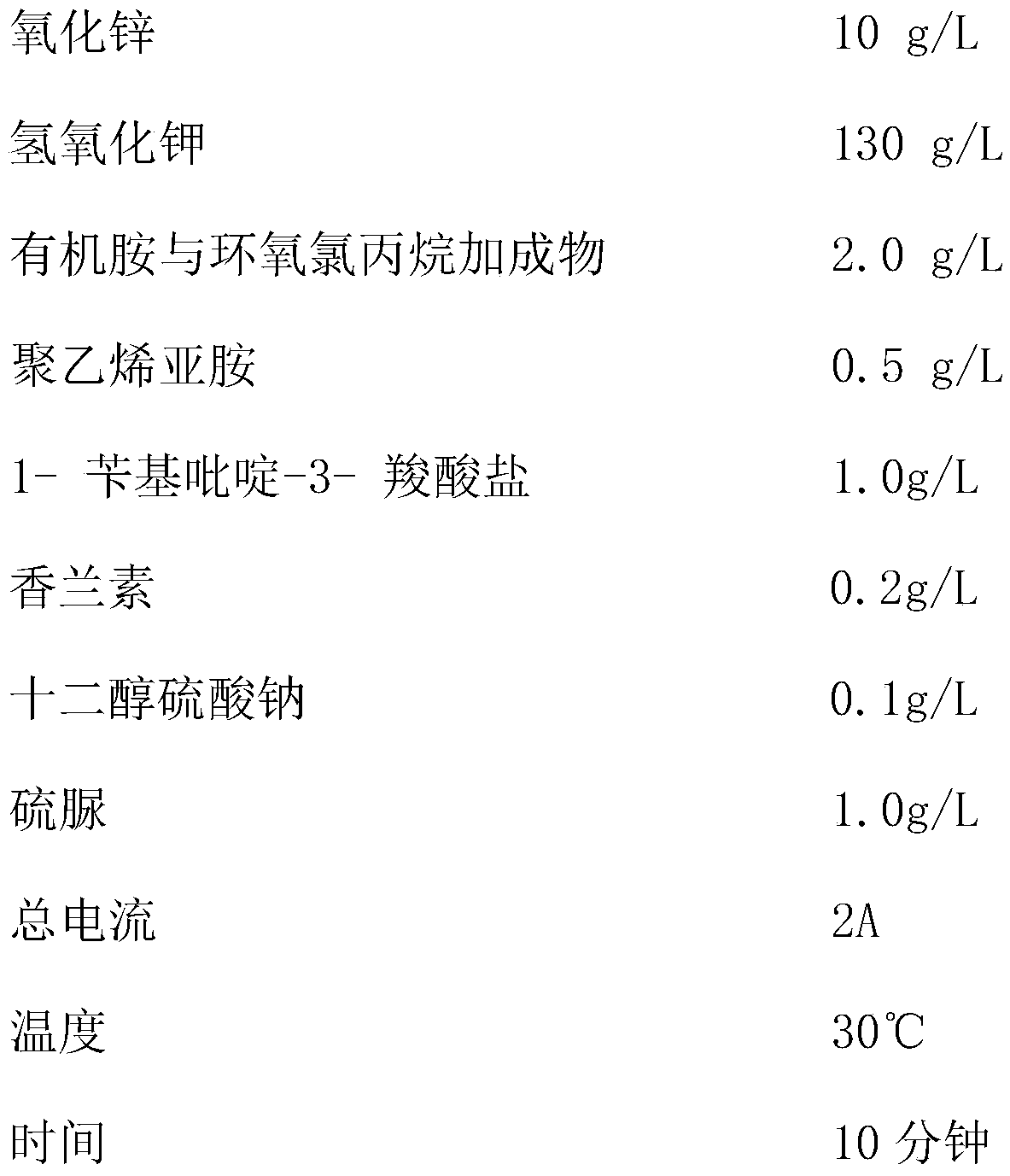

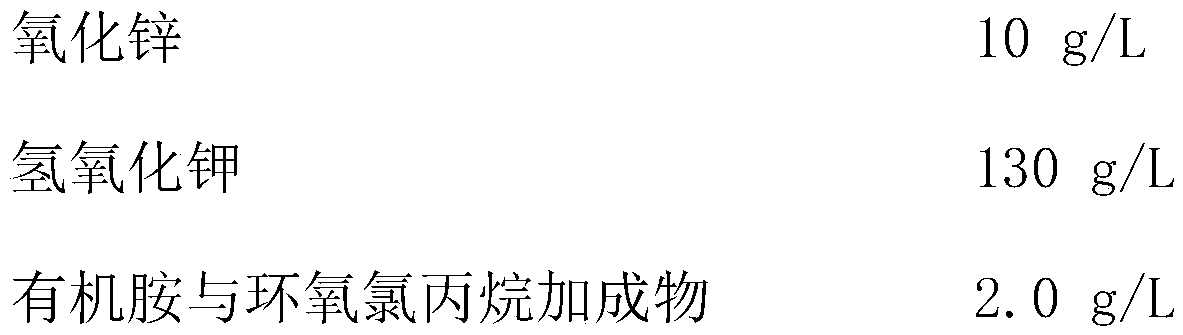

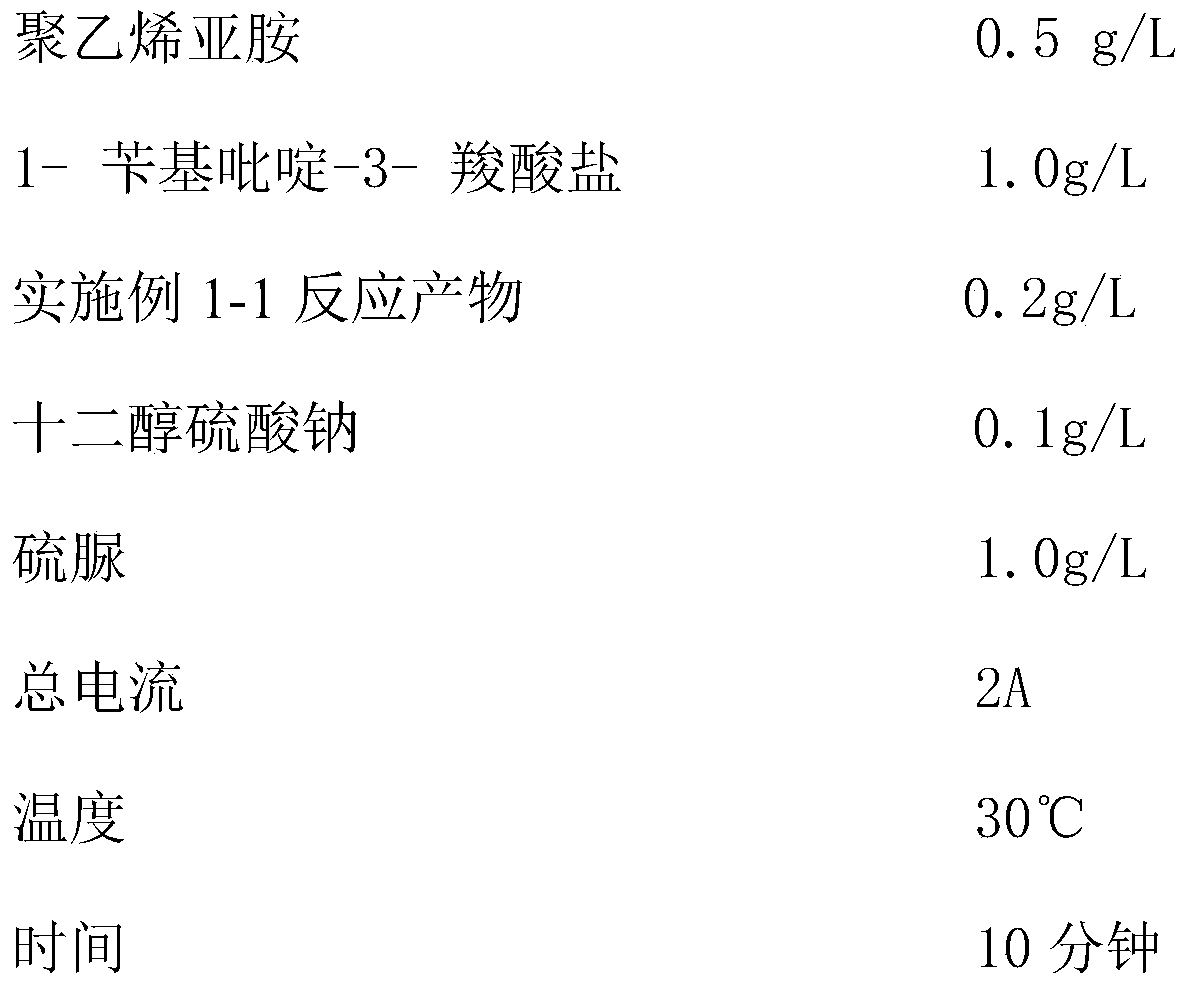

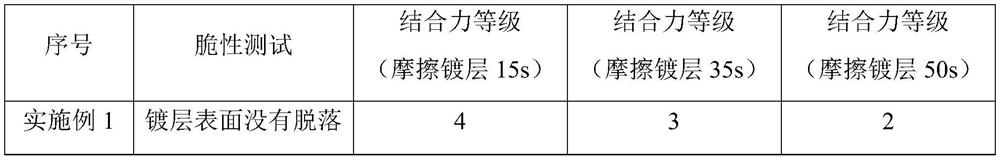

A kind of preparation method of cyanide-free zinc plating brightener specially used for potassium salt system

ActiveCN107937941BFast depositionImprove densification performanceDrugs solutionReaction temperature

The invention discloses a preparation method of a cyanide-free zinc-plating brightener special for a sylvite system. The preparation method comprises the following steps that (A) 13.6-27.2 g of organic aldehyde compound, 45.8-75.8 g of secondary solvents and 300-500 ml of water are added into a reaction vessel, then heating is conducted, and the temperature rises to 40-50 DEG C, 10.5-22.5 g of reductive drug solution is dropped, and the dropping time is 50-80 minutes; (B) after dropping of the reductive drug solution is completed, the temperature of the reaction vessel rises to 80-85 DEG C, and after heat preservation and stirring for reacting are conducted for 6-10 hours under the temperature of 80-85 DEG C, a first step reaction intermediate can be obtained; (C) then 12.4-24.6 g of phytic acid aqueous solution is slowly dropped into the first step reaction intermediate, and the dropping time is 30-40 minutes; and (D) after dropping is completed, the reaction temperature is 70-90 DEGC, constant temperature is kept for 3-4 hours, cooling and recovery are conducted, and the cyanide-free zinc-plating brightener is obtained. According to the brightener obtained through the preparation method of the cyanide-free zinc-plating brightener, the deposition rate of a plating can be increased stably, brittleness of the plating is low, the working temperature range is wide, environment pollution is very little, and the brightener is beneficial to environmental protection.

Owner:江门市高信科技有限公司

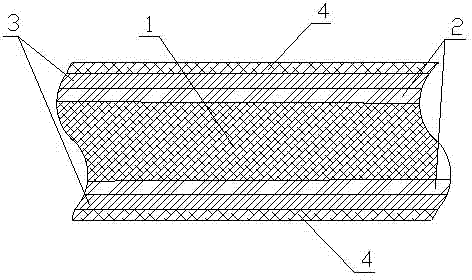

Plastic surface coating structure and preparation method thereof

PendingCN113718251AImprove bindingImprove hydrophilicityVacuum evaporation coatingSputtering coatingPlasticizerThin membrane

The invention relates to the technical field of plastic product surface electroplating, and particularly discloses a plastic surface coating structure and a preparation method thereof. The plastic surface coating structure sequentially comprises a conductive metal layer, an electroplated nickel layer, a PVD color layer and a transparent silicon dioxide thin film layer from a plastic surface layer, wherein plastic is treated by a surface treating agent, and the surface treating agent is mainly prepared from the following raw materials: a plasticizer, lauryl sodium sulfate, a coupling agent and water. The preparation method of the plastic surface coating structure comprises the following steps: (1) pretreating a plastic product, specifically, treating the plastic product by the surface treating agent to obtain a plastic product I; (2) pre-metallizing the plastic product, specifically, plating the conductive metal layer on the plastic product I obtained in the step (1); (3) electroplating nickel on the plastic product; and (4) electroplating a functional layer on the plastic product. The plastic surface coating structure is relatively high in plating absorption capacity.

Owner:深圳市金源康实业有限公司

A process for continuous production of electroplated nickel-zinc anti-fingerprint plate

The invention discloses a technique for continuously producing a nickel-zinc electroplated anti-fingerprint plate, which comprises the following steps: carrying out alkaline nickel electroplating on a substrate steel plate, and carrying out acidic zinc electroplating. The electroplating section technique is organically added into the production line to continuously produce the nickel-zinc electroplated anti-fingerprint plate. The product obtained by using the technique has the advantages of smooth surface, uniform and fine plating crystal, high bonding strength, high adhesive force, high corrosion resistance and excellent mechanical properties, and is especially applicable to harsh environments, such as high heat, high coldness, high humidity, strong heat and the like.

Owner:山东恒达精密薄板科技有限公司

Zinc-impregnating layer anodic oxidation method colouring process and its treatment solution formula

InactiveCN1207440CNo pollution in the processSolve pollutionSuperimposed coating processPotassiumPotassium hydroxide

The invention relates to a process for anodic oxidation colorization of a magnesium alloy or an aluminum alloy surface and a formula of an electroplating solution thereof, belonging to the technical field of electroplating. The process is as follows: the pulse anodic oxidation method and the treatment solution composed of potassium hydroxide, aniline and potassium oxalate are used to colorize the zinc-coated layer on the surface of the magnesium alloy or aluminum alloy. First, the magnesium alloy or aluminum alloy substrate as the anode is pretreated. That is, degreasing, pickling, alkali washing, activation, zinc dipping, and then preparing a treatment solution, and then passing an electric current in the treatment solution to generate electric energy, so that a dense color film is formed on the surface of the magnesium alloy or aluminum alloy substrate of the pretreated anode. The components of the treatment solution and their weight percentages are: 20%-45% of potassium hydroxide, 30%-40% of aniline, and 20%-45% of potassium oxalate. The invention has simple process and basically no environmental pollution, and is suitable for the colorization of the galvanized layer of magnesium and aluminum alloy, and is also used for the colorization of the galvanized layer. The treatment solution has good stability, strong dispersing ability and deep plating ability, the obtained treatment film layer has good uniformity, and is excellently combined with the substrate, and the obtained dense oxide film in the form of colorful patterns is obtained.

Owner:SHANGHAI AIERSI LIGHT ALLOY

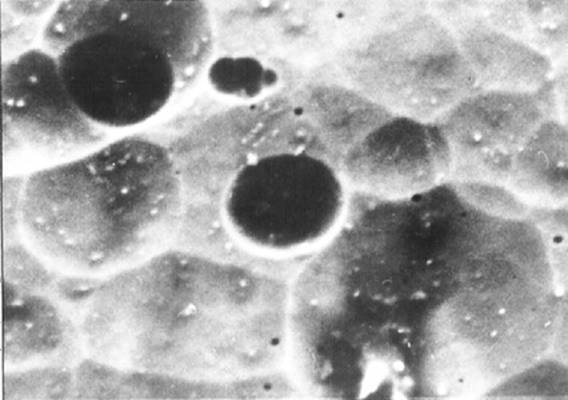

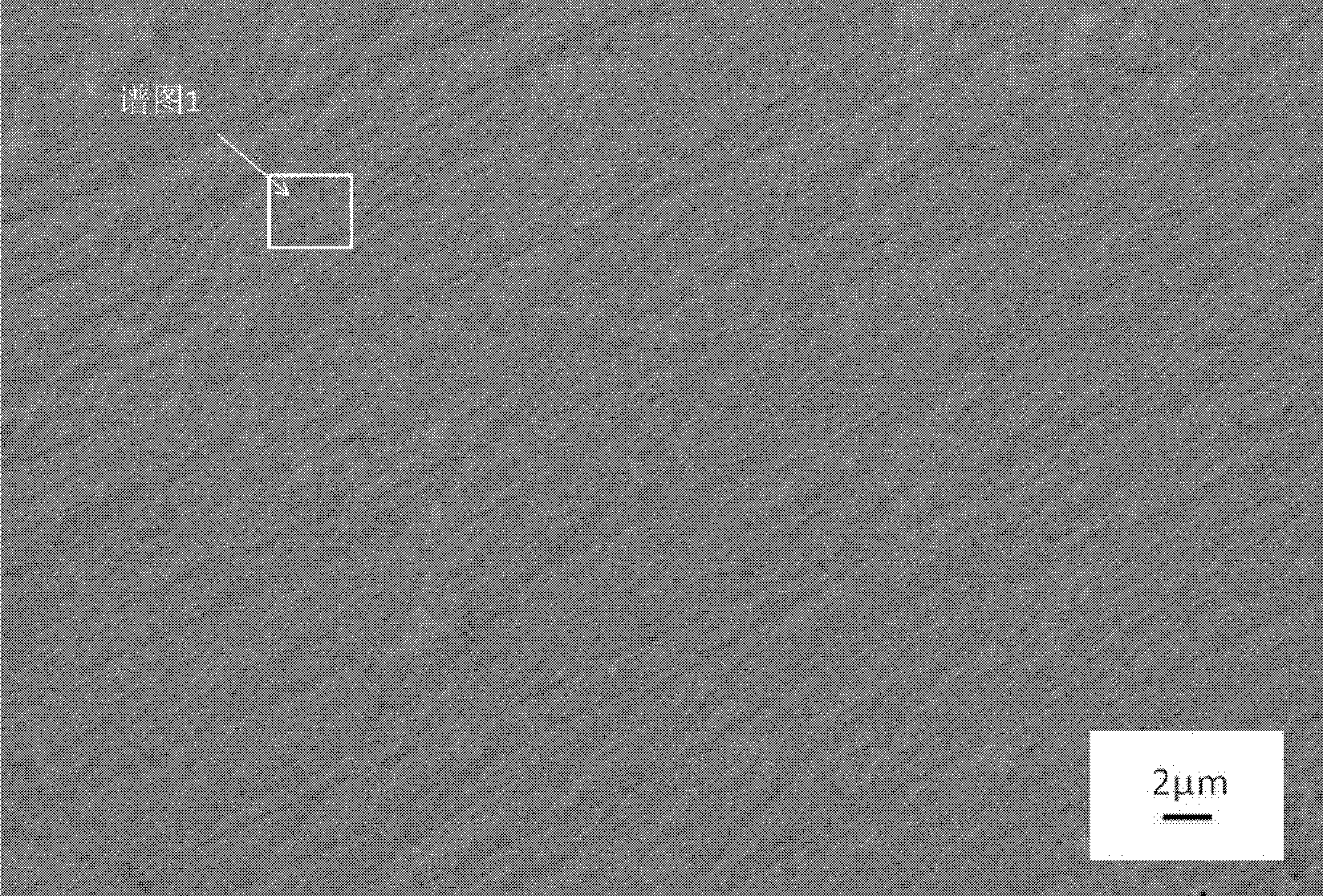

Ni-Cu-P ternary alloy coating serving as welding spot reaction barrier layer and electroplating preparation technology thereof

InactiveCN102560576BReduce energy consumptionHigh bath stabilitySoldering apparatusInterconnectionAlloy coating

The invention discloses a Ni-Cu-P ternary alloy coating serving as a welding spot reaction barrier layer and an electroplating preparation technology thereof. The Ni-Cu-P ternary alloy coating serving as the welding spot reaction barrier layer comprises the following components in percentage by weight: 70-90% of Ni, 3-10% of Cu and 7-20% of P. The thickness of the coating is 2-15mu m. The preparation method comprises the following steps of: putting an electroplated cathode piece (metallized Si chip or Cu piece) and an electroplated anode sheet (Pt piece) into electroplate liquid; introducing dipulse current for dipulse electroplating; and forming an Ni-Cu-P alloy coating on the surface of the cathode piece. The components of the Ni-Cu-P alloy coating prepared by using the electroplating preparation technology conform to the use requirement of a welding spot reaction barrier layer for electronic packaging and interconnection, the coating and the cathode piece substrate (metallized Si chip or Cu piece) are tightly combined, a plating layer is flat, and the Ni-Cu-P ternary alloy coating is fine in cellular tissue, even in thickness, and compact in structure and is basically free from holes.

Owner:HEFEI UNIV OF TECH

Continuously self-catalyzed deposition chemical plating solution of tin and using method thereof

InactiveCN101724834BEnables continuous autocatalytic depositionFast depositionLiquid/solution decomposition chemical coatingAntioxidantBenzaldehyde

The invention discloses continuously self-catalyzed deposition chemical plating solution of tin and a using method thereof. Half-bright and silvery-white tin-copper alloy deposition layers are obtained on pure copper and a copper alloy substrate. In the chemical plating solution, stannous chloride serves as a main salt, thiourea serves as a main complexing agent, trisodium citrate serves as an auxiliary complexing agent, sodium hypophosphite serves as a reducing agent, disodium ethylene diamine tetraacetate serves as an antioxidant, a hydrochloric acid serves as a stabilizing agent, gelatin serves as a leveling agent and benzaldehyde serves as an auxiliary brightening agent. The using method comprises the following operating conditions that: the pH value of the plating solution is 0.8 to 2.0; the temperature is 80 to 90 DEG C; the loading capacity is 0.8 to 1.5 dm2 / L; and the mechanical stirring speed is 50 to 100 rpm. The continuously self-catalyzed deposition chemical plating solution of the tin and the using method thereof have the advantages of capability of obtaining half-bright and silvery-while tin-copper alloy clad layers with different thicknesses by controlling chemical plating time, high deposition rate, remarkable grain refinement, improvement on surface evenness of the clad layer and batch production stability, secure interface combination, strong change resistance of the clad layer after being passivated, and broad application prospect in the products of deep hole elements, blind hole elements, difficult-to-handle miniature electronic components and parts, printed circuit boards PCBs and the like.

Owner:KUNMING UNIV OF SCI & TECH

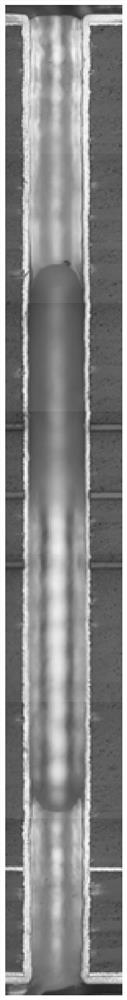

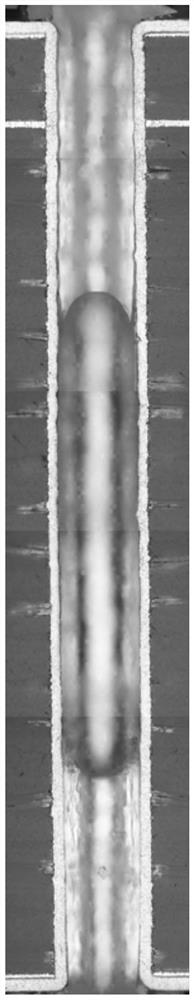

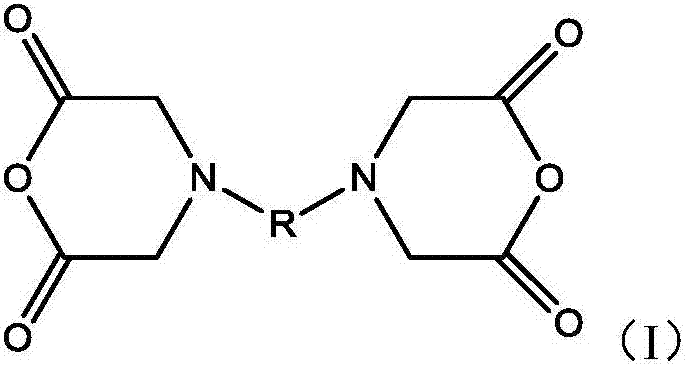

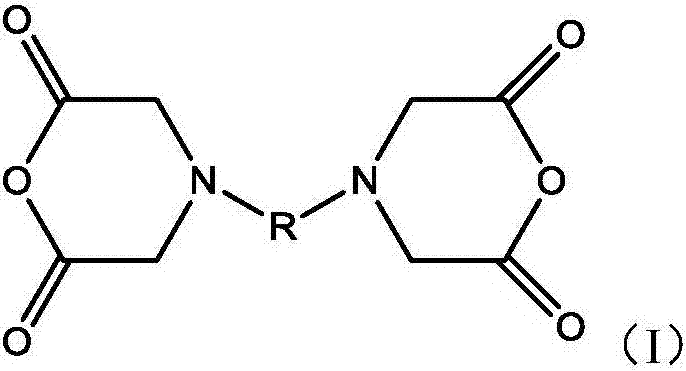

Reaction products of diamines with reaction products of monoamines and bisanhydrides as additives for electroplating baths

ActiveCN107454908AEfficient depositionStrong plating abilityOrganic chemistryCode division multiplexMetallurgyPhysical chemistry

Reaction products of diamines with the reaction products of monoamines and bisanhydrides are included as additives in metal electroplating baths. The metal electroplating baths have good throwing power and deposit metal layers having substantially planar surfaces. The metal plating baths may be used to deposit metal on substrates with surface features such as through-holes and vias.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC +1

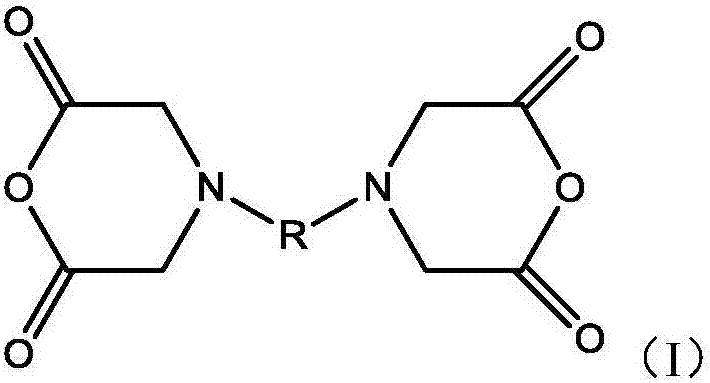

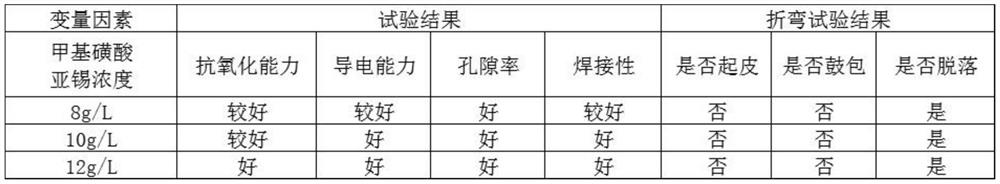

Tin plating solution for copper electronic material as well as preparation method and application method of tin plating solution

PendingCN114574840ATo preventEasy to degradeLiquid/solution decomposition chemical coatingPhosphorous acidMeth-

The invention discloses a copper electronic material tin plating solution, a preparation method and an application method, and the formula of an additive of the copper electronic material tin plating solution comprises the following components: main salt: stannous methanesulfonate with the concentration of 10-13g / L; a hydrolysis agent: 96 to 112 ml / L of methanesulfonic acid; the complexing agent is thiourea with the concentration of 75 g / L or 80 g / L; a tin whisker inhibitor: 0.8-1.2 g / L of silver methanesulfonate; the antioxidant is ethylenediamine tetraacetic acid with the concentration of 3-5g / L; the auxiliary brightening agent is benzaldehyde with the concentration of 0.2 g / L to 0.3 g / L; the reducing agent is at least one of hypophosphorous acid and sodium hypophosphite, and the concentration of the reducing agent is 50-82ml / L; gelatin is also added into the plating solution, and the concentration of the gelatin is 0.2-1.0 g / L; the complex solubilizer is polyalcohol with the concentration of 50 to 500g / L; and the crystal refiner is a polyoxyalkylene ether or amino acid type solution with the concentration of 0.1-10g / L.

Owner:深圳市虹喜科技发展有限公司

A kind of electroplating engineering plastic with high binding force

The invention discloses a high-binding-force electroplating engineering plastic which comprises a polycarbonate resin, a polystyrene resin, erucyl amide, an MPI resin, a polyolefin elastomer, calcium stearate, a coupling agent, 8 parts of conductive filler, a compatilizer and aids. The electroplating engineering plastic disclosed by the invention has higher hydrophilicity and higher binding force for the coating. The product prepared from the engineering plastic has the advantages of favorable electric properties, favorable mechanical properties, favorable high-temperature resistance and the like, and thus, has excellent comprehensive properties.

Owner:SUZHOU JIN TENG ELECTRONICS TECH

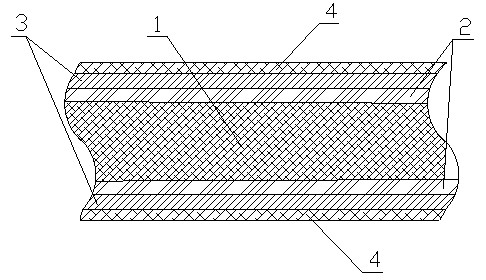

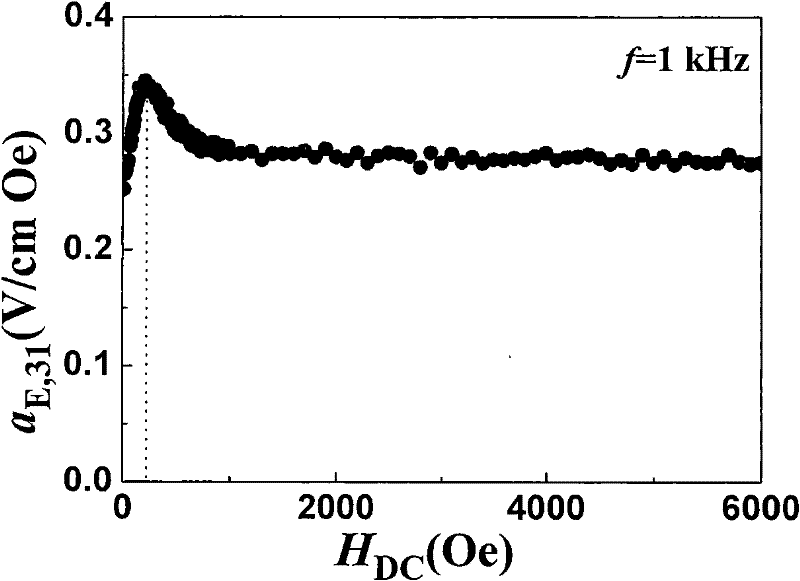

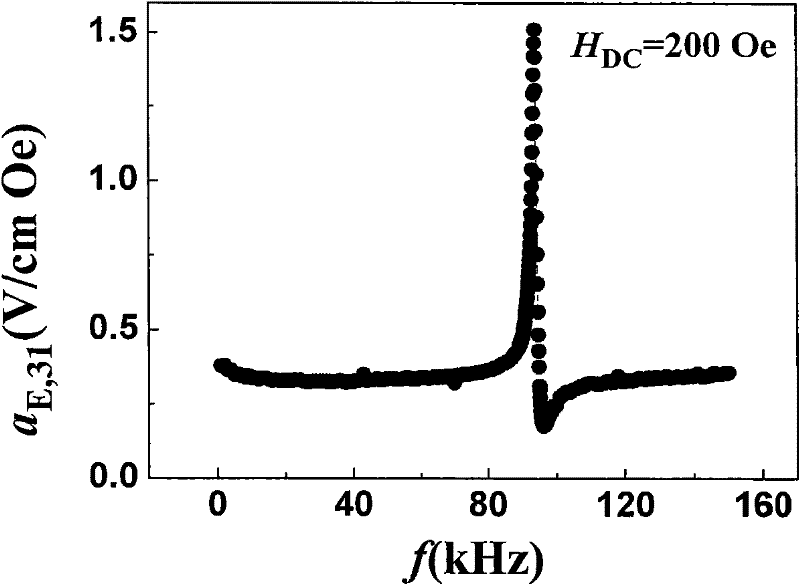

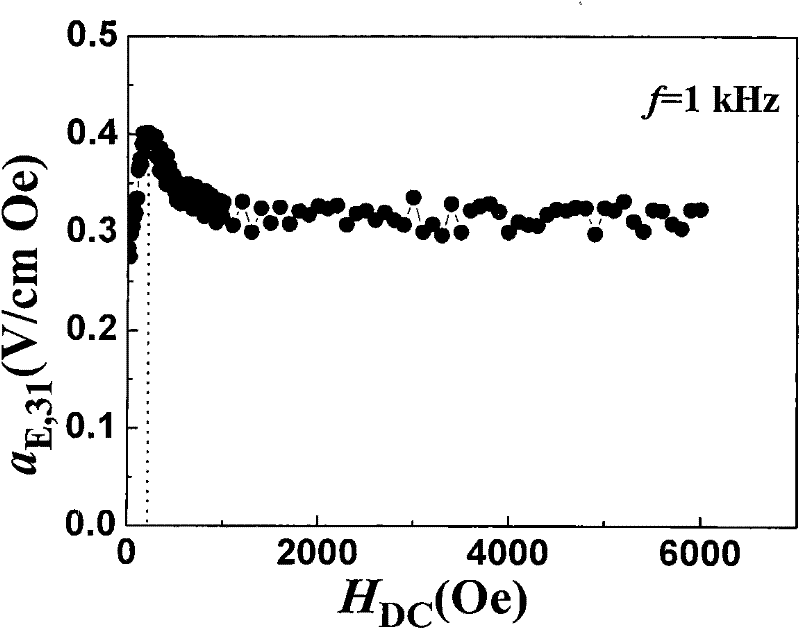

Electroless plating method for preparing magnetoelectric composite material

ActiveCN101709458BImprove the coupling effectEliminate loss of elasticityLiquid/solution decomposition chemical coatingBonding processElectric coupling

The invention discloses an electroless plating method for preparing magnetoelectric composite materials, which belongs to the technical field of magnetoelectric composite materials. In this method, piezoelectric ceramics with piezoelectric effect are sliced, cut into required sizes, and subjected to chemical plating pretreatments such as grinding, degreasing, chemical roughening, sensitization, activation, and reduction; then the pretreated piezoelectric The ceramic sheet is placed in the prepared chemical plating solution for chemical plating, and after the chemical plating is reached to the required thickness, the polarization is taken out to obtain a magnetoelectric composite material. Compared with the existing preparation methods of magnetoelectric composite materials, the electroless plating method not only eliminates the elastic loss caused by the bonding layer produced in the bonding process and the electrode layer required in the electroplating process, but also eliminates the elastic loss caused by the thermocompression curing process. The adverse effects of interfacial mixing can enhance the elastic bonding force between the ferroelectric phase and the ferromagnetic phase, improve the magnetoelectric coupling performance of the composite material, and simplify the production process.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com