Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Regulation uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

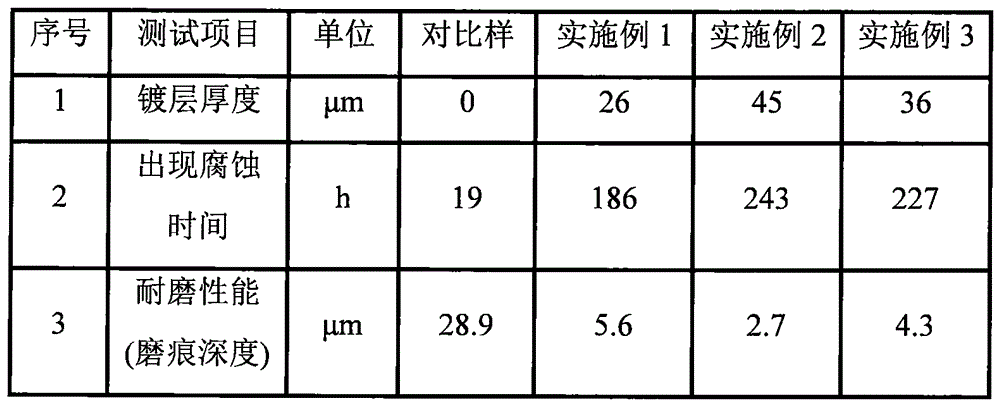

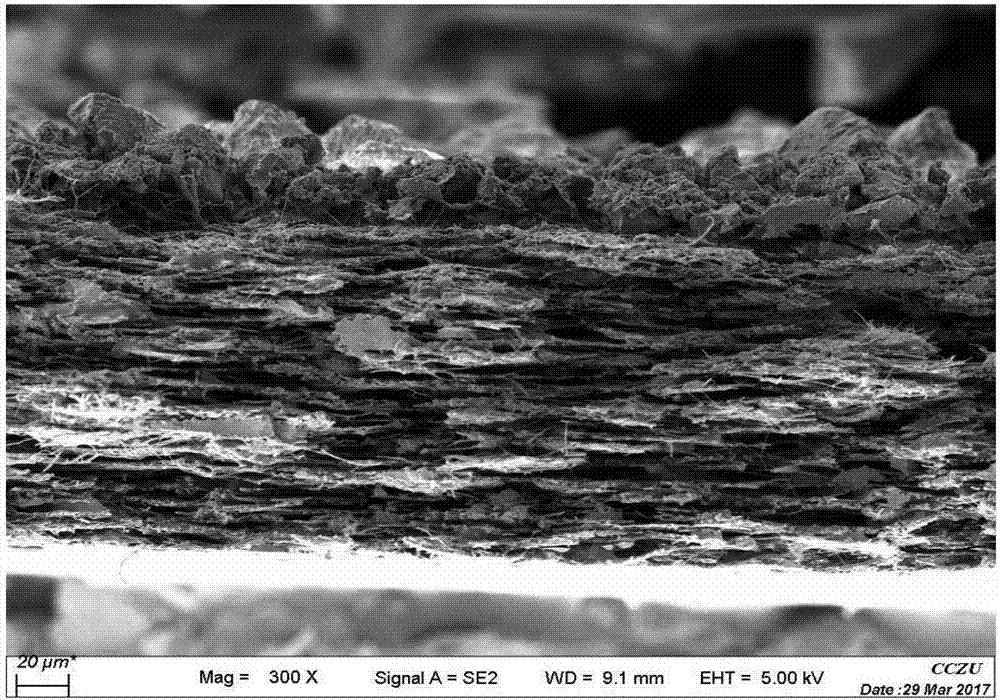

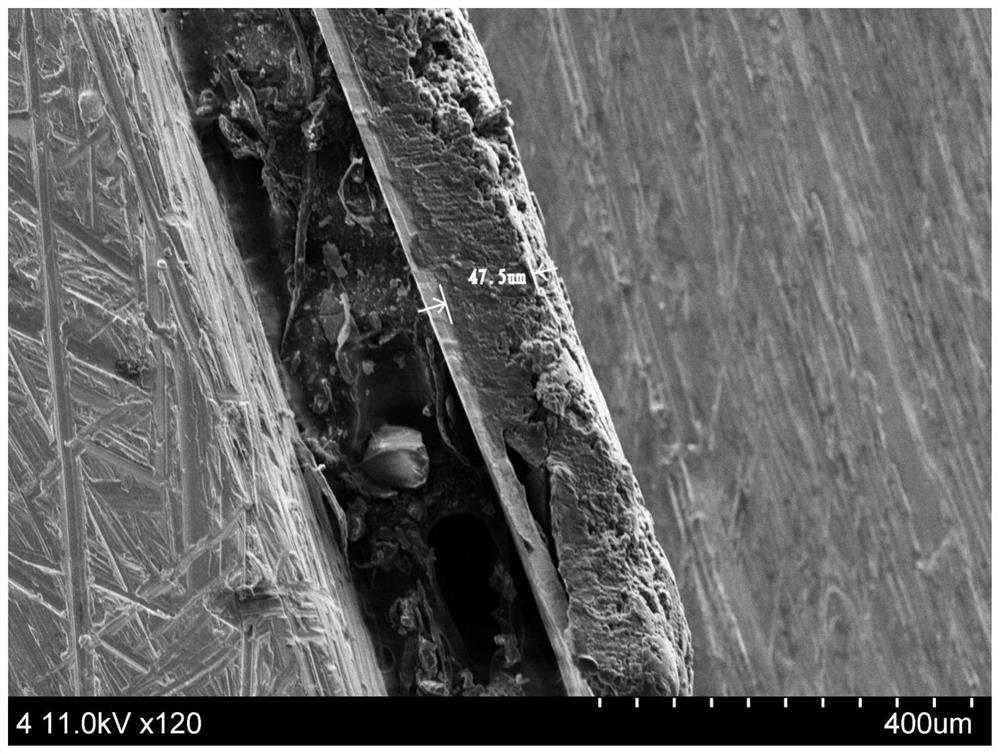

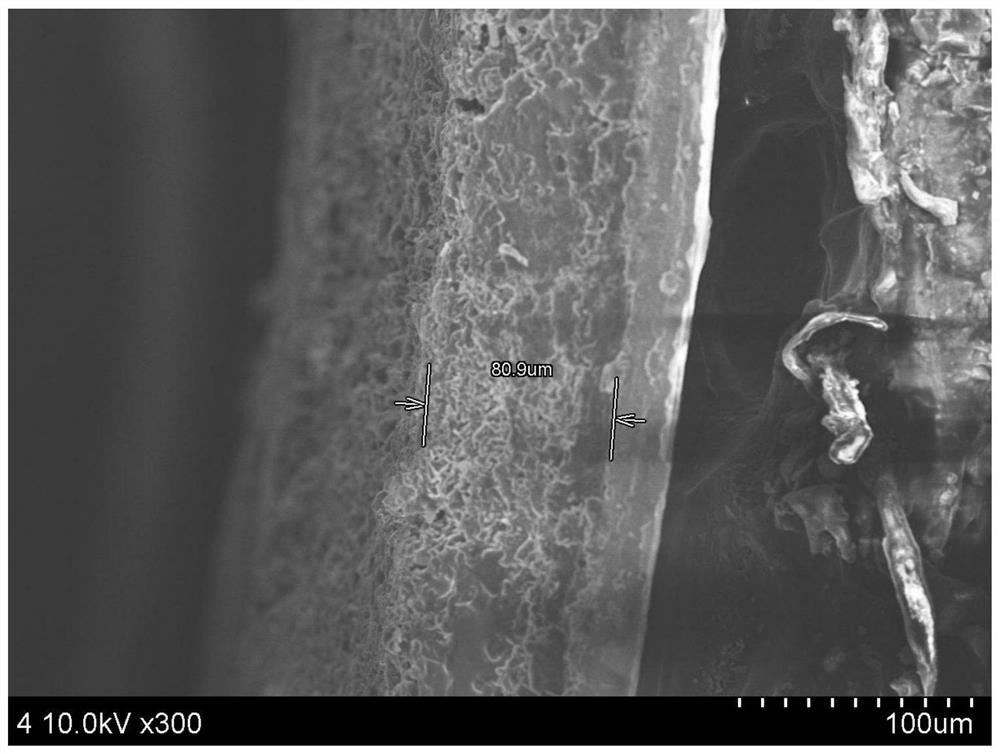

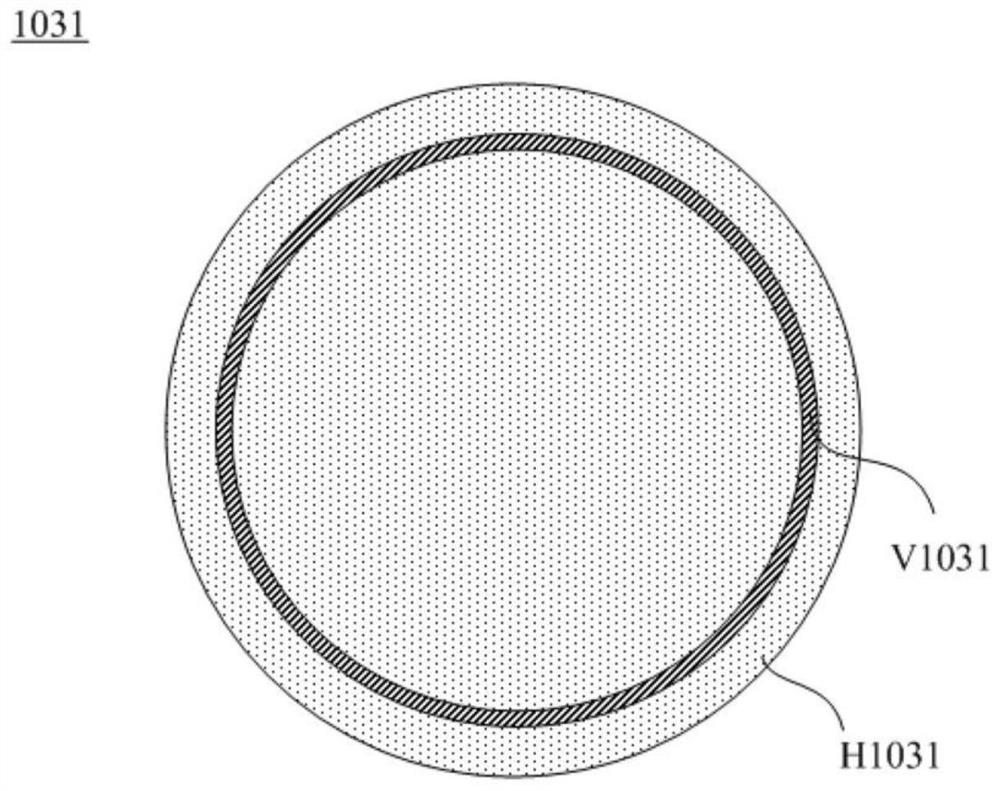

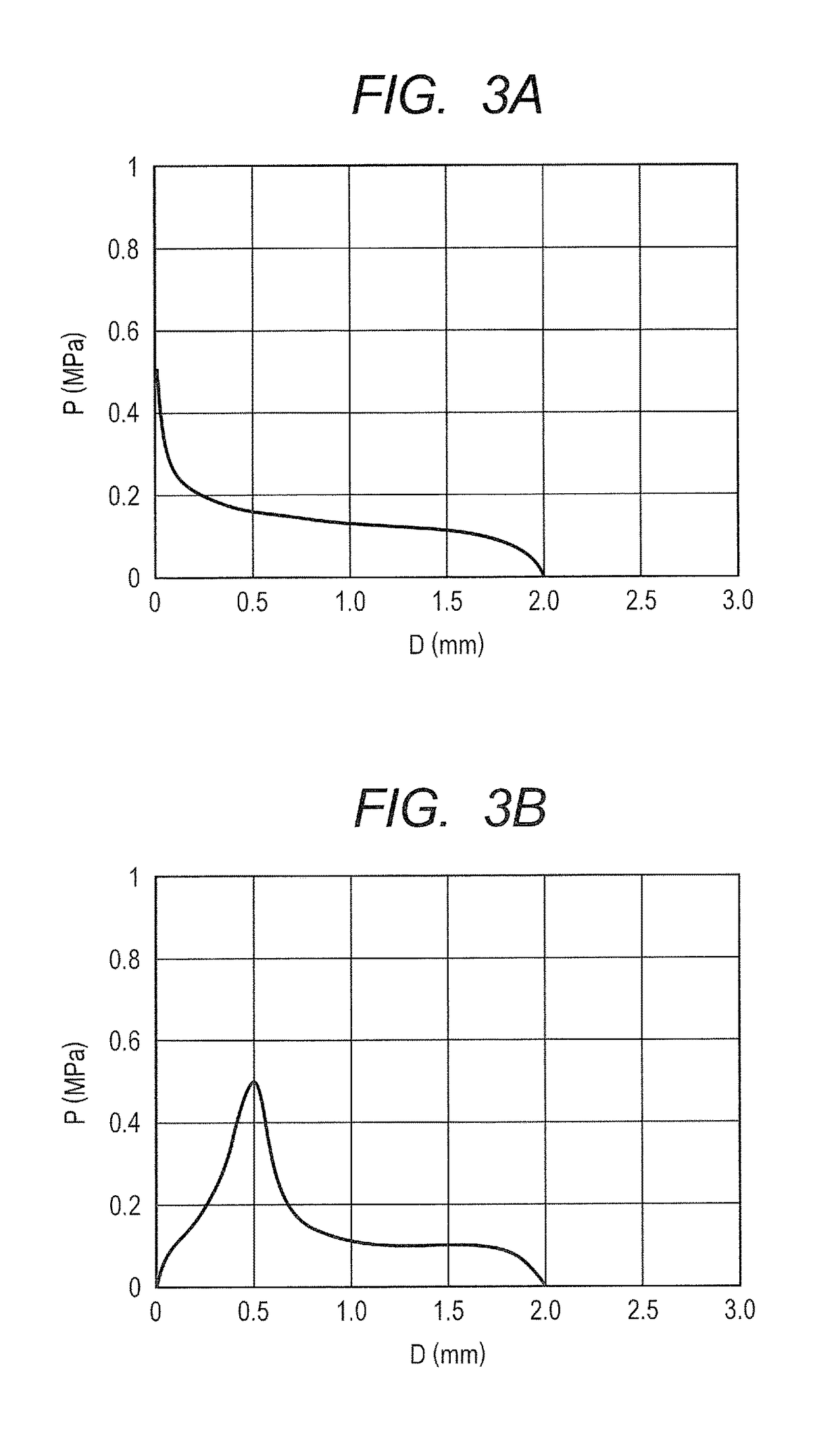

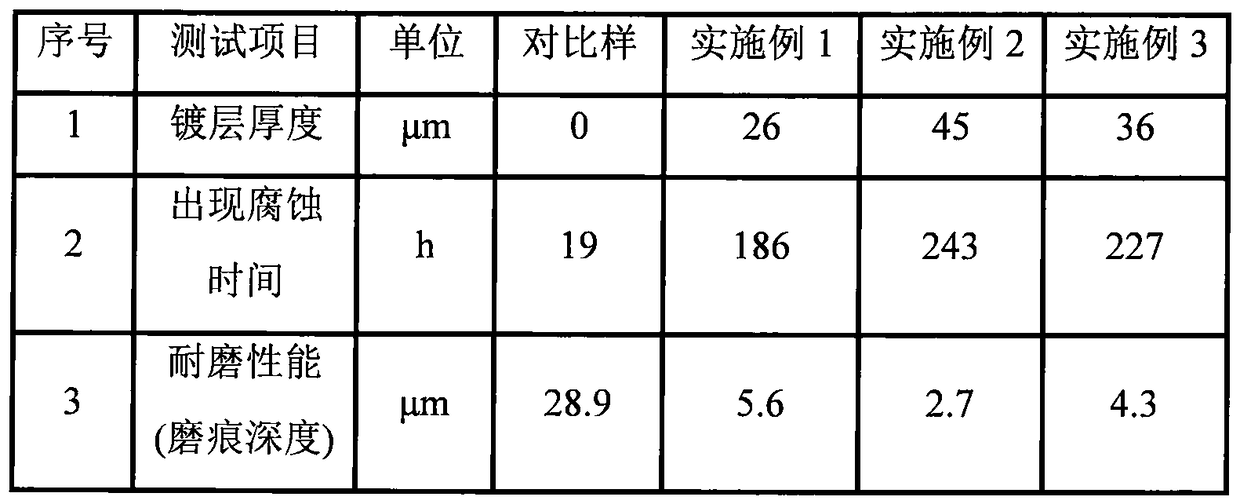

Corrosion-resistant multi-coating neodymium iron boron and preparation process

ActiveCN106710767AAccelerated corrosionImprove wear resistanceMagnetic materialsSuperimposed coating processSingle processDysprosium

The invention provides corrosion-resistant multi-coating neodymium iron boron and a preparation process. The corrosion-resistant multi-coating neodymium iron boron is composed of a neodymium iron boron permanent magnet and multiple coatings arranged on the outer surface of the neodymium iron boron permanent magnet, the multiple coatings sequentially include a nickel-plated layer, a dysprosium-plated aluminum alloy thin film layer and a nickel-chromium composite coating, thickness of the nickel-plated layer is 10-15um, thickness of the dysprosium-plated aluminum alloy thin film layer is 10-20um, and thickness of the nickel-chromium composite coating is 6-10um; modification of the multiple coatings can be realized on the surface of the permanent magnet, binding strength between the coatings and a permanent magnet base is guaranteed, the defect that the coatings are thin and poor in corrosion resistance and wear resistance caused by single process is overcome, and the corrosion-resistant multi-coating neodymium iron boron prepared by the process has high corrosion resistance and wear resistance.

Owner:宁波元辰新材料有限公司

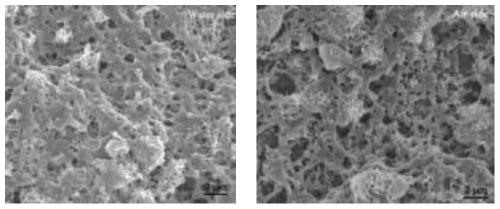

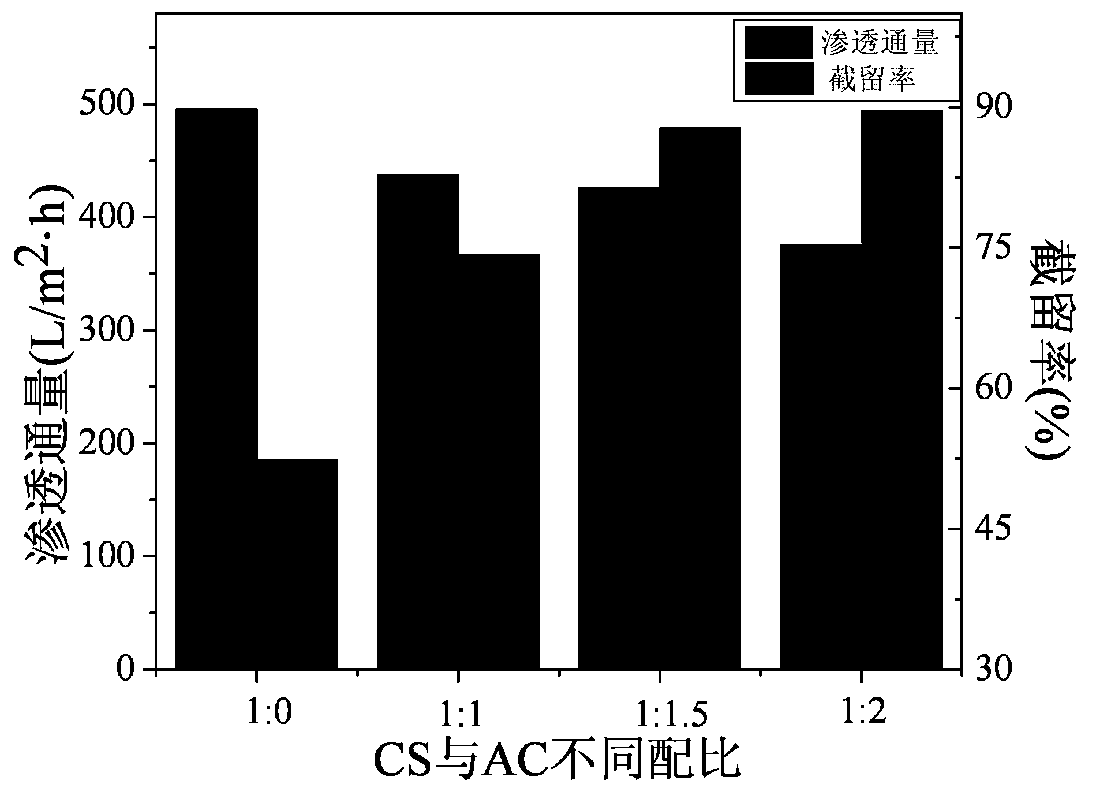

New method for preparing nanometer-structure composite ultra-filtration membrane

ActiveCN107081078AReduce usageEmission reductionUltrafiltrationWater/sewage treatment bu osmosis/dialysisFiberFiltration membrane

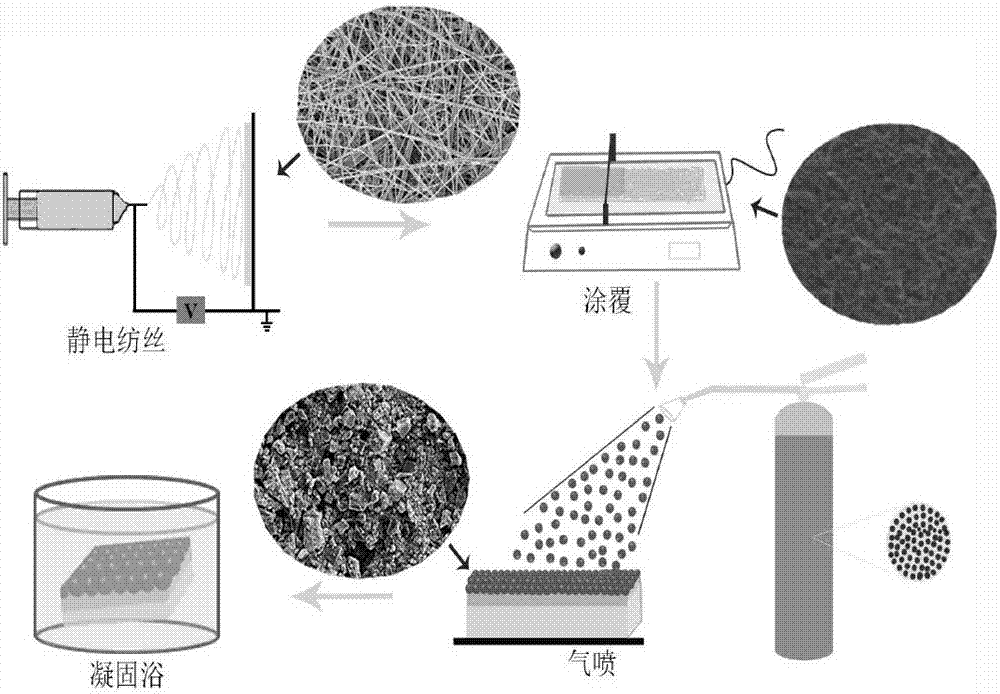

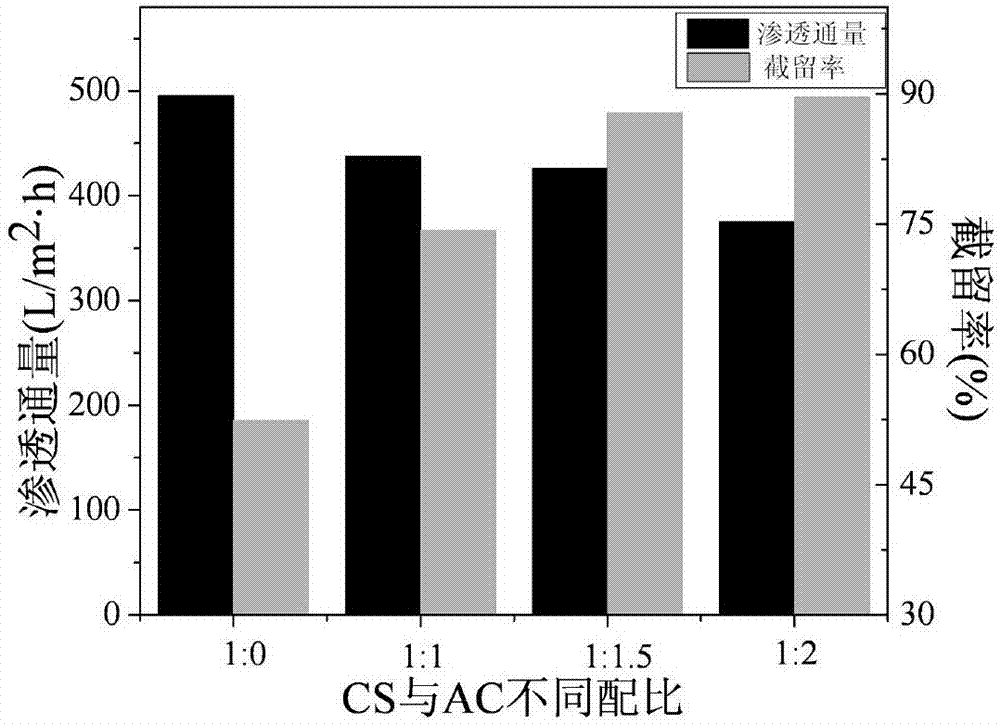

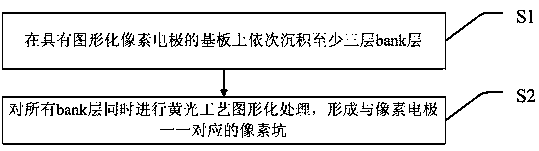

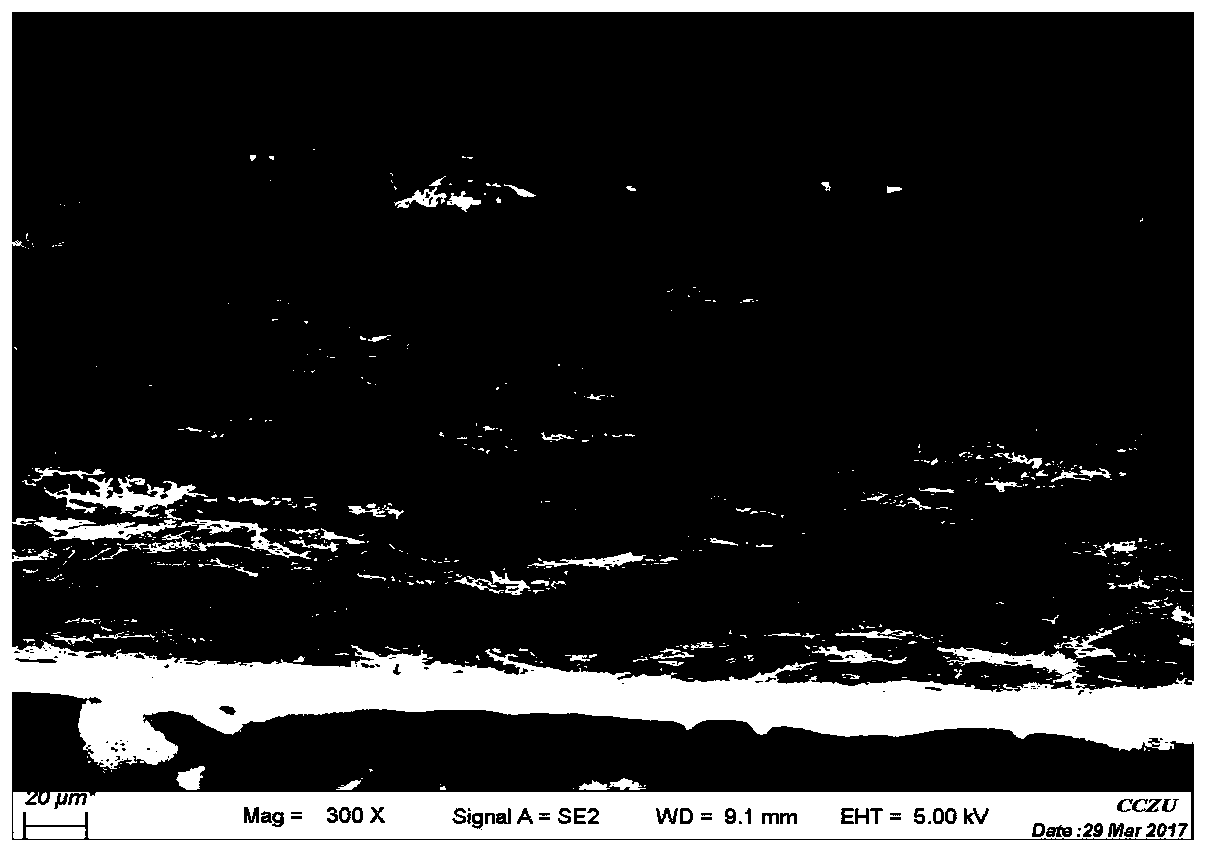

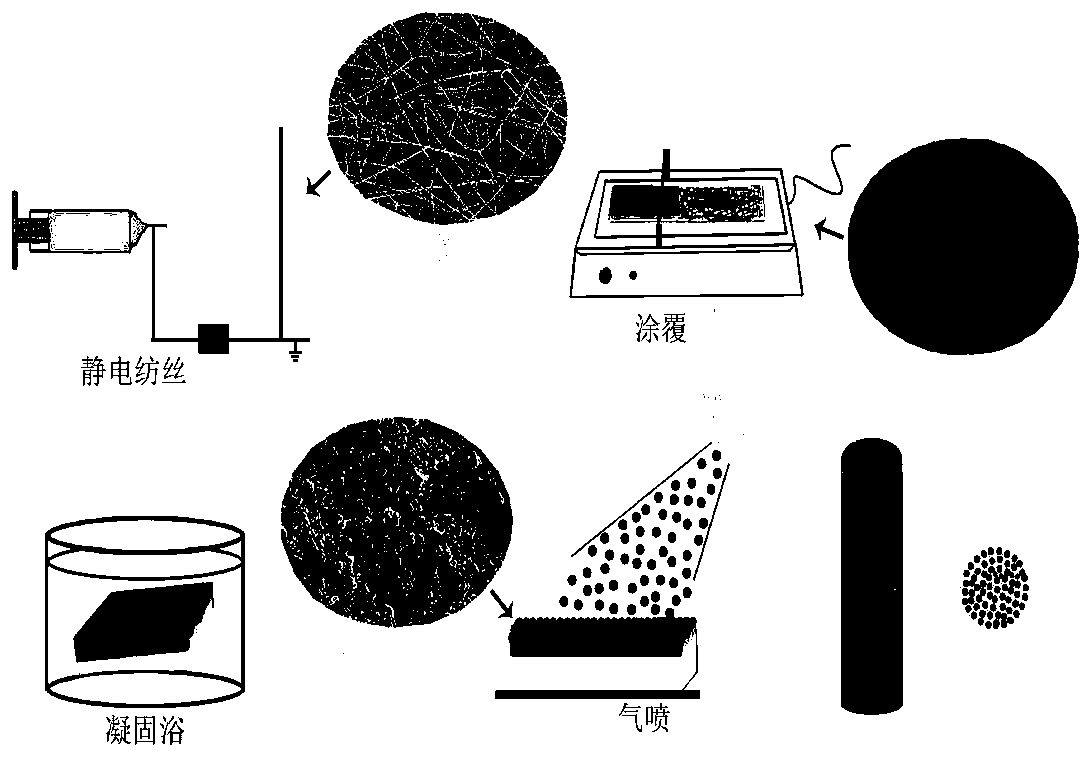

The invention discloses a new method for preparing a nanometer-structure composite ultra-filtration membrane. According to the new method, in the prior art, the defect that the interception adsorption performance of an electro-spinning fiber membrane is low is overcome. The new method in the technical scheme includes the following steps that (1) polymer materials are dissolved in a solvent to be prepared into an electrostatic spinning solution for preparing a fiber membrane, and the fiber membrane serves as a base layer of the composite membrane; (2) a hydrophilic polymer is dissolved in the solvent, then a plasticizer and a pore-forming agent are added into the mixture, the mixture is heated, dissolved, subjected to standing and defoamed, a coating solution is formed, and the base layer is coated with the coating solution; (3) when the coating solution is gelatinous, porous functional materials are evenly sprayed and pressed to the surface of the base layer with the air-spraying-pressing method. The nanometer-structure composite membrane is prepared with the soaking-pore-opening method, and using of a traditional chemical cross-linking agent is avoided; the new method is simple in preparing process, and has the high adsorption capacity for organic pollutants, heavy metal ions and the like.

Owner:CHANGZHOU UNIV

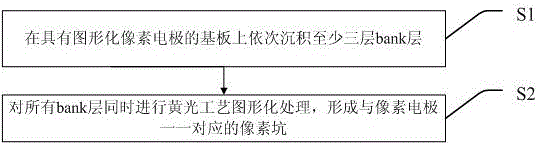

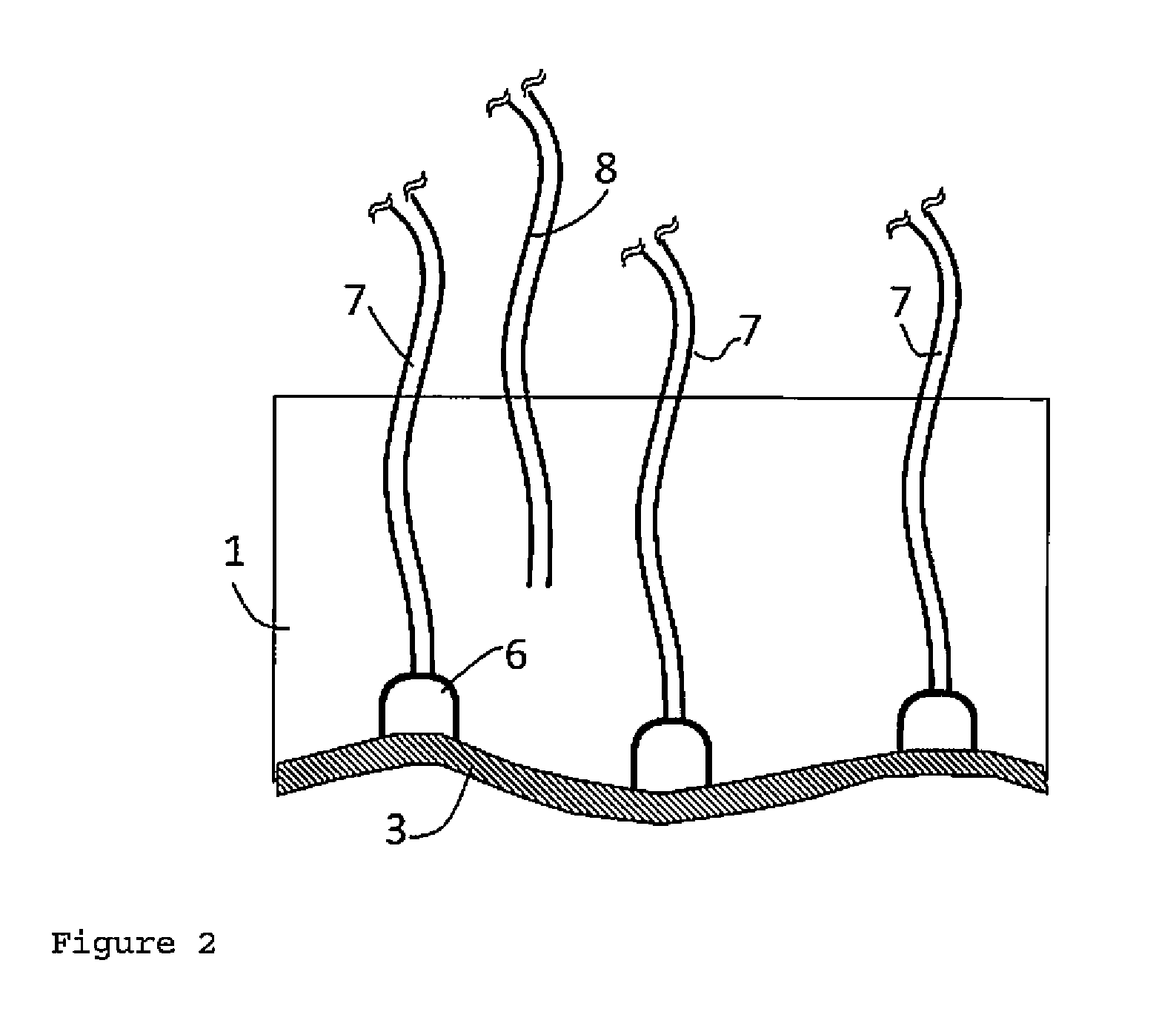

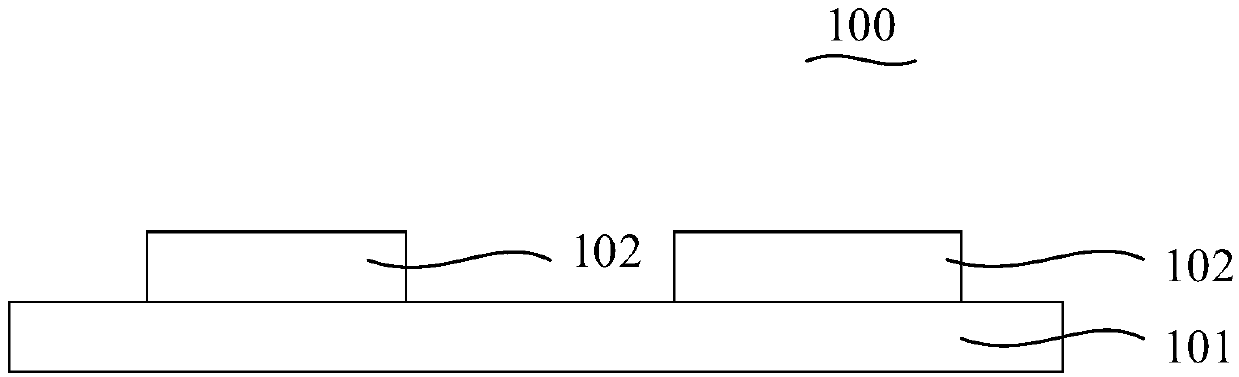

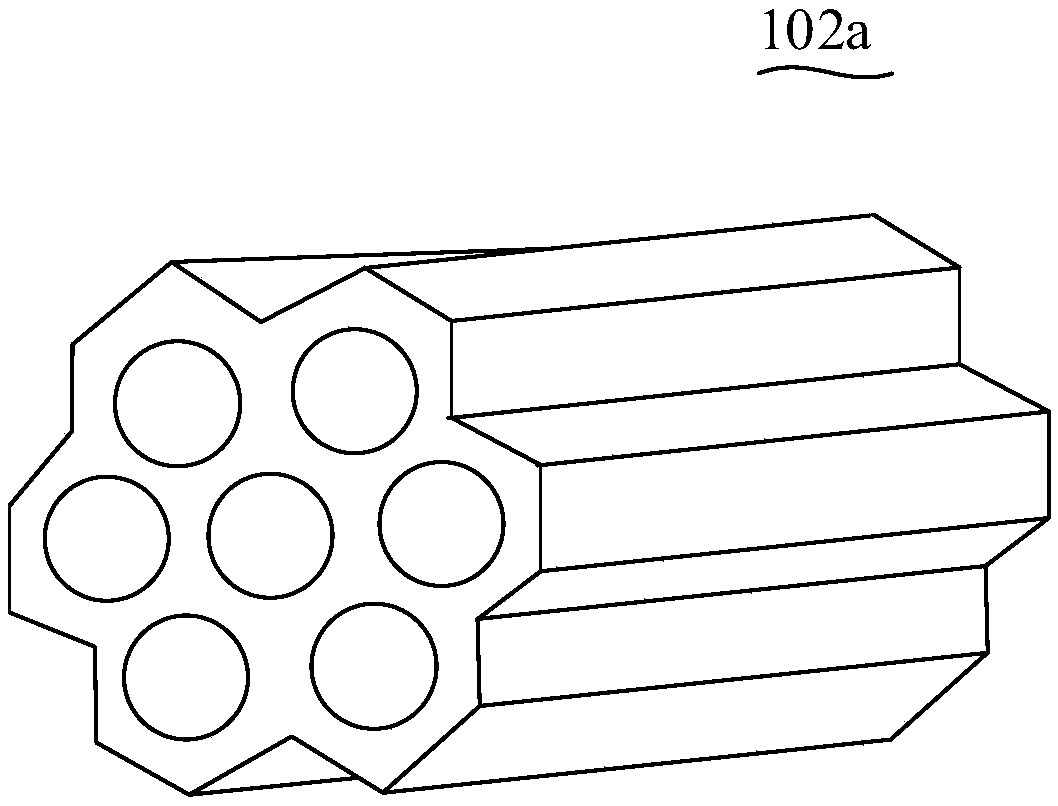

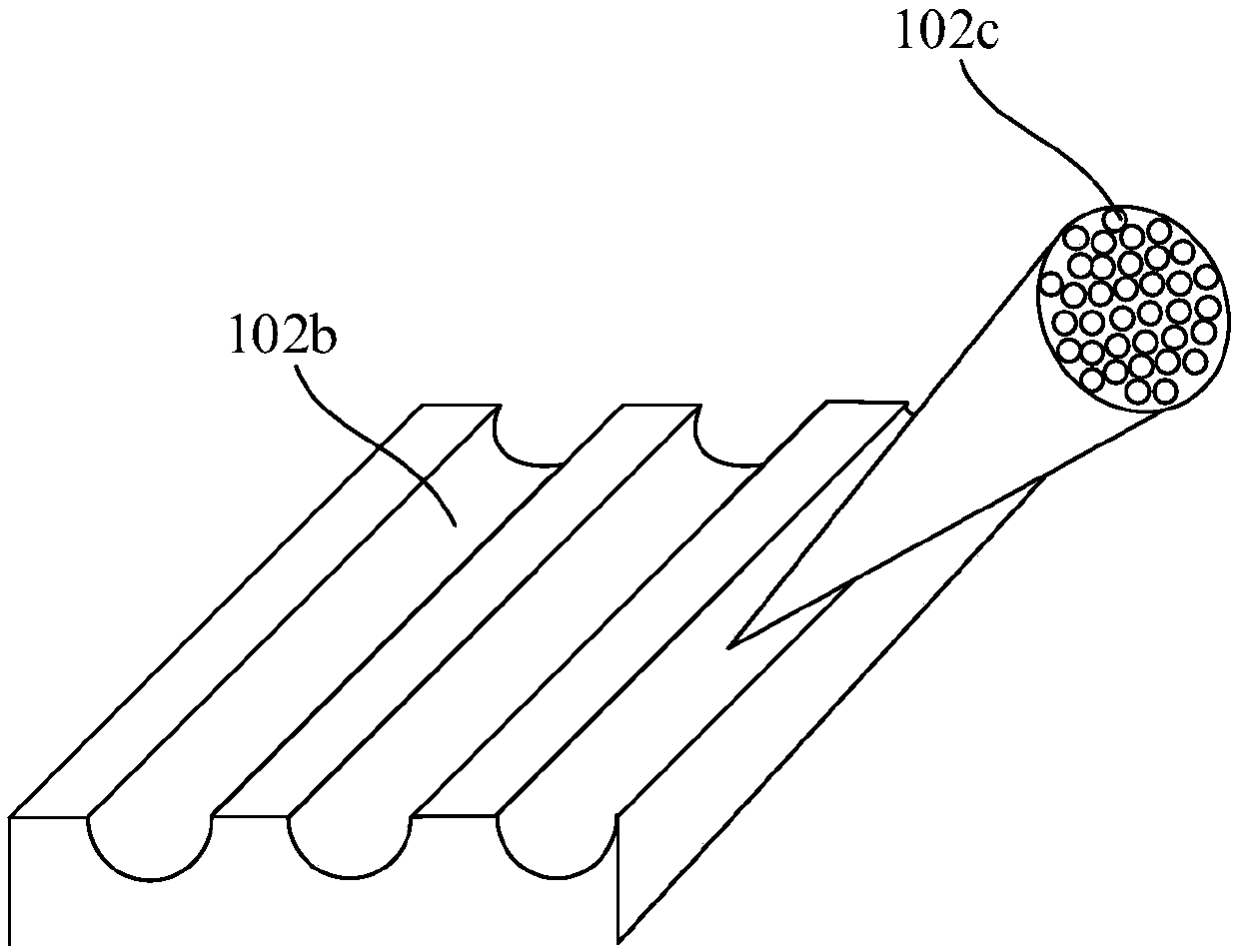

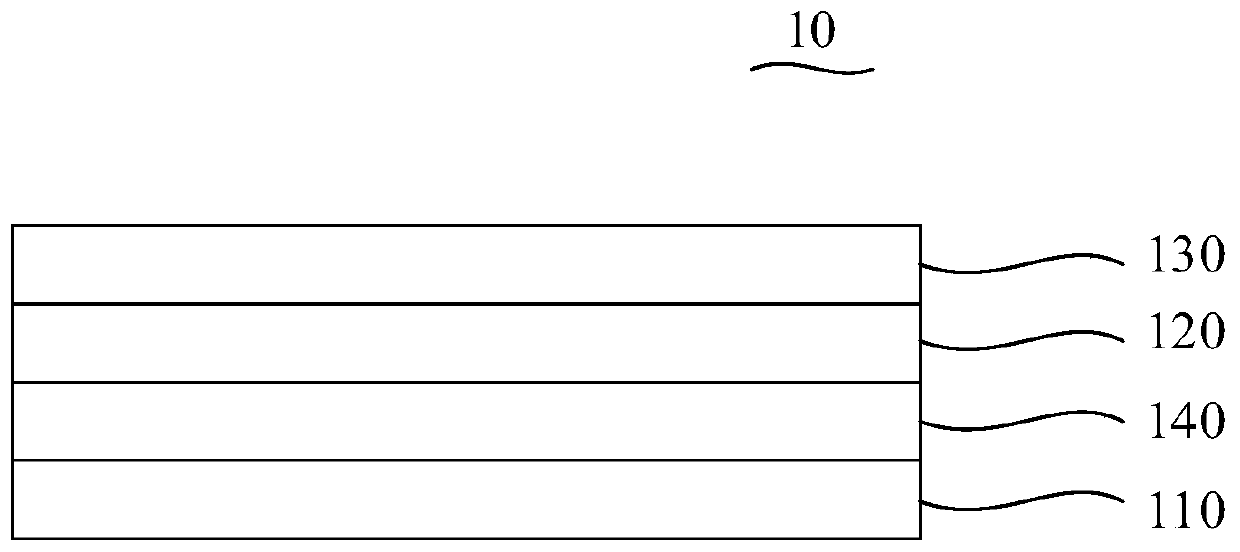

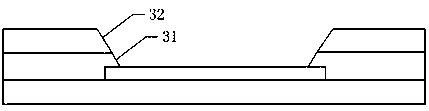

Printed pixel bank structure and preparation method thereof

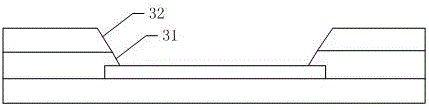

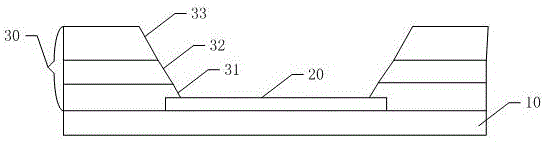

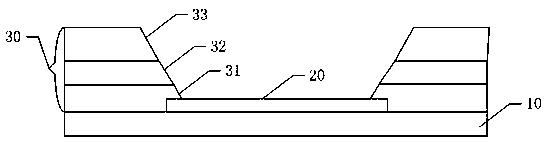

ActiveCN106601774ARegulation uniformityPrevent overflowDuplicating/marking methodsSolid-state devicesPinning pointsEngineering

The invention discloses a printed pixel bank structure and a preparation method thereof. The pixel bank structure comprises a substrate, a pixel electrode and a pixel bank, wherein the substrate, the pixel electrode and the pixel bank are successively arranged from bottom to top. The pixel bank is obtained through stacking at least three bank layers. The lyophobicity of at least three bank layers gradually increases from bottom to top, and lyophily gradually reduces from bottom to top. According to the printed pixel bank structure, the pixel bank is formed through stacking at least three bank layers with different lyophily and different lyophobicity. Through designing the multiple bank layers, a plurality of boundaries with different lyophily and different lyophobicity can be formed, thereby forming pinning points at different positions for different kinds of ink, and effectively controlling uniformity of different printing film layers.

Owner:武汉国创科光电装备有限公司

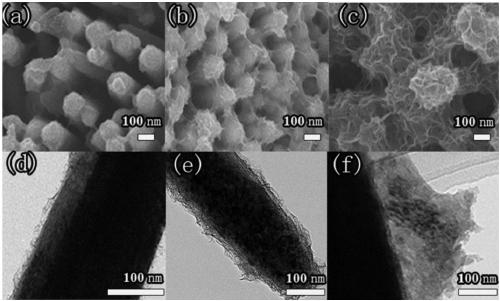

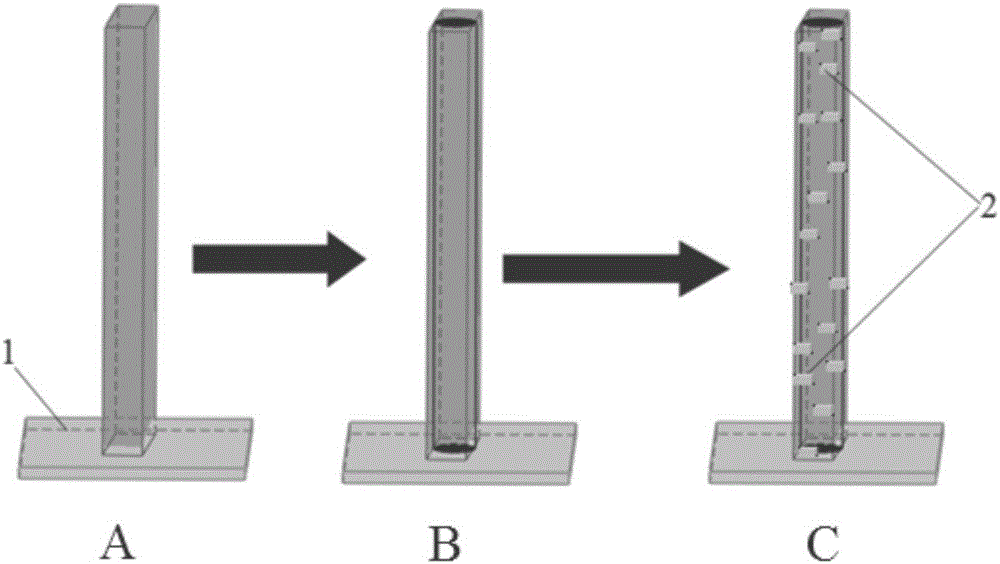

Titanium dioxide-metal organic framework array with uniformly and continuously coated nuclear-sheath structure, and preparation method and application of titanium dioxide-metal organic framework array

ActiveCN109851802AUniform nucleosheath structureRegulation uniformityOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationNanowireMetal-organic framework

The invention discloses a titanium dioxide-metal organic framework array with a uniformly and continuously coated nuclear-sheath structure, and a preparation method and application of the titanium dioxide-metal organic framework array. The titanium dioxide-metal organic framework array is provided with the uniformly and continuously coated core-sheath structure, wherein titanium dioxide is used asa core, and a metal organic framework is used as a sheath layer; the titanium dioxide is titanium dioxide nanowires, and the metal organic framework is a Ti-based bdc-(NH2)x, wherein the x is 0, 1 or2. The number of amino groups in the titanium dioxide-metal organic framework array can be regulated and controlled, and the thickness and uniformity of the metal organic framework which is used as the sheath layer can also be regulated and controlled. Performance of the array structure can be changed through the regulation and control of the thickness and uniformity of the metal organic framework which is used as the sheath layer, and through the regulation and control of the number of amino groups contained in ligands in the metal organic framework which is used as the sheath layer, the change of performance of the metal organic framework can be influenced by regulating the visible light absorption capacity of the metal organic framework.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

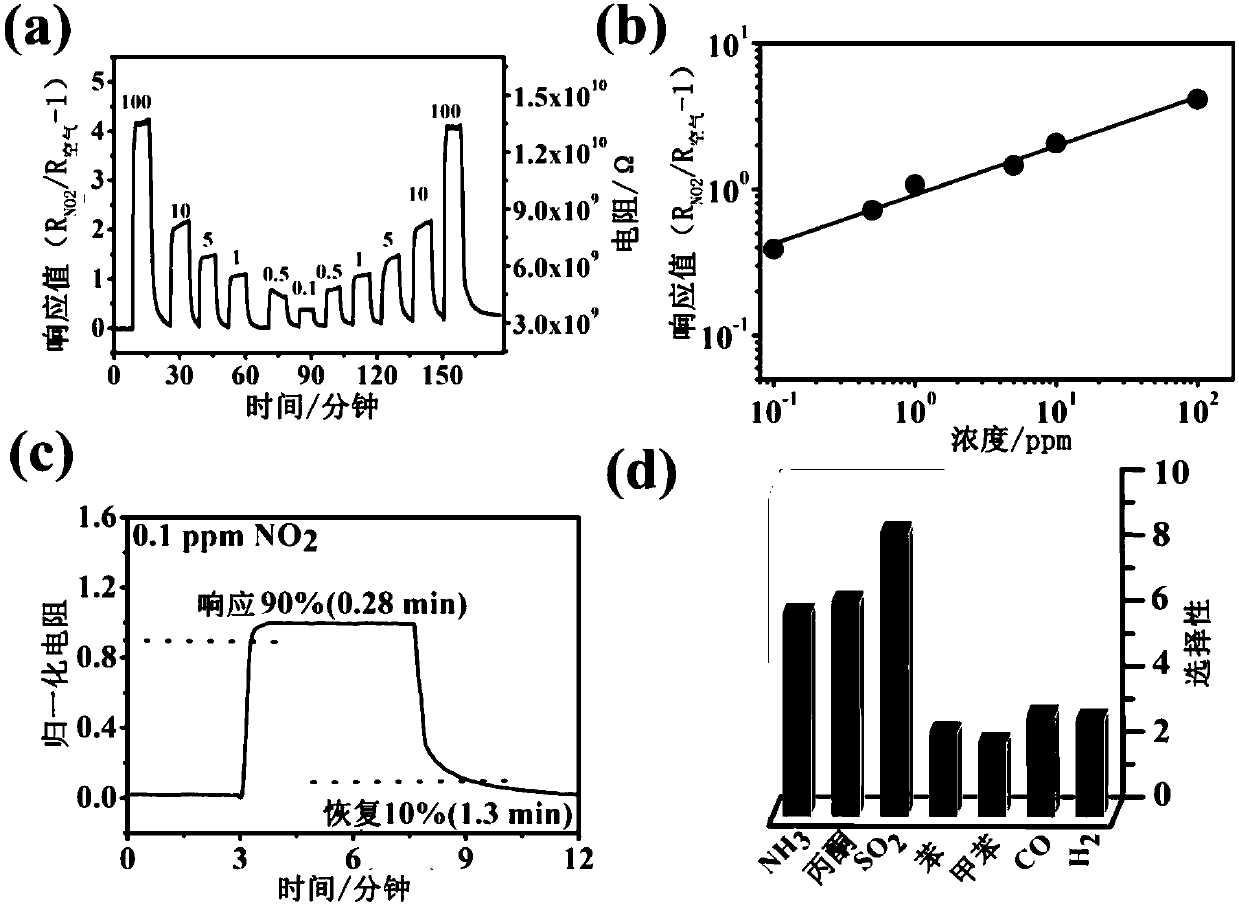

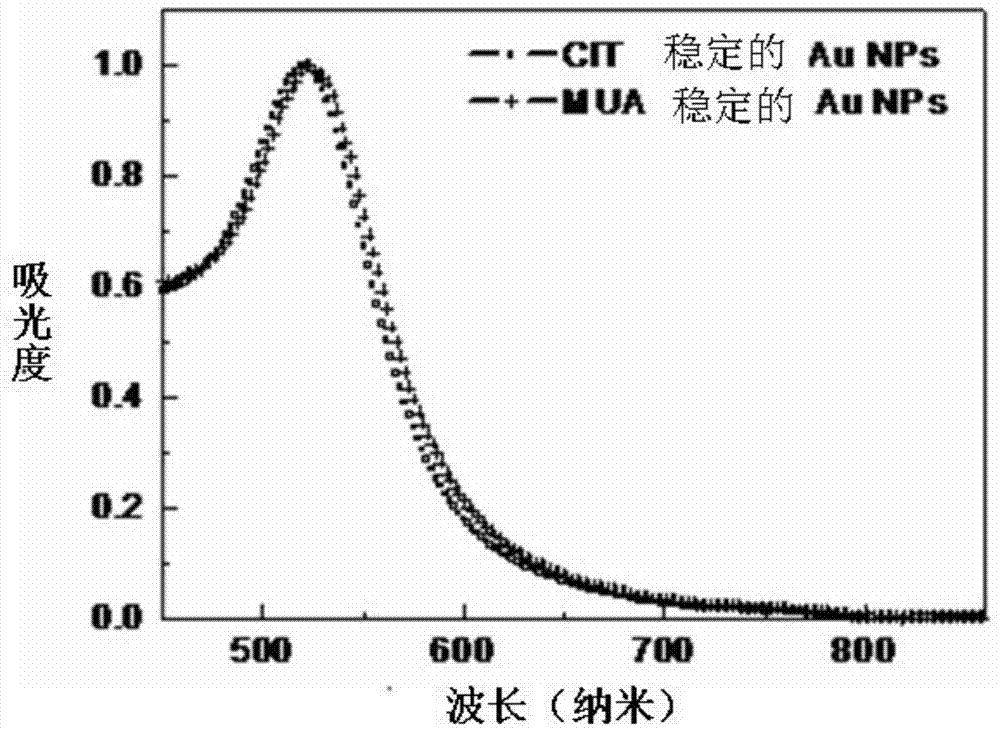

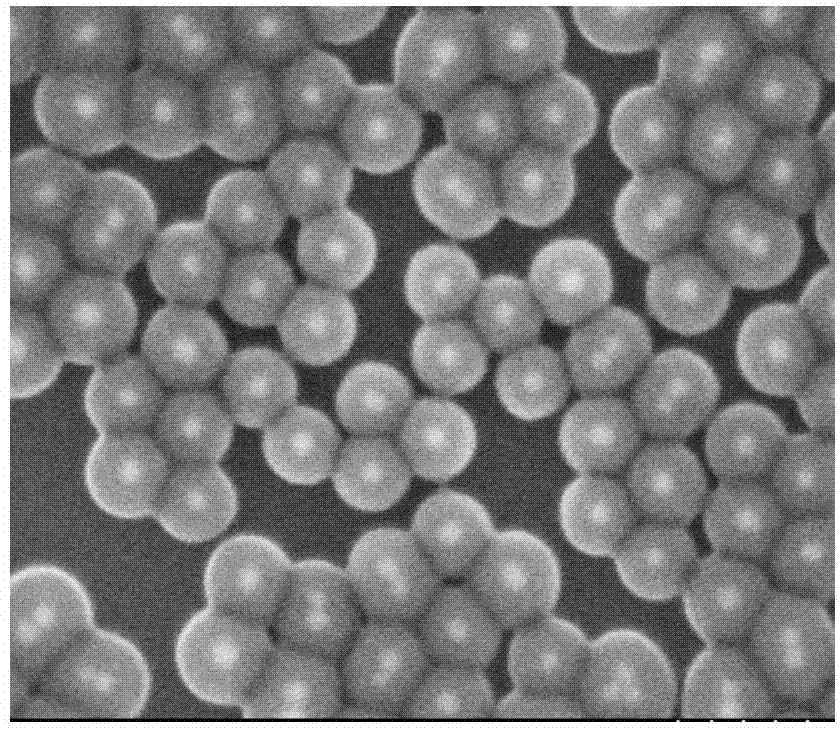

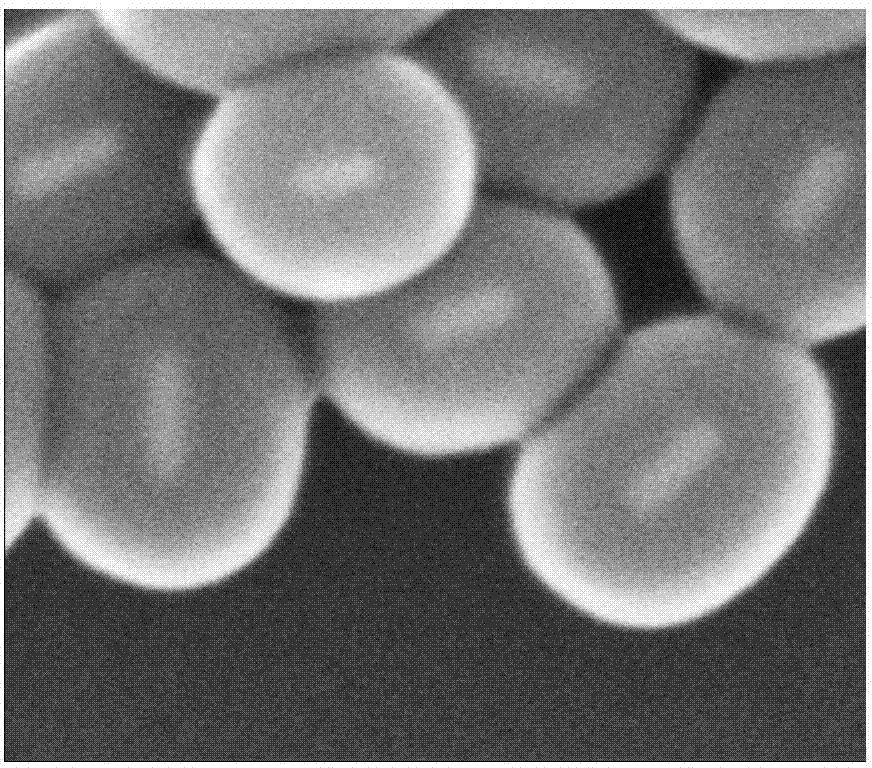

Method for preparing silicon dioxide coated noble metal nanocrystalline

The invention provides a method for preparing silicon dioxide coated noble metal nanocrystalline, and belongs to the technical field of a nanocrystalline preparation method of a core-shell structure. The method comprises the steps: mixing noble metal nanocrystalline aqueous solution modified by mercaptocarboxylic acid with alcoholic solution to obtain a mixed solution; adding ammonium hydroxide and n-ethyl acetate into the mixed solution, stirring to obtain a reaction mixture; centrifuging and dissolving the obtained reaction mixture to obtain the silicon dioxide coated noble metal nanocrystalline. According to the method, the silicon dioxide is coated at the surface of the noble metal nanocrystalline to form the core-shell structure; the mercaptocarboxylic acid is used as a bifunctional molecule and can modify the noble metal nanocrystalline with different phases or the surface of the noble metal nanocrystalline with different forms. The preparation method is simple, and the nanocrystalline of the composite core-shell structure is stable.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

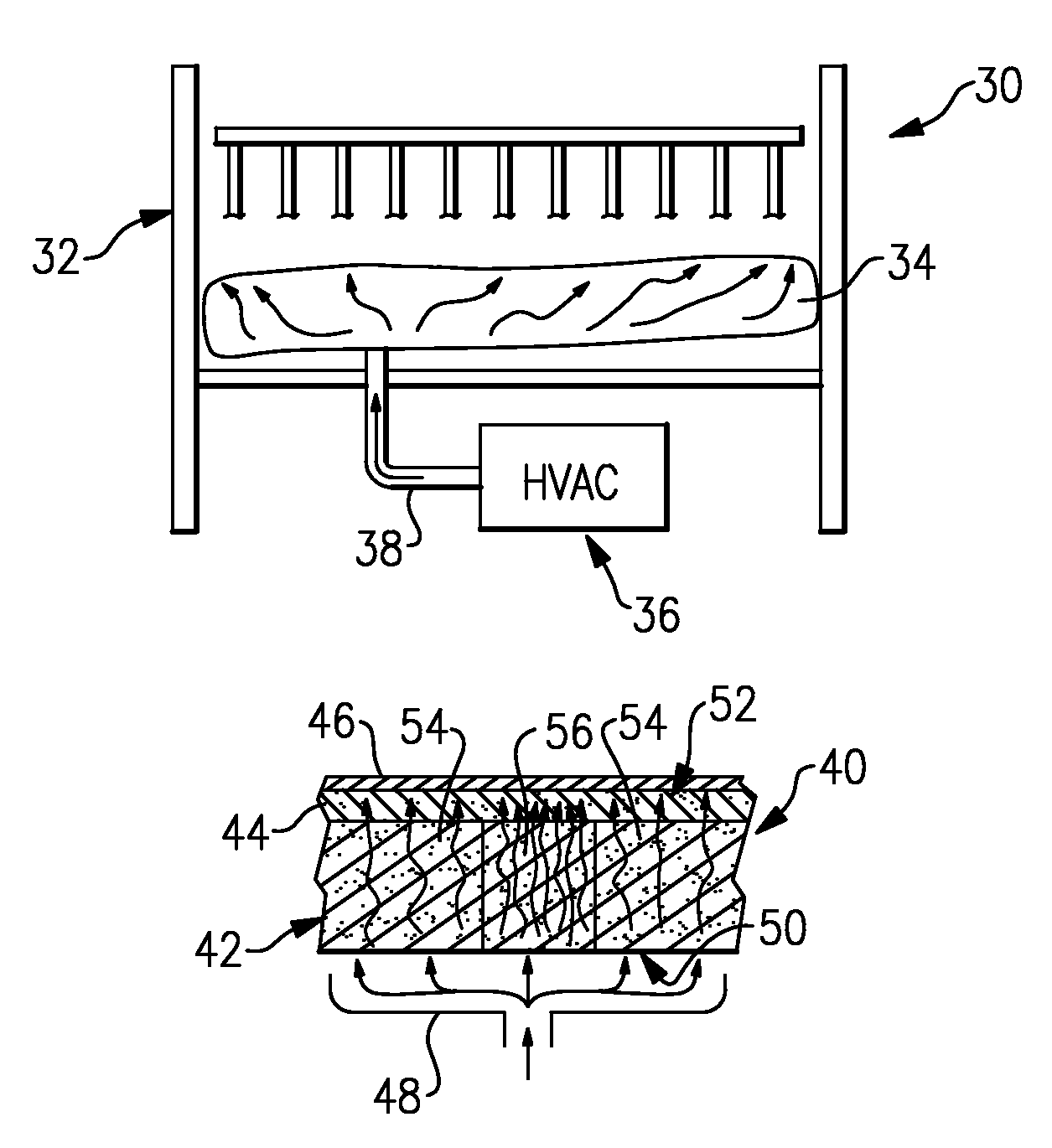

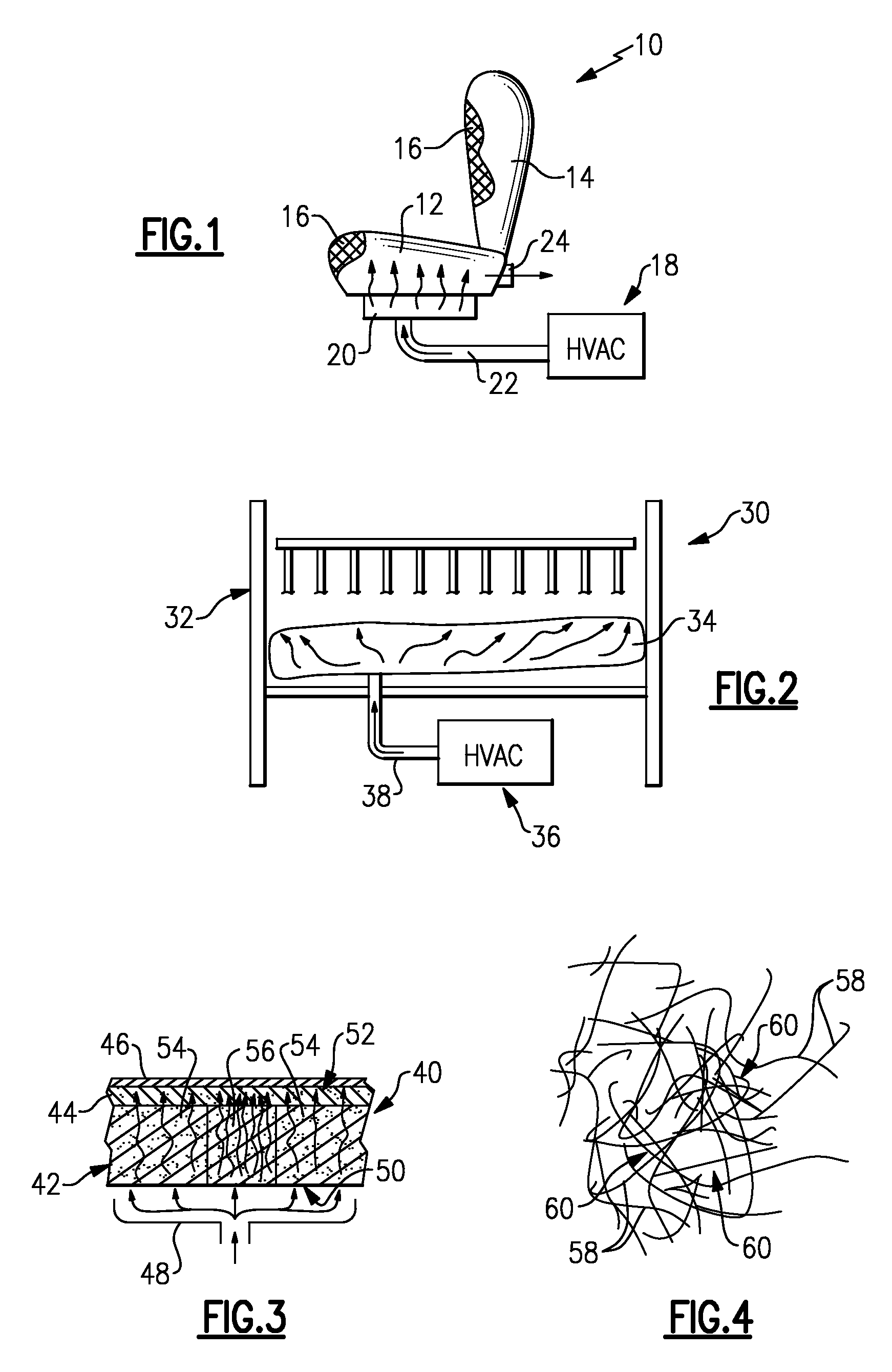

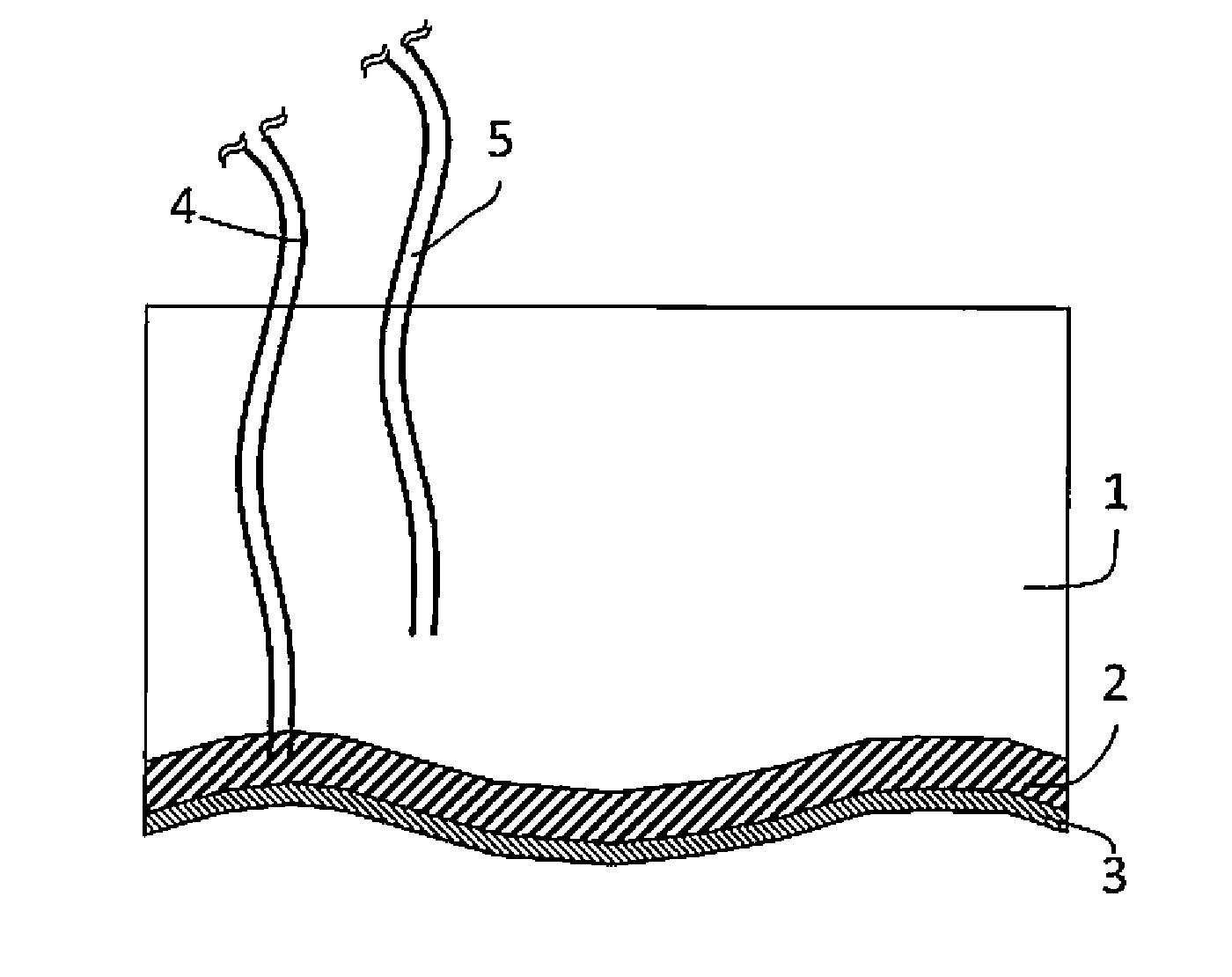

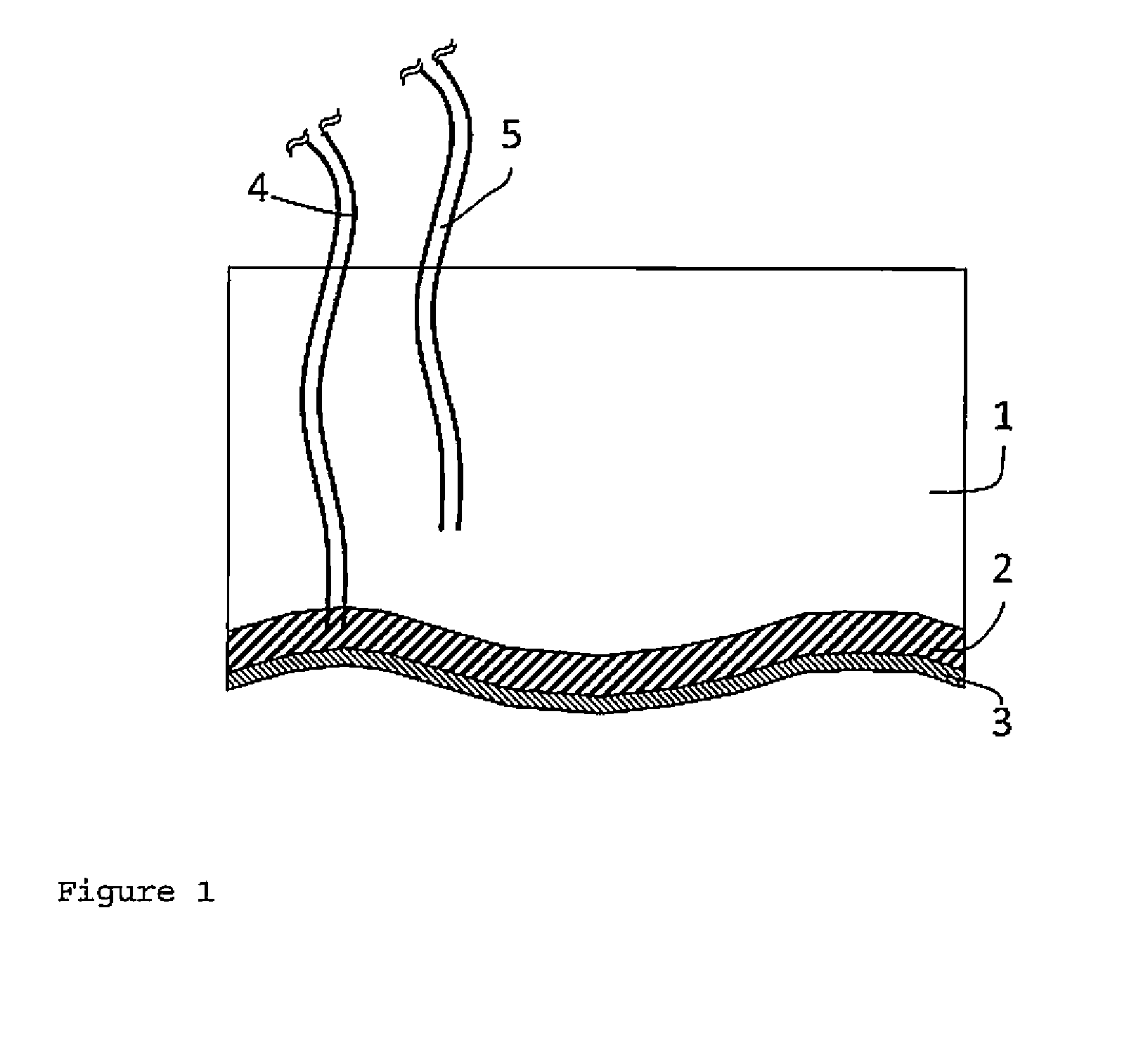

Transformable Adaptive Gripper System

InactiveUS20140292010A1Regulation uniformityEven airflowGripping headsThrusting weaponsStable stateEngineering

An end effector that includes: a flexible container which contains a filler, wherein the filler is switchable between a flowable or deformable state and a rigid or dimensionally stable state, and one or more working elements for gripping, temperature regulation and / or compaction.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

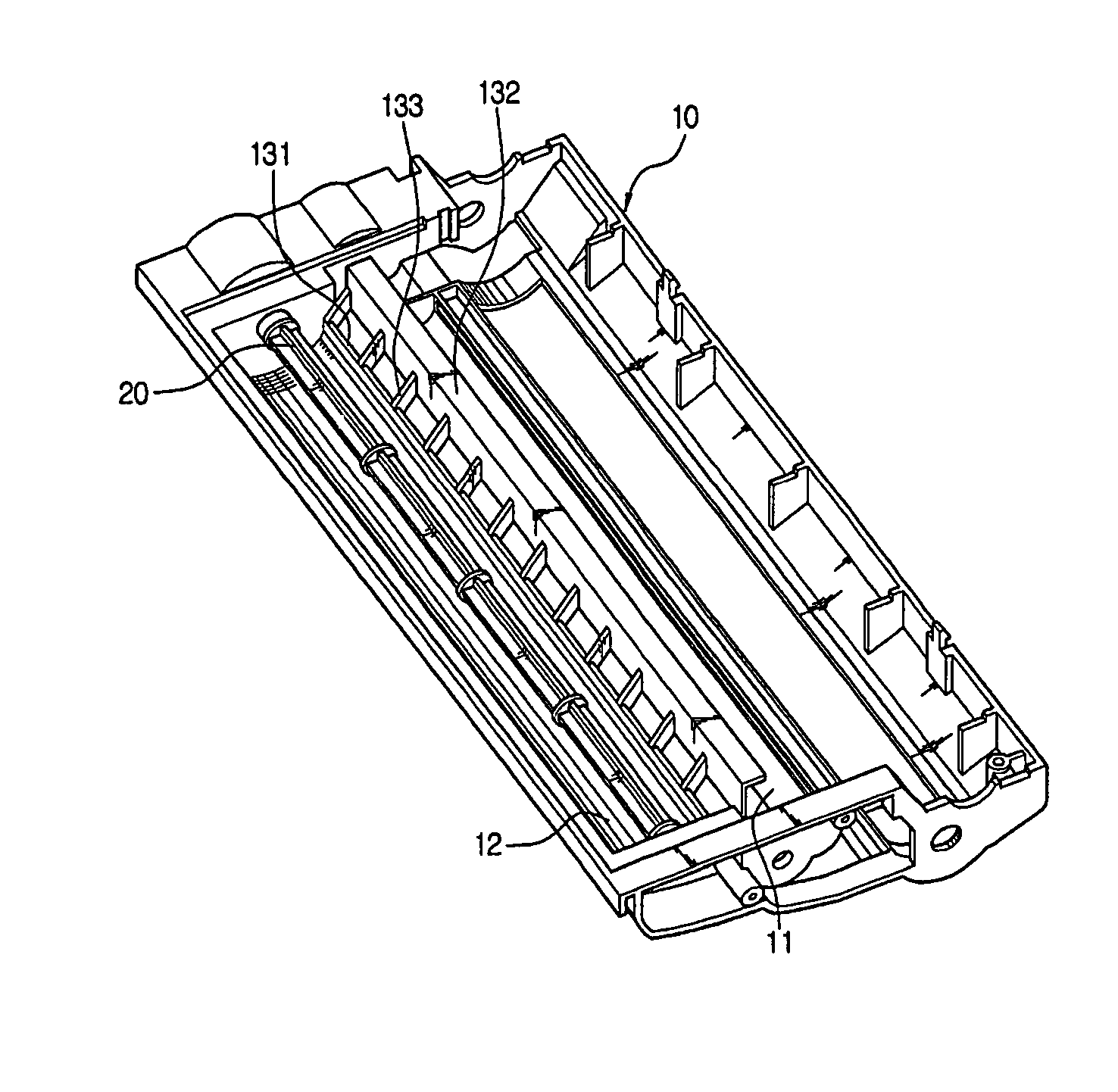

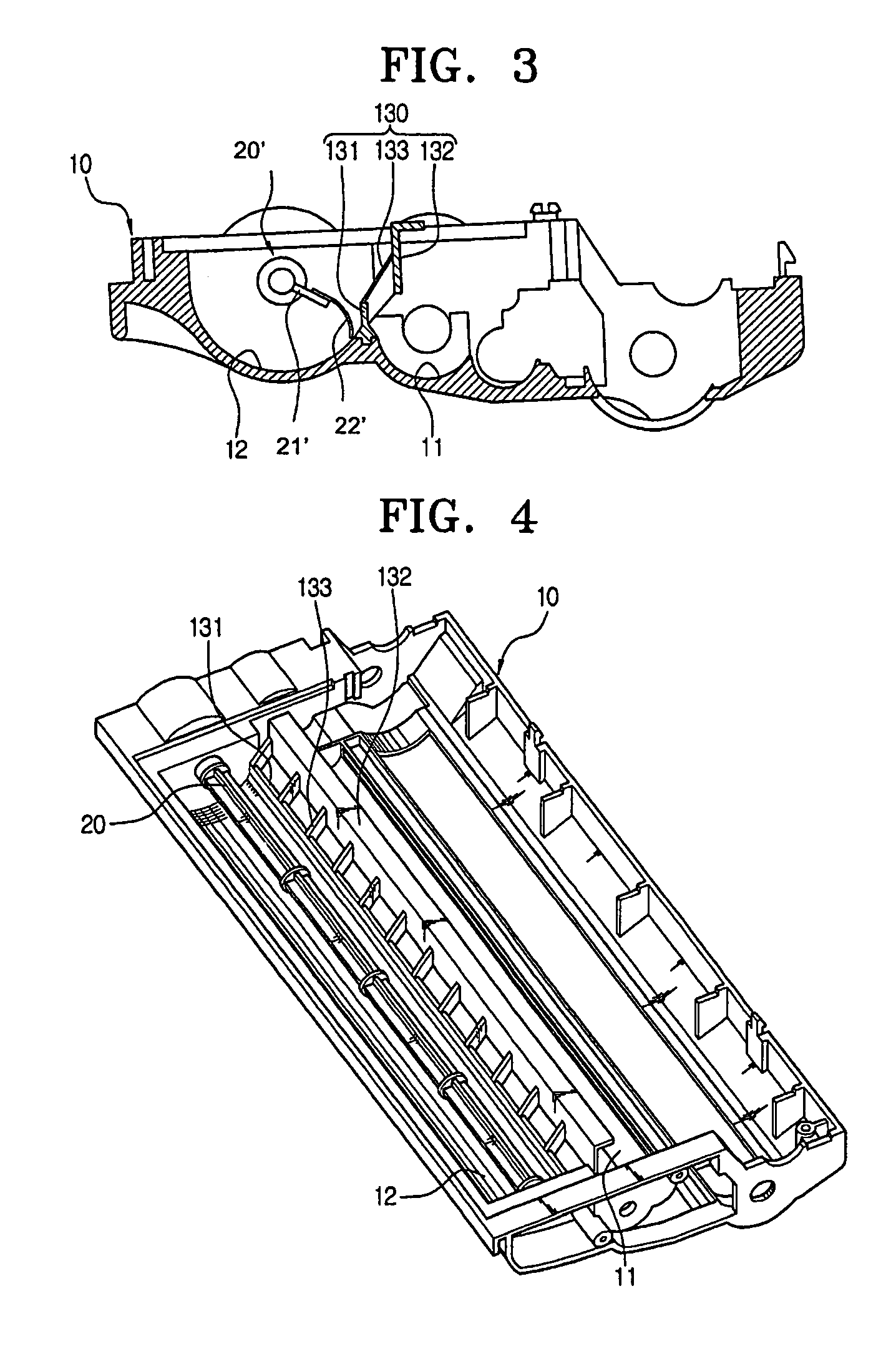

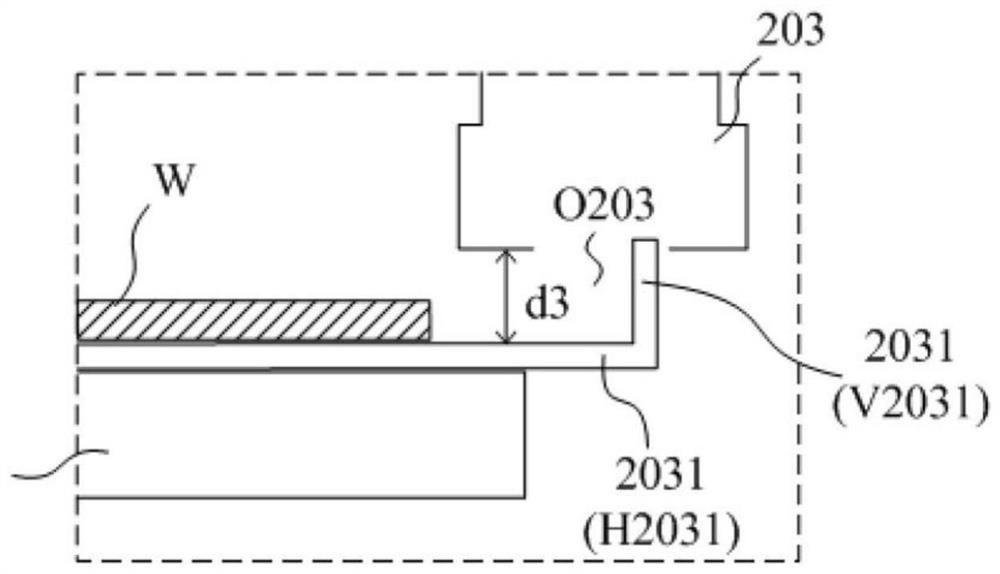

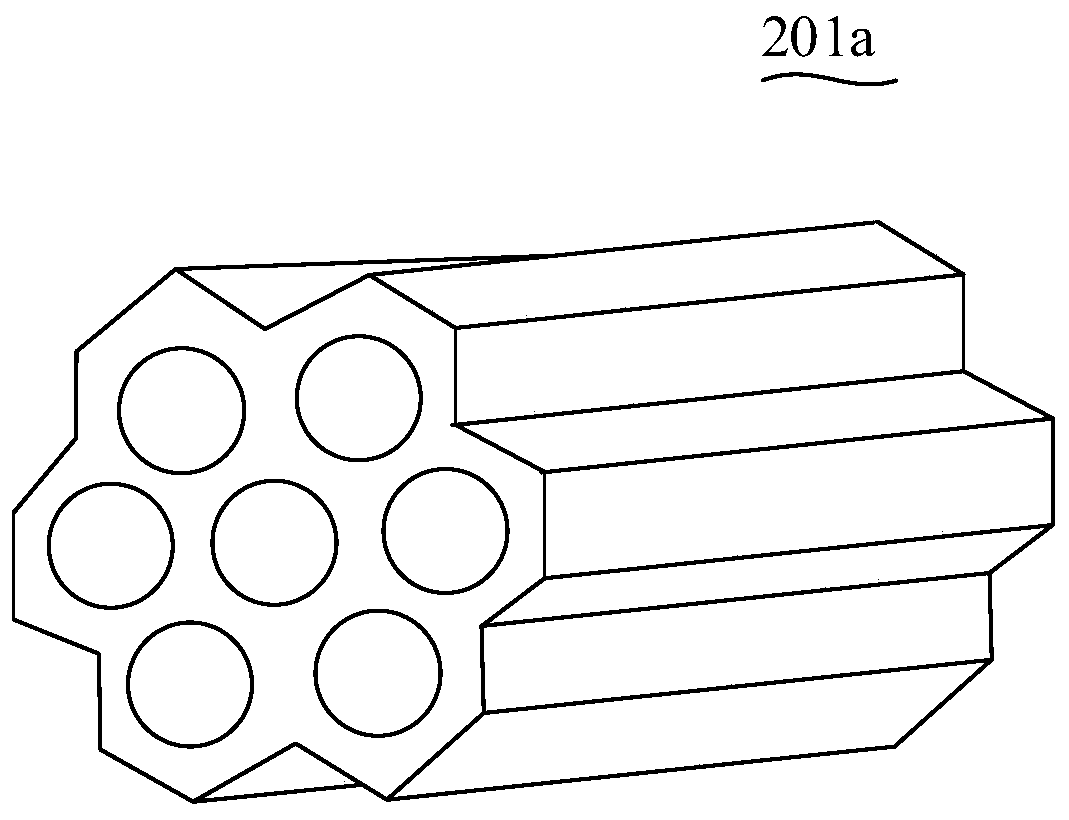

Developing unit for image forming apparatus

InactiveUS7058342B2Prevents the toner from leaking outRelieve stressElectrographic process apparatusImage formationEngineering

A developer for an image forming apparatus includes a developing casing having a plurality of toner chambers to contain toner, an agitator having a resilient wing and rotatably disposed in the toner chamber for agitating and transferring toner, a toner supplying roller rotatably disposed adjacent to one of the toner chambers of the developing casing, a developing roller for transferring and attaching the toner supplied from the toner supplying roller to a photoconductive medium, and a partition disposed in the developing casing to separate the two toner chamber. The partition has a plurality of slits at a center potion to transfer toner from one toner chamber to another toner chamber therethrough, while the agitator rotates. Also, the partition has a rib sloped upward at a predetermined angle from a lower portion of the slit. While the agitator rotates, the resilient wing of the agitator resiliently contacts with the rib so as to splash the toner upward. The toner being splashed then drops due to gravity and moves through the slit.

Owner:S PRINTING SOLUTION CO LTD

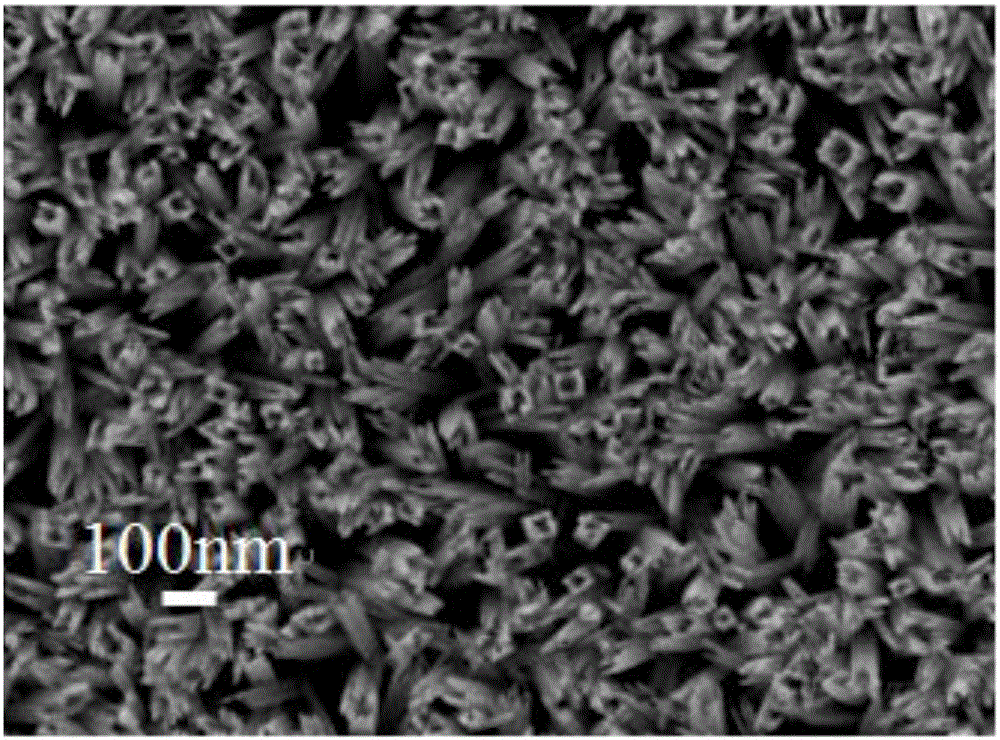

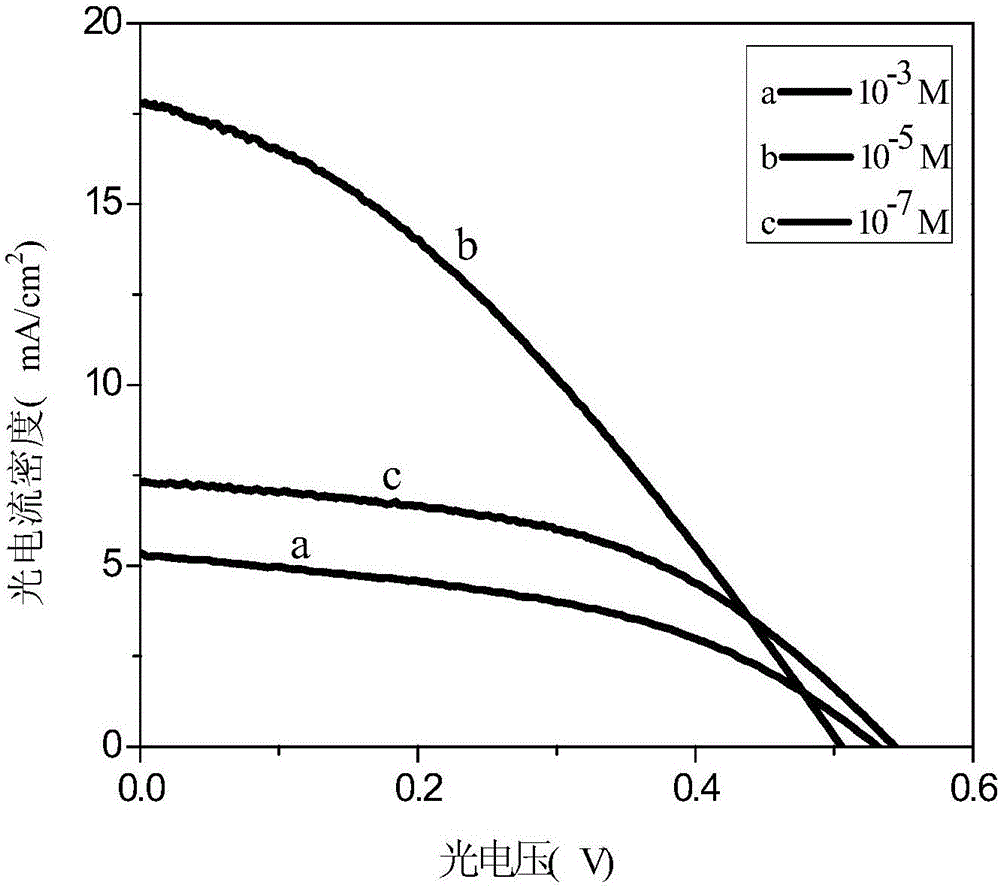

Strontium titanate-titanium dioxide composite nanotube array film and preparation method and application thereof

ActiveCN106431005AGentle synthesis processEnvironmentally friendlyLight-sensitive devicesNanotechnologyChemistryHydrothermal synthesis

The invention relates to a strontium titanate-titanium dioxide composite nanotube array film and a preparation method and application thereof. The film is obtained through direct growth on a conductive glass substrate with a three-step hydrothermal method; hydrothermal synthesis of titanium dioxide nanorods is carried out in the first step, the titanium dioxide nanorods are etched to generate titanium dioxide nanotubes in the second step of hydrothermal treatment, strontium hydroxide serves as a strontium source in the third step of hydrothermal reaction, and finally the composite film with perovskite type strontium titanate nanoparticles uniformly distributed on the surface of the titanium dioxide nanotube array is obtained, wherein the titanium dioxide nanotubes are vertically arrayed on the conductive glass substrate. The composite film can serve as an anode material of solar cells or serve as a photocatalyst for degradation treatment of photolysis water or organic matter. The three-step hydrothermal method is adopted for in-situ synthesis, the preparation process and needed equipment are simple, the controllability is high, and production is safe, free of toxin and environmentally friendly; by assembling the film into solar cells, the sunlight capturing capability of photoanodes can be improved, and the photoelectric conversion efficiency can be improved.

Owner:QINGDAO UNIV OF SCI & TECH

Three-dimensional layered boron-doped titanium carbide as well as preparation method and application thereof

PendingCN113697811AUniform depositionGrowth inhibitionTitanium carbideElectrode carriers/collectorsTitanium carbideLithium-ion battery

The invention provides three-dimensional layered boron-doped titanium carbide as well as a preparation method and application thereof, and belongs to the technical field of lithium ion battery materials. According to the preparation method, a raw material Ti3AlC2 is etched into titanium carbide, then the titanium carbide and boric acid in different proportions are subjected to a hydrothermal reaction, and finally the three-dimensional layered boron-doped titanium carbide is obtained. According to the obtained three-dimensional layered boron-doped titanium carbide, the effect of uniform deposition is achieved due to existence of nucleation site boron, growth of lithium dendrites in the deposition and precipitation process is limited due to small interlayer spacing, the safety and coulombic efficiency of a lithium negative electrode are improved to a great extent, the cycle life of the lithium negative electrode is prolonged to a great extent, and the preparation method is simple and easy to operate and suitable for industrial production.

Owner:HEBEI NORMAL UNIV

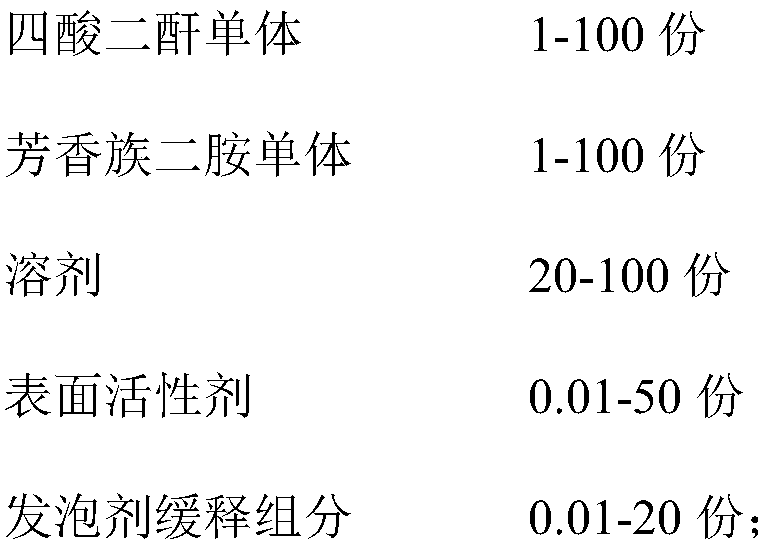

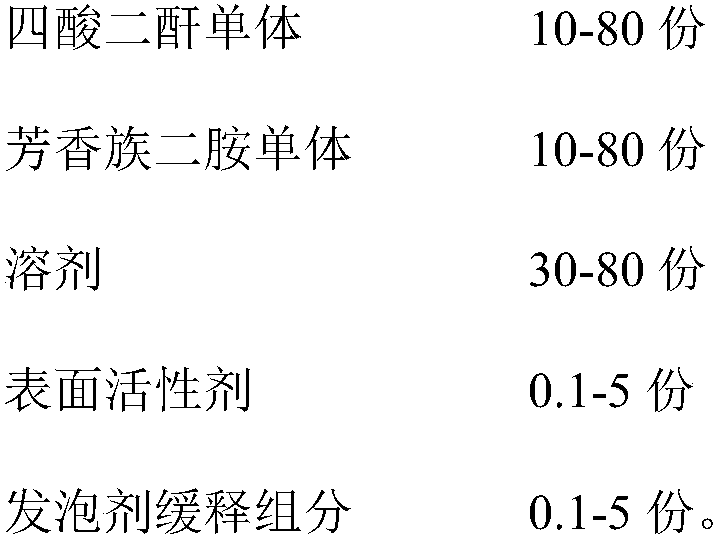

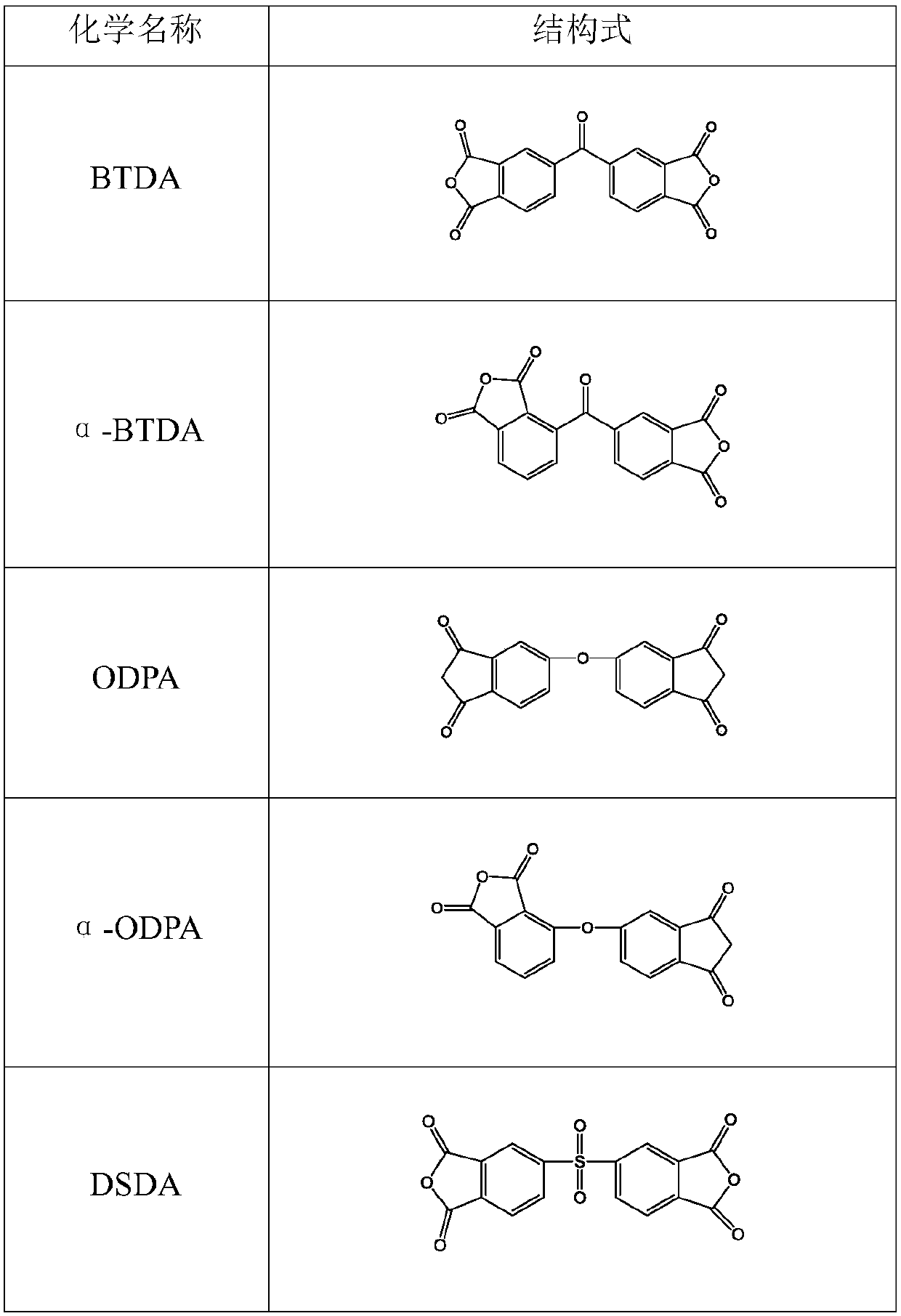

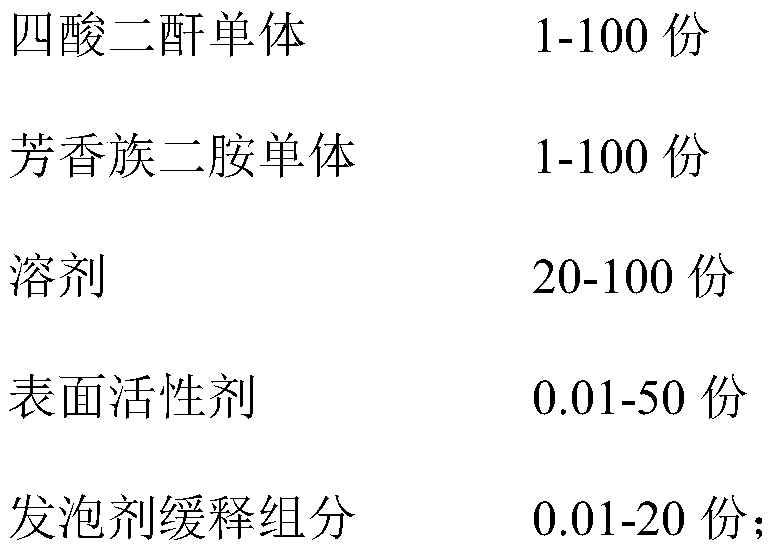

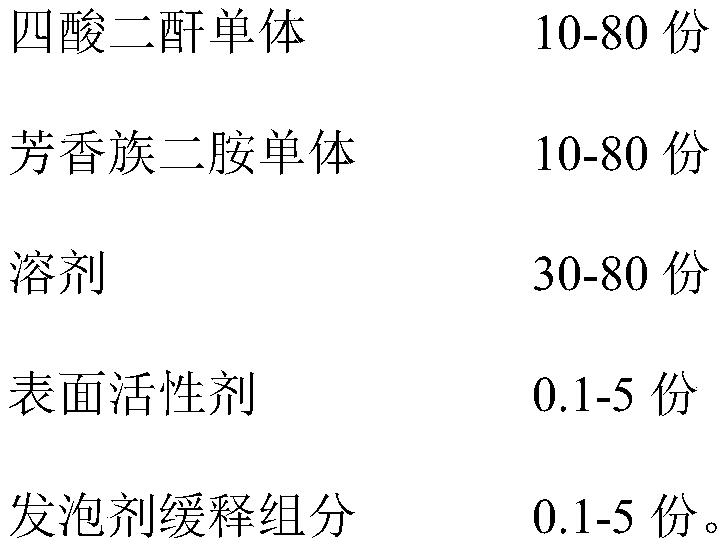

Flexible polyimide foam and preparation method and applications thereof

ActiveCN109593199AProtection against excessive volatilizationUniform pore sizeFoaming agentMicrometer

The present invention relates to flexible polyimide foam and a preparation method and applications thereof. The flexible polyimide foam is obtained by foaming a block / plate-shaped polyimide foam precursor containing slow-release components of a foaming agent; and the flexible polyimide foam has the average density of 14.7-47.7 kg / m<3> and the pore size of 130-530 micrometers. The flexible polyimide foam disclosed by the invention has the beneficial effects that by adopting a foaming form of a polyimide (PI) precursor block / plate, the problem of large density deviation in the thickness direction, of a polyimide precursor powder foaming method, can be effectively solved and the product yield of the foam made from the prepolymerized powder is improved; by adopting the PI precursor containingthe slow-release components and by regulating and controlling the type and the using amount of the slow-release components of the foaming agent, the density of the PI flexible foam can be adjusted andcontrolled, so that the foaming process window is wider and the pore size of the foam is more uniform; and meanwhile, by adopting the polyimide precursor plate, the water absorption rate can be effectively reduced and the storage time of the material is prolonged in the preservation process, so that the quality stability of the final foam product is improved.

Owner:INST OF CHEM CHINESE ACAD OF SCI

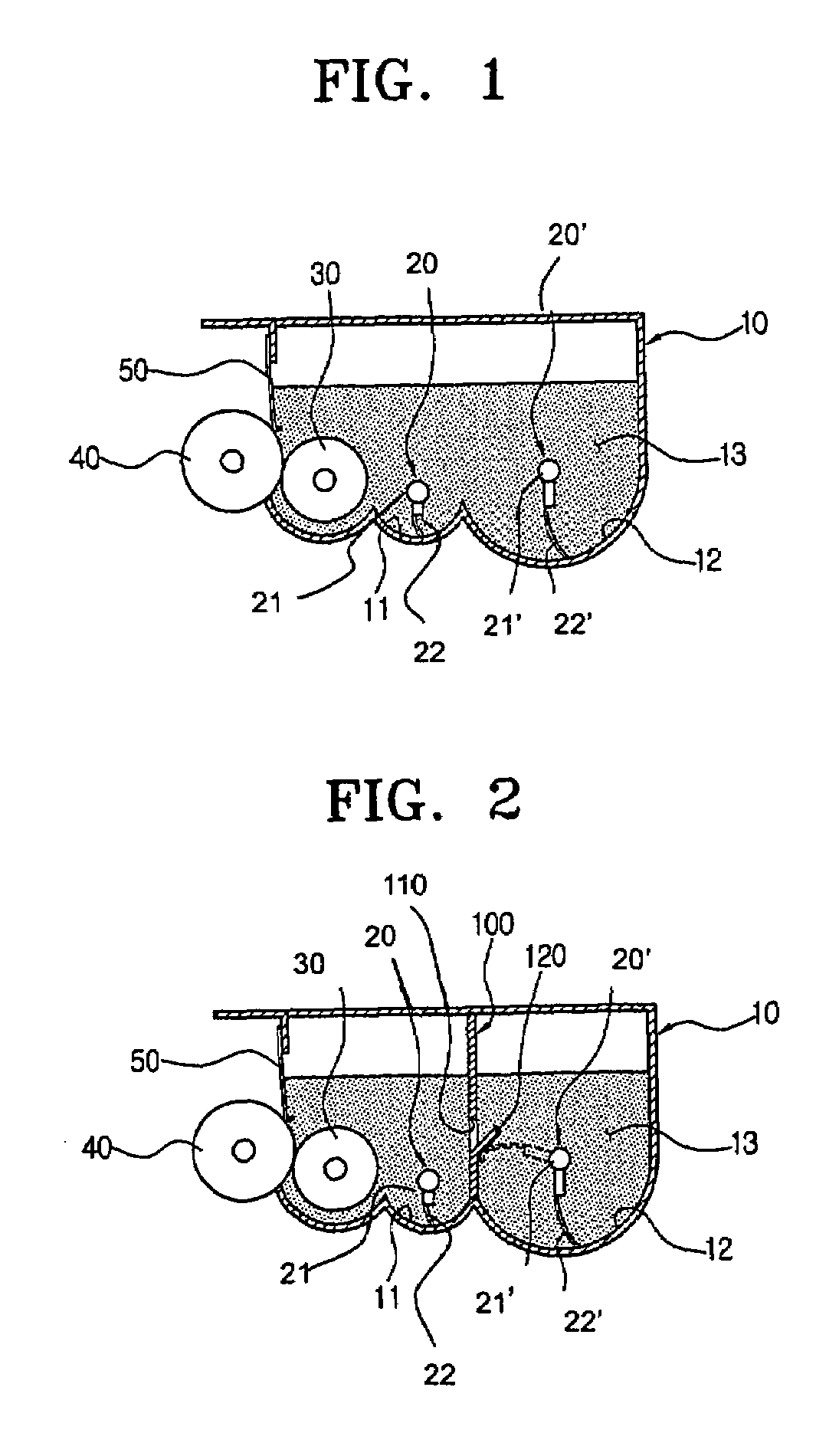

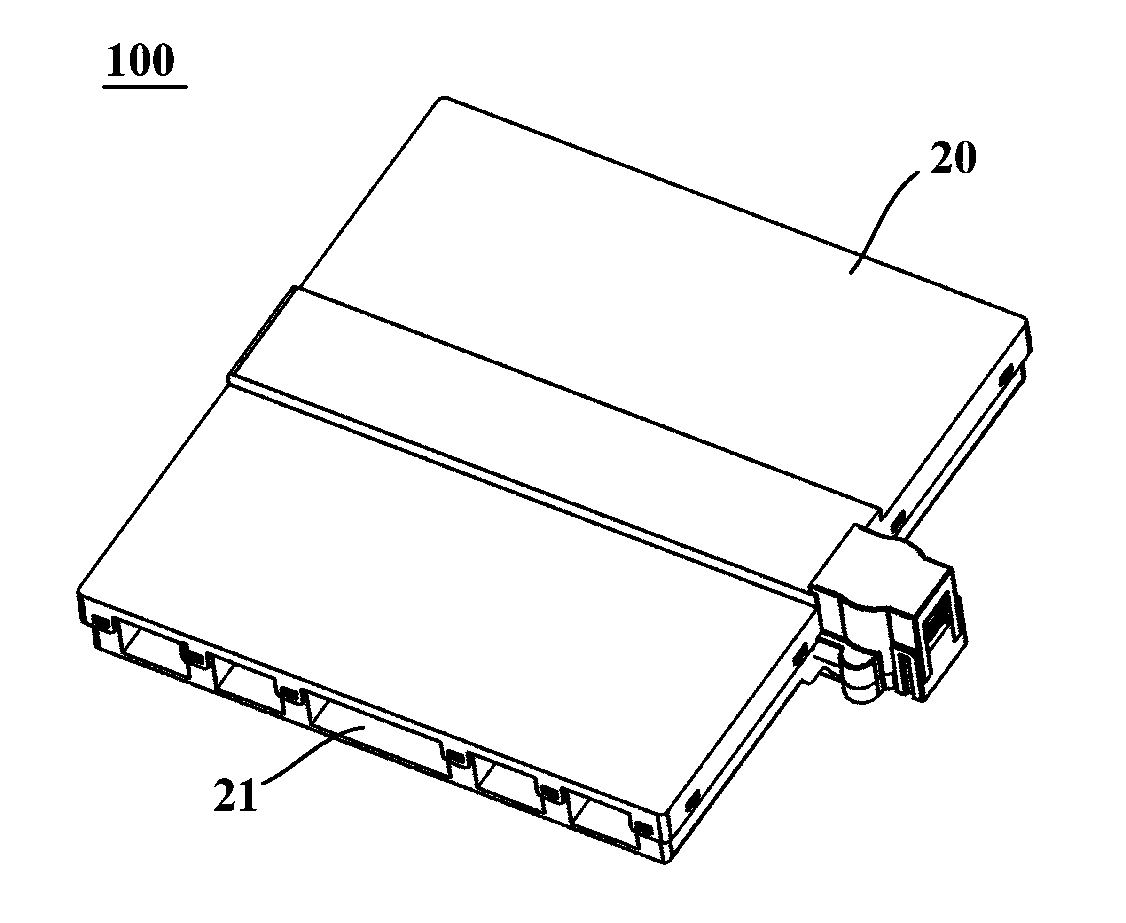

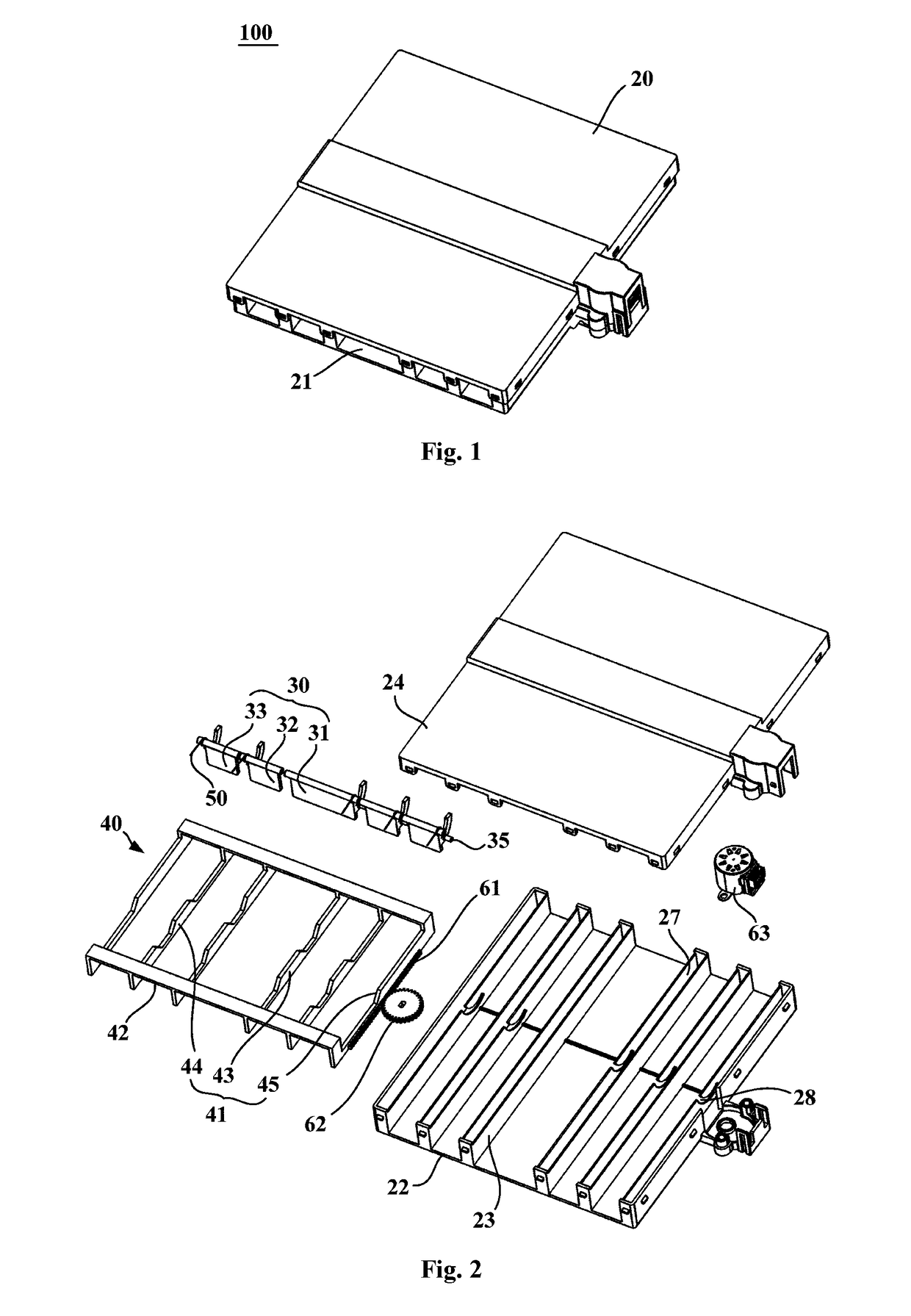

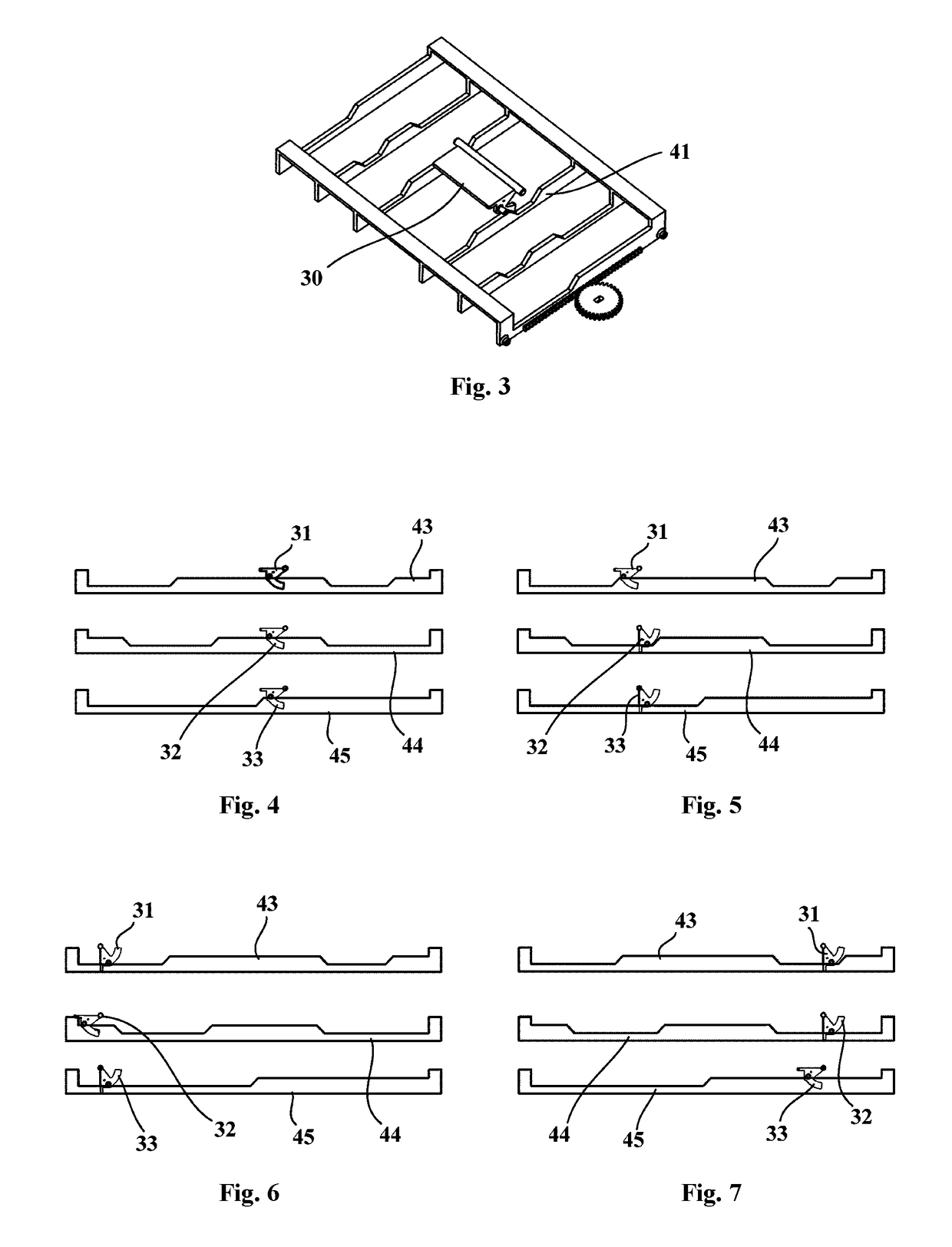

Branching air supply device and refrigerator with same

ActiveUS20180306483A1Simple structureConvenience and unified supervisionLighting and heating apparatusDomestic refrigeratorsRefrigerated temperatureHolding room

Provided are a branching air supply device and a refrigerator with the branching air supply device. The branching air supply device comprises a housing, a plurality of airflow passages provided in parallel being defined in the housing; a plurality of baffle plates, each baffle plate being movably mounted to the housing and being configured to perform complete blocking, partial conducting or complete conducting of one airflow passage in different positions; and a linkage device movably mounted to the housing and configured to move each of the baffle plates intermittently when the linkage device moves. The branching air supply device and the refrigerator can perform uniform adjustment for cooling air, according to cold requirements for different storage compartments or cold requirements for different positions of one storage compartment.

Owner:HAIER SMART HOME CO LTD

Preparing method and application of cobalt tantalum zirconium alloy target material

ActiveCN110735068AHigh purityImprove performanceMetal-working apparatusVacuum evaporation coatingThin membraneManufactured material

The invention discloses a preparing method and application of a cobalt tantalum zirconium alloy target material, and belongs to the technical field of preparation of special materials. The preparing method comprises the steps of component design, high-vacuum vertical sintering and high-vacuum electron beam melting, three-dimensional isothermal hot forging cogging, angle-varying controlled rollingand the like. In this way, the organization structure of the alloy and the performance of the target material are controlled, and the high-quality cobalt tantalum zirconium alloy target material is prepared. The oxygen content of the cobalt tantalum zirconium alloy target material is smaller than or equal to 15 ppm, the average grain size of the cobalt tantalum zirconium alloy target material is 5-20 micrometers, the phase distribution of the target material is uniform, the magnetic permeability is larger than 40%, and the heterogeneity of magnetic permeability is smaller than 2%. By means ofthe designed process, the oxygen content, organization structure heterogeneity and magnetic performance of the finished product target material can be effectively controlled, and a raw material guarantee is provided for sputtering high-quality thin films by means of the preparing method.

Owner:CENT SOUTH UNIV

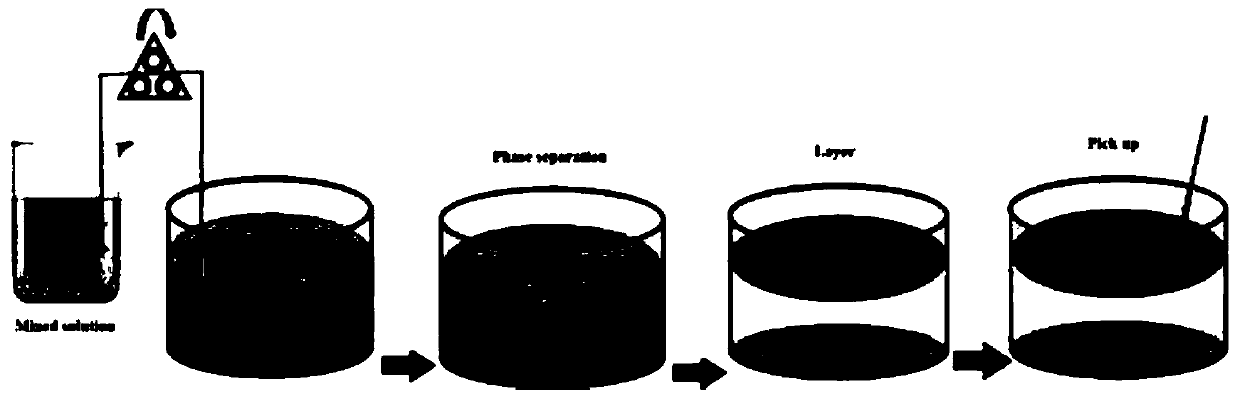

Preparation method of self-supporting flexible conductive super-hydrophobic film

The invention discloses a self-supporting flexible conductive super-hydrophobic film and a preparation method thereof, and the self-supporting flexible conductive super-hydrophobic film comprises surface microstructure design of a film material. The preparation method comprises the following steps: forming a self-supported flexible conductive super-hydrophobic film on the surface of a liquid phasesystem by using a solvent-non-solvent method, wherein the effective regulation and control of a high-molecular polymer on the microstructure of the conductive nano material on the surface of the liquid phase system is an important condition for the synergy of conductivity and super-hydrophobic performance. The process is simple. Expensive preparation instruments, high-temperature action and catalysts are not needed, consumed time is short, and film materials can be continuously collected on a large scale. The self-supporting film produced by the invention has good strength, can form a stableself-supporting structure, has good conductivity, stable super-hydrophobic performance and certain elastic conductive super-hydrophobic performance, and can effectively improve the performance of flexible conductive super-hydrophobic electronic equipment.

Owner:SHAANXI UNIV OF SCI & TECH

Quantum dot colour film substrate and display device

InactiveCN109669301AConvenient ArrangementOrderly adjustment and control arrangementNon-linear opticsGamutDisplay device

The invention relates to a quantum dot colour film substrate and a display device. The quantum dot colour film substrate comprises a substrate and one or more quantum dot film layer units arranged onthe substrate, wherein each quantum dot film layer unit comprises a nanoporous framework and quantum dots arranged on the nanoporous framework. As the excited quantum dot film layer units can generatelight with different wavelengths to match the colours of different pixel units, the colour effect can be controlled, and meanwhile, the utilization rate of a light source is improved; meanwhile, thequantum dot film layer units comprise the nanoporous frameworks and the quantum dots arranged on the nanoporous framework, so that the nanoporous frameworks can be used for orderly adjusting and controlling the distribution conditions and the sizes of the quantum dots, thus making the quantum dots more uniform, stable and ordered; and therefore, a luminescent spectrum, as well as the distributionand uniformity of the colours are orderly adjusted and controlled; the colour gamut is widened; and the better colour displaying effect is realized.

Owner:HKC CORP LTD

A kind of soft polyimide foam, its preparation method and its application

ActiveCN109593199BSolve the problem of large thickness control deviationUniform pore sizeImidePolymer science

The present invention relates to flexible polyimide foam and a preparation method and applications thereof. The flexible polyimide foam is obtained by foaming a block / plate-shaped polyimide foam precursor containing slow-release components of a foaming agent; and the flexible polyimide foam has the average density of 14.7-47.7 kg / m<3> and the pore size of 130-530 micrometers. The flexible polyimide foam disclosed by the invention has the beneficial effects that by adopting a foaming form of a polyimide (PI) precursor block / plate, the problem of large density deviation in the thickness direction, of a polyimide precursor powder foaming method, can be effectively solved and the product yield of the foam made from the prepolymerized powder is improved; by adopting the PI precursor containingthe slow-release components and by regulating and controlling the type and the using amount of the slow-release components of the foaming agent, the density of the PI flexible foam can be adjusted andcontrolled, so that the foaming process window is wider and the pore size of the foam is more uniform; and meanwhile, by adopting the polyimide precursor plate, the water absorption rate can be effectively reduced and the storage time of the material is prolonged in the preservation process, so that the quality stability of the final foam product is improved.

Owner:INST OF CHEM CHINESE ACAD OF SCI

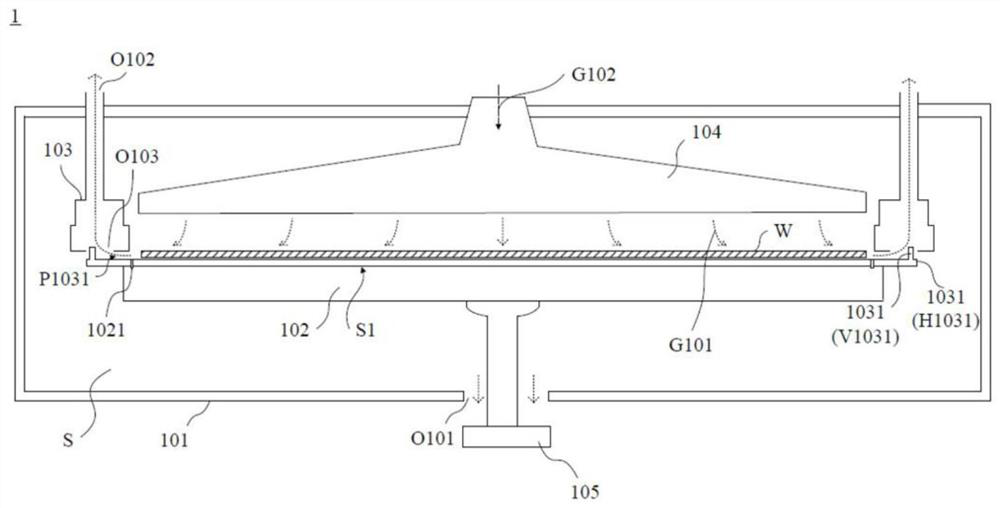

Atomic layer deposition equipment and process method

The invention provides atomic layer deposition equipment and a process method. The atomic layer deposition equipment comprises a cavity, heating tables, carrying discs, a hollow assembly, a bottom extraction opening and a spray head assembly, wherein the carrying discs are located on the top surfaces of the heating tables and are used for bearing a base material, and the carrying discs and the hollow assembly can form an upper extraction path. According to the atomic layer deposition equipment and the process method, a process fluid (such as a precursor) is slowly extracted through the upper air extraction path, a flow field of the process fluid can be stably regulated and controlled, and then the base material in the atomic layer deposition process can be uniformly deposited by the precursor.

Owner:鑫天虹(厦门)科技有限公司

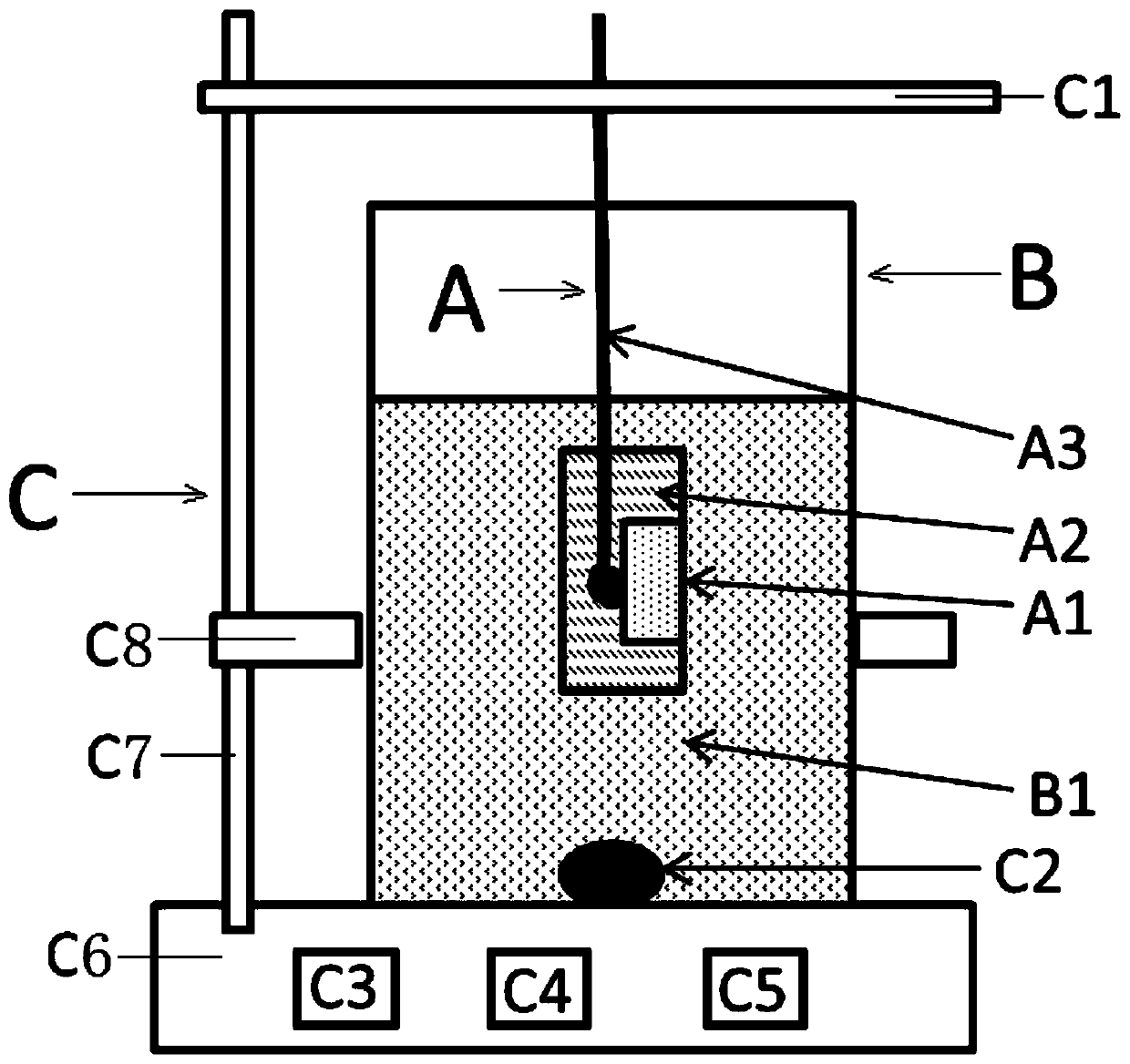

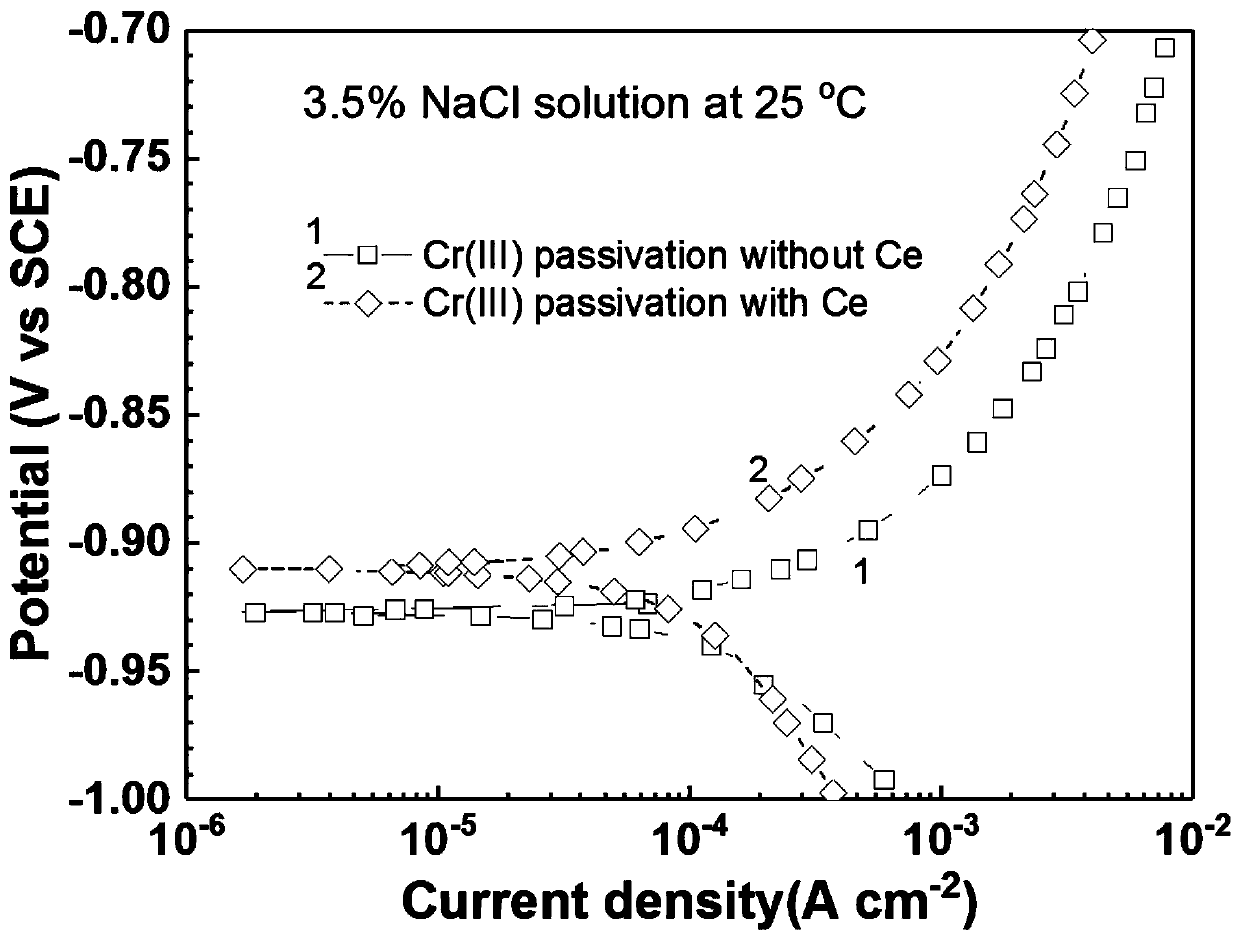

Zinc layer trivalent chromium iridescent passivation treating fluid used under normal temperature and usage method thereof

The invention relates to the technical field of metal surface passivating treatment, in particular to a zinc layer trivalent chromium iridescent passivation treating fluid used under normal temperature and a usage method thereof. Based on calculation per liter, the zinc layer trivalent chromium iridescent passivation treating fluid consists of 15-20g of chromium trichloride, 5-10g of sodium nitrate, 8-15g of propane diacid, 15-20g of citric acid, 5-10g of sodium dihydrogen phosphate, 8-15g of thiourea, 0.8-1.5g of ferrous sulfate, 0.6-1.0g of cerium sulfate and the balance of deionized water.Under a continuous stirring condition, the chromium trichloride is dissolved in a part of the deionized water, the sodium nitrate, the propane diacid, the citric acid, the sodium dihydrogen phosphateand the thiourea are sequentially added and fully dissolved, the cerium sulfate is added and stirred to completely dissolve, the ferrous sulfate and the remaining deionized water are added, and the zinc layer trivalent chromium iridescent passivation treating fluid is obtained after standing. The zinc layer trivalent chromium iridescent passivation treating fluid has the characteristics of being capable of performing normal temperature treatment, simple and convenient, easy to control, stable and the like, and a colored passive film bright, uniform and compact, and good in corrosion resistancecan be obtained by passivating an encapsulated galvanized sample under the condition that PH (potential of hydrogen) value is 2.2 in a laboratory.

Owner:NORTHEASTERN UNIV

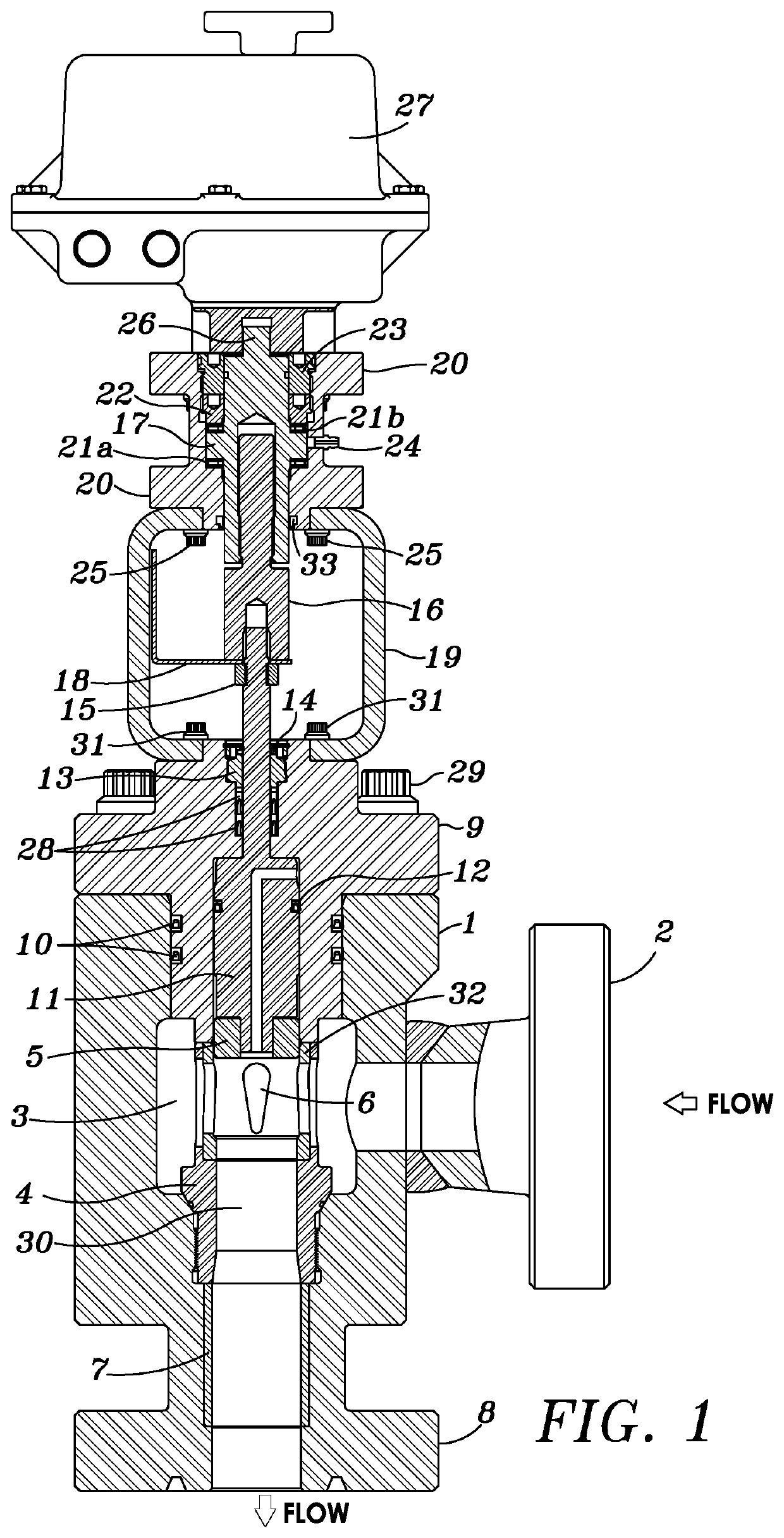

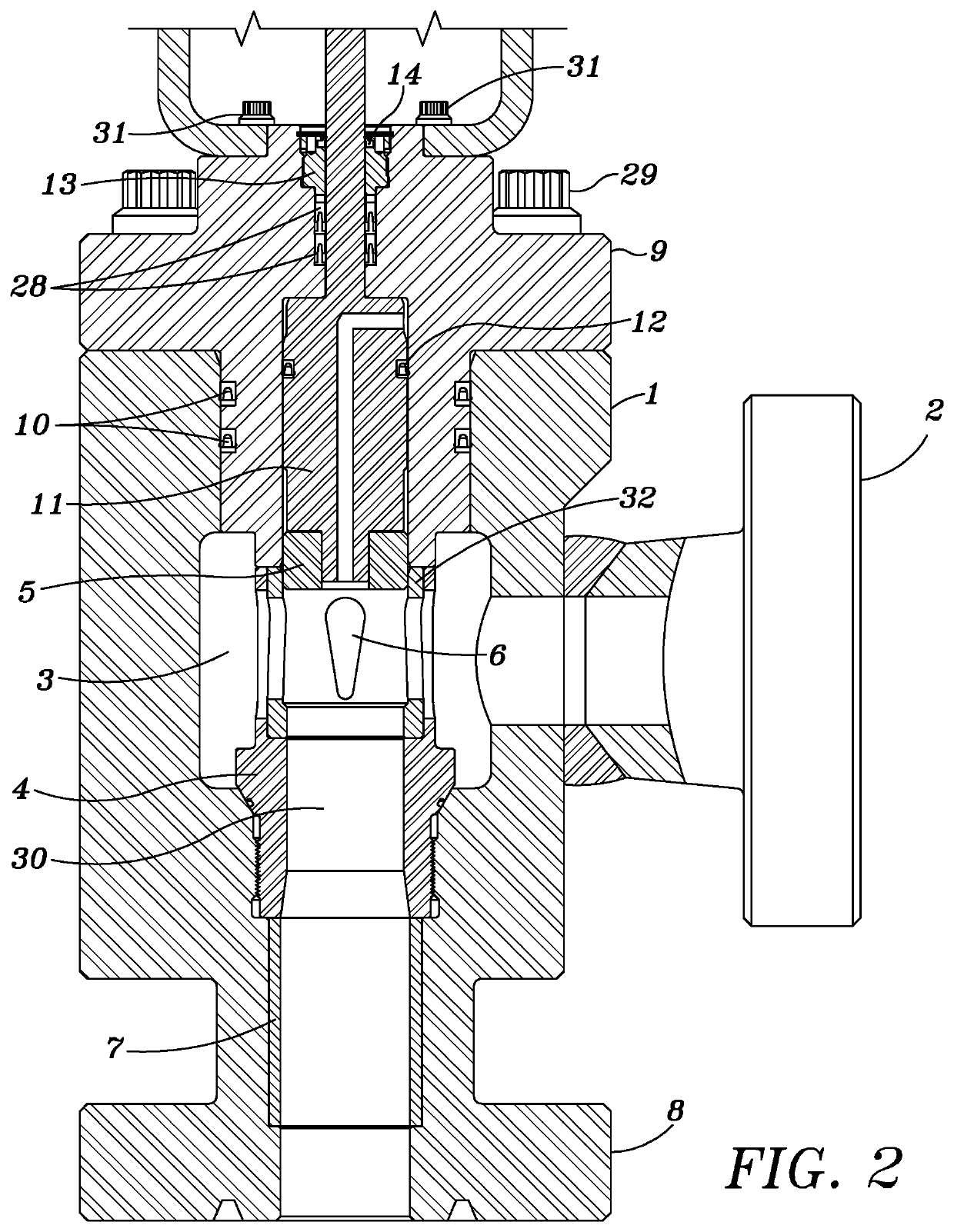

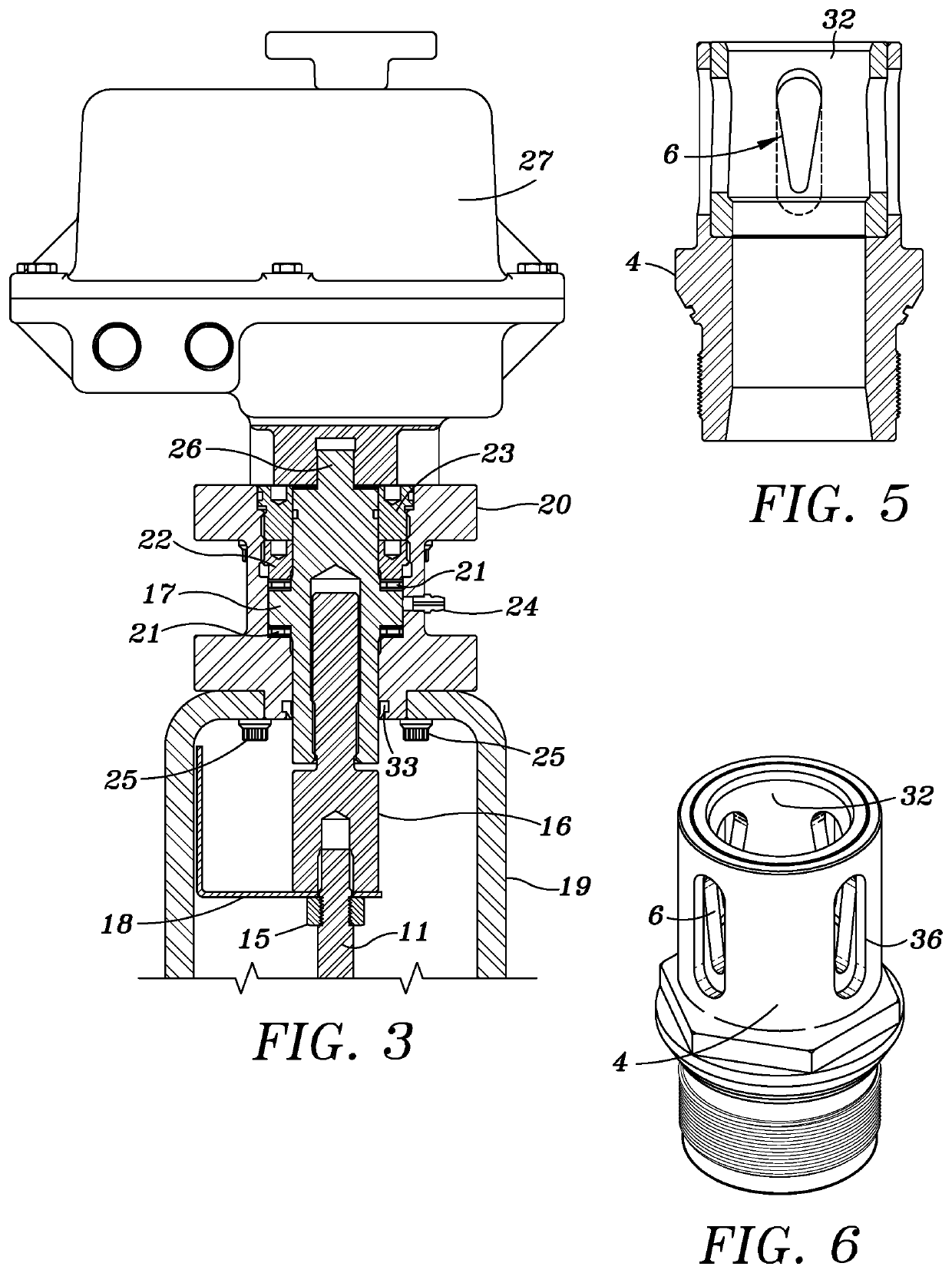

Oilfield choke with teardrop shaped flow orifices

ActiveUS10907443B2Reduce shear forceReduce erosionOperating means/releasing devices for valvesSlide valveMechanicsChoke valve

Owner:ALLEN JACK

Display panel and display device

InactiveCN109860263AReduce sizeConvenient ArrangementSolid-state devicesSemiconductor/solid-state device manufacturingSensor arrayColor effect

The invention relates to a display panel and a display device. The display panel comprises a control backboard, a light-emitting unit, a packaging layer and a light sensor array, wherein the light-emitting unit comprises a quantum dot film layer. Because the quantum dot film layer can be excited to generate light with different wavelengths to control the color effect, the utilization rate of a light source is improved. The quantum dot film layer comprises a nano-porous frame and quantum dots arranged on the nano-porous frame, so the arrangement condition of the quantum dots and the size of thequantum dots can be adjusted and controlled in order through the nano-porous frame, and the quantum dots are more uniform, stable and ordered, so as to adjust and control the light-emitting spectrum,color arrangement and color uniformity, widening the color gamut, and achieving a better color display effect. Therefore, the light sensor array is combined with the quantum dot film layer, and a sensing image with higher quality and richer colors can be obtained.

Owner:HKC CORP LTD

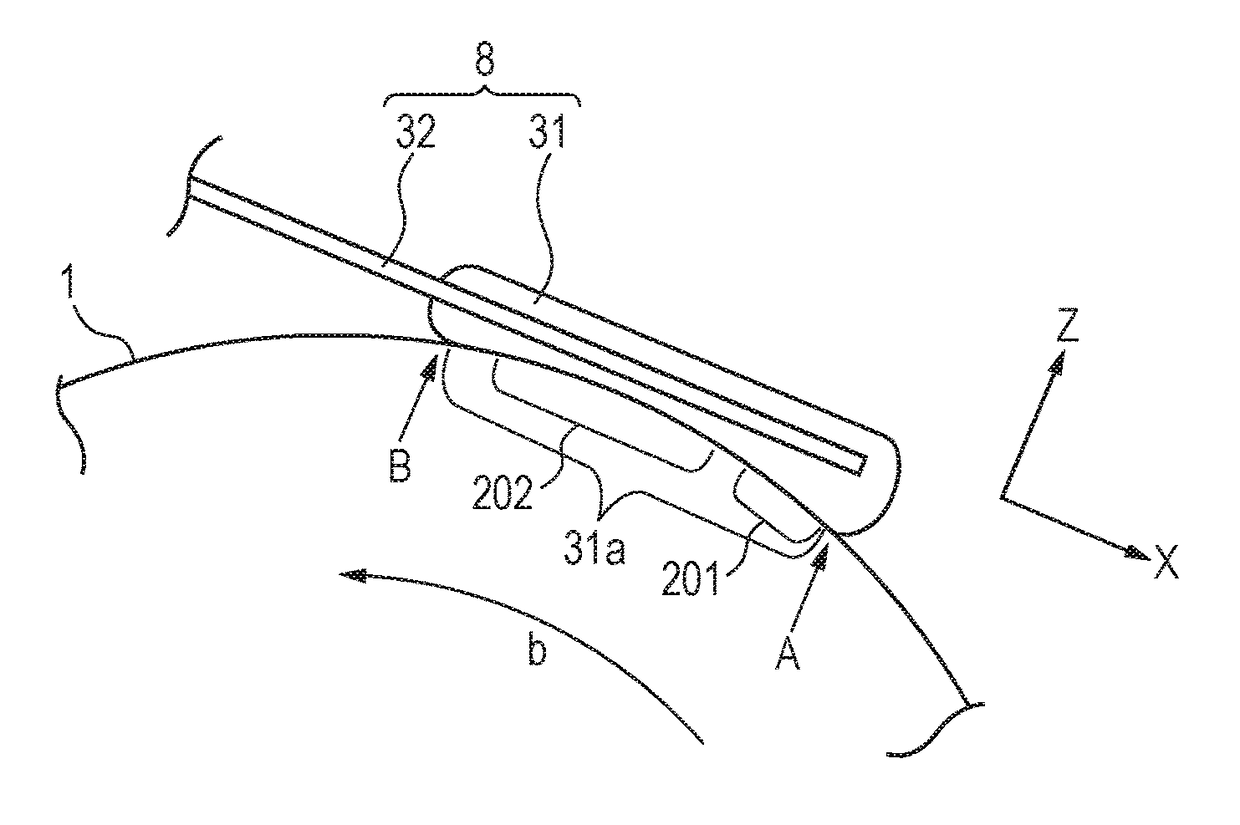

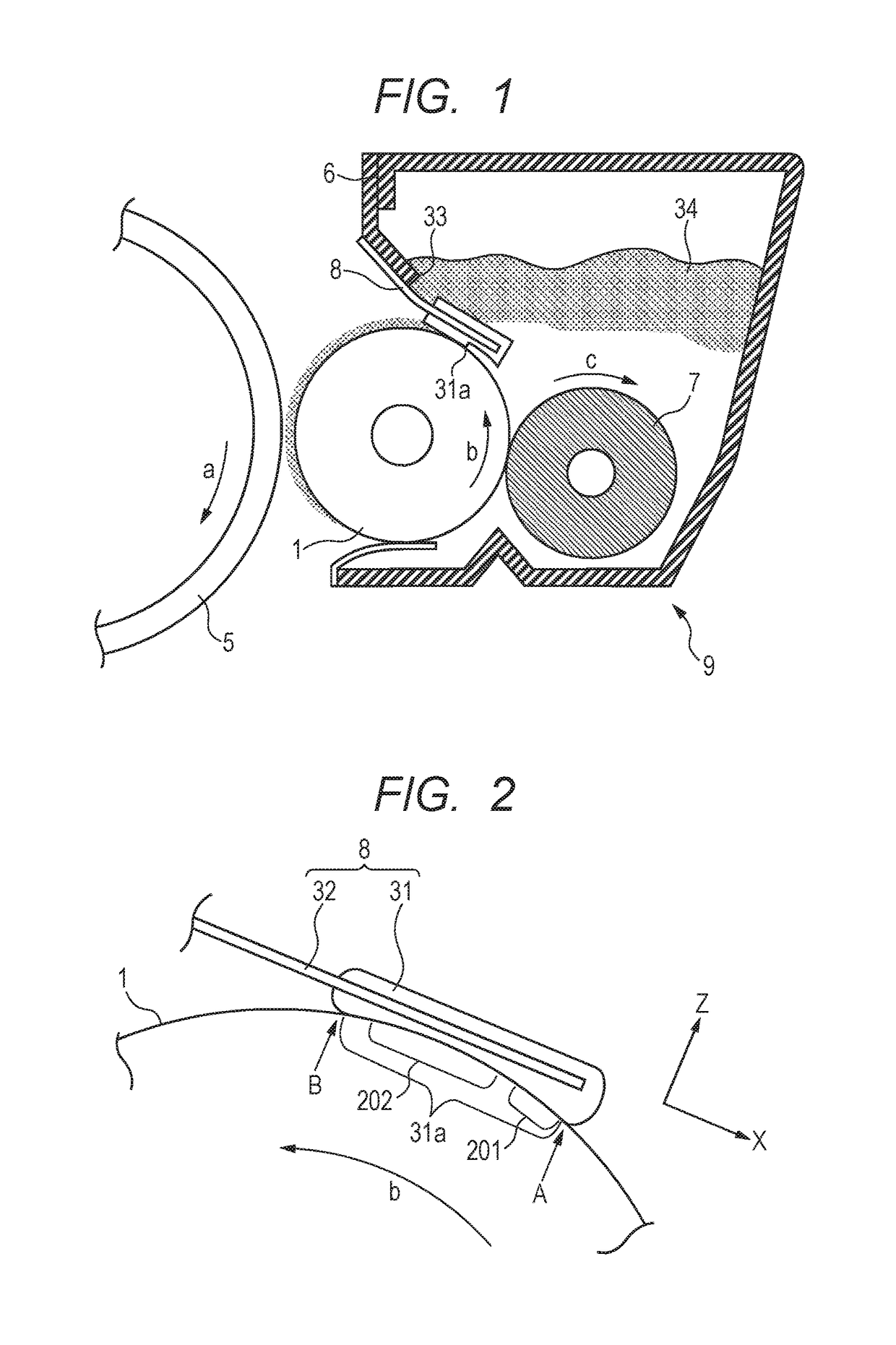

Developing apparatus, process cartridge and electrophotographic image forming apparatus

ActiveUS9989883B2Avoid distractionImage degradationElectrographic process apparatusEngineeringMechanical engineering

Owner:CANON KK

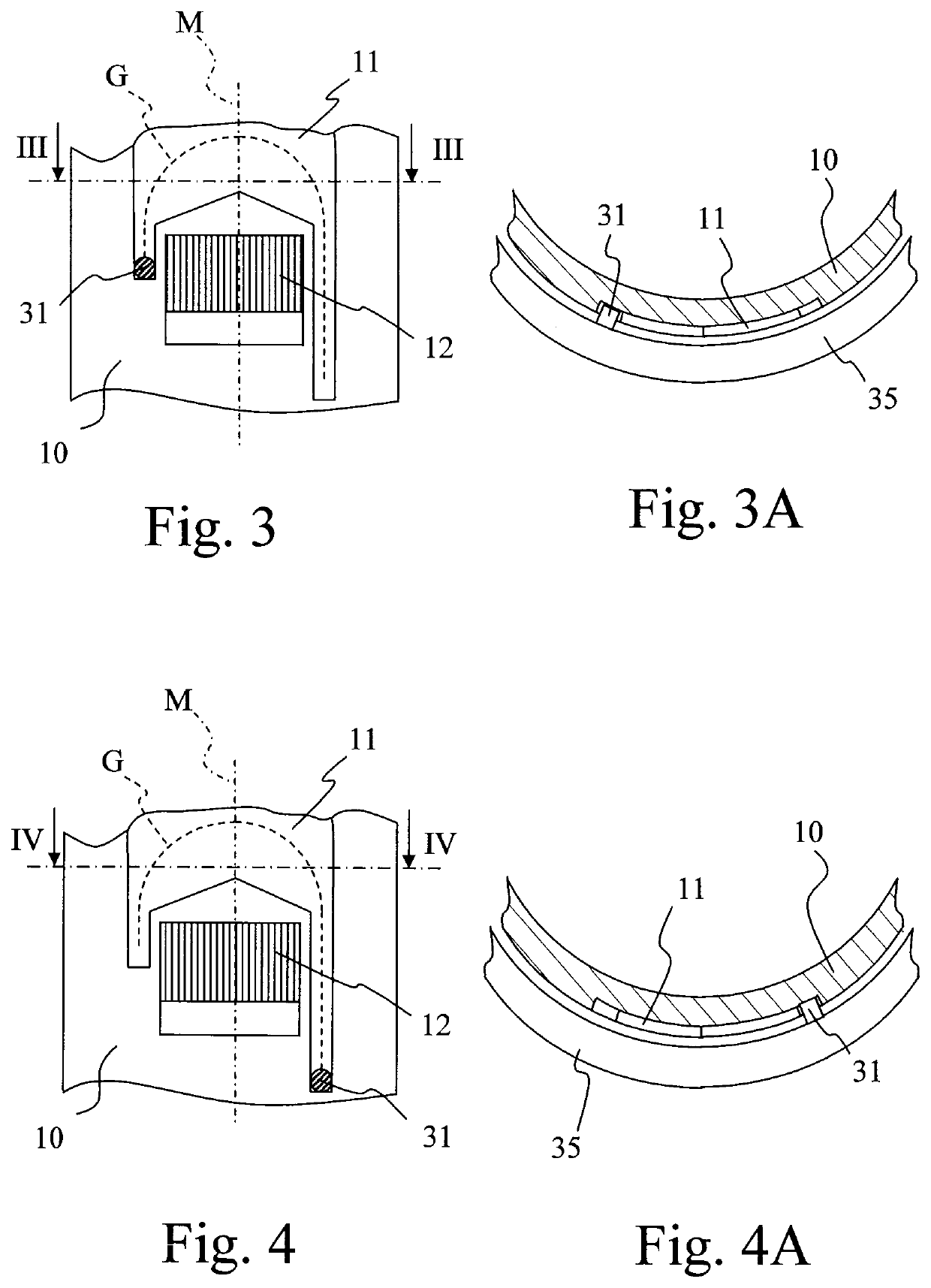

Feeding dispenser for animal breeding with improved adjustment of the feed level

An automatic feeding dispenser (100) for poultry breeding is described, comprising in general a cylindrical feed supply conduit (10), an accumulation tray (20) to supply the feed to poultry and a shutter (30) having at least one cylindrical portion (35), outer sliding and rotatable with respect to the supply conduit (10). The cylindrical portion (35) of the shutter (30) and the cylindrical supply conduit (10) are coupled and free to slide between one another by means of a protuberance (231, 31) engaged in a groove (11, 211). The groove (11, 211) is shaped to provide two bearing seats at different heights, respectively an upper height and a lower height. The upper bearing seat of the two bearing seats is defined by a bump (215) that can be surmounted by the protuberance (231, 31) by elastic deformation of part of the cylindrical supply conduit (10) and / or part of the cylindrical portion (35) of the shutter (30) following an upward or downward thrust exerted on the shutter (30) with force sufficient to exceed the elastic reaction of part of the cylindrical supply conduit (10) and / or part of the cylindrical portion (35) of the shutter (30).

Owner:CORTI ZOOTECNICI

A corrosion-resistant multi-coated NdFeB and its preparation process

ActiveCN106710767BAccelerated corrosionImprove wear resistanceMagnetic materialsSuperimposed coating processNichromeAlloy thin film

The invention provides corrosion-resistant multi-coating neodymium iron boron and a preparation process. The corrosion-resistant multi-coating neodymium iron boron is composed of a neodymium iron boron permanent magnet and multiple coatings arranged on the outer surface of the neodymium iron boron permanent magnet, the multiple coatings sequentially include a nickel-plated layer, a dysprosium-plated aluminum alloy thin film layer and a nickel-chromium composite coating, thickness of the nickel-plated layer is 10-15um, thickness of the dysprosium-plated aluminum alloy thin film layer is 10-20um, and thickness of the nickel-chromium composite coating is 6-10um; modification of the multiple coatings can be realized on the surface of the permanent magnet, binding strength between the coatings and a permanent magnet base is guaranteed, the defect that the coatings are thin and poor in corrosion resistance and wear resistance caused by single process is overcome, and the corrosion-resistant multi-coating neodymium iron boron prepared by the process has high corrosion resistance and wear resistance.

Owner:宁波元辰新材料有限公司

A printed pixel bank structure and its preparation method

ActiveCN106601774BPrevent overflowAvoid short circuit problemsDuplicating/marking methodsSolid-state devicesEngineeringMaterials science

The present invention discloses a printing pixel Bank structure and its preparation method. The pixel Bank structure includes substrates, pixel electrodes, and pixel banks from the bottom to top.At least three layers of bank liquid liquid increased from bottom to top, and the liquid liquid decreased from bottom to top.The present invention uses a Bank layer stacking with at least three layers of different pro -liquid liquids to form a pixel BANK. Through the design of multi -layer Bank layer, a multi -liquid liquid characteristics can be formed., Effectively regulate the uniformity of different print layers.

Owner:武汉国创科光电装备有限公司

A kind of preparation method of nanostructure composite ultrafiltration membrane

ActiveCN107081078BReduce usageEmission reductionUltrafiltrationWater/sewage treatment bu osmosis/dialysisFiberFiltration membrane

The invention discloses a new method for preparing a nanometer-structure composite ultra-filtration membrane. According to the new method, in the prior art, the defect that the interception adsorption performance of an electro-spinning fiber membrane is low is overcome. The new method in the technical scheme includes the following steps that (1) polymer materials are dissolved in a solvent to be prepared into an electrostatic spinning solution for preparing a fiber membrane, and the fiber membrane serves as a base layer of the composite membrane; (2) a hydrophilic polymer is dissolved in the solvent, then a plasticizer and a pore-forming agent are added into the mixture, the mixture is heated, dissolved, subjected to standing and defoamed, a coating solution is formed, and the base layer is coated with the coating solution; (3) when the coating solution is gelatinous, porous functional materials are evenly sprayed and pressed to the surface of the base layer with the air-spraying-pressing method. The nanometer-structure composite membrane is prepared with the soaking-pore-opening method, and using of a traditional chemical cross-linking agent is avoided; the new method is simple in preparing process, and has the high adsorption capacity for organic pollutants, heavy metal ions and the like.

Owner:CHANGZHOU UNIV

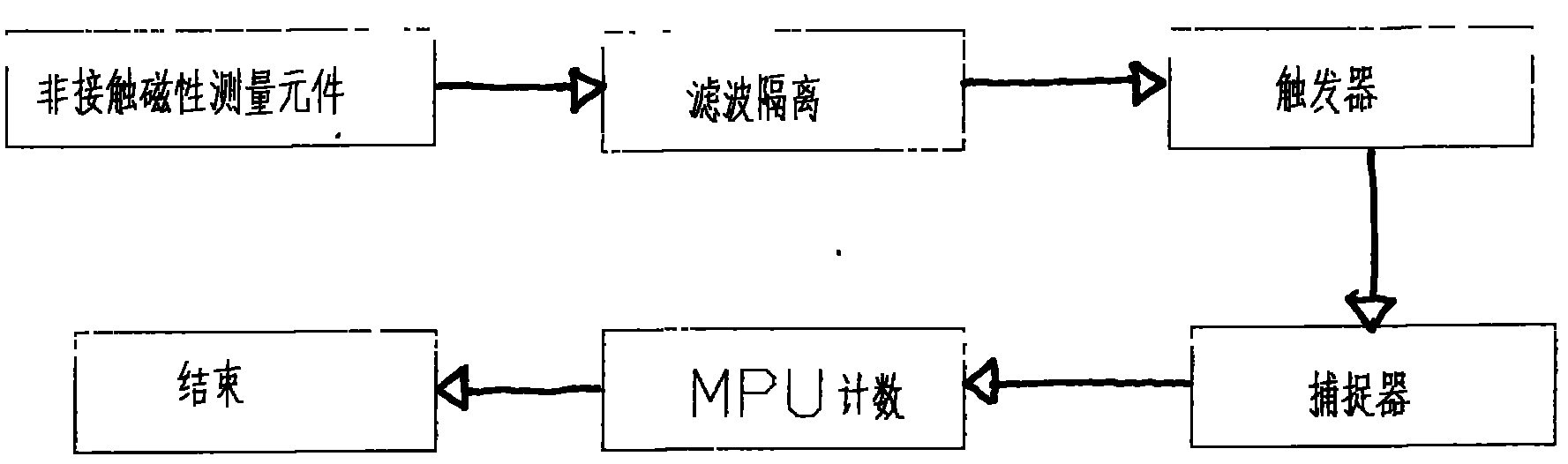

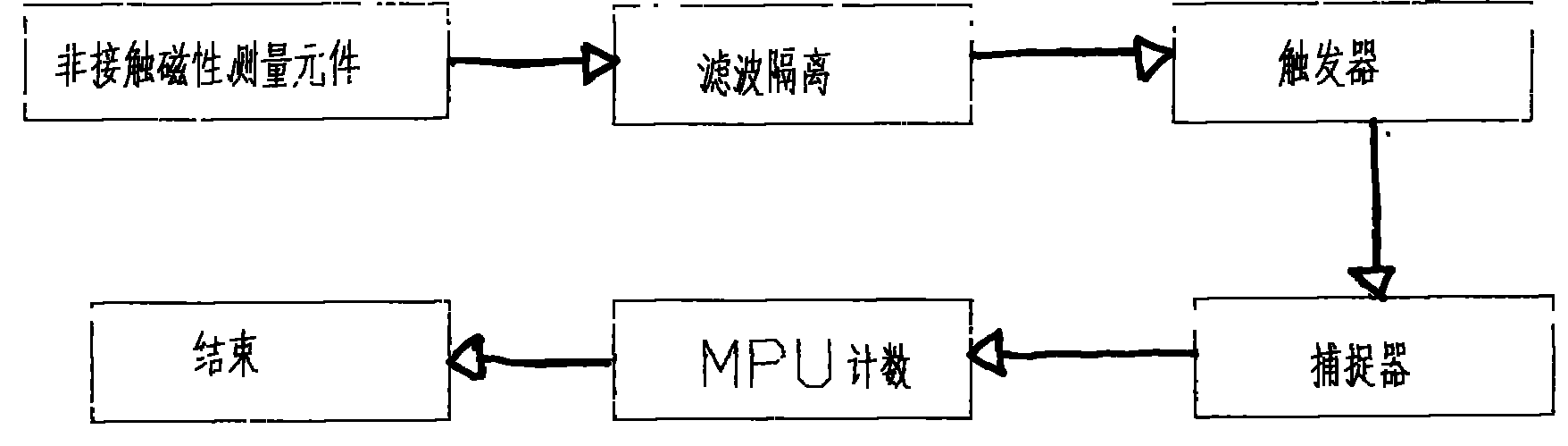

Non-contact magnetic measuring element

InactiveCN102043066ARegulation uniformityEnsure consistencyLinear/angular speed measurementControl systemEngineering

The invention discloses a non-contact magnetic measuring element, which relates to a detection control system. The technical scheme of the non-contact magnetic measuring element is as follows: the non-contact magnetic measuring element measures electrical pulse signals formed by the running of a fan blade; then the electrical pulse signals are subject to filtering isolation and pass through a trigger and a catcher; and finally, the processed electrical pulse signals are output to an MPU (micro processing unit) system to count, thereby obtaining the revolving speed value of the fan blade. The non-contact magnetic measuring element provided by the invention has the beneficial effects that because of adopting the technical scheme, the measuring element can measure the revolving speed value of the fan blade, and control the uniformity of a temperature field, thereby guaranteeing the consistency of temperatures of hatching eggs and the birth rate of the hatching eggs.

Owner:蚌埠市双利电器有限责任公司

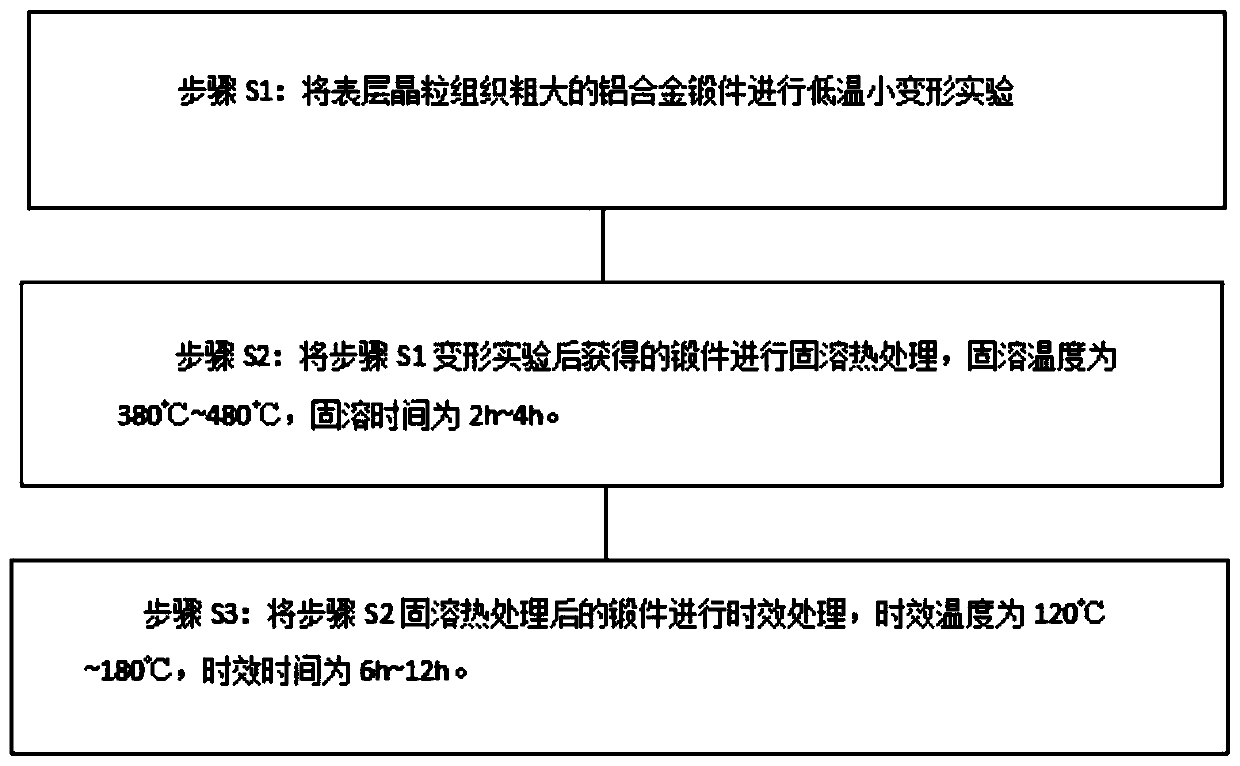

A Method for Regulating the Uniformity of Grain Structure of Aluminum Alloy Forgings

The invention provides a method for regulating and controlling the grain structure uniformity of an aluminum alloy forge piece. The method comprises the following steps of S1, carrying out a low-temperature small deformation experiment on the aluminum alloy forge piece with a thick surface layer grain structure; S2, carrying out solid solution heat treatment on the forge piece obtained after the deformation experiment in the step S1, wherein the solid solution temperature is 380 DEG C-480 DEG C, and the solid solution time is 2 h-4 h; and S3, carrying out aging treatment on the forge piece subjected to the solid solution heat treatment in the step S2, wherein the aging temperature is 120 DEG C-180 DEG C, and the aging time is 6 h-12 h. According to the method, the purpose of regulating andcontrolling the grain structure uniformity of the aluminum alloy forge piece is achieved by using the low temperature and the small deformation, and a novel technology is provided for improving the quality of the aluminum alloy forge piece.

Owner:CANGZHOU DONSHENG METAL ADDING AGENT MFG

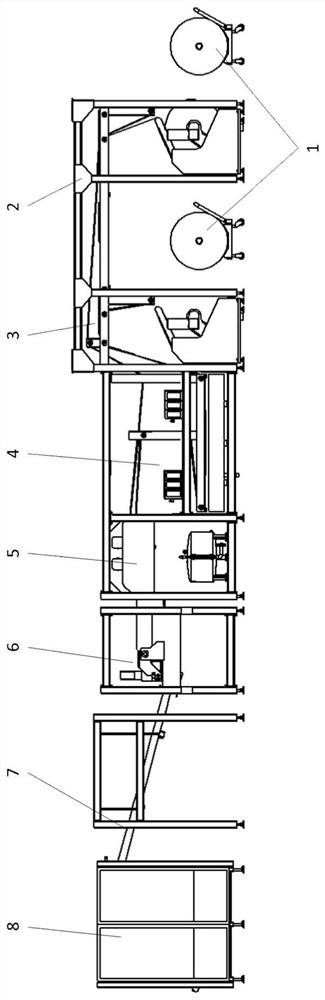

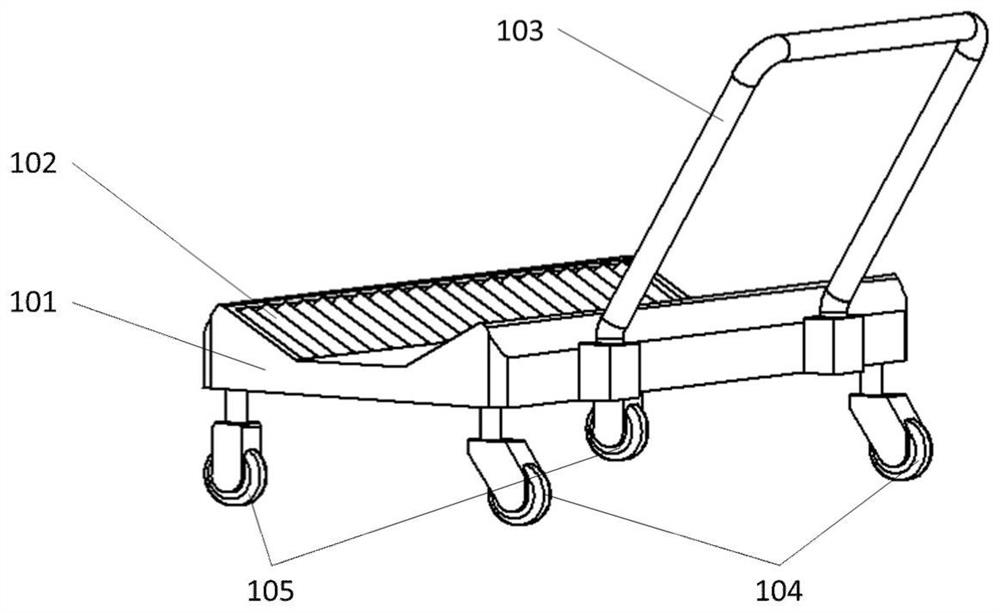

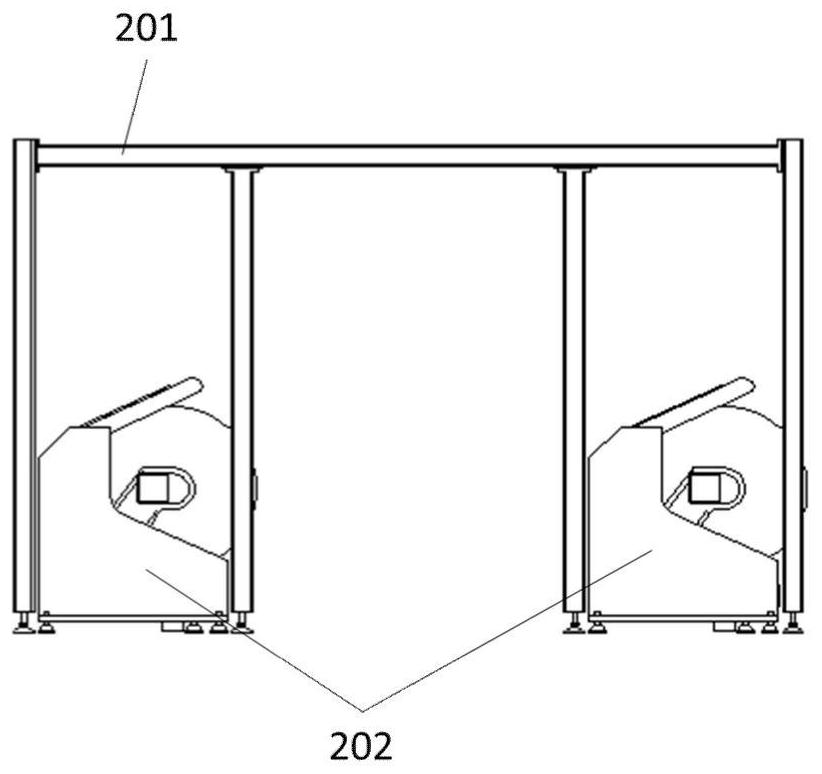

Roll type strip filamentation system

ActiveCN114652002AImprove machinabilityLength regulationTobacco preparationTobacco treatmentEngineeringMoisture regain

The invention provides a roll-type strip filamentation system. The roll-type strip filamentation system is characterized by comprising a feeding trolley for transferring strip rolls; the unwinding machine is connected with the feeding trolley in a matched mode and controls the strip coil to unwind the strip; the threading mechanism is connected with the unreeling machine in a matched mode and controls threading of the strip; the traction mechanism is connected with the threading mechanism in a matched mode and controls the strip to move; the moisture regaining and / or feeding mechanism is used for regaining moisture and feeding the front and back surfaces of the strip during traction; the fixed-width slitting mechanism is connected with the traction mechanism in a matched mode and controls the strips to be slit into tows in a fixed-width mode; the tow gathering mechanism is connected with the fixed-width slitting mechanism in a matched mode and controls gathering of the fixed-width slitting tows; the fixed-length slitting mechanism is connected with the tow gathering mechanism in a matched mode and controls the tows to be slit into tow sections in a fixed-length mode. Double-sided moisture regaining and / or feeding, fixed-width slitting, tow gathering and fixed-length slitting into tow sections with the width of 0.5 mm are completed, and the filling rate and sensory quality of cigarettes are improved.

Owner:云南烟草机械有限责任公司 +1

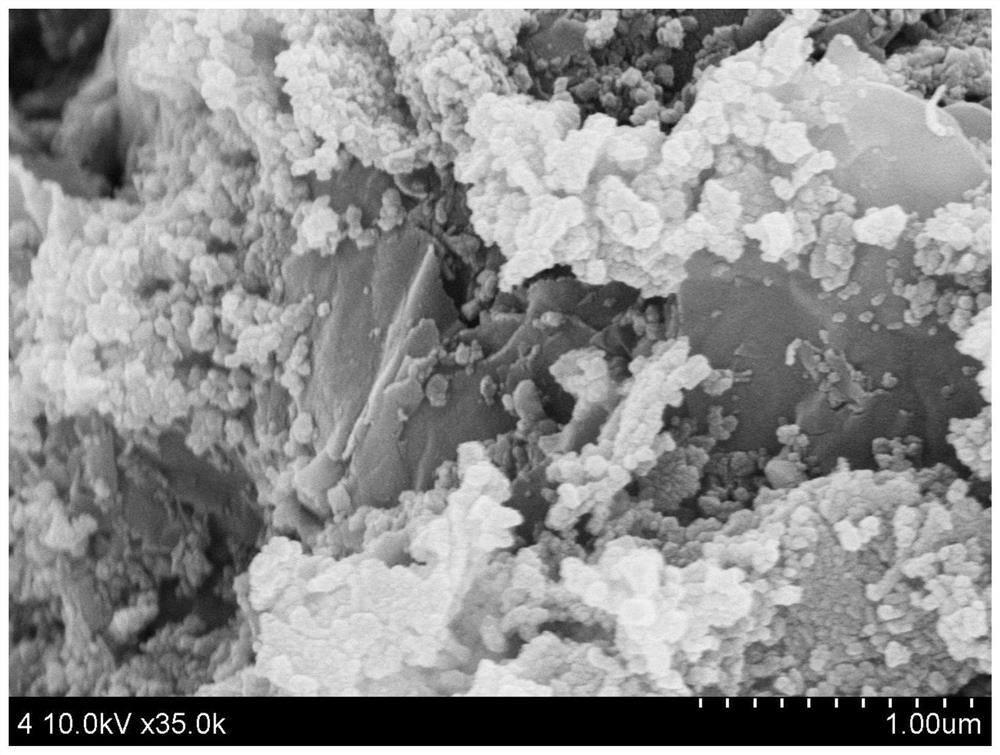

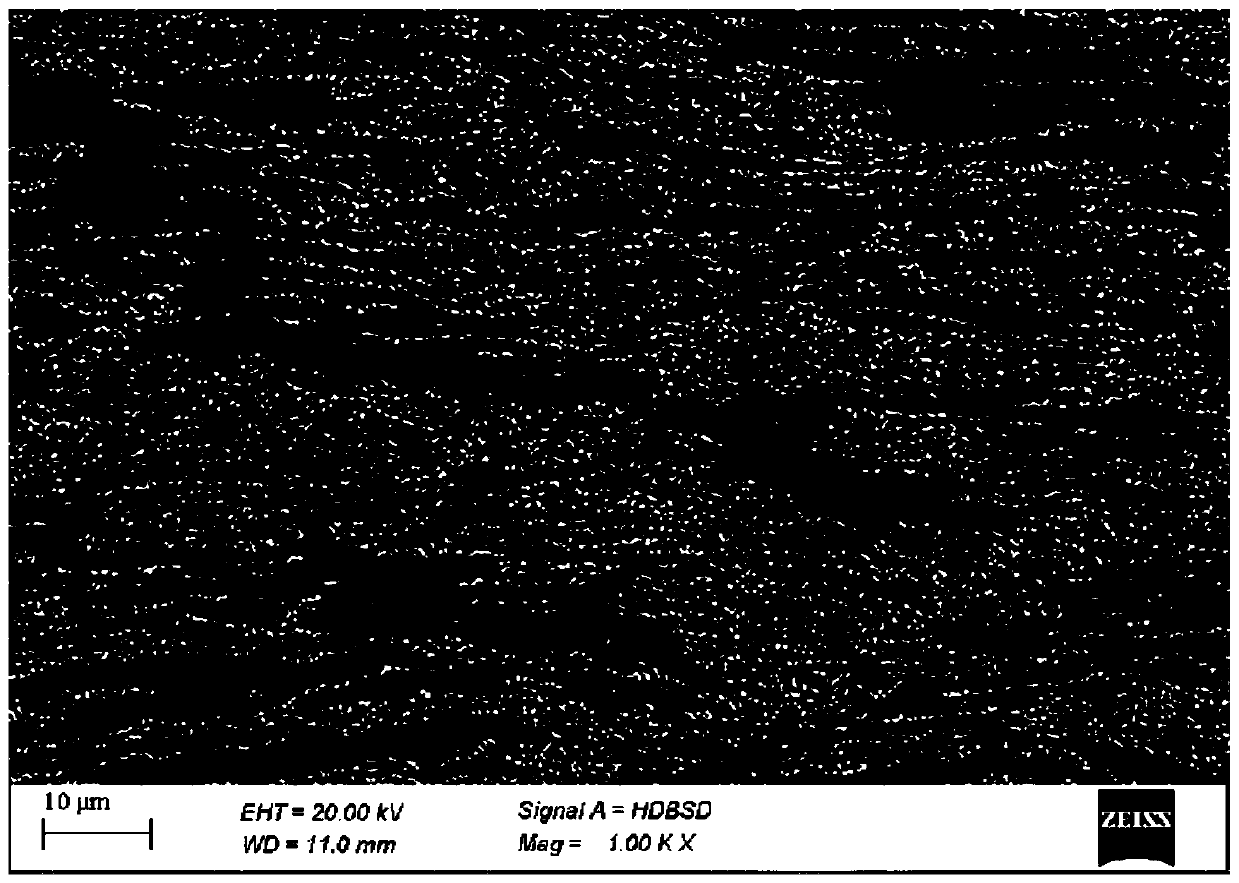

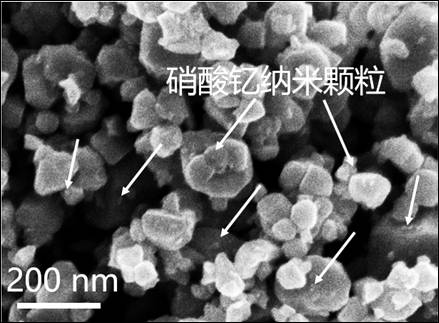

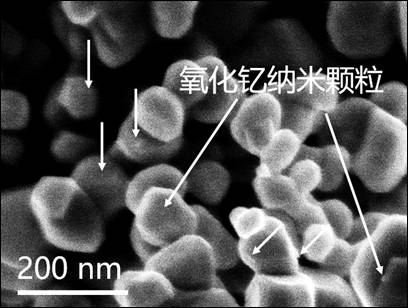

Nano tungsten powder doped with metal oxide nanoparticles and preparation method thereof

ActiveCN112222420BIncrease nucleation rateGranularityTransportation and packagingMetal-working apparatusMetal oxide nanoparticlesCarbon Nanoparticles

The invention discloses a method for preparing nano-tungsten powder doped with metal oxide nanoparticles. The method comprises: 1. dispersing tungsten trioxide or blue tungsten and drying to obtain pretreated tungsten source powder; 2. oxidizing the metal The ultrafine / nano-droplets obtained by ultrasonic atomization of the aqueous solution of the precursor salt of the substance are sprayed on the pretreated tungsten source powder to obtain the doped tungsten source powder; 3. The doped tungsten source powder is mixed with carbon nanoparticles and then heated and kept warm The pre-reduction powder is obtained; 4. The pre-reduction powder is reduced by hydrogen to obtain nano-tungsten powder doped with metal oxide nanoparticles; the invention also discloses the nano-tungsten powder doped with metal oxide nanoparticles prepared by the above method. In the present invention, carbon nanoparticles and doped metal oxide nanoparticles are used respectively to increase the nucleation rate of the corresponding reduction products, refine the particle size of the corresponding reduction products, and realize the control of the particle size of the metal oxide nanoparticles and tungsten powder , to obtain nano-tungsten powder uniformly doped with metal oxide nanoparticles.

Owner:西安稀有金属材料研究院有限公司

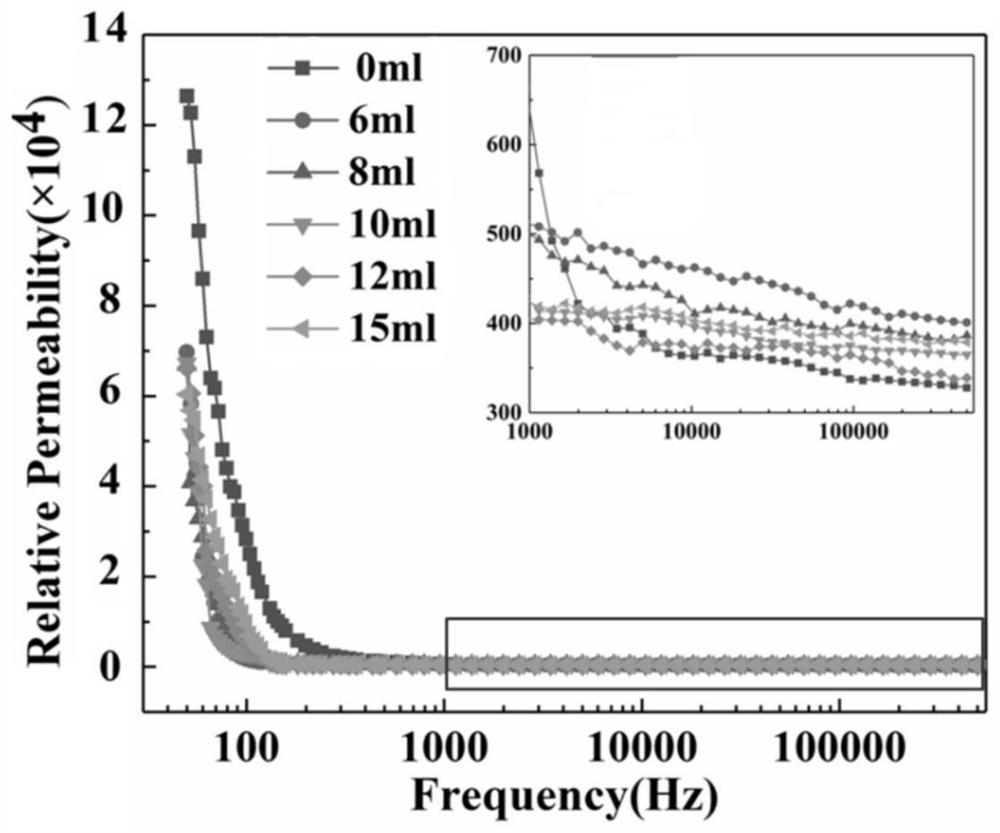

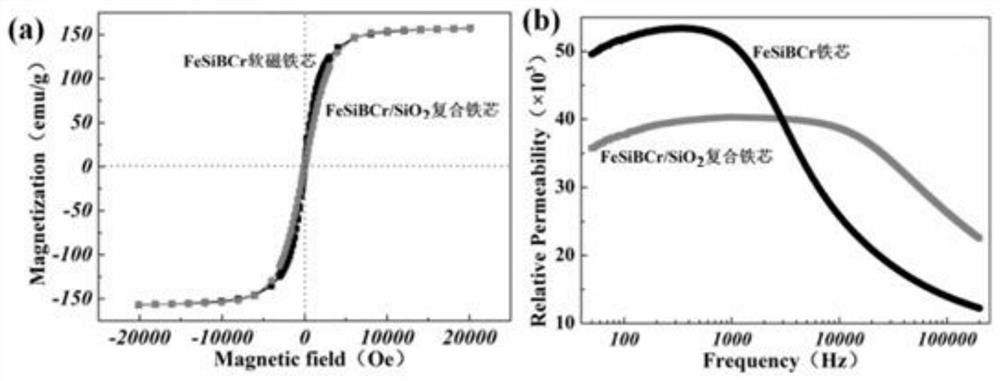

A fesibcr/sio 2 Preparation method of nanocrystalline soft magnetic composite iron core

ActiveCN110767441BRealize the structure ideaCoated evenlyTransportation and packagingMetal-working apparatusSilanesHigh resistivity

The invention provides a FeSiBCr / SiO 2 The invention discloses a method for preparing a nanocrystalline soft magnetic composite iron core, which belongs to the technical field of powder metallurgy and soft magnetic materials. Firstly, the FeSiBCr amorphous powder with a purity of 99.0wt.% or more is used as the raw material, and the surface of the FeSiBCr amorphous powder particles is modified by using a silane coupling agent to improve the surface activity of the FeSiBCr amorphous particles, followed by chemical liquid phase in-situ deposition Process coated SiO on the surface of FeSiBCr magnetic particles 2 Insulating shell layer, combined with hot pressing and sintering, and stress relief annealing to prepare FeSiBCr / SiO with interparticle insulation 2 Nanocrystalline soft magnetic composite iron core. FeSiBCr / SiO prepared by the present invention 2 Nanocrystalline soft magnetic composite iron core exhibits excellent electromagnetic properties such as high magnetic induction, high resistivity, good frequency stability, low coercive force, and low iron loss, which can effectively fill the gap in the performance of existing soft magnetic composite materials .

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com