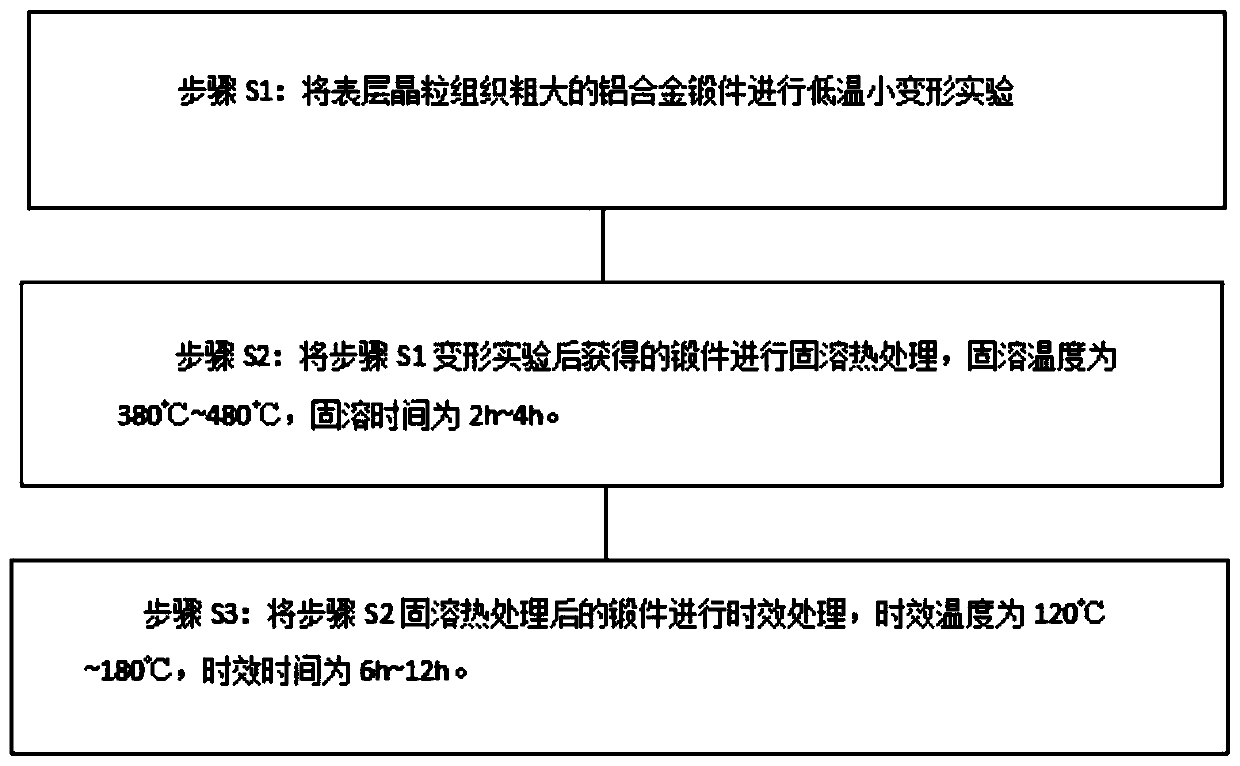

A Method for Regulating the Uniformity of Grain Structure of Aluminum Alloy Forgings

A technology with uniform structure and aluminum alloy, which is applied in the field of forging to achieve the effects of grain refinement, control of uniformity of grain structure, and consistent grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0051] The present invention is a method for controlling the grain structure uniformity of aluminum alloy forgings with low temperature and small deformation. In all the following examples, 7050 aluminum alloy forgings are selected as objects, and its chemical composition is shown in Table 1.

[0052] Table 1 Alloy composition (wt.%) of the material 7050 aluminum alloy used in Example 1 of the present invention

[0053] Al Zn Mg Cu Si Fe Cr mn 86.11 6.5 4.68 1.66 0.368 0.288 0.262 0.089

[0054] Step S1: The aluminum alloy forging with uneven deformation structure is subjected to small deformation at low temperature. The structure of the aluminum alloy forging is as follows figure 2 As shown, the deformation parameters are: the deformation amount is 30%, the deformation temperature is 150°C, and the deformation speed is 0.1s -1 , the uneven structure of aluminum alloy forgings such as Figure 3a and Figure 3b as shown, Figure 3a It i...

specific Embodiment 2

[0061] The present invention is a method for controlling the grain structure uniformity of aluminum alloy forgings with low temperature and small deformation. In all the following examples, 7050 aluminum alloy forgings are selected as objects, and its chemical composition is shown in Table 2.

[0062] Table 2 Alloy composition (wt.%) of the material 7050 aluminum alloy used in Example 2 of the present invention

[0063] Al Zn Mg Cu Si Fe Cr mn 86.11 6.5 4.68 1.66 0.368 0.288 0.262 0.089

[0064] Step S1: The aluminum alloy forging with uneven deformation structure is subjected to low-temperature small deformation, and the deformation parameters are: the deformation amount is 20%, the deformation temperature is 250°C, and the deformation speed is 1s -1 ; The uneven structure of aluminum alloy forgings such as figure 2 As shown, the microstructure of the aluminum alloy forging after step S1 is as follows Figure 6a and Figure 6b as shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com