A corrosion-resistant multi-coated NdFeB and its preparation process

A preparation process, NdFeB technology, applied in metal material coating process, inductor/transformer/magnet manufacturing, coating and other directions, can solve the problems of poor corrosion resistance and oxidation resistance, and ensure uniformity and smoothness. degree, improve corrosion resistance, and ensure the effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

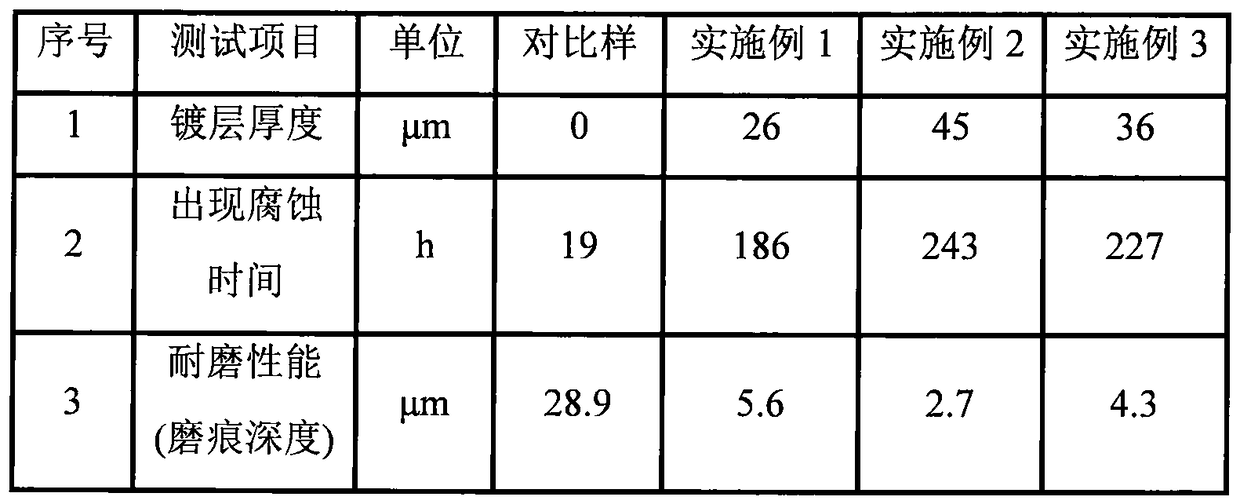

Examples

Embodiment 1

[0026] A preparation process for corrosion-resistant multi-coated NdFeB, comprising the steps of:

[0027] (1) Pretreatment, add 500ml of dilute nitric acid with a concentration of 0.5mol / L and 500ml of 0.5g / L thiourea to prepare pickling solution, place the NdFeB permanent magnet in the acid solution for cleaning for 2-3min, and then place Ultrasonic cleaning in 500mL of absolute ethanol for 1-2min, after completion, place in 500ml of 20g / L sulfosalicylic acid and 500ml of 10g / L ammonium bifluoride mixture for activation, activation time 1min, activation temperature 25°C ;

[0028] (2) Electroless nickel plating, take by weighing the 26g / L nickel sulfate hexahydrate solution of 300ml, the sodium hypophosphite solution of the 30g / L of 300ml, the borax solution of the 30g / L of 100ml, the sodium citrate of the 30g / L of 100ml solution, 100ml of 30g / L ammonium fluoride solution, and 100ml of 3g / L succinic acid solution to prepare the chemical plating solution, place the pretreate...

Embodiment 2

[0032] A preparation process for corrosion-resistant multi-coated NdFeB, comprising the steps of:

[0033](1) Pretreatment, add 500ml of dilute nitric acid with a concentration of 1.0mol / L and 500ml of 0.5g / L thiourea to prepare pickling solution, place the NdFeB permanent magnet in the acid solution for cleaning for 2-3min, and then place Ultrasonic cleaning in 500mL of absolute ethanol for 1-2min, after completion, place in 500ml of 20g / L sulfosalicylic acid and 500ml of 10g / L ammonium bifluoride mixture for activation, activation time 1min, activation temperature 25°C ;

[0034] (2) Electroless nickel plating, take by weighing the 26g / L nickel sulfate hexahydrate solution of 300ml, the sodium hypophosphite solution of the 30g / L of 300ml, the borax solution of the 30g / L of 100ml, the sodium citrate of the 30g / L of 100ml solution, 100ml of 30g / L ammonium fluoride solution, and 100ml of 3g / L succinic acid solution to prepare the chemical plating solution, place the pretreated...

Embodiment 3

[0038] A preparation process for corrosion-resistant multi-coated NdFeB, comprising the steps of:

[0039] (1) Pretreatment, add 500ml of dilute nitric acid with a concentration of 0.8mol / L and 500ml of 0.5g / L thiourea to prepare pickling solution, place the NdFeB permanent magnet in the acid solution for cleaning for 2-3min, and then place Ultrasonic cleaning in 500mL of absolute ethanol for 1-2min, after completion, place in 500ml of 20g / L sulfosalicylic acid and 500ml of 10g / L ammonium bifluoride mixture for activation, activation time 1min, activation temperature 25°C ;

[0040] (2) Electroless nickel plating, take by weighing the 26g / L nickel sulfate hexahydrate solution of 300ml, the sodium hypophosphite solution of the 30g / L of 300ml, the borax solution of the 30g / L of 100ml, the sodium citrate of the 30g / L of 100ml solution, 100ml of 30g / L ammonium fluoride solution, and 100ml of 3g / L succinic acid solution to prepare the chemical plating solution, place the pretreate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com