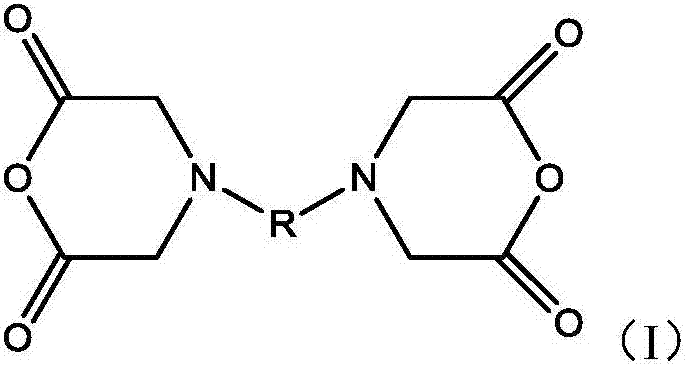

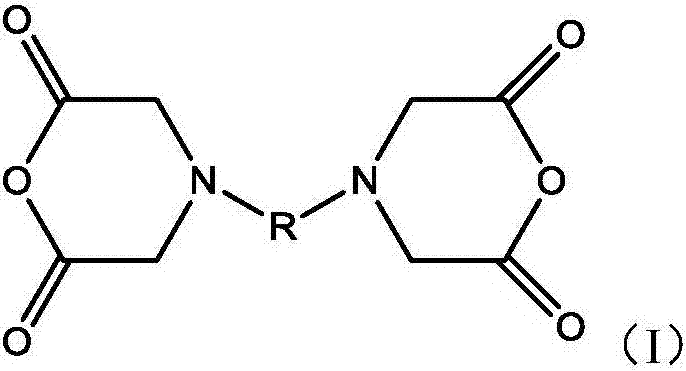

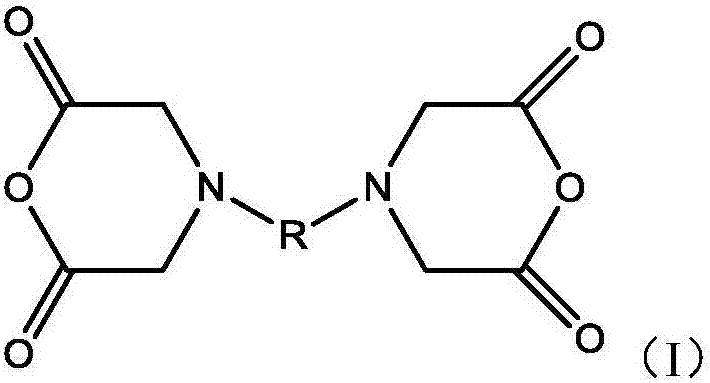

Reaction products of diamines with reaction products of monoamines and bisanhydrides as additives for electroplating baths

一种反应产物、二胺的技术,应用在电气元件、无线电传输系统、基于链路质量的传输修改等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0102] In Step 1, ethylenediaminetetraacetic acid (EDTA) bisanhydride (10 mmol) was dissolved in 30 mL of dimethylformamide (DMF), and 20 mmol of 1H-imidazole-1-propanamine (structure A) was dissolved in 30 mL of DMF. The EDTA bisanhydride solution was added dropwise to the 1H-imidazole-1-propanamine solution for 12 hours at room temperature. The reaction product was precipitated by adding 60 mL of absolute ethanol, then washed with acetone and dried under vacuum. The reaction product includes the inner salt as shown by structure (B).

[0103] In Step 2, 10 mmol of the reaction product of Step 1 and 10 mmol of hexamethylenediamine (C) were mixed at room temperature. The mixture was then heated at 145° C. for 6 hours under a nitrogen atmosphere. The final product (D) was used without further purification.

[0104]

[0105] Three aqueous acid copper electroplating baths were prepared with the basic formulations disclosed in Table 1 below.

[0106] Table 1

[0107]

...

example 3

[0116] In Step 1, EDTA bisanhydride (10 mmol) was dissolved in 30 mL of dimethylformamide (DMF), and 20 mmol of benzimidazole-2-propanamine compound of structure A' was dissolved in 30 mL of DMF. The EDTA bisanhydride solution was added dropwise to the benzimidazole-2-propanamine solution for 12 hours at room temperature. The reaction product was precipitated by adding 60 mL of absolute ethanol, then washed with acetone and dried under vacuum. The reaction product includes an inner salt as shown by structure (B').

[0117] In Step 2, 10 mmol of the reaction product of Step 1 and 10 mmol of hexamethylenediamine (C) were mixed at room temperature. The mixture was then heated at 145° C. for 6 hours under a nitrogen atmosphere. The final product (D') was used without further purification.

[0118]

[0119]

[0120] The desired reaction product, compound D' described above, provides a copper electroplating bath with good throwing power.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com