Method for preparing silicon dioxide coated noble metal nanocrystalline

A technology of noble metal nanocrystals and silicon dioxide, which is applied in the direction of coating, etc., can solve the problems of poor affinity of silicon dioxide, etc., and achieve the effects of stable nanocrystals, easy preparation, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing silicon dioxide-coated noble metal nanocrystals, comprising:

[0030] Step 1: mixing the aqueous solution of noble metal nanocrystals modified with mercaptocarboxylic acid and the alcohol solution to obtain a mixed solution;

[0031] Step 2: adding ammonia water and n-ethyl acetate (TEOS) to the mixed solution described in Step 1, and stirring to obtain a reaction mixture;

[0032] Step 3: Centrifuge and dissolve the reaction mixture obtained in Step 2 to obtain silica-coated noble metal nanocrystals.

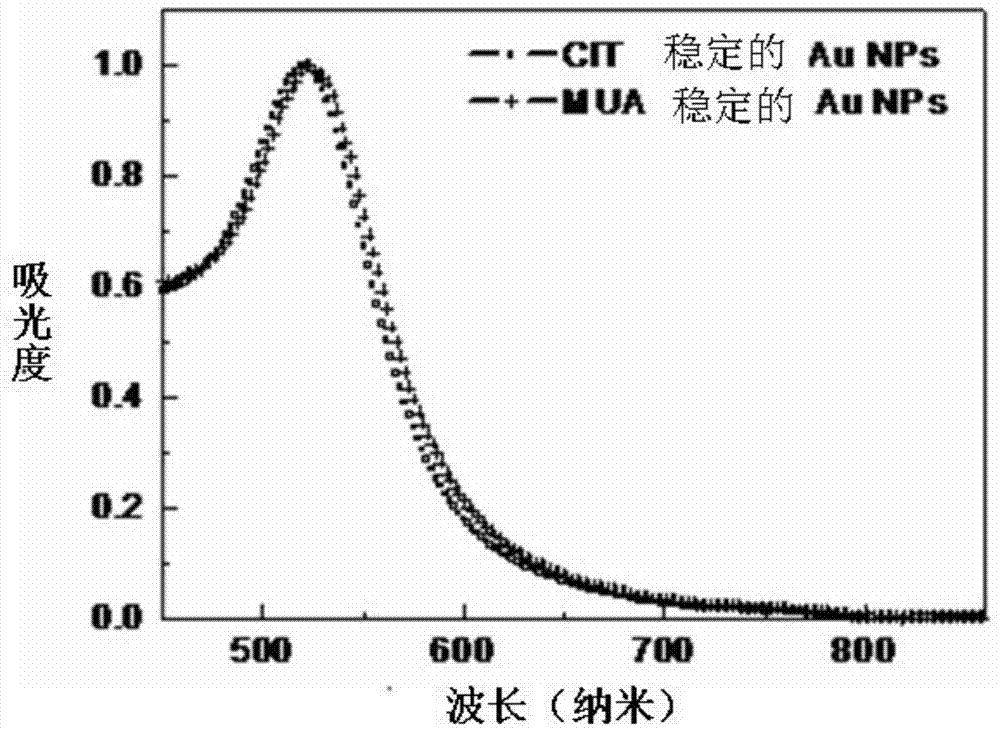

[0033] Compared with the prior art, the preparation method provided by the present invention can keep the stability of the noble metal nanocrystal in the alcohol aqueous solution during the preparation process, and can improve the chemical affinity of the noble metal nanocrystal to the silicon dioxide coated on its surface. It can be used for the coating of noble metal nanocrystals such as citric acid-stabilized gold or silv...

Embodiment 1

[0080] The preparation of spherical gold nanocrystals with a particle diameter of about 15nm stabilized by citric acid in embodiment 1:

[0081] 1mL of 1% by mass percentage of chloroauric acid aqueous solution was added to 50mL of deionized water to obtain chloroauric acid solution;

[0082]Add the above-mentioned chloroauric acid solution into a three-necked bottle and heat to boiling; dissolve 0.1147g of sodium citrate in deionized water to obtain a 5% sodium citrate solution by mass; quickly add 0.8mL of sodium citrate solution into the three-necked flask, react under boiling for 1 hour, and cool to room temperature to obtain a citric acid-stabilized spherical gold nanocrystal solution with a particle size of about 15 nm.

Embodiment 2

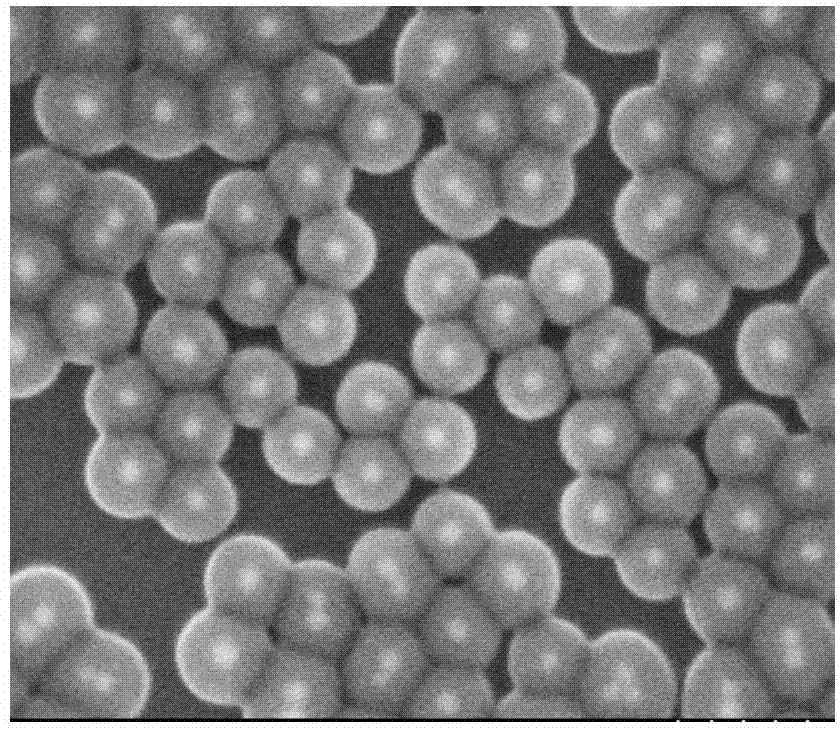

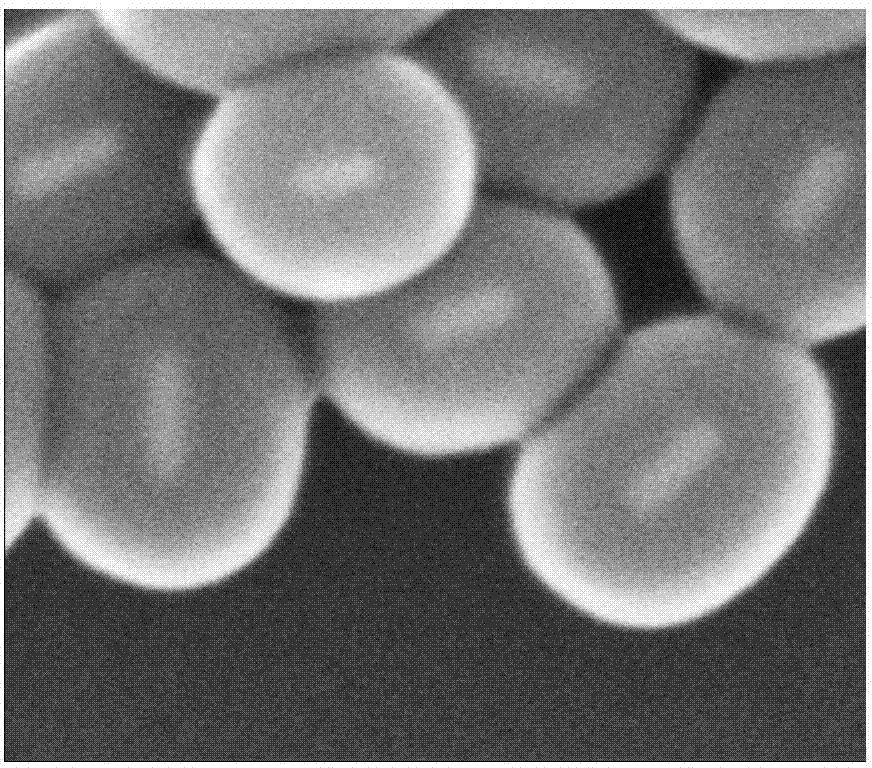

[0083] Preparation of spherical gold nanocrystals with a particle diameter of about 40nm stabilized by citric acid in embodiment 2:

[0084] 3mL mass percentage is that 1% chloroauric acid aqueous solution is added to the deionized water of 75mL, obtains chloroauric acid solution;

[0085] The spherical gold nanocrystal solution described in 30mL embodiment 1 is mixed with 20mL deionized water and 2.4mL mass percent concentration of 5% sodium citrate solution and added to a 100mL flask to obtain a mixed solution;

[0086] A chloroauric acid aqueous solution was added to the above mixed solution, reacted at 70° C. for 1 h, and cooled to room temperature to obtain citric acid-stabilized spherical gold nanocrystals with a particle size of 40 nm;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com