Atomic layer deposition equipment and process method

A technology of atomic layer deposition and equipment, which is applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of poor deposition uniformity of the substrate, a large amount of precursors, and precursor disturbances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The same symbols represent components or devices with the same or similar functions.

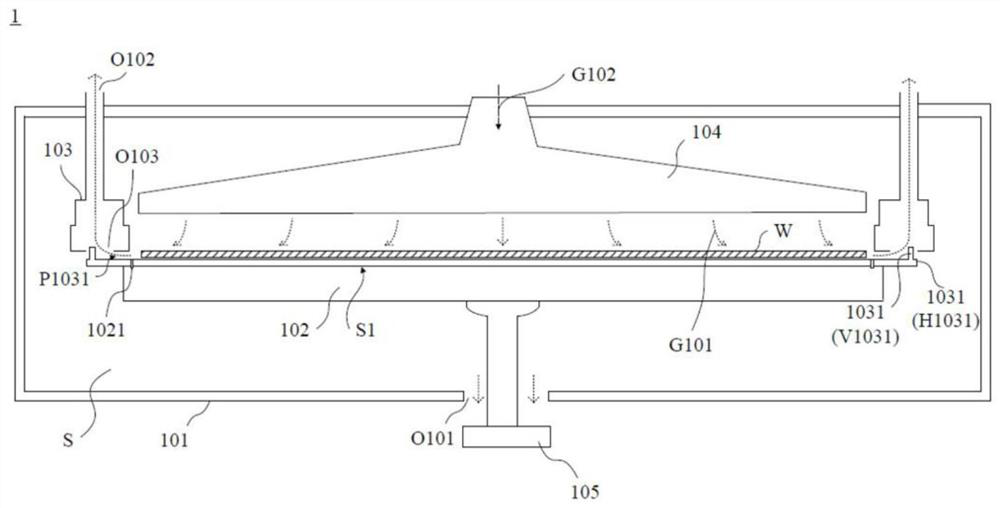

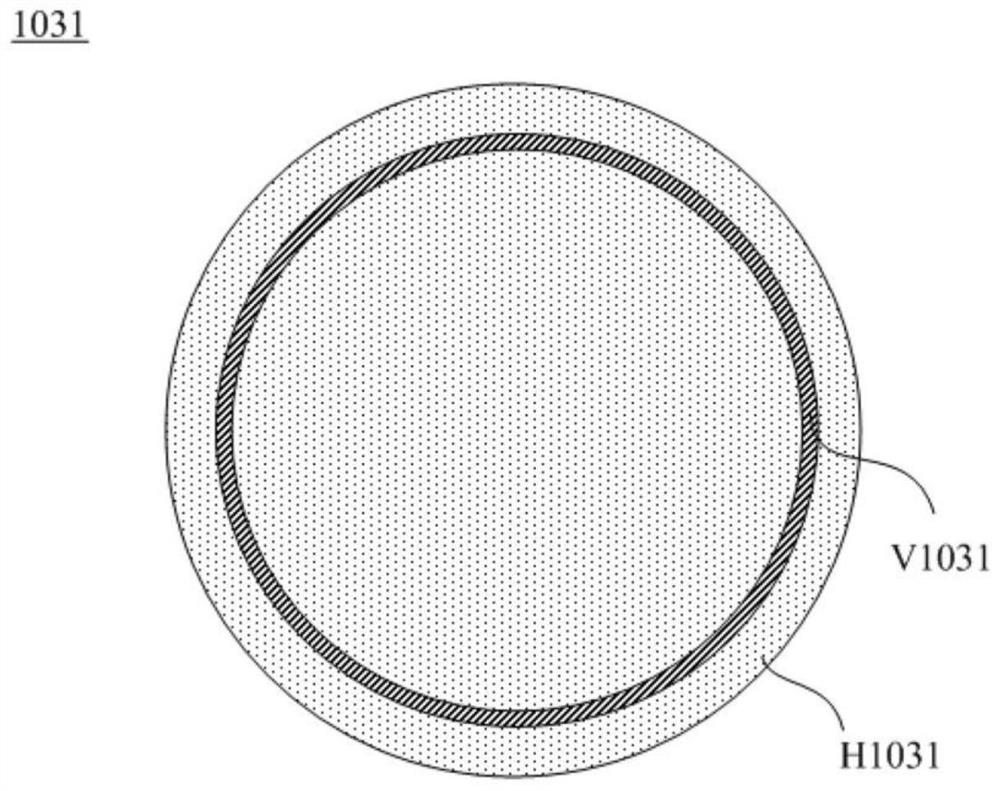

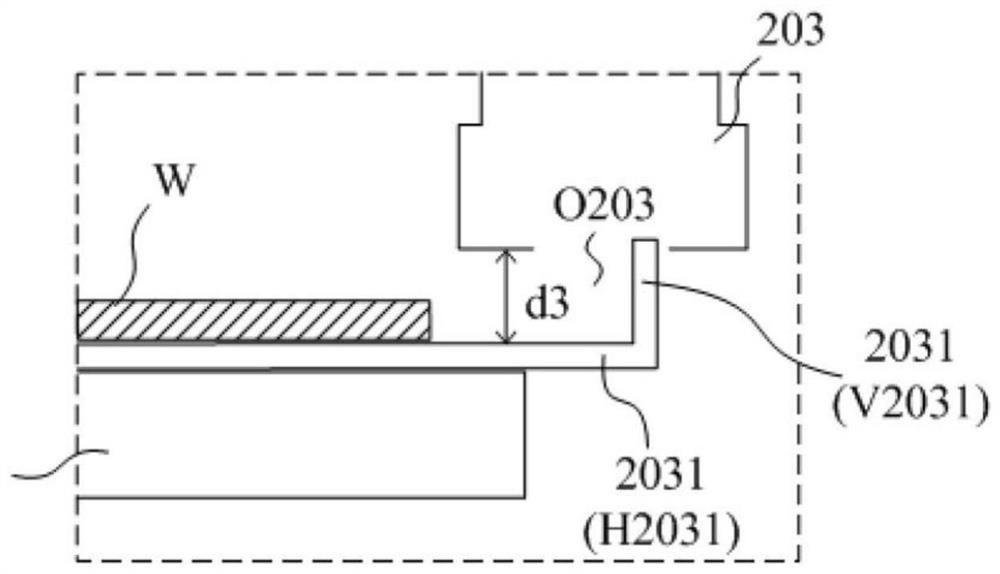

[0025] The invention provides an atomic layer deposition equipment and an atomic layer deposition process method using the same. In addition to the bottom pumping port connected to the chamber, the atomic layer deposition equipment can also form an upper pumping path through the hollow part and the carrier plate to guide the excess precursor to be drawn out of the chamber, which is different from the existing The deposition equipment of the technology can only pump out the excess precursor through the bottom suction port. Through the structural design of the carrier plate, the excess precursor can form a stable and slow air flow, so that the substrate can be uniformly deposited by the precursor.

[0026] The first distance between the hollow part and the car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com