Zinc layer trivalent chromium iridescent passivation treating fluid used under normal temperature and usage method thereof

A technology of passivation treatment and trivalent chromium, applied in the coating process of metal materials, etc., can solve the problems of rough surface of passivation film, existence of micropore defects, unfavorable repeated use, etc., and achieve good anode protection and surface compactness High, the effect of improving uniformity and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In this embodiment, the preparation method of the trivalent chromium color high-efficiency passivation treatment liquid for zinc layer at normal temperature, the steps are as follows:

[0044] First, under the condition of continuous stirring, dissolve 15-20g of chromium trichloride in part of deionized water; then, add 5-10g of sodium nitrate, 8-15g of malonic acid, 15-20g of citric acid, 5- After fully dissolving 10g of sodium dihydrogen phosphate, add 8-15g of thiourea and make it fully dissolve, heat to 50°C, add 0 or 0.8g of cerous sulfate and stir until completely dissolved, then add 0.8-1.5g of ferrous sulfate, and finally Then add the remaining amount of deionized water, and let it stand for 24 hours to get a kind of zinc layer trivalent chromium high-efficiency passivation treatment solution at room temperature, adjust the passivation treatment with 10wt% sodium hydroxide aqueous solution and 10wt% nitric acid solution The pH value of the solution was 2.2, and ...

Embodiment 2

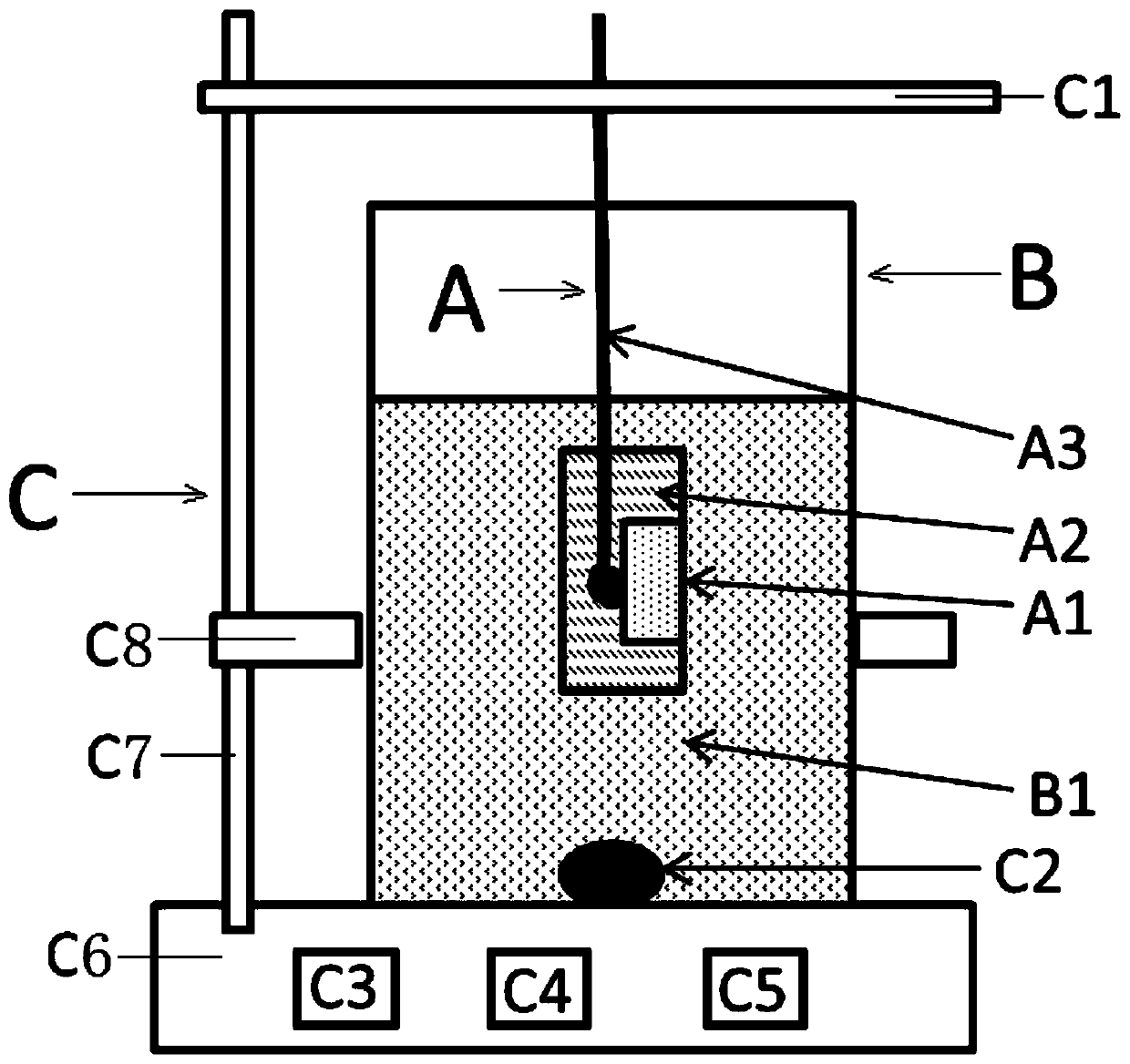

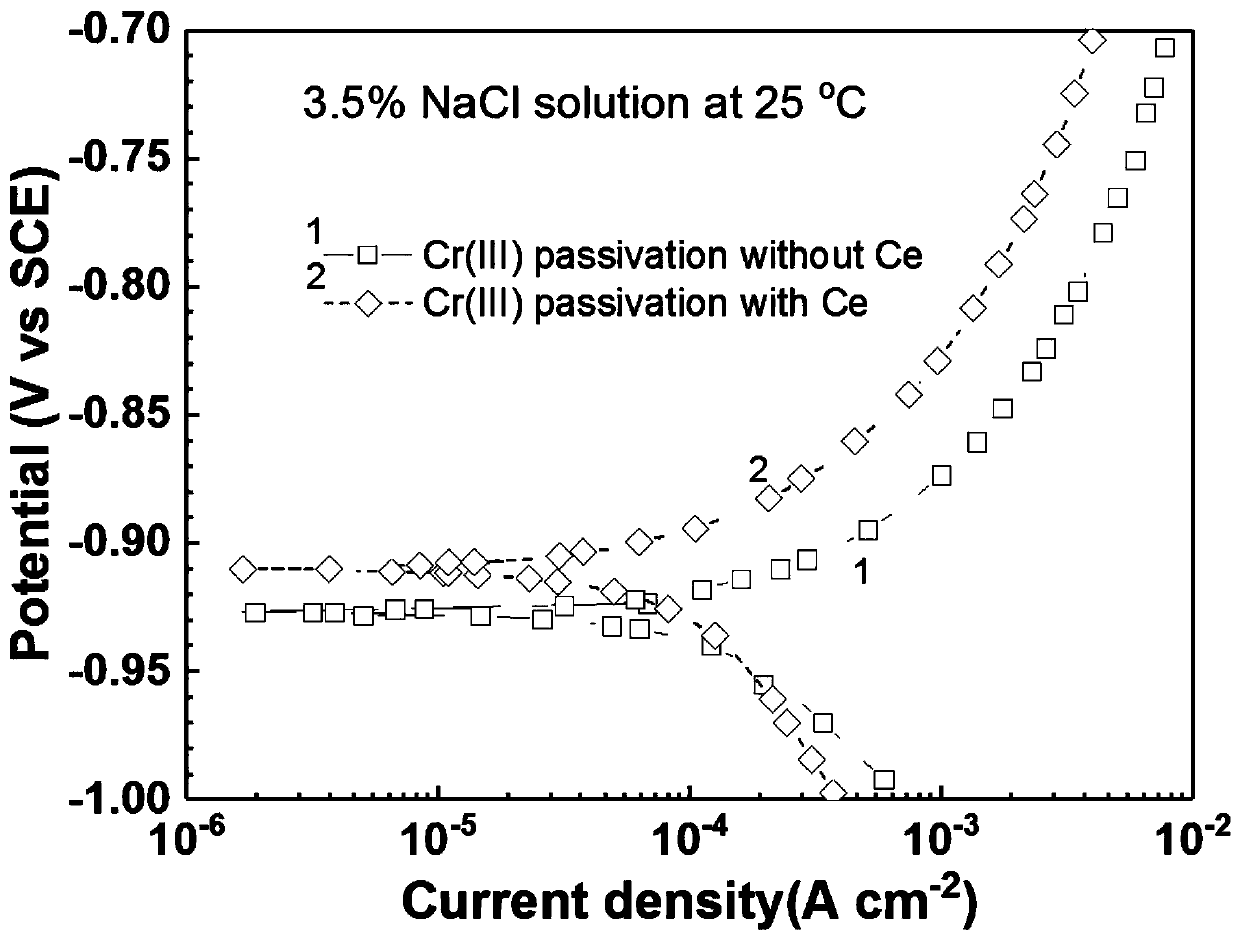

[0061] In this example, the test experiment of the electrochemical corrosion performance of the passivation layer adopts a three-electrode system. The passivation package sample A obtained in Example 1 is used as the working electrode, and the counter electrode is a 20mm×20mm×0.5mm Pt sheet, on which the The Φ0.5mm Pt lead wire is sealed and insulated with a polytetrafluoroethylene (PTFE) tube, and the reference electrode is a KCl saturated calomel electrode (SCE). Configure CHI660D Electrochemical Workstation (produced by Shanghai Chenhua Instrument Co., Ltd.), and carry out the potentiodynamic polarization curve test to the modified passivation film that the above-mentioned embodiment 1 control test obtains in the sodium chloride aqueous solution of concentration 3.5wt%, the result sees figure 2 . Before adding Ce, the corrosion current of the film layer was 5.331×10 -6 A·cm 2 , through linear fitting, the corrosion resistance is 2122Ω·cm 2 ; After adding Ce, the passiva...

Embodiment 3

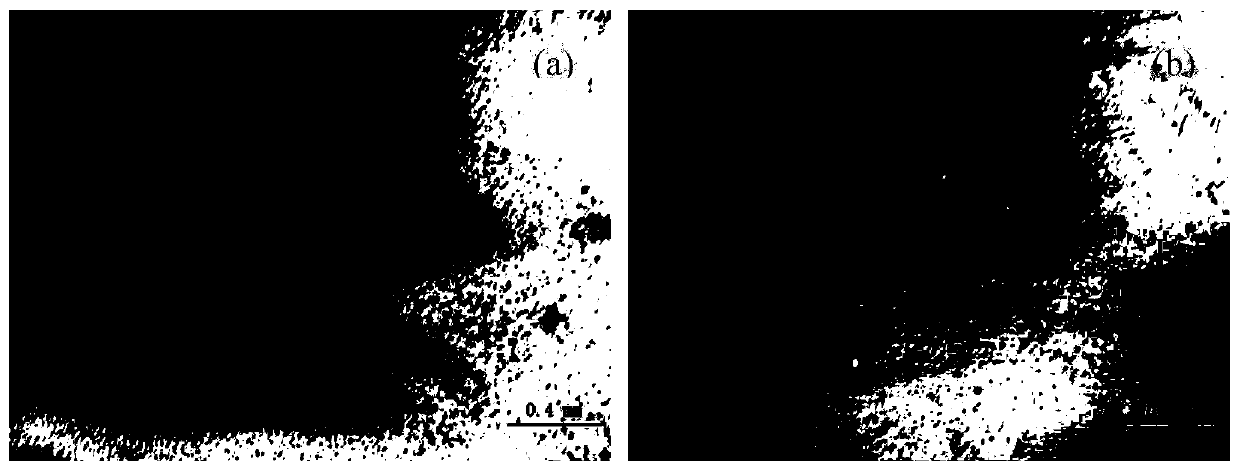

[0063] Such as image 3 (a)-(b), using OLYMPUS Z61 stereoscope to scan the surface structure of the passivation film obtained at pH 2.2, from the passivation film processed with zinc layer trivalent chromium color high-efficiency passivation treatment solution at room temperature As can be seen from the stereoscopic view of the film, compared with the passivation film obtained by non-cerium treatment in Example 1, the passivation film obtained after the surface passivation containing rare earth cerium is more uniform, and the surface of the passivation film is obviously smoother. And the porosity of the passivation film is lower. The surface porosity was calculated from the surface topography photos, and the porosity decreased from 10% to about 4% after Ce-containing treatment.

[0064] The results of the examples show that the present invention adds Ce(IV) salt to the Cr(III) green treatment solution to modify the passivation film during the normal temperature growth process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com