Lubricating oil capable of remarkably reducing engine noise and preparation method of lubricating oil

An engine and lubricating oil technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of poor noise reduction and noise reduction, achieve the effect of mute effect, prolong the oil change period, and improve the driving experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

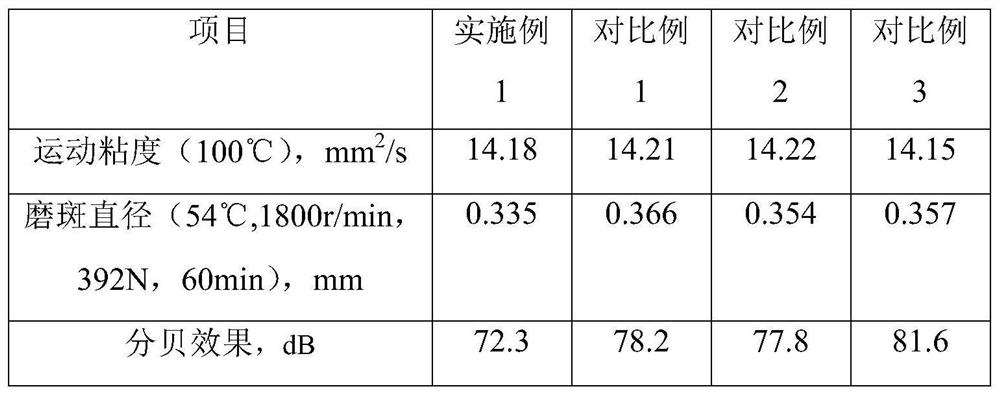

Embodiment 1

[0040] A kind of lubricating oil that significantly reduces engine noise of the present embodiment is made up of the raw material of following mass percent: gasoline engine oil compounding agent is Afton HiTEC 9890: 8%; Viscosity index improver is Lubrizol 7067C: 10%; Antifriction The agent is Pacific Union POUPC 1001: 1%; the pour point depressant is Romax 1-248: 0.5%; the base oil A is Abu Dhabi Group III 150N base oil: 40.5%; the base oil B is SK III Group 100N base oil : 40%.

[0041] The preparation method is as follows: add the above-mentioned gasoline engine oil compounding agent, viscosity index improver, friction reducer, pour point depressant, base oil A, and base oil B into the blending kettle in sequence according to the order of components, and heat up to 55°C. Heat and stir for 2 hours until the components are mixed evenly and the appearance is transparent, filter while hot, and cool down to room temperature to obtain the lubricating oil product.

[0042] Carry ...

Embodiment 2

[0044] A lubricating oil that significantly reduces engine noise in this embodiment is composed of the following raw materials in mass percentage: gasoline engine oil compounding agent is Afton H9325G: 12%; viscosity index improver is Infineum SV261: 15%; friction reducer It is a mixture of Vanderbilt MOLYVAN 855 and Vanderbilt MOLYVAN 3000 (mixed in any proportion), which accounts for 0.1% of the total components; the pour point depressant is Romax 1-300: 0.1%; base oil A is Xiamen Zhonglu Group III 150N base oil: 37.8%; base oil B is Group III base oil 100N: 35%.

[0045] The preparation method is as follows: add the above-mentioned gasoline engine oil compounding agent, viscosity index improver, friction reducer, pour point depressant, base oil A, and base oil B into the blending kettle in sequence according to the order of components, and heat up to 50°C. Heat and stir for 2.5 hours until the components are mixed evenly and the appearance is transparent, filter while it is...

Embodiment 3

[0048] A kind of lubricating oil that significantly reduces engine noise of the present embodiment is made up of the raw material of following mass percent: gasoline engine oil compounding agent is Afton HiTEC 11100: 6%; Viscosity index improver is Chevron 8900E: 10.1%; The agent is Vanderbilt MOLYVAN 855: 0.4%; the pour point depressant is polymethacrylate: 0.5%; the base oil A is three types of base oil 150N: 45%; the base oil B is SK three types of 100N base oil: 38 %.

[0049] The preparation method is as follows: add the above-mentioned gasoline engine oil compounding agent, viscosity index improver, friction reducer, pour point depressant, base oil A, and base oil B into the blending kettle in sequence according to the order of components, and heat up to 60°C. Heat and stir for 3 hours until the components are mixed evenly and the appearance is transparent, filter while hot, and cool down to room temperature to obtain the lubricating oil product.

[0050] The prepared l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com