Nano tungsten powder doped with metal oxide nanoparticles and preparation method thereof

A nano-particle and nano-tungsten powder technology, applied in metal processing equipment, nanotechnology, transportation and packaging, etc., can solve the problems of difficult to meet commercial application, difficult process control, many influencing factors, etc., to improve the nucleation rate, The effect of improving uniformity and refining particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment includes the following steps:

[0029] Step 1. The nanocrystalline tungsten trioxide with a mass purity of 99.9% is crushed and dispersed by ball milling with the assistance of ethanol and dispersant PEG-1000, and the pretreated tungsten source powder is obtained after drying; the average crystallinity of the nanocrystalline tungsten trioxide is The particles are smaller than 100nm, and the specific surface area is 7.5g / cm 3 , the addition of the ethanol is 60% of the quality of nanocrystalline tungsten trioxide, the addition of the dispersant PEG-1000 is 0.5% of the quality of nanocrystalline tungsten trioxide; , the time is 6h;

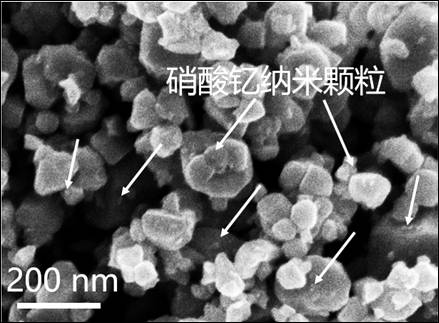

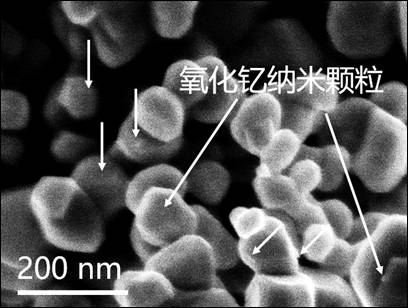

[0030] Step 2: ultrasonically atomize the aqueous solution of yttrium nitrate to obtain ultrafine / nano droplets, and then evenly spray the ultrafine / nano droplets on the pretreated tungsten source powder obtained in step 1, and obtain after drying Doped tungsten source powder; the concentration of the aqueous solution of ytt...

Embodiment 2

[0036] This embodiment includes the following steps:

[0037] Step 1. The nanocrystalline tungsten trioxide with a mass purity of 99.95% is crushed and dispersed by ball milling with the assistance of ethanol and dispersant PEG-1000, and the pretreated tungsten source powder is obtained after drying; the average crystallinity of the nanocrystalline tungsten trioxide is The particles are smaller than 80nm, and the specific surface area is 7.5g / cm 3 , the addition of the ethanol is 60% of the mass of nanocrystalline tungsten trioxide, the addition of the dispersant PEG-1000 is 0.3% of the mass of nanocrystalline tungsten trioxide; , the time is 2h;

[0038] Step 2: ultrasonically atomize the aqueous solution of yttrium nitrate to obtain ultrafine / nano droplets, and then evenly spray the ultrafine / nano droplets on the pretreated tungsten source powder obtained in step 1, and obtain after drying Doping tungsten source powder; the concentration of the aqueous solution of yttrium ...

Embodiment 3

[0042] This embodiment includes the following steps:

[0043] Step 1. The blue tungsten with a mass purity of 99.95% is ball milled and dispersed with the assistance of ethanol and dispersant PEG-1000, and the pretreated tungsten source powder is obtained after drying; the average grain size of the blue tungsten is less than 70nm, The specific surface area is 10g / cm 3 , the addition of ethanol is 70% of the mass of blue tungsten, the addition of PEG-1000 of the dispersant is 0.5% of the mass of blue tungsten; the speed of ball milling and dispersing is 250 rpm, and the time is 4h ;

[0044] Step 2: ultrasonically atomize the aqueous solution of yttrium nitrate to obtain ultrafine / nano droplets, and then evenly spray the ultrafine / nano droplets on the pretreated tungsten source powder obtained in step 1, and obtain after drying Doping tungsten source powder; the concentration of the aqueous solution of yttrium nitrate is 0.1g / mL, and the ultrafine / nano droplets are sprayed ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com