Roll type strip filamentation system

A strip and wire forming technology, applied in the direction of winding strip, thin material processing, tobacco, etc., can solve the problems of high knife gate pressure, difficult tobacco width consistency, uneven distribution of tobacco, etc., to meet the moisture content and Feeding requirements, improve filling rate and sensory quality, silk quality and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0149] The present invention will be further described below with reference to the accompanying drawings.

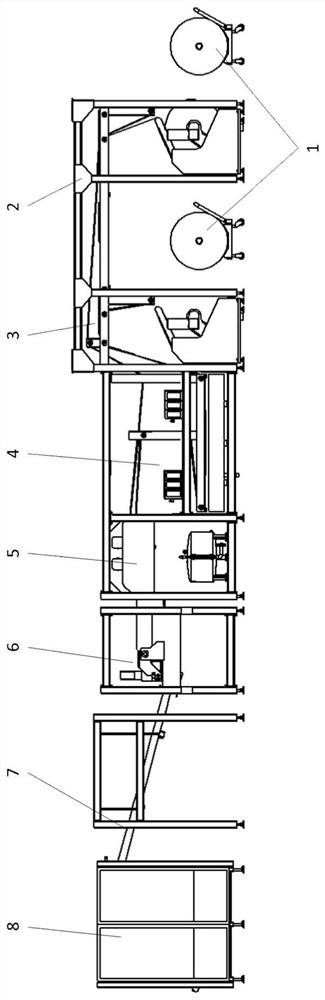

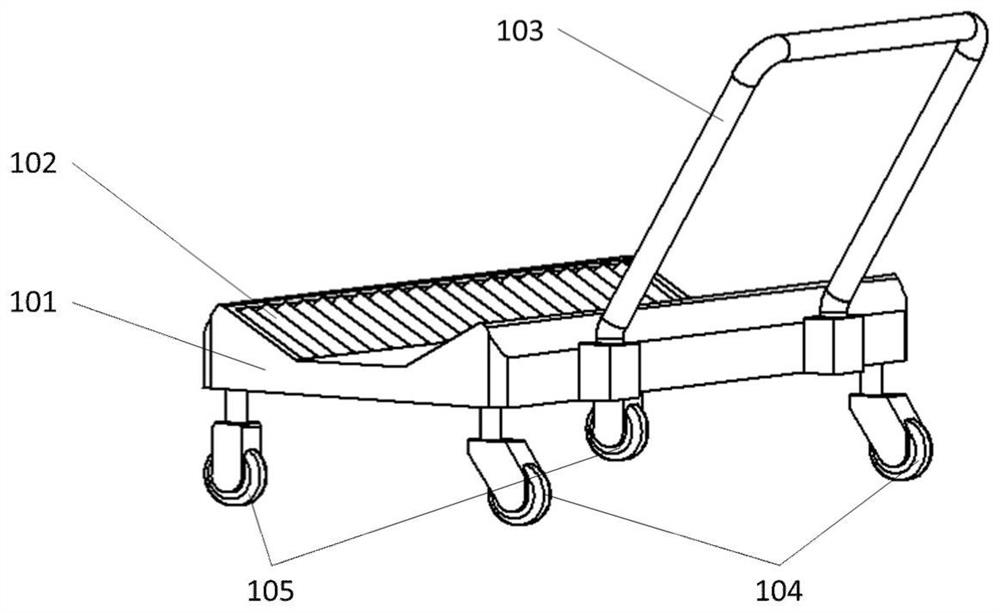

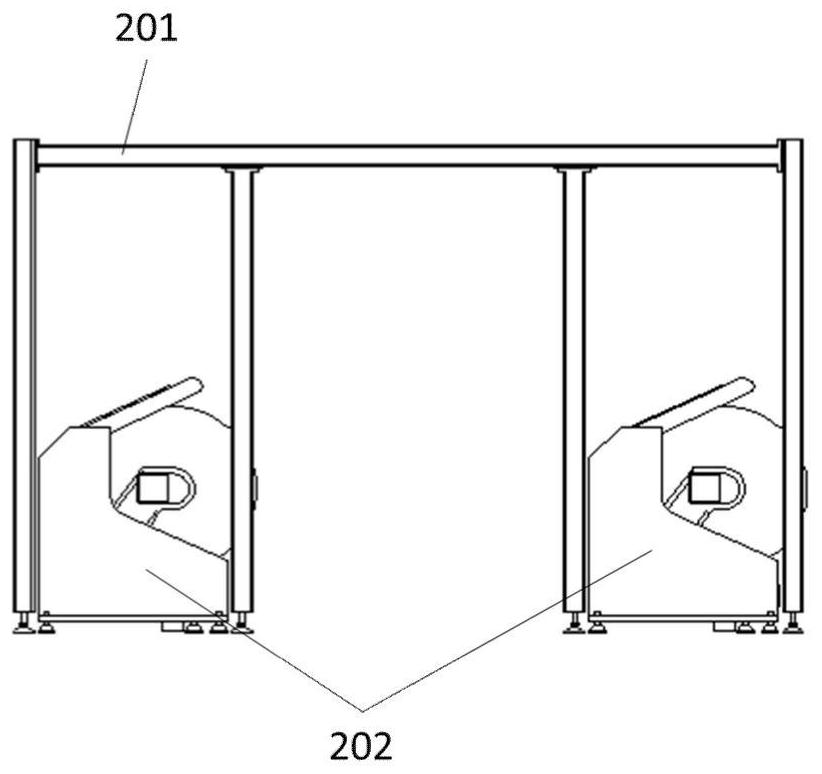

[0150] The invention provides a coil-type strip wire-forming system, which includes a feeding trolley 1 for transferring the strip roll; an unwinding machine 2 matched with the feeding trolley 1 and operating the strip roll to unwind the strip; and the unwinding machine 2. The threading mechanism 3 which is matched and controls the threading of the strip; the traction mechanism 5 which is matched with the threading mechanism 3 and controls the movement of the strip; / or feeding mechanism 4; fixed-width slitting mechanism 6 matched with the traction mechanism 5, which operates the fixed-width slitting of the strip into tows; matched with the fixed-width slitting mechanism 6, operates the fixed-width slitting tow The gathered tow gathering mechanism 7; the fixed-length slitting mechanism 8 that is matched with the tow gathering mechanism 7 and controls the tow to be cut t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com