Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Reduce wear scar diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

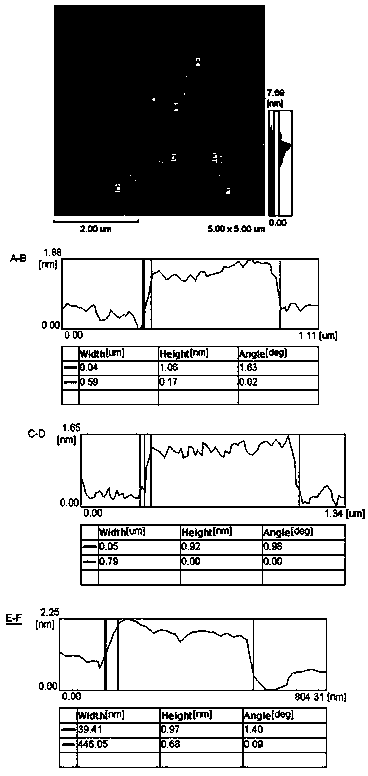

High-thermal conductivity lubricating oil and preparation method thereof

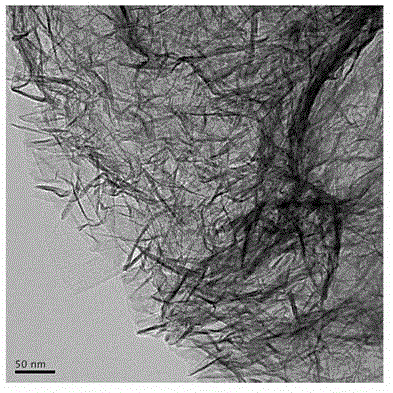

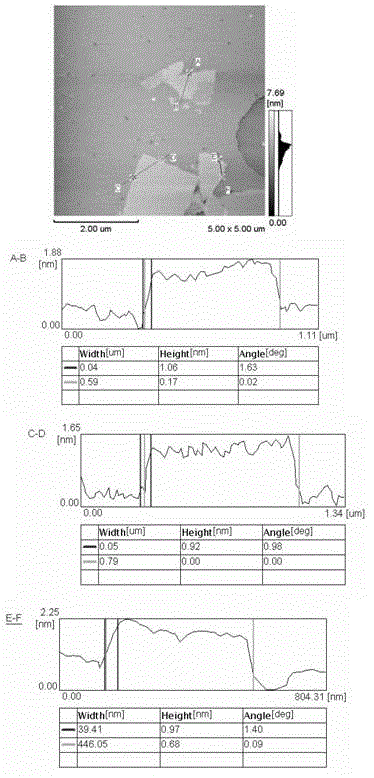

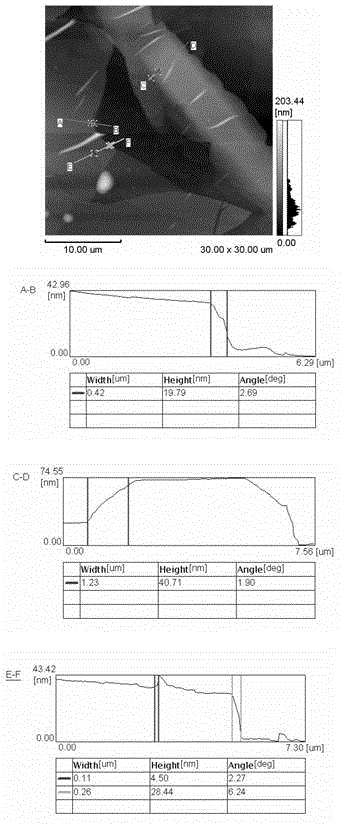

ActiveCN102911762AImprove anti-friction and anti-wear effectImprove thermal conductivityAdditivesGrapheneBase oil

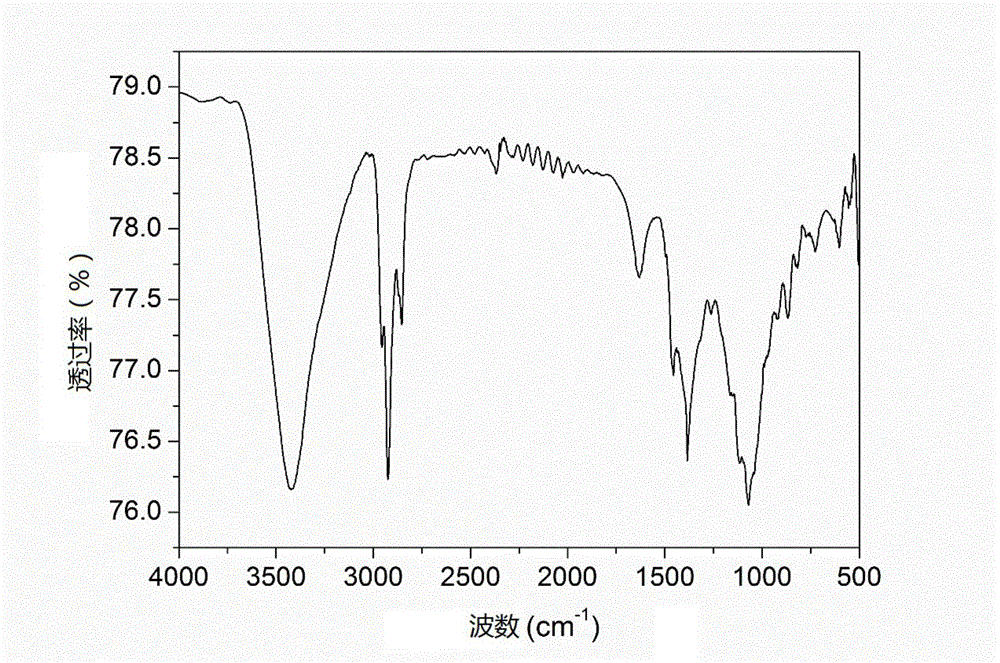

The invention relates to high-thermal conductivity lubricating oil and a preparation method thereof. The lubricating oil contains base oil and fluorinated graphene nanosheets, wherein the weight percent of content of the fluorinated graphene nanosheets is 0.01 to 10.0 %; and the preparation method comprises the steps as follows: firstly, preparing the fluorinated graphene nanosheets; and secondly, preparing the lubricating oil containing the fluorinated graphene nanosheets. The lubricating oil provided by the invention has the advantages of excellent antifriction effect, extremely high heat conduction capability and excellent stability and dispersibility.

Owner:青岛康普顿石油化工有限公司

High performance nano metal/mine ore powder composite self repairing agent and its preparing method

The present invention discloses one kind of high performance nanometer metal / ore powder composite self-repairing agent and its preparation process. The composite self-repairing agent is prepared with nanometer magnesium hydroxyl silicate ore powder 15-25 wt%, nanometer composite metal powder 6-12 wt%, nanometer magnesium hydroxyl silicate ore powder dispersant 0.5-2 wt%, nanometer composite metal powder dispersant 0.5-2 wt%, catalyst 0.2-2 wt%, stabilizer 1-5 wt%, cooperative metal friction additive 0.5-3 wt%, nanometer dispersant 2-5 wt%, auxiliary performance regulator 1-3 wt% and dispersing medium 41-73.3 wt%, and through certain technological process in certain technological conditions. It is used in lubricant oil and lubricant grease for nanometer composite repairing.

Owner:MIYOU GROUP

Cutting liquor composition

The invention discloses a cutting liquid composition, which is characterized by the following: allocating the cutting liquid composition with antirust agent, alcohol amine, inorganic alkaline or their composition, tetrazoline compound and water; fitting for manufacturing knife with cobalt or each cutting course.

Owner:CHINA PETROLEUM & CHEM CORP

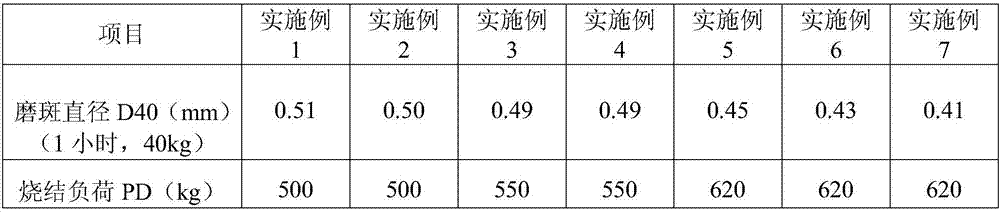

Lubricating oil additive based on modified nano alumina and preparation method of lubricating oil additive

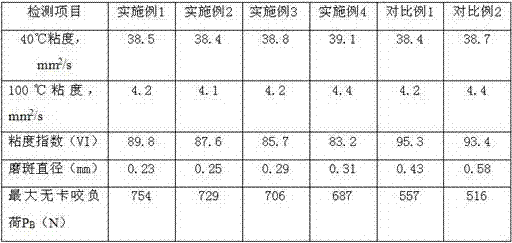

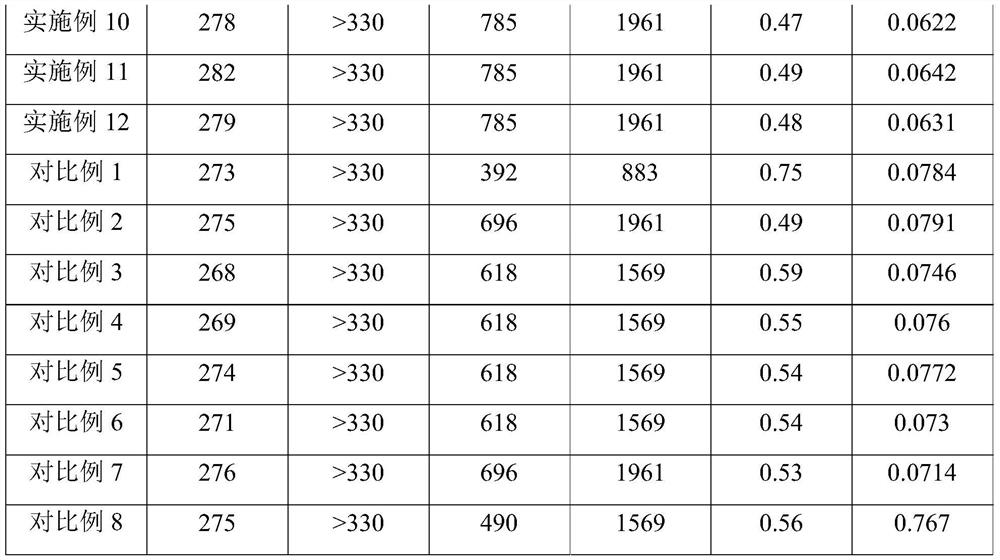

The invention provides a lubricating oil additive based on modified nano alumina and a preparation method of the lubricating oil additive. The preparation method comprises steps as follows: (1) nano alumina is modified; (2) molybdenum disulfide, titanium dioxide, graphene oxide, oleic acid and modified nano alumina are put in a ball mill for ball milling, and a powdery mixture is obtained; (3) thepowdery mixture prepared in the step (2), dodecyl methyl methacrylate and vinyl acetate are mixed uniformly, and the lubricating oil additive is obtained. The prepared additive is added to the lubricating oil, so that the wear resistance of the lubricating oil is greatly improved, and besides, the wear spot diameter is notably reduced. The performance parameters of the lubricating oil with the additive oil added have no obvious change after the lubricating oil is stored for 3 months and 6 months, which proves that the modified nano alumina and doping of nano alumina with other nanoparticles have great influence on the performance of lubricating oil.

Owner:苏州市宽道模具机械有限公司

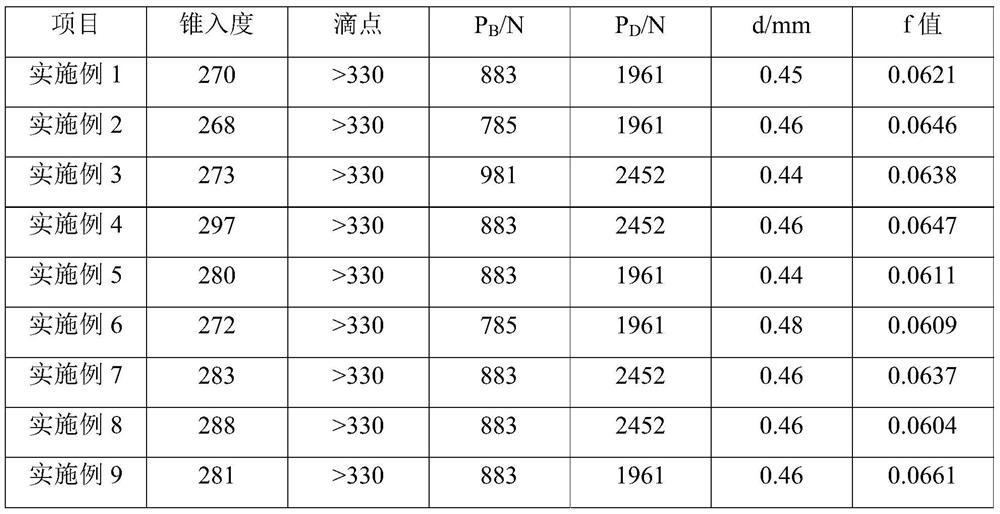

Heat-conducting lubricating grease for high-speed all-steel angular contact bearing and preparation method thereof

ActiveCN102703179ASimple manufacturing methodReduce manufacturing costLubricant compositionLow noiseElectricity

The invention relates to heat-conducting lubricating grease for a high-speed all-steel angular contact bearing and a preparation method of the lubricating grease; the heat-conducting lubricating grease for the high-speed all-steel angular contact bearing is composed of the following raw materials by weight: 85-95% of barium-base lubricating grease, 3-10% of a heat-conducting agent and 2-5% of antioxidant; according to a technical proposal of the invention, the heat-conducting agents namely nano particles are added based on composite barium-base lubricating grease; so that the heat-conducting lubricating grease has a higher speed coefficient and a preferable heat-conducting performance; the bearing is characterized by low noise, low temperature rising, low vibration and longer service life; in addition, situations that speed coefficient of current domestic lubricating grease is short of an operation demand and the current domestic lubricating grease has poor heat conductivity are solved; an electric main shaft oil supply device is eliminated; noise when the high-speed all-steel angular contact bearing is operated is reduced; and temperature rising and vibration values are reduced.

Owner:国创(洛阳)轴承产业技术研究院有限公司

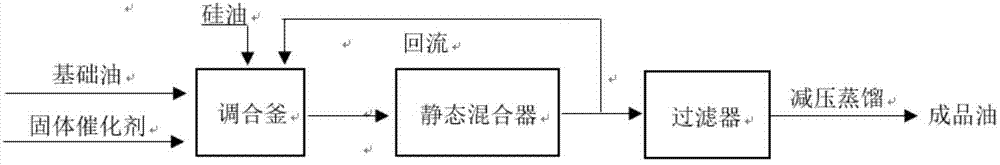

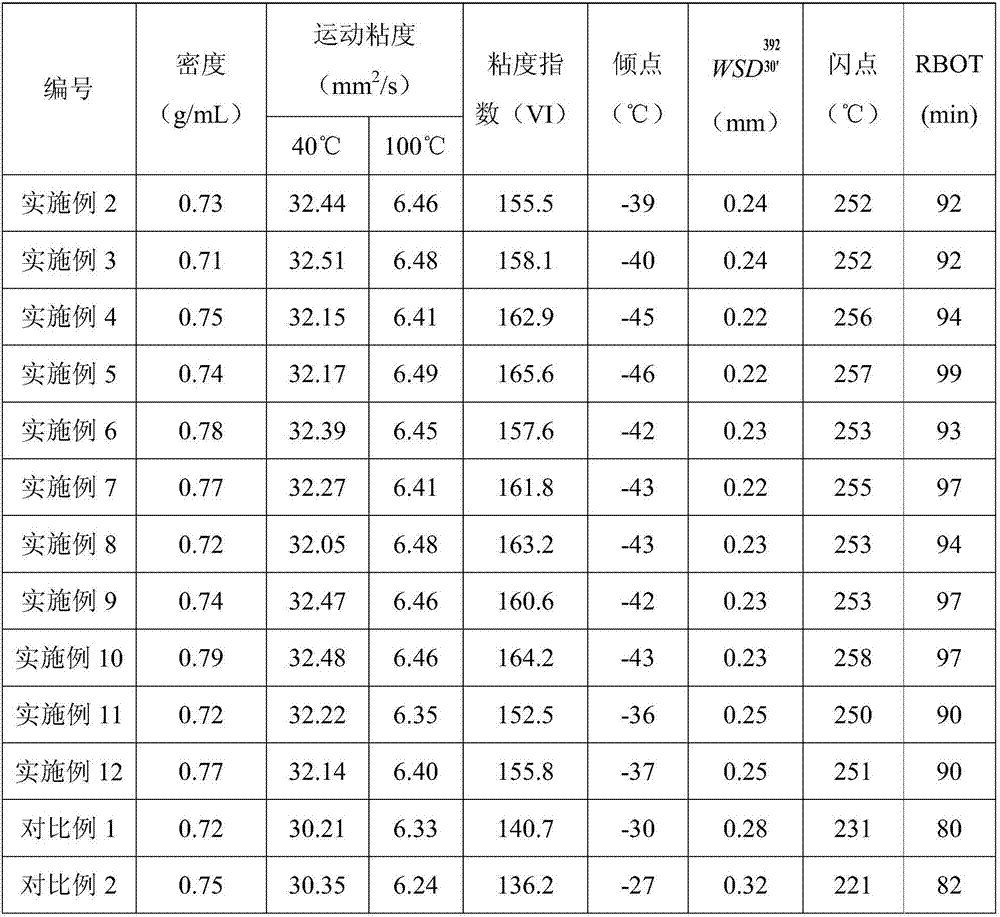

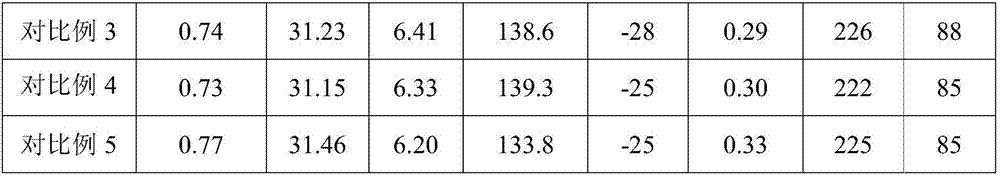

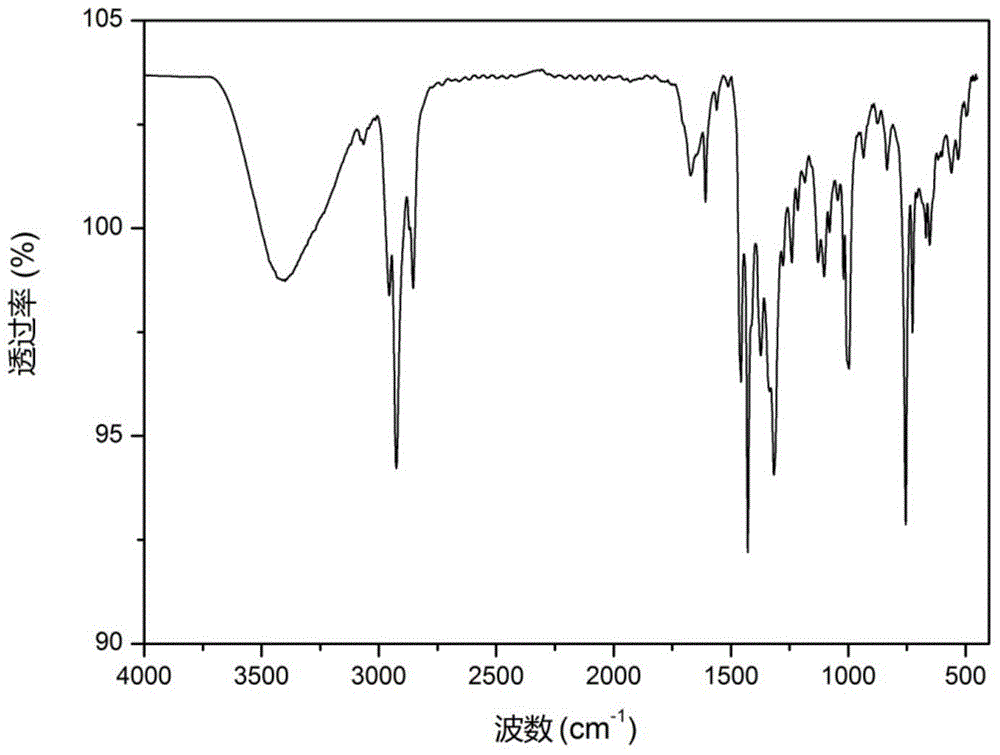

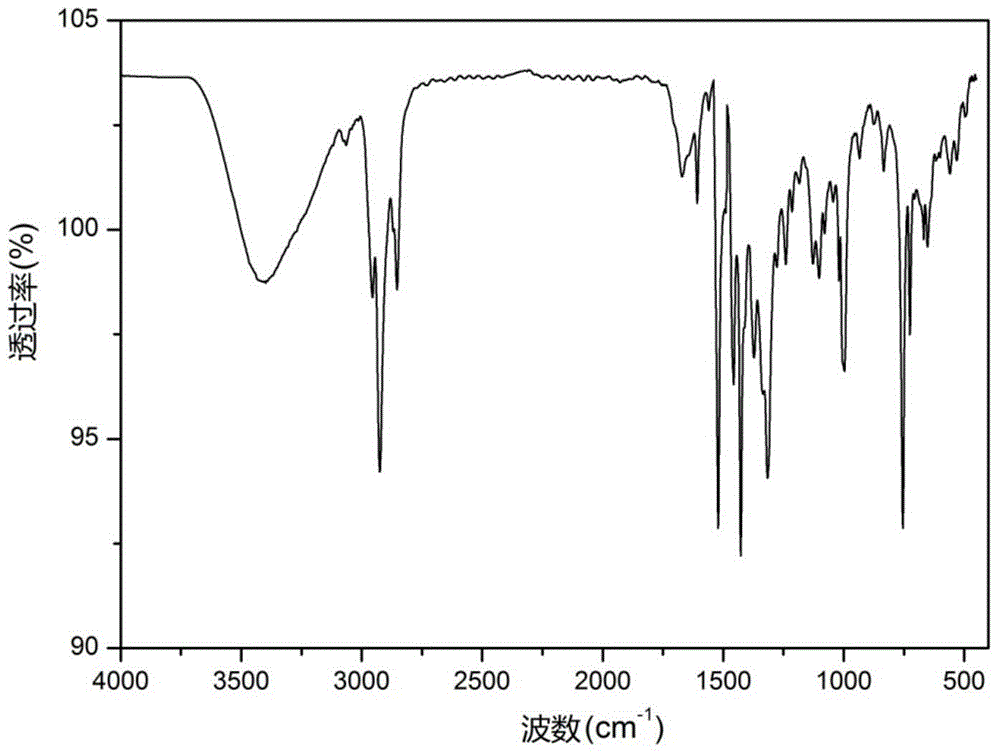

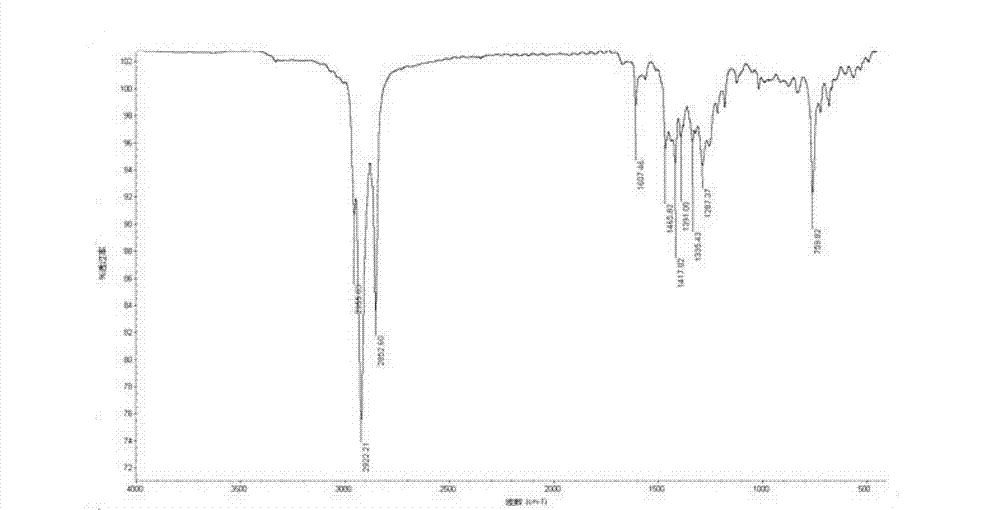

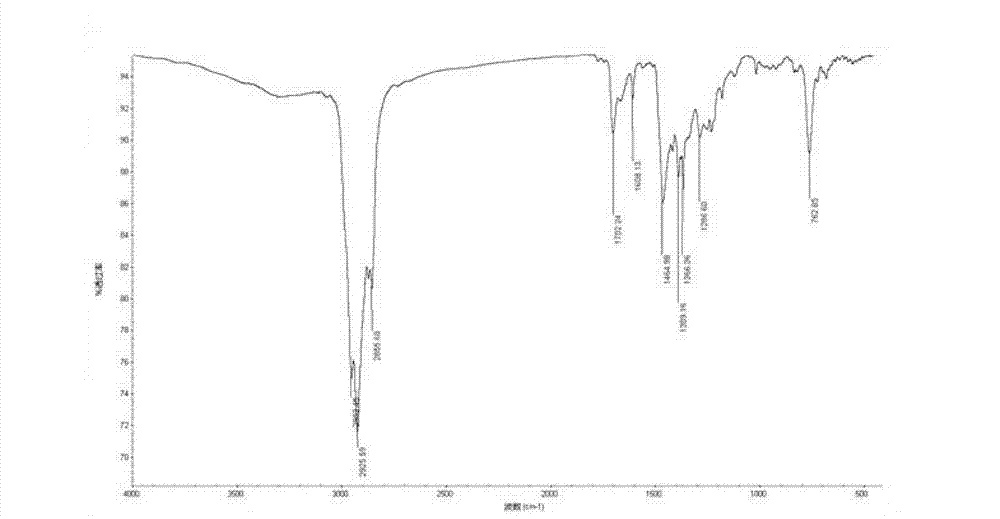

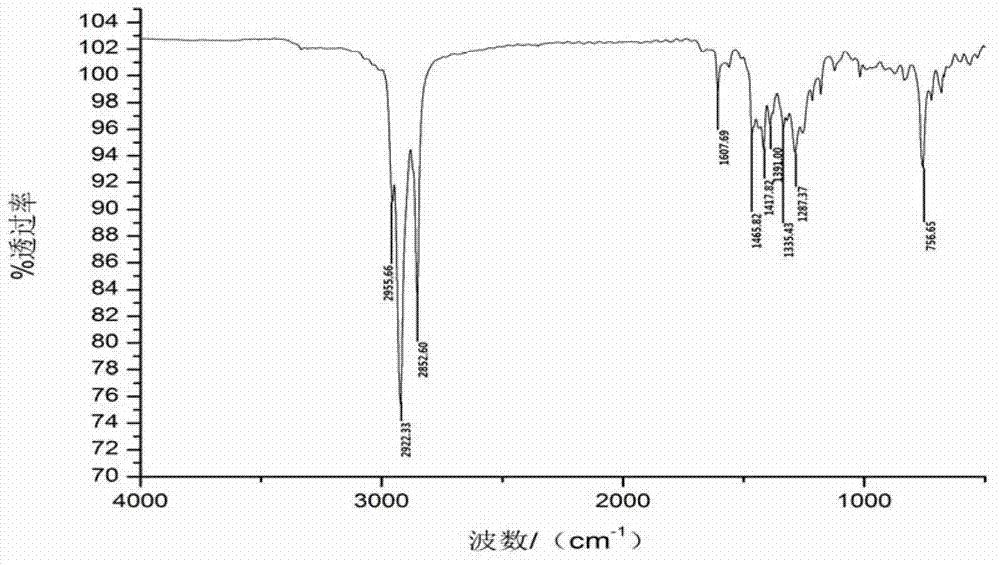

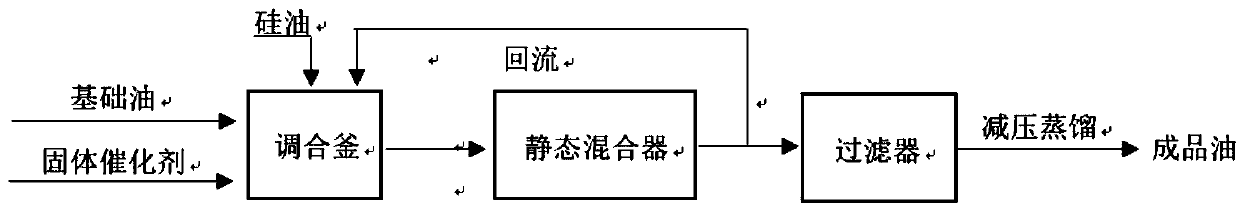

Lubricant base oil and preparation method thereof

ActiveCN107325121ALow pour pointHigh flash pointGroup 4/14 element organic compoundsCatalyst activation/preparationDistillationReaction temperature

The invention discloses lubricant base oil and a preparation method thereof. The preparation method comprises the following steps: mixing silicone oil with a solid catalyst, stirring and heating to a reaction temperature, adding acetic acid vinyl ester to perform reaction, stopping reaction when an iodine value is smaller than 3.0g / 100g, separating the catalyst out and then performing reduced pressure distillation on obtained liquid to obtain the lubricant base oil. The preparation method of the lubricant base oil disclosed by the invention has simple technology, lower cost, low equipment requirement, no acid wastewater generation in a preparation process and no pollution to environment; the utilized platinum solid catalyst has higher catalyzing performance; the lubricant base oil synthesized by the acetic acid vinyl ester and the silicone oil has low pour point, high flash point, good viscosity-temperature property, good oxidation stability and excellent friction lubricating property.

Owner:JIANGSU ZHONGSHENG GAOKE ENVIRONMENTAL CO LTD

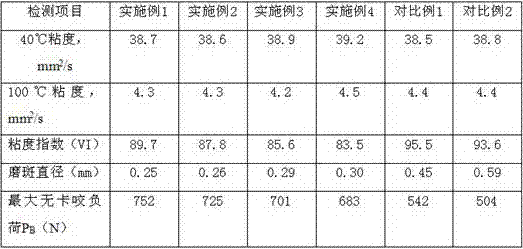

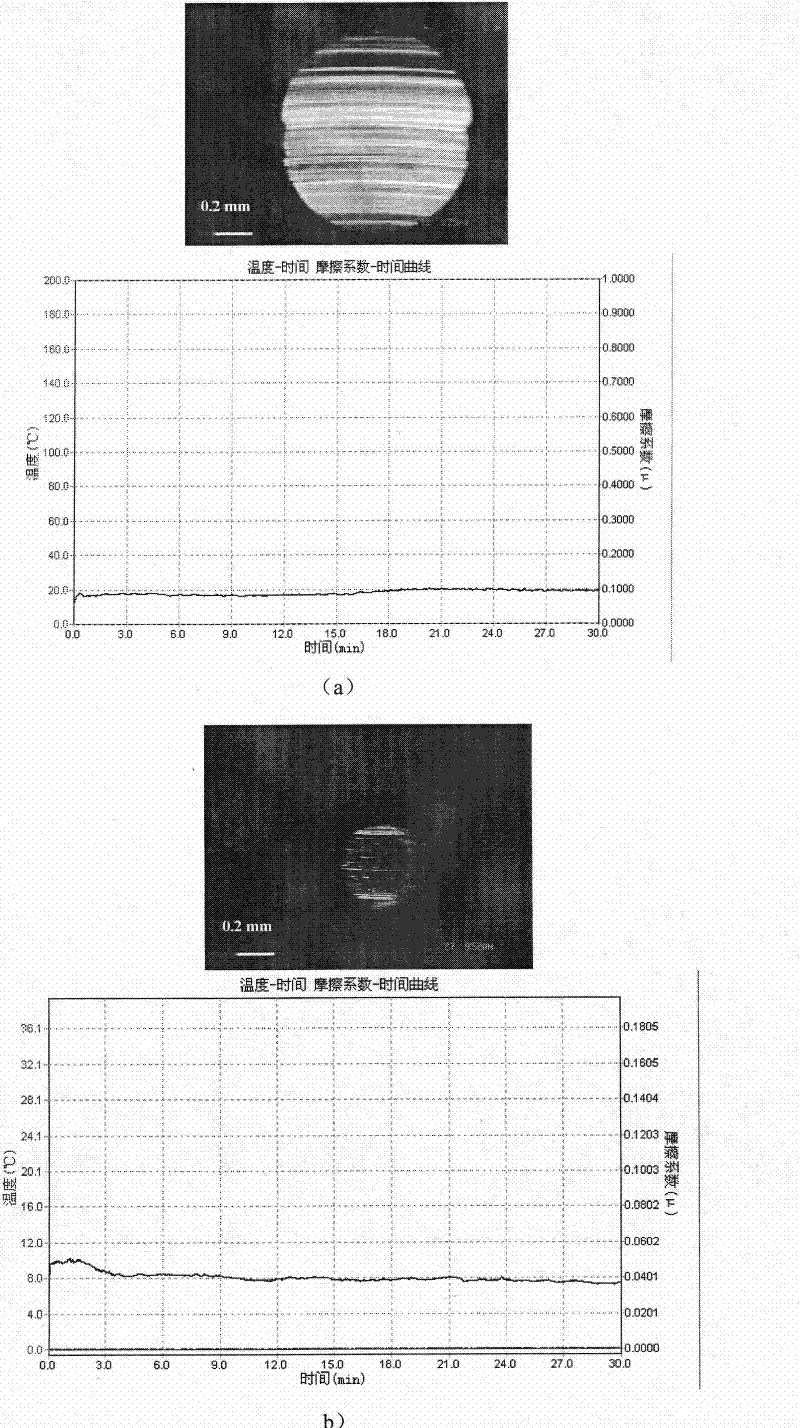

High-dispersion modified nanometer molybdenum disulfide lubricant and preparation method thereof

InactiveCN108913279AGood dispersionNot easy to reuniteAdditivesPigment treatment with macromolecular organic compoundsDispersityWear resistance

The invention discloses a high-dispersion modified nanometer molybdenum disulfide lubricant and a preparation method thereof. The dispersity of the prepared modified nanometer molybdenum disulfide inthe lubricant is good, the prepared modified nanometer molybdenum disulfide is not easy to agglomerate and stable in property, and the obtained lubricant has relatively high maximum non-seizure load,the grinding spot diameter is small, the friction coefficient is low, and the anti-compression and anti-wear performance is excellent. After the nano molybdenum disulfide is pretreated, the internal structure of the nano molybdenum disulfide is loose and dispersed, and the dispersity is improved and the stability of the nano-molybdenum disulfide in the lubricant is enhanced; and the surface of thenano-molybdenum disulfide is wrapped by using zirconium dioxide; on one hand, the nano-molybdenum disulfide is collaborative with the zirconium dioxide, so that the friction coefficient of the lubricant is reduced, the compression resistance and wear resistance are enhanced, and on the other hand, the dispersity of molybdenum disulfide and its own in a lubricant is also promoted, and the agglomeration phenomenon is avoided.

Owner:界首市鑫全龙粮食机械购销有限公司

Lubricant additive containing Ni-P powder recycled from electroless plating waste liquid, preparation and application thereof

InactiveCN101747985AExtend oil change intervalsIncrease pressureAdditivesElectroless nickelLiquid waste

The invention discloses a Ni-P alloy nano-powder lubricant additive prepared from nickel and phosphorus recycled from electroless nickel plating waste liquid, and a using method thereof in different friction occasions, wherein Ni-P powder is subjected to in-situ dispersion and recovered from electroless nickel plating waste liquid, dispersed again and then prepared into the lubricant additive through certain steps, together with metal chemical friction modifiers, detergent-dispersant, oxygen corrosion-resistant agents, auxiliary performance regulator, stabilizer and base oil. The lubricant additive has the advantages of good suspension stability, capability of greatly reducing equipment friction and wear, greatly reducing the frequency of equipment maintenance and parts replacement and prolonging equipment lifespan and overhaul time limit, as well as good effect of saving energy and protecting environment. The lubricant additive can be widely used in gasoline / diesel internal combustion engines, general fluid machinery, mechanical chemical sealing pieces, transmission gearboxes and other occasions, can realize the recycling of nickel and phosphorus in the electroless nickel plating waste liquid with high added value in order to change pollutants into useful things, and realizes the coordination and unification of economic, environmental and social benefits.

Owner:NANJING UNIV OF TECH

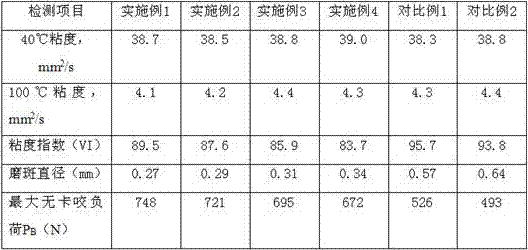

Metal cutting fluid containing nanometer titania of different particle sizes and preparation method of metal cutting fluid

InactiveCN109370717ALow tapping torque valueImprove the lubrication effectLubricant compositionVegetable oilSubstance.toxic

The invention discloses metal cutting fluid containing nanometer titania of different particle sizes and a preparation method of the metal cutting fluid. The prepared metal cutting fluid has low tapping torque and is excellent in lubricating property and low in grinding spot diameter, the wear resistance of the metal cutting fluid is excellent, the maximum non-seizure load PB value is great, the extreme pressure resistance is obvious, and the antibacterial property is outstanding. The metal cutting fluid does not contain sodium nitrite or any other substance toxic and harmful to the environment, takes vegetable oil as a main ingredient, is added with some high-efficiency additives, and is green, environmental-friendly, high-efficiency, simple in formula, excellent in antibacterial propertyand difficult to deteriorate. Due to the addition of silver-loaded graphene, silver particles are loaded among graphene sheet layers, so that the dispersion property of the graphene is further enhanced, the sheet stripping is full, and the anti-wear and friction reducing properties of the prepared cutting fluid are enhanced. Meanwhile, the cutting fluid is endowed with an antibacterial effect, the cutting fluid is difficult to deteriorate, and the storage period is prolonged.

Owner:五河富强鑫金属制品有限公司

Antiwear low corrosion nanometer hydraulic medium and preparation method thereof

InactiveCN104845728AImprove dispersion stabilityGood dispersionLubricant compositionNanoparticleViscosity modifier

The invention discloses an antiwear low corrosion nanometer hydraulic medium and a preparation method thereof. The nanometer hydraulic medium is composed of the following materials by mass: 92%-97% of water, 1%-3% of nanoparticles, 0.4%-1.5% of a dispersion stabilizer, 0,25%-1% of an antisettling stabilizer, 1.3%-2.35% of an antirust agent, and 0.05%-0.15% of a viscosity regulator. The nanometer hydraulic medium prepared by the method provided by the invention has good dispersion stability, good rheological properties, proper and adjustable viscosity, and has good antirust, friction reduction and antiwear properties. When the medium is applied in a hydraulic transmission system, the hydraulic system operates well, and has low leakage and reduced corrosion degree on hydraulic elements, and the wear scar diameter decreases.

Owner:KUNMING UNIV OF SCI & TECH

Carbon steel forming oil composition and preparation method thereof

InactiveCN107129852AReduce wear on metal surfacesImprove extreme pressure and anti-wear performanceLubricant compositionMachining processAntioxidant

The invention relates to the technical field of metal processing lubricating oil, discloses a carbon steel forming oil composition, and further discloses a preparation method of the carbon steel forming oil composition. The carbon steel forming oil composition comprises, by weight, 1-5 parts of extreme pressure agents, 60-90 parts of base oil, 1-15 parts of friction reducing agents, 1-10 parts of clearing agents, 1-15 parts of dispersing agents and 1-10 parts of antioxidants. The extreme pressure agents are organic sulfide with carbon-sulfur bonds, the friction reducing agents are sulfurized vegetable fatty acid ester carbureted hydrogen and / or fatty acid, the organic sulfide can rapidly permeate and adsorb on metal surfaces in the processing process, the temperature of contact points instantaneously rises, so that the carbon-sulfur bonds crack, oil films fracture, so that the metal surfaces and the organic sulfide chemically react to generate metal sulfide films which are low melting point and shearing strength and has bearing capacity, abrasion, scratch and fusion welding of the metal surfaces under high load are decreased, and unique extreme-pressure abrasion-resistant effects are achieved.

Owner:杭州旭森化工科技有限公司

Machining cutting liquid

The invention provides machining cutting liquid and relates to the technical field of industrial cooling and lubricating. The machining cutting liquid is prepared from, by weight, 15-25% of mahogany petroleum sulfonate, 10-15% of nonionic surfactant, 0.5-1% of silica powder, 1-5% of chlorinated paraffin, 0.2-0.6% of polydimethylsiloxane and the balance deionized water. The cutting liquid is simple in formula, convenient to prepare and easy to popularize, and has good cooling and lubricating performance and other performance.

Owner:HUBEI UNIV OF ARTS & SCI +1

High-wear-resistance lubricating oil and preparation method thereof

InactiveCN110835574AIncrease activationImprove anti-wear and anti-friction performanceRotary stirring mixersTransportation and packagingVulcanizationActive agent

The invention discloses high-wear-resistance lubricating oil, which is prepared from the following raw materials by weight: 80 to 90 parts of base oil, 2 to 3 parts of nano tungsten disulfide, 0.4 to0.6 part of a surfactant, 0.8 to 1 parts of a defoamer and 1.5 to 2 parts of an antiwear additive. The invention also discloses a preparation method of the lubricating oil. According to the lubricating oil, the nano tungsten disulfide is uniformly dispersed in the lubricating oil through the compounding of the nano tungsten disulfide and the surfactant, and the anti-wear and anti-friction effect of the nano-particles is exerted; by adding the anti-wear additive, a composite protective film is generated at the bearing friction interface and has excellent anti-wear and anti-friction performance;the lubricating oil is processed through special processing equipment, the lubricating oil can be fully, thoroughly and efficiently blended and processed so that components are evenly dispersed in the lubricating oil to exert corresponding effects and to ensure quality of the lubricating oil. The wear-resistant high-quality lubricating oil is obtained and suitable for tapered roller bearings, heavy-duty gear and other fields.

Owner:安徽中天石化股份有限公司

Formula of wear-resistant and oxidation-resistant hydraulic oil composite agent and preparation process thereof

ActiveCN109797028ALow content of metal zinc ionsLow in zinc ionsLubricant compositionWear resistantOxidation resistant

The invention discloses a formula of a wear-resistant and oxidation-resistant hydraulic oil composite agent, which comprises, by mass, the following components: 10-25% of long-chain primary alcohol dialkyl dithiophosphate zinc, 10-30% of di-tert-butyl-p-cresol, 0-15% of alkylated diphenylamine, 10-25% of tricresyl phosphate, 1-10% of high-base-number synthetic calcium sulfonate, 1-10% of dipolyisobutylene imide, 0-1% of dodecenyl succinic acid half ester, 1-8% of basic barium dinonylnaphthalene sulfonate, 1-3% of benzotriazole octadecylamine salt and 10-30% of base oil. The invention also discloses a preparation process of the composite agent, which comprises the following steps of: adding the hydraulic oil composite agent into a reaction kettle according to the mass percentage of each component in the formula of the hydraulic oil composite agent, heating to 70-80 DEG C, and stirring and cooling. The hydraulic oil prepared by the composite agent matched with the base oil has excellentoxidation and corrosion resistance, excellent abrasion resistance and better cleaning and dispersing performances.

Owner:中沃能源(湖北)集团股份有限公司

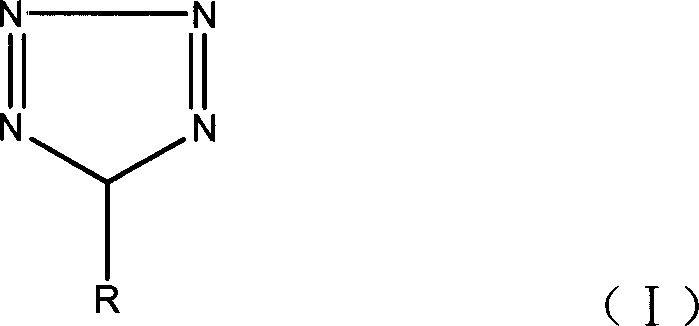

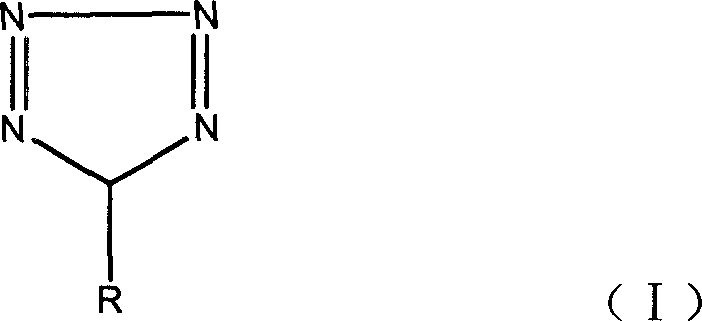

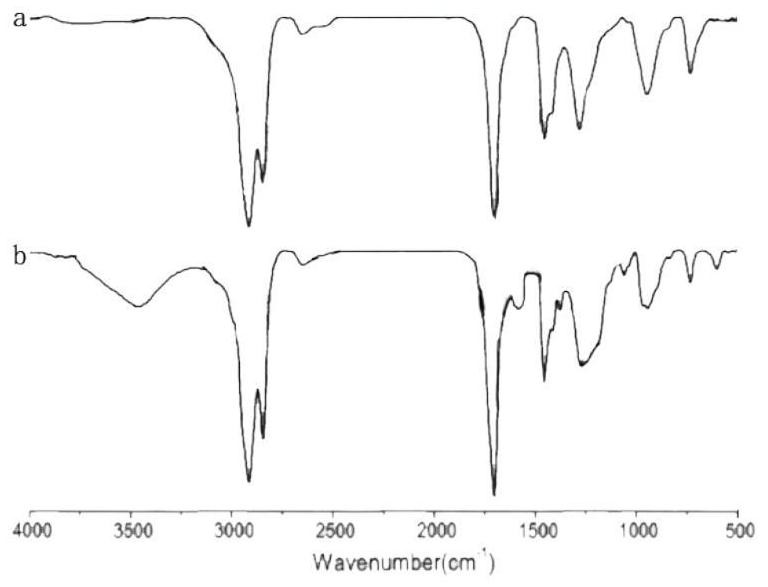

Hydroxyalkylated heterocycle boric acid ester and preparation method and purpose thereof

ActiveCN103601748AImprove extreme pressure and anti-wear performanceImprove PB valueGroup 3/13 element organic compoundsAdditivesCompound aAlcohol

The invention relates to hydroxyalkylated heterocycle boric acid ester and preparation method and purpose thereof; the structural formula of the additive is shown in the formula (I) or (II); the invention also relates to a preparation method of the hydroxyalkylated heterocycle boric acid ester lubrication additive, which comprises the following steps: 1. with organic solvent and catalyst, a heterocyclic compound and a alkyl epoxide are reacted, and a compound A is generated; 2. with organic solvent and catalyst, compound B and compound A or heterocycle-containing alcohol are reacted; the invention also relates to the purpose of hydroxyalkylated heterocycle boric acid ester.

Owner:SHANGHAI JIAO TONG UNIV

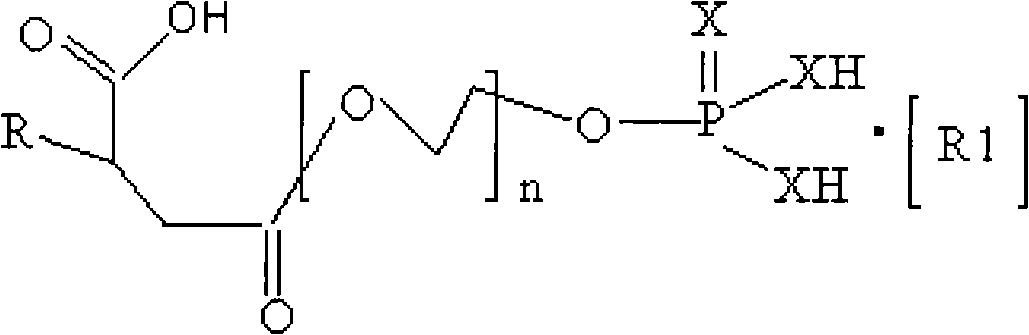

Phosphate amine salt and preparation method thereof

ActiveCN102268034AOutstanding resistance to hard water stabilityGood stability against hard waterPhosphorus organic compoundsWater basedPhosphate

The invention relates to amine phosphates and a preparation method thereof. The amine phosphates allow the hard water resistant stability of a cutting fluid to be substantially improved when an additive in the invention improves the emulsification capability, the lubrication performance and the antirust performance of the cutting fluid. According to the invention, a molecular structural formula of the amine phosphates is shown in the specification, and in the molecular structural formula, X is S or O, R is a long chain alkene group of C8-C100, R1 is hydramine or alkamine, and n is from 1 to 100. Above technical scheme allows problems in the specification to be well solved, and the amine phosphates can be used in industrial production of water-based cutting fluids.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method of copper wire

The invention discloses a preparation method of a copper wire, which belongs to the technical field of bonding wires. The method comprises the following steps: performing wire drawing and intermediateannealing on a copper rod through a wire drawing die, soaking the copper rod in a copper wire drawing solution, performing annealing heat treatment in the wire drawing process until a required size is formed, and performing final annealing heat treatment to obtain the copper wire. The copper wire drawing liquid comprises the following components, by weight: 13-16 parts of castor oil, 2-5 parts ofsulfonated castor oil, 2-5 parts of pentaerythritol oleate, 6-13 parts of triethanolamine borate, 12-25 parts of tall oleic acid emulsifier and 1000 parts of deionized water. According to the preparation method, the copper wire drawing liquid containing the tall oleic acid emulsifier is adopted, so that the phenomena of wire breakage and wire shrinkage are not easy to occur during wire drawing, the surface of a wire rod is smooth and free of scratches, a cone pulley is smooth in wiring, a copper wire with finer microstructure and more uniform distribution can be obtained, and the prepared copper wire has higher strength, hardness and resistivity; and no obvious oxidation sign exists on the surface.

Owner:河北临泰电子科技有限公司

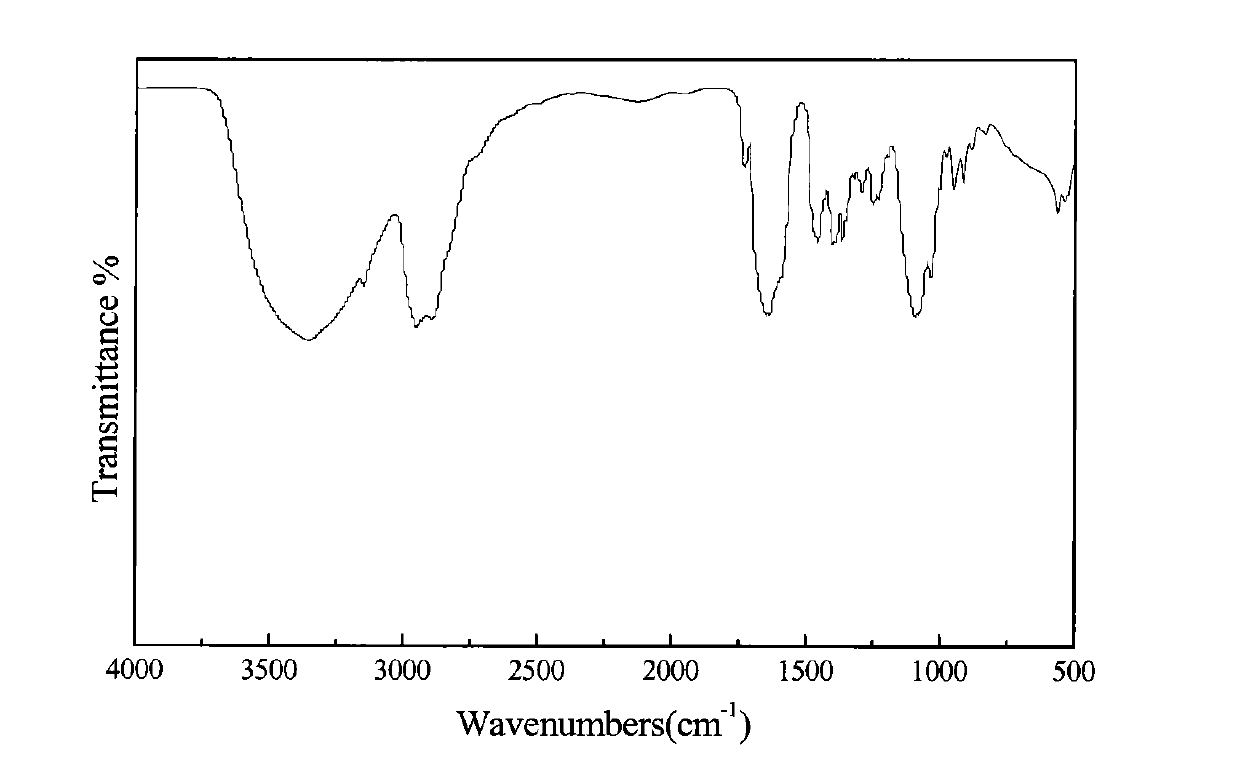

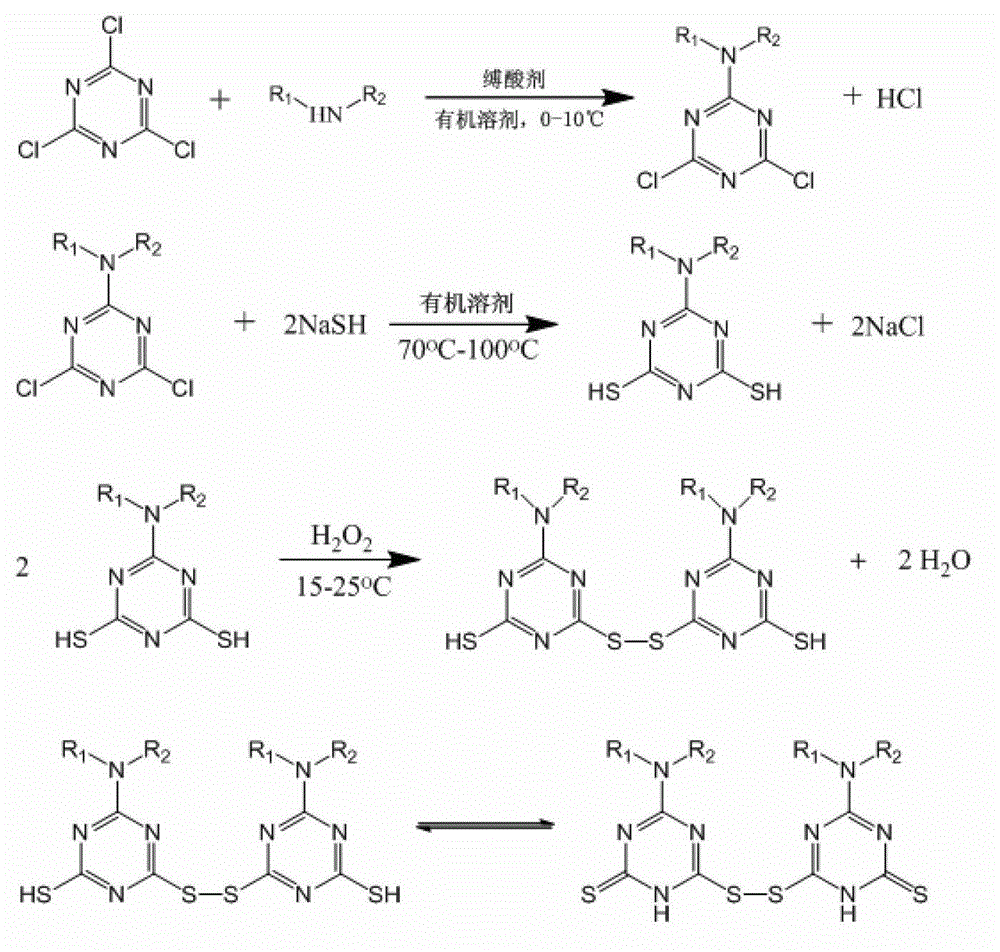

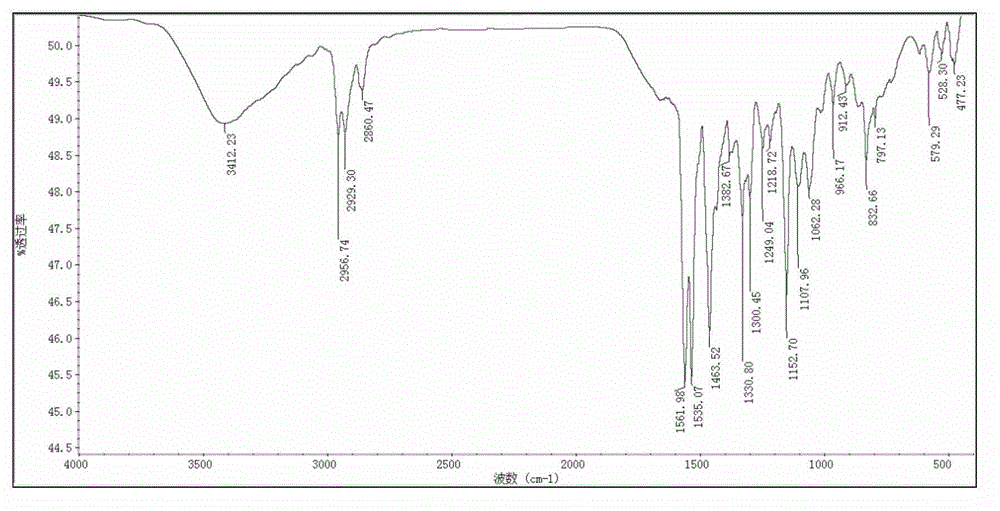

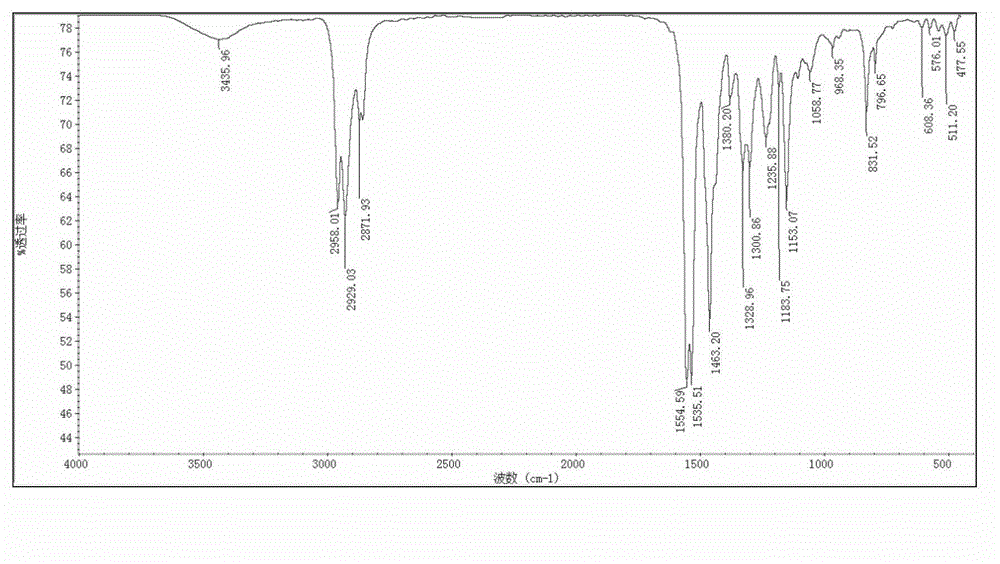

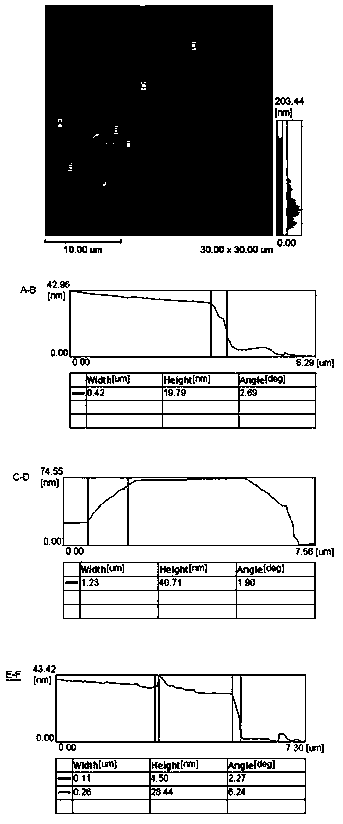

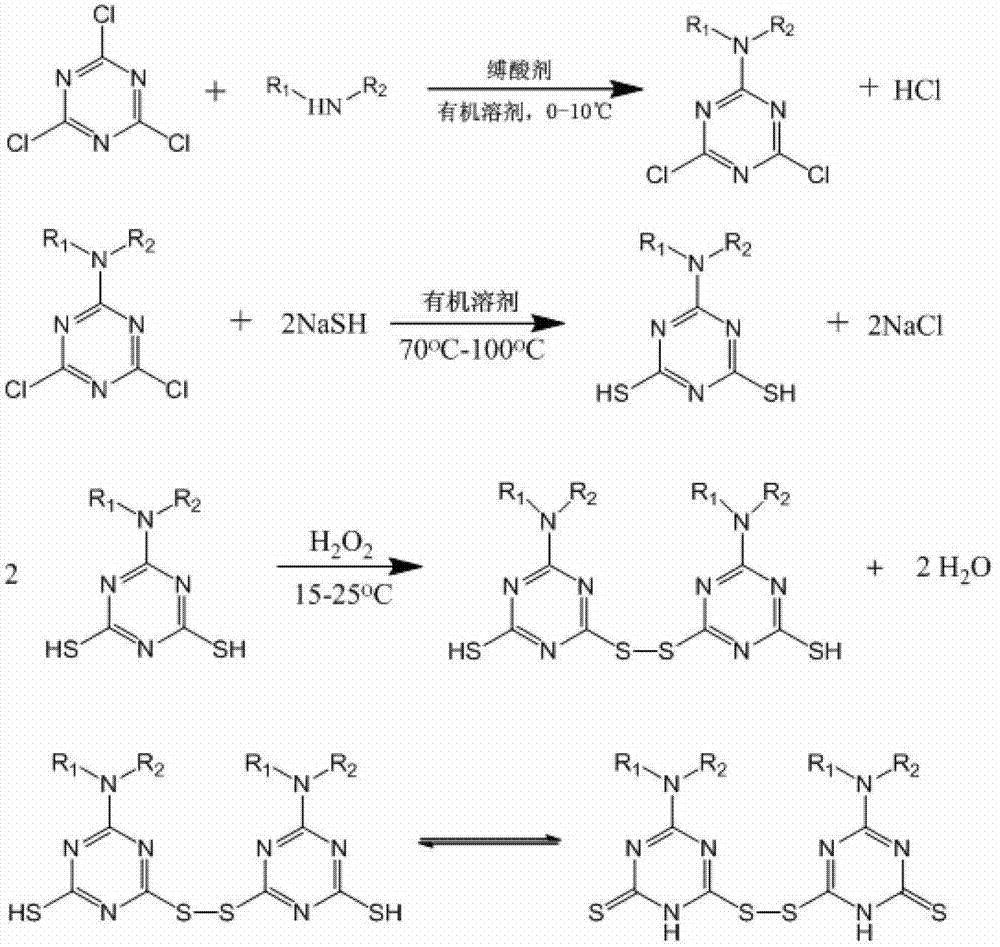

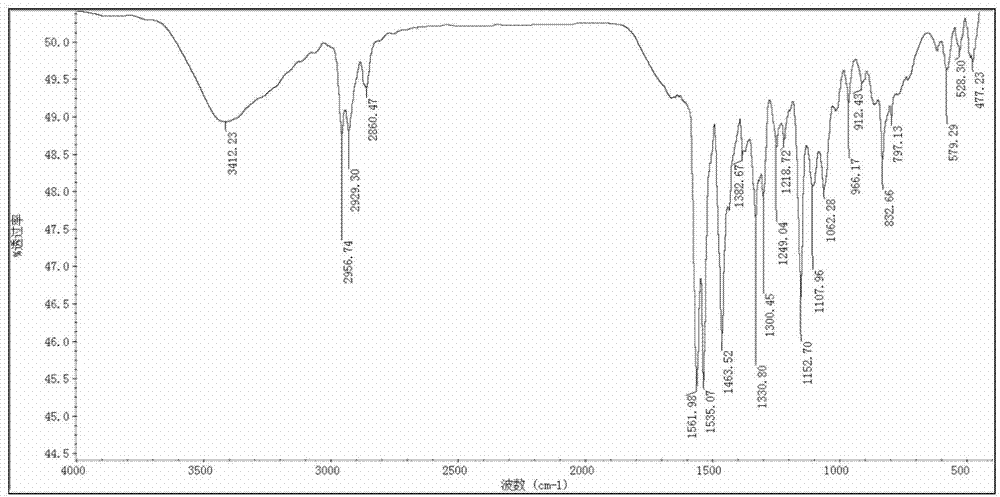

Coupled dimercaptotriazine derivative, and preparation method and use thereof

ActiveCN103145634AImprove wear resistanceGood extreme pressure resistanceOrganic chemistryAdditivesFood additiveLithium

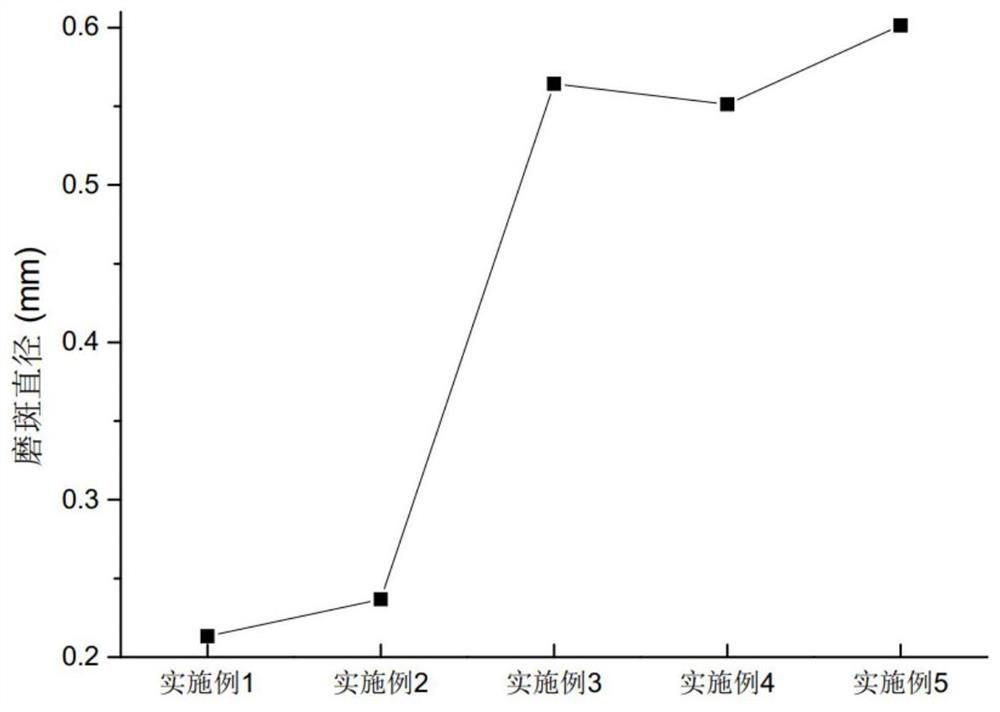

The invention discloses a coupled dimercaptotriazine derivative, and a preparation method and a use thereof. 2,4,6-trichloro-1,3,5-triazine, amine and sodium bisulfide are adopted as raw materials and undergo substitution and coupling reactions to obtain the coupled dimercaptotriazine derivative. The coupled dimercaptotriazine derivative can be used through the combination with other lubricating greases and lubricating oil additives as an extreme-pressure anti-wear agent, and can also be individually used as a lubricating oil or a lubricating grease additive to make a lubricant have very good wear and extreme pressure resistances; the derivative in lithium-based grease can improve the PB value by 40-100% and reduce the wear scar diameter by 35-50%; and the derivative in rapeseed oil can improve the PB value by 45-65% and reduce the wear scar diameter by 25-45%.

Owner:SHANGHAI JIAO TONG UNIV

High-hydrolysis stability organic ammonium borate extreme-pressure antiwear additive and preparation method thereof

ActiveCN103113959AImprove extreme pressure and anti-wear performanceHybrid empty orbital stabilizationGroup 3/13 element organic compoundsAdditivesBromineOil additive

The invention provides a high-hydrolysis stability organic ammonium borate extreme-pressure antiwear additive and a preparation method of the additive. The structural formula of the additive is shown as in formula (I). The invention further relates to a preparation method of the additive; and according to the preparation method, the additive is prepared from alkylbenzene, bromine, tributyl borate and alkylamine. The additive prepared by the preparation method disclosed by the invention can be independently added into lubricating oil to obtain a lubrication system with good antiwear performance and extreme pressure resistance, so that PB value of the lubricating oil is increased by 30%-110% and the wear scar diameter is reduced by 30%-50%. The additive prepared by the preparation method disclosed by the invention can be further compounded with other lubricating oil additives for use so as to achieve a synergistic interaction effect. The additive prepared by the preparation method disclosed by the invention has good antiwear performance and extreme pressure resistance, as well as excellent corrosion resistance, anti-oxidation performance and the like, and has good application prospect.

Owner:SHANGHAI JIAO TONG UNIV

Emulsified cutting fluid

InactiveCN106906036AImprove PB valueReduce wear scar diameterLubricant compositionReducerLubrication

The invention discloses emulsified cutting fluid, and relates to the technical field of industrial engineering lubrication. The emulsified cutting fluid is prepared from, by weight, 20-40 parts of mineral oil, 4-12 parts of tall oil, 3-7 parts of extreme pressure additives, 0.1-0.6 part of antirust agent, 0.2-1.5 parts of copper alloy anticorrosive agent, 0.1-1 part of antioxidant, 0.5-2 parts of defoaming agent, 0.5-1.5 parts of pour point reducer, and the balance deionized water. The emulsified cutting fluid has the good lubricity, diffusivity, cooling performance, cleaning performance, deslagging performance, corrosion resistance, rust resistance and foam resistance.

Owner:HUBEI UNIV OF ARTS & SCI +1

A kind of lubricating oil base oil and preparation method thereof

ActiveCN107325121BImprove catalytic performanceNo pollution in the processGroup 4/14 element organic compoundsCatalyst activation/preparationPtru catalystDistillation

Owner:JIANGSU ZHONGSHENG GAOKE ENVIRONMENTAL CO LTD

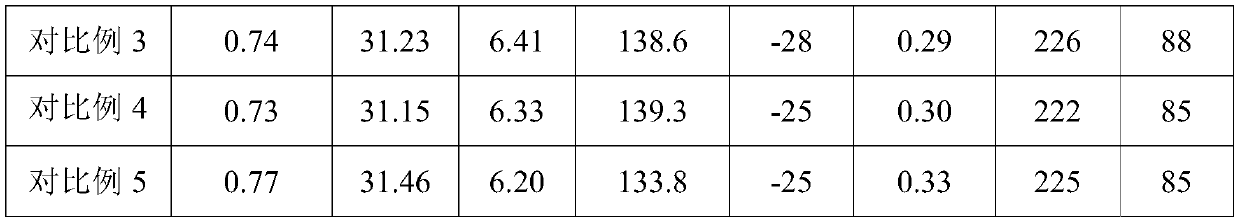

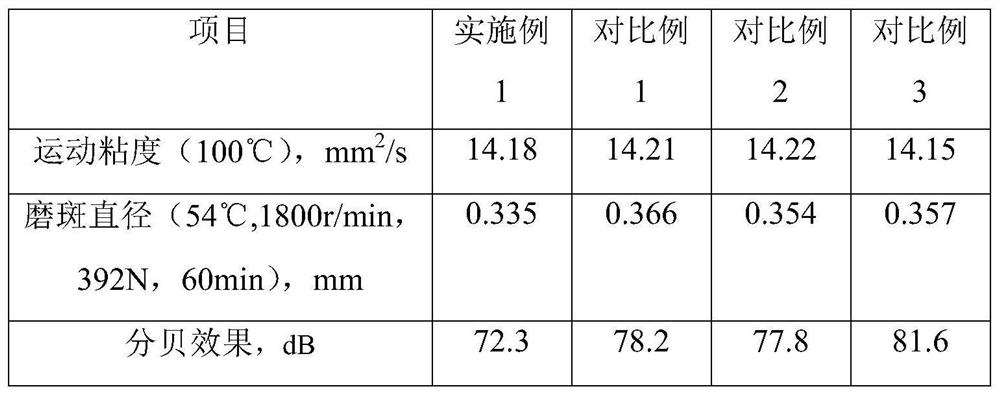

Lubricating oil capable of remarkably reducing engine noise and preparation method of lubricating oil

InactiveCN112877118AReduce working noiseReduce wear scar diameterLubricant compositionGasolineProcess engineering

The invention discloses lubricating oil capable of remarkably reducing engine noise and a preparation method thereof, and belongs to the technical field of lubricating oil and additives. The lubricating oil is composed of the following components: 6-12% of a gasoline engine oil complexing agent; 5-15% of a viscosity index improver; 0.1-1% of a friction reducing agent; 0.1-0.5% of a pour point depressant; 38%-45% of base oil A; and 35-40% of base oil B. The preparation method comprises the following steps: sequentially adding the components into a blending kettle according to the high-low sequence, heating to 50-60 DEG C, heating and stirring for 2 hours, uniformly mixing, filtering while hot, and cooling to room temperature to obtain the product. By optimizing component selection, proportion and preparation process, the obtained lubricating oil has excellent wear resistance, cleaning and dispersing performance, high-temperature oxidation resistance and the like, can remarkably reduce the working noise of an engine, and is beneficial to improving the driving feeling of people.

Owner:金雪驰科技(马鞍山)有限公司

High-thermal conductivity lubricating oil and preparation method thereof

ActiveCN102911762BImprove anti-friction and anti-wear effectImprove thermal conductivityAdditivesGrapheneBase oil

The invention relates to high-thermal conductivity lubricating oil and a preparation method thereof. The lubricating oil contains base oil and fluorinated graphene nanosheets, wherein the weight percent of content of the fluorinated graphene nanosheets is 0.01 to 10.0 %; and the preparation method comprises the steps as follows: firstly, preparing the fluorinated graphene nanosheets; and secondly, preparing the lubricating oil containing the fluorinated graphene nanosheets. The lubricating oil provided by the invention has the advantages of excellent antifriction effect, extremely high heat conduction capability and excellent stability and dispersibility.

Owner:青岛康普顿石油化工有限公司

Synthetic ester type fire resistant hydraulic oil

ActiveCN109439404AReduce wear scar diameterHigh FZG Failure LevelLubricant compositionTert butyl phenolAlkylphosphate

The invention discloses synthetic ester type fire resistant hydraulic oil. The synthetic ester type fire resistant hydraulic oil is prepared from the following components in percentage by weight: 96 to 98 percent of trimethylolpropane oleate, 0.1 to 0.7 percent of alkyl diphenol, 0.2 to 1.4 percent of sulfurized di-tert-butyl phenol, 0.05 to 0.3 percent of methylbenzotriazole, 0.2 to 1.4 percent of octylbutyldiphenylamine, 0.1 to 0.4 percent of phosphate, 0.001 to 0.05 percent of an ethylene glycol / propylene glycol copolymer, 0.25 to 1 percent of alkyl phosphate ammonium salt and 0.001 to 0.01percent of an antifoaming agent. Compared with existing fire resistant hydraulic oil, the synthetic ester type fire resistant hydraulic oil disclosed by the invention has a smaller wear spot diameter(less than or equal to 2.5 mm) and a higher FZG failure level (12 levels), and the oxidation life based on a rotary oxygen bomb method is longer than 400 min; and the synthetic ester type fire resistant hydraulic oil is very suitable for being applied to hydraulic systems in various high temperature, high pressure and severely cold working environments.

Owner:WUXI GAORUNJIE CHEM

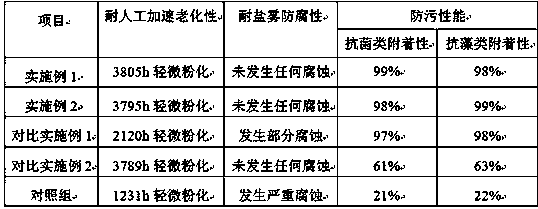

Method for preparing anti-aging, anti-corrosion and anti-fouling lubricating oil

InactiveCN110791353AImprove anti-corrosion and anti-fouling performanceControl release speedAdditivesPolyaspartic acidActive agent

The invention discloses a method for preparing anti-aging, anti-corrosion and anti-fouling lubricating oil. The method includes dissolving polyaspartic acid into a buffer solution, adding sodium stearate organic modified hydrotalcite, performing ultrasonic dispersion, then performing magnetic stirring, centrifuging and washing, dispersing in a cerium nitrate aqueous solution, performing ultrasonicdispersion, performing magnetic stirring, centrifuging and washing to obtain cerium ion-sodium stearate compound modified hydrotalcite; adding copper chloride dehydrate and polyethylene glycol into deionized water for dissolving, dropwise adding a sodium hydroxide solution and a glucose solution, then adding modified nano-zinc oxide, stirring for reaction, dropwise adding a sodium chloride solution, stirring for reaction at constant temperature, filtering, washing, drying in vacuum and grinding to obtain antifouling microcapsules; mixing nano cerium dioxide and nano serpentine, adding a compound surfactant, carrying out ultrasonic dispersion to obtain a lubricating additive, adding the lubricating additive into lubricating oil base oil, and uniformly mixing with the cerium ion-sodium stearate compound modified hydrotalcite and the antifouling microcapsules to obtain the anti-aging, anti-corrosion and anti-fouling lubricating oil.

Owner:界首市鑫一龙机械设备购销有限公司

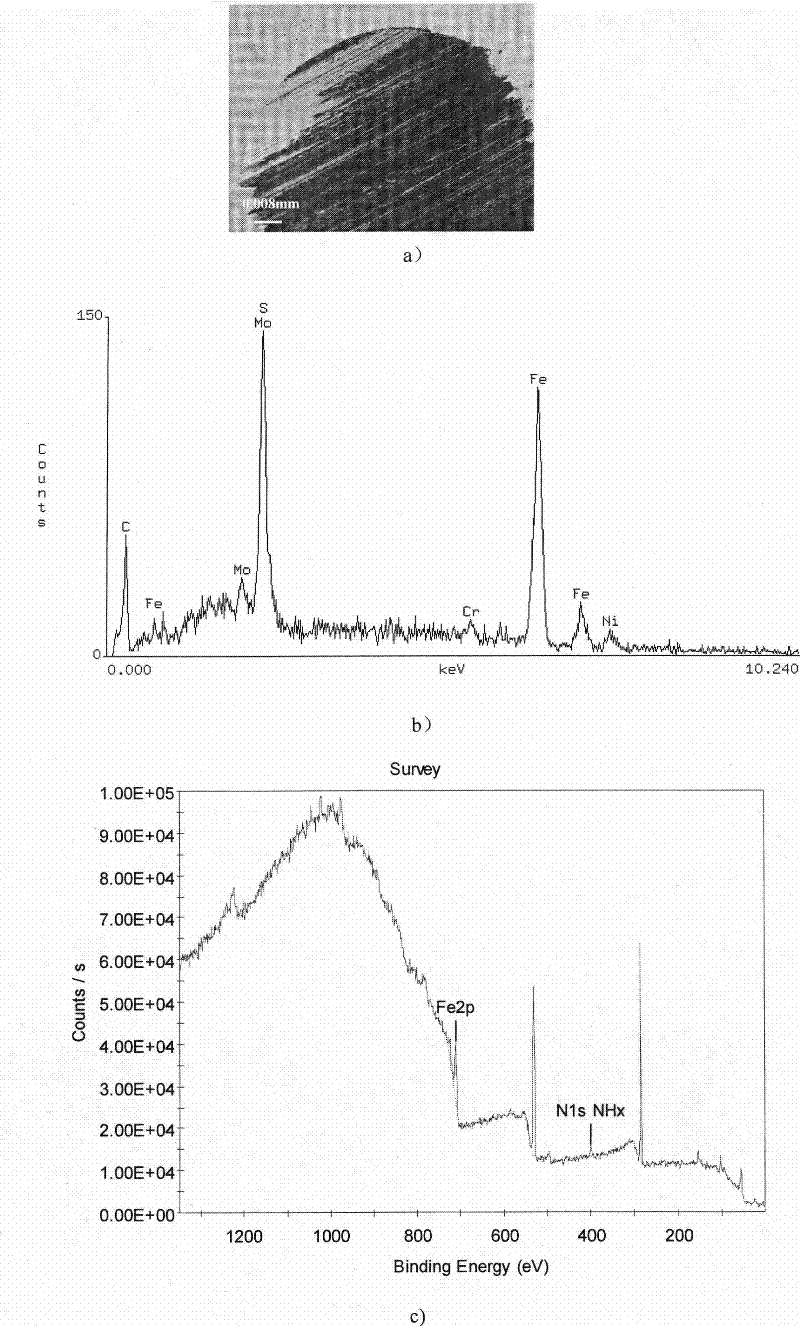

Lubricating oil compound nanometer antiwear agent preparation method

The invention relates to a lubricating oil compound nanometer antiwear agent preparation method, belonging to the technical field of lubricating oil additive preparation. The preparation method comprises the following steps: first, by taking fresh pork livers as raw materials, extracting the same to obtain a pork liver extract; mixing an ammonium paramolybdate solution and a thiourea solution, dropwise adding hydrochloric acid to adjust the pH (Potential Of Hydrogen), heating, standing, filtering and drying to obtain nanometer particles; mixing and dispersing the nanometer particles with a tris(hydroxymethyl)methyl aminomethane solution and absolute ethyl alcohol to obtain uniform suspension liquid; finally, attaching to the surfaces of the nanometer particles by using dopamine and adsorbing the pork liver extract to the surface layer of the shell of the dopamine to obtain a double-layer shell, then filtering and drying to obtain the lubricating oil compound nanometer antiwear agent. The lubricating oil compound nanometer antiwear agent prepared according to the method cannot release corrosive matters during using, and cannot corrode metal, so that the service life of a used part is prolonged; the lubricating oil compound nanometer antiwear agent has excellent antiwear performance, and the wear spot diameter is less than 0.40mm.

Owner:CHANGZHOU YAHUAN ENVIRONMENTAL PROTECTION TECH

Coupled dimercaptotriazine derivative, and preparation method and use thereof

ActiveCN103145634BImprove wear resistanceGood extreme pressure resistanceOrganic chemistryAdditivesFood additiveSodium hydrosulfide

The invention discloses a coupled dimercaptotriazine derivative, and a preparation method and a use thereof. 2,4,6-trichloro-1,3,5-triazine, amine and sodium bisulfide are adopted as raw materials and undergo substitution and coupling reactions to obtain the coupled dimercaptotriazine derivative. The coupled dimercaptotriazine derivative can be used through the combination with other lubricating greases and lubricating oil additives as an extreme-pressure anti-wear agent, and can also be individually used as a lubricating oil or a lubricating grease additive to make a lubricant have very good wear and extreme pressure resistances; the derivative in lithium-based grease can improve the PB value by 40-100% and reduce the wear scar diameter by 35-50%; and the derivative in rapeseed oil can improve the PB value by 45-65% and reduce the wear scar diameter by 25-45%.

Owner:SHANGHAI JIAO TONG UNIV

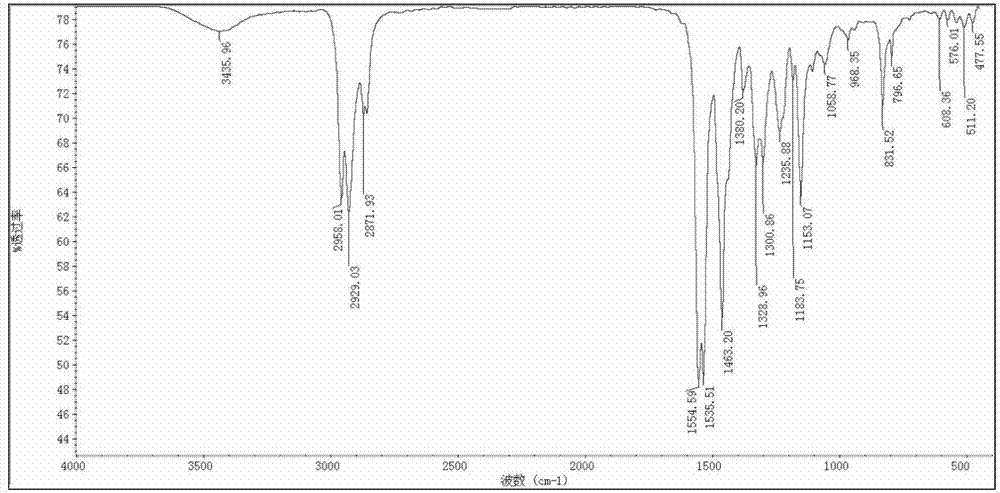

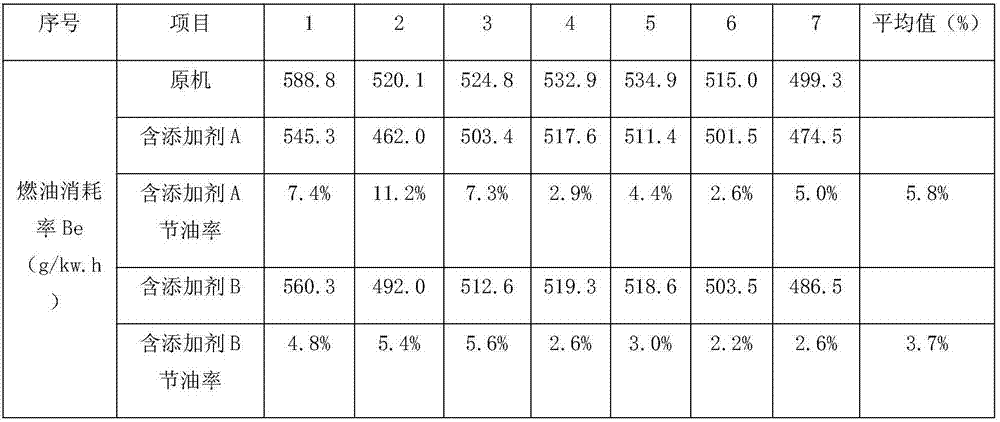

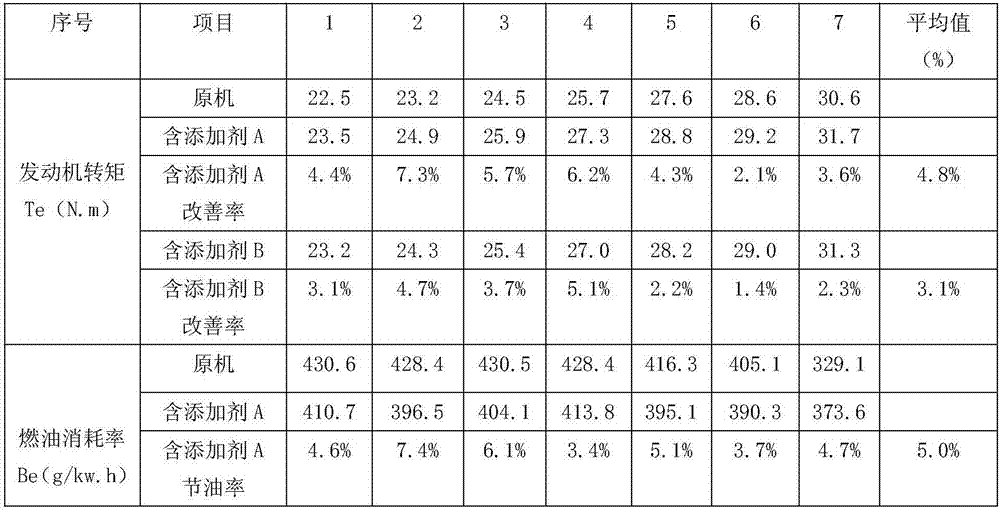

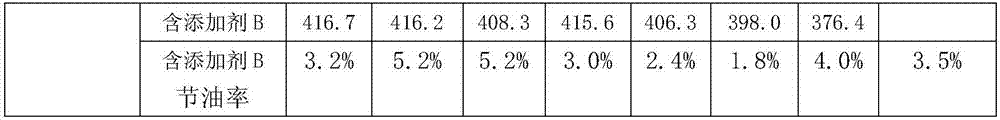

Network lattice nanosphere lubricating oil improver

The invention relates to a network lattice nanosphere lubricating oil improver, which belongs to a chemical composition and relates to a composition additive for improving the performance of lubricating oil. The lubricating oil improver includes polyethylene glycol and organic molybdenum, wherein the weight proportion of polyethylene glycol is 1.5-35%, and the weight proportion of organic molybdenum is 65-98.5%, and the polyethylene glycol includes polyethylene glycol Diol 200, Macrogol 400, Macrogol 600, Macrogol 800, Macrogol 1000, Macrogol 1500, Macrogol 2000, Macrogol 4000, Polyethylene Glycol 6000, polyethylene glycol 8000, polyethylene glycol 10000 and polyethylene glycol 20000; the organic molybdenum includes dialkyl molybdenum dithiophosphate and dialkyl disulfide One or a mixture of two molybdenum carbamates. The invention can not only improve the combustion rate of fuel oil, but also greatly reduce the discharge of exhaust gas from fuel combustion.

Owner:广东新科态节能减排技术研究所有限公司

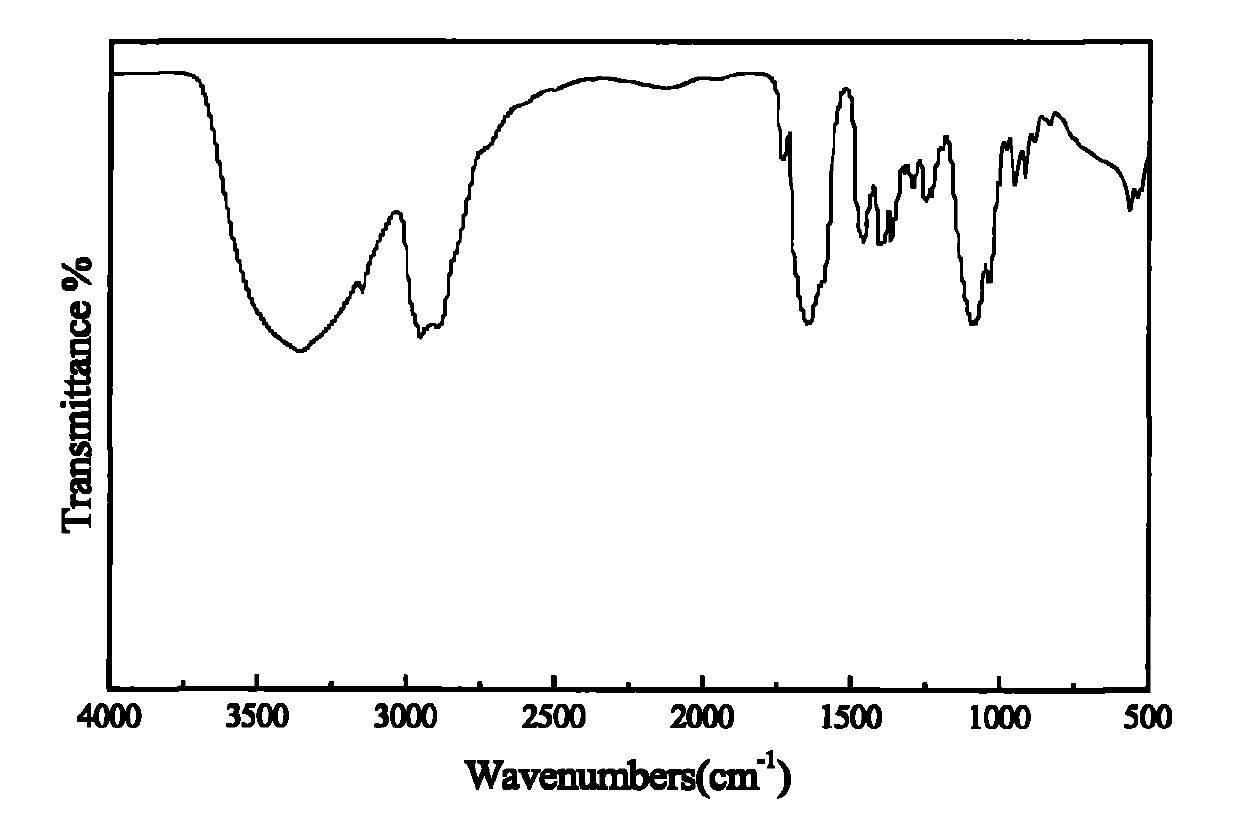

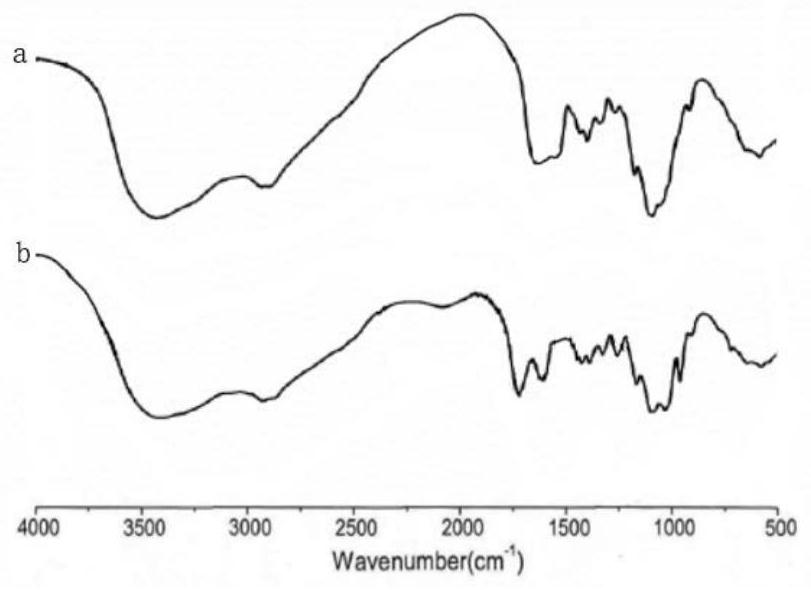

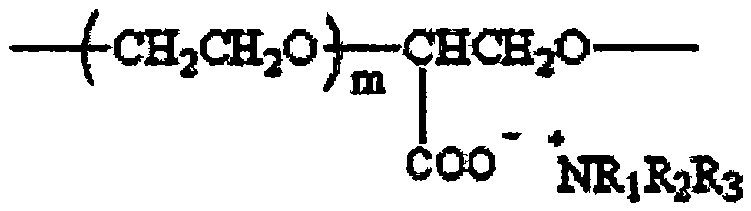

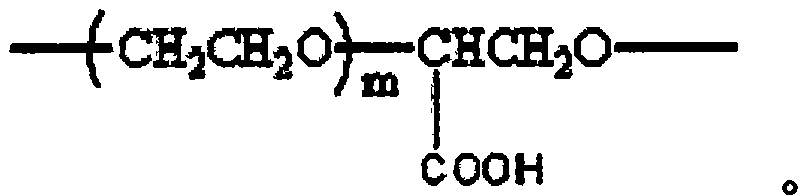

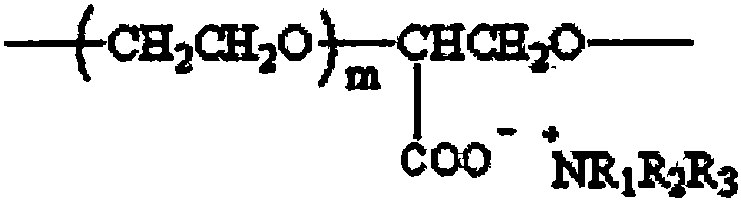

Water-based hydraulic fluid anti-wear additive, namely carboxylic acid amine salt modified polyethylene oxide

InactiveCN111040825AExtended service lifeImprove job stabilityAdditivesPolyethylene oxideEthylene oxide

The invention discloses a water-based hydraulic fluid anti-wear additive, namely carboxylic acid amine salt modified polyethylene oxide. The carboxylic acid amine salt modified polyethylene oxide is prepared through the following steps: uniformly mixing carboxylic acid modified polyethylene oxide and fatty amine according to a certain ratio, carrying out stirring, carrying out a reaction at a normal temperature for 50-70 minutes, carrying out heating to 35-45 DEG C, and carrying out stirring for 50-70 minutes so as to obtain the carboxylic acid amine salt modified polyethylene oxide. The carboxylamine salt modified polyethylene oxide provided by the invention is used as the water-based hydraulic fluid anti-wear agent; a certain concentration of the anti-wear agent provided by the inventionis added into a water-ethylene glycol flame-retardant liquid base solution; in a four-ball experiment, the wear spot diameter is reduced by 60.0% at most; the maximum non-seizure load can be increased by 77.5% at most; the total wear weight loss in a vane pump friction experiment is only about 50 mg; and excellent wear resistance is achieved. The anti-wear agent provided by the invention enablesthe anti-wear performance of a hydraulic medium to be greatly improved, prolongs the service life of a hydraulic element and improves the working stability of a whole hydraulic system.

Owner:BEIJING XINXIANGYUAN CHANGSHUN LUBRICATING OIL CO LTD

Bentonite-containing grease composition and preparation method thereof

The invention relates to the field of bentonite grease, and discloses a bentonite-containing grease composition and a preparation method thereof. The grease composition contains a base oil, an organic bentonite, an inorganic metal salt, and an optional dispersant, wherein the inorganic metal salt is selected from the group consisting of alkali metal carbonates, alkali metal chlorides, transition metal carbons At least one of acid salts and transition metal chlorides; the content of inorganic metal salts is 8-110 g per kilogram of base oil. The invention also discloses a method for preparing the lubricating grease composition, which comprises: mixing organic bentonite, inorganic metal salt, dispersant and part of base oil, heating and heating, and then mixing with the remaining base oil. Through the above technical solutions, the present invention can effectively improve the anti-wear performance of the grease. Specifically, the grease composition of the present invention has higher maximum non-seizing load and sintering load, and has smaller wear scar diameter.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com