Three-dimensional layered boron-doped titanium carbide as well as preparation method and application thereof

A technology of boron doping and titanium carbide, applied in the direction of titanium carbide, carbide, electrochemical generator, etc., can solve the problems of complex preparation methods, unsatisfactory results, high cost, etc., and achieve simple and easy operation and inhibited growth , Improve the effect of cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing a three-dimensional layered boron-doped titanium carbide, comprising the following steps:

[0033] 1) Put Ti 3 AlC 2 React with LiF in HCl solution, the obtained product is washed to neutrality, and Ti is obtained after drying 3 C 2 powder;

[0034] 2) Put Ti 3 C 2 powder, water and H 3 BO 3 Three-dimensional layered boron-doped titanium carbide can be obtained by mixed hydrothermal reaction.

[0035] In the present invention, the Ti 3 AlC 2 , The mass volume ratio of LiF and HCl solution is 10-2000mg: 10-3000mg: 1-50mL, preferably 50-1800mg: 100-2800mg: 5-45mL, more preferably 200-1500mg: 200-2500mg: 20-40mL .

[0036] In the present invention, the concentration of the HCl solution is 3-12 mol / L, preferably 5-10 mol / L, more preferably 8 mol / L.

[0037] In the present invention, in step 1), the reaction temperature is 20-30°C, the reaction time is 1-72h, preferably the reaction temperature is 22-28°C, the reactio...

Embodiment 1

[0047] (1) Preparation of three-dimensional layered boron-doped titanium carbide:

[0048] 1500mgTi at room temperature 3 AlC 2 Add 2000mgLiF to 25mL10mol / L HCl and react for 70 hours. The semi-finished product is washed with deionized water until neutral. In addition, the powder was collected by centrifugation at 8000 rpm for 20 minutes. Finally, the obtained product was dried in a vacuum oven at 100° C. for 10 hours. 800mgTi 3 C 2 The powder was evenly dispersed in deionized water. Then, 500mgH 3 BO 3 Added to Ti 3 C 2 in the dispersion and stirred for half an hour. The suspension was transferred to a polytetrafluoroethylene reaction furnace and heated at 380°C for 60 hours to produce a gray-black precipitate. After centrifugation, the obtained product is vacuum-dried at 100° C. to obtain a three-dimensional layered boron-doped titanium carbide.

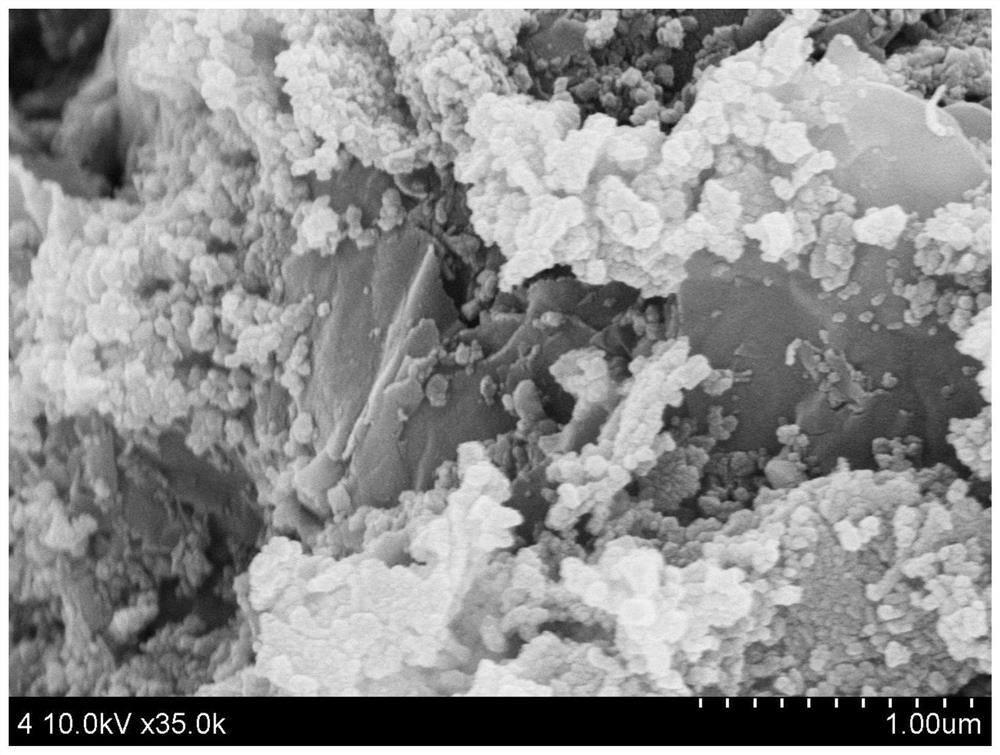

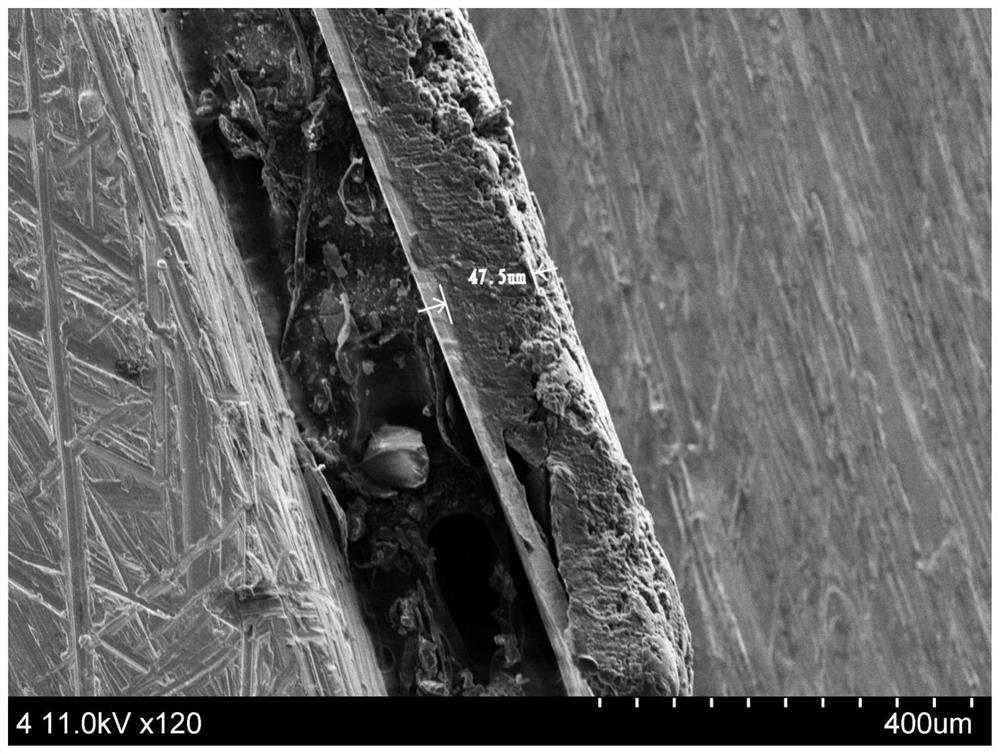

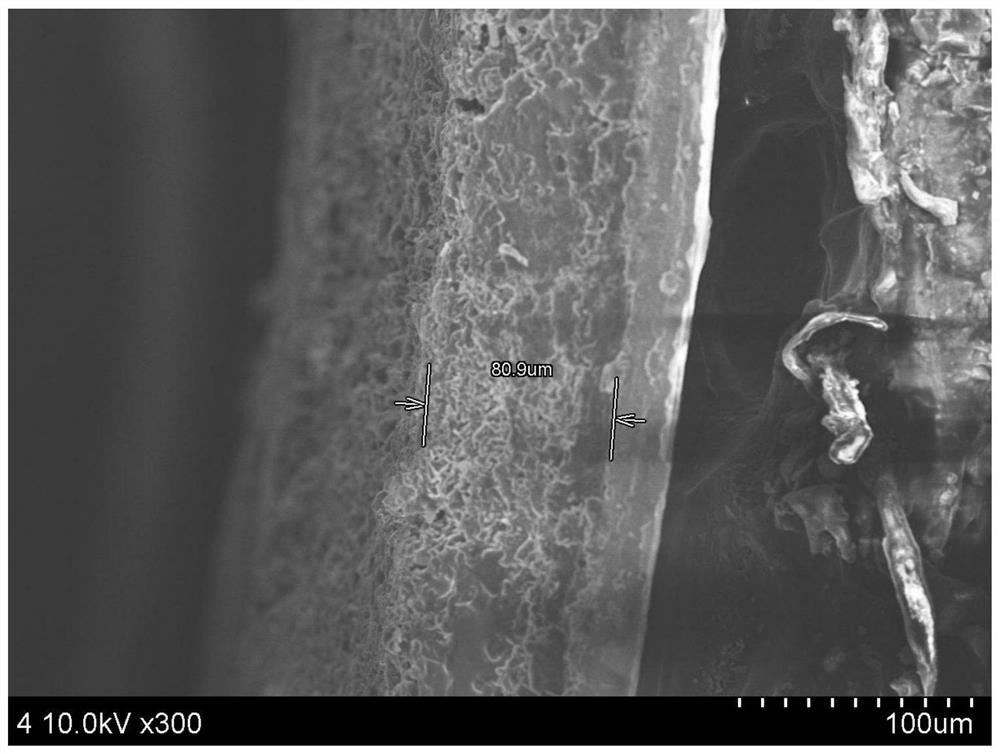

[0049] from figure 1 The scanning electron micrographs of the three-dimensional layered boron-doped titanium carbide ...

Embodiment 2

[0065] 1000mgTi at room temperature 3 AlC 2 Add 1500mgLiF to 20mL5mol / LHCl and react for 60 hours. The semi-finished product is washed with deionized water until neutral. In addition, the powder was collected by centrifugation at 8000 rpm for 20 minutes. Finally, the obtained product was dried in a vacuum oven at 100° C. for 10 hours. 800mgTi 3 C 2 The powder was evenly dispersed in deionized water. Then, 1000mgH 3 BO 3 Added to Ti 3 C 2 in the dispersion and stirred for half an hour. The suspension was transferred to a polytetrafluoroethylene reaction furnace and heated at 400°C for 50 hours to produce a gray-black precipitate. After centrifugation, the obtained product is vacuum-dried at 100° C. to obtain a three-dimensional layered boron-doped titanium carbide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com