Silver Electrode Paste

A silver electrode and electrode technology, applied to conductive materials dispersed in non-conductive inorganic materials, transformer/inductor coils/windings/connections, etc., can solve problems such as unstable quality, general adhesion, and high price, and achieve Wide range of silver content, strong plateability and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

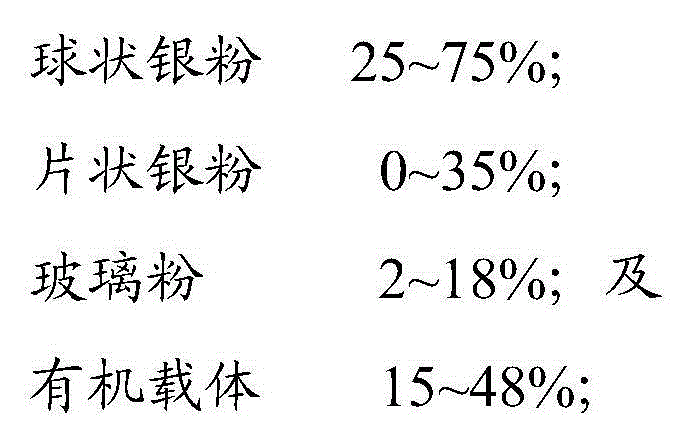

[0039] A kind of silver electrode paste, by mass percentage, comprises following component:

[0040] 75% spherical silver powder, 0% flake silver powder, 10% glass powder and 15% organic vehicle.

[0041] Among them, the particle diameter of the spherical silver powder is 4.0 microns.

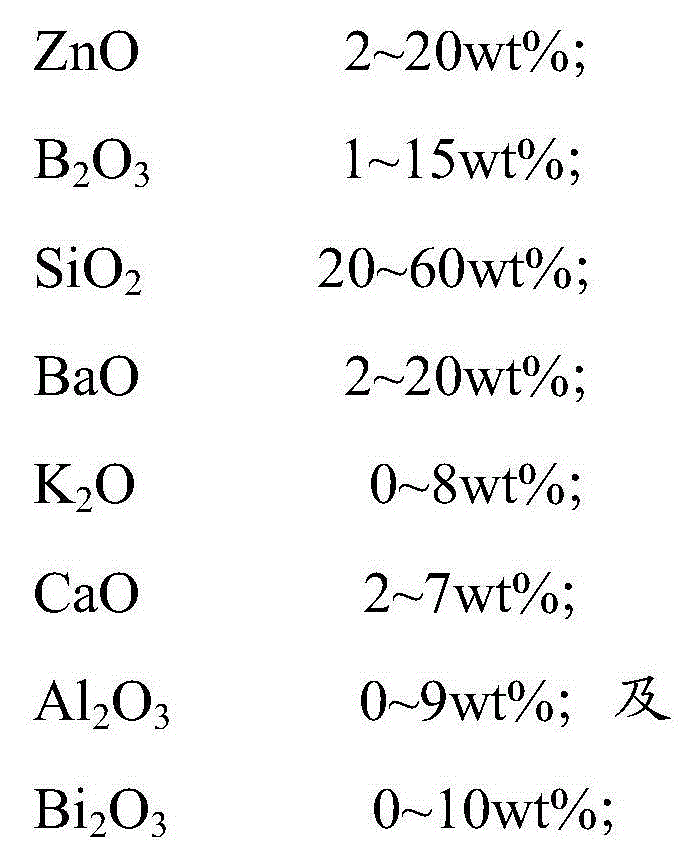

[0042] Glass powder includes the following components by mass percentage:

[0043] ZnO13.56wt%, B 2 o 3 12.01wt%, SiO 2 59.31wt%, BaO2.36wt%, K 2 O0.00wt%, CaO6.09wt%, Al 2 o 3 0.00wt% and Bi 2 o 3 6.67wt%.

[0044] The organic carrier includes terpineol and ethyl cellulose dissolved in terpineol, and the mass ratio of terpineol to ethyl cellulose is 86.7:13.3.

Embodiment 2

[0046] A kind of silver electrode paste, by mass percentage, comprises following component:

[0047] Spherical silver powder 70%, flake silver powder 0%, glass powder 3.5%, organic carrier 26.5%.

[0048] Wherein, the particle diameter of the spherical silver powder is 2.5 microns.

[0049] Glass powder includes the following components by mass percentage:

[0050] ZnO2.36wt%, B 2 o 3 14.42wt%, SiO 2 58.03wt%, BaO15.65wt%, K 2 O1.65wt%, CaO2.66wt%, Al 2 o 3 5.23wt% and Bi 2 o 30.00wt%.

[0051] The organic vehicle includes a mixed solvent of terpineol and ethyl acetate and ethyl cellulose and hydrogenated rosin resin dissolved in a mixed solvent of terpineol and ethyl acetate, terpineol, ethyl acetate, ethyl cellulose and hydrogenated rosin resin The mass, ratio is 30:53:9:8.

Embodiment 3

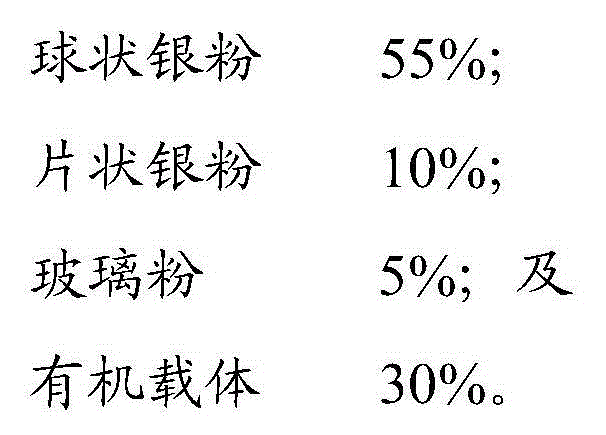

[0053] A kind of silver electrode paste, by mass percentage, comprises following component:

[0054] Spherical silver powder 65%, flake silver powder 2%, glass powder 7.8%, organic carrier 25.2%.

[0055] Wherein, the particle size of the spherical silver powder is 1.0 micron, and the particle size of the flake silver powder is 10.0 micron.

[0056] Glass powder includes the following components by mass percentage:

[0057] ZnO9.22wt%, B 2 o 3 2.73wt%, SiO 2 51.45wt%, BaO16.43wt%, K 2 O6.82wt%, CaO5.42wt%, Al 2 o 3 0.87wt% and Bi 2 o 3 7.26wt%.

[0058] The organic carrier includes a mixed solvent of terpineol and ethyl acetate and polyurethane resin dissolved in the mixed solvent of terpineol and ethyl acetate, and the mass ratio of terpineol, ethyl acetate and polyurethane resin is 40:40:20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com