Phosphate amine salt and preparation method thereof

A phosphate ester amine salt, alcohol amine technology, applied in chemical instruments and methods, phosphorus organic compounds, organic chemistry and other directions, can solve the basic functions of emulsification, anti-wear, anti-rust and anti-hard water stability, which are not disclosed, etc. problems, to achieve the effect of highlighting the stability of hard water resistance, reducing the degree of rust, and good rust resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

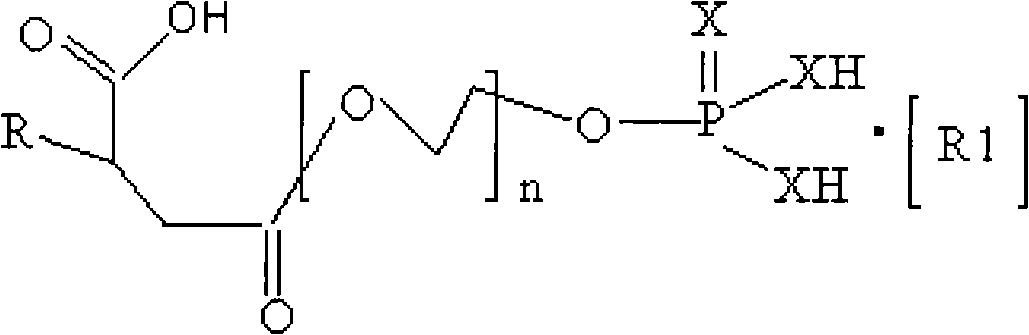

[0026] 1 mole C 71 Add long-chain alkenyl succinic anhydride and 1 mole of polyethylene glycol (PEG400) into the reaction vessel, install a reflux condenser, and heat while stirring. The temperature is controlled at 35°C. After stirring evenly, heat to 100°C. React for 20 hours. After the above reaction mixture is cooled, add 0.5 mole of phosphorus pentoxide, heat to 80°C, stir for 2 hours, then add 1 mole of triethanolamine into the container, stir and react for 2 hours at 80°C, the final product after cooling is as follows:

[0027]

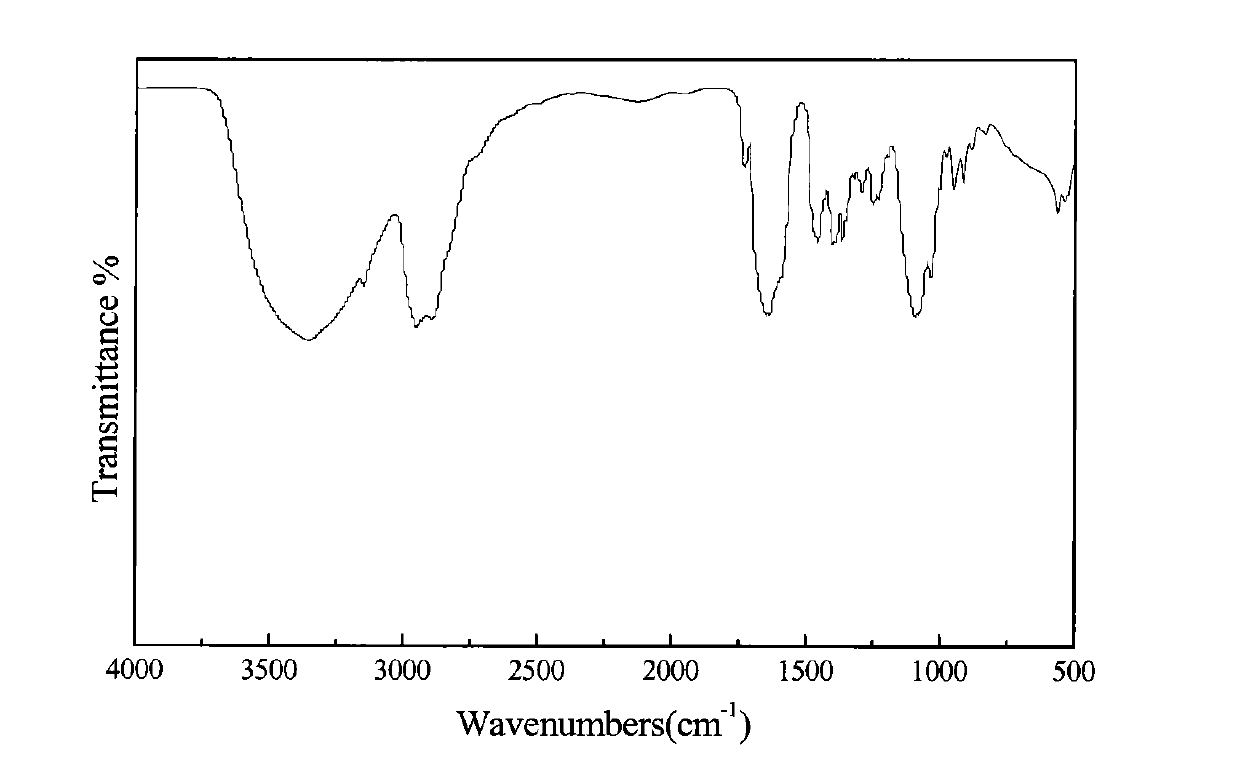

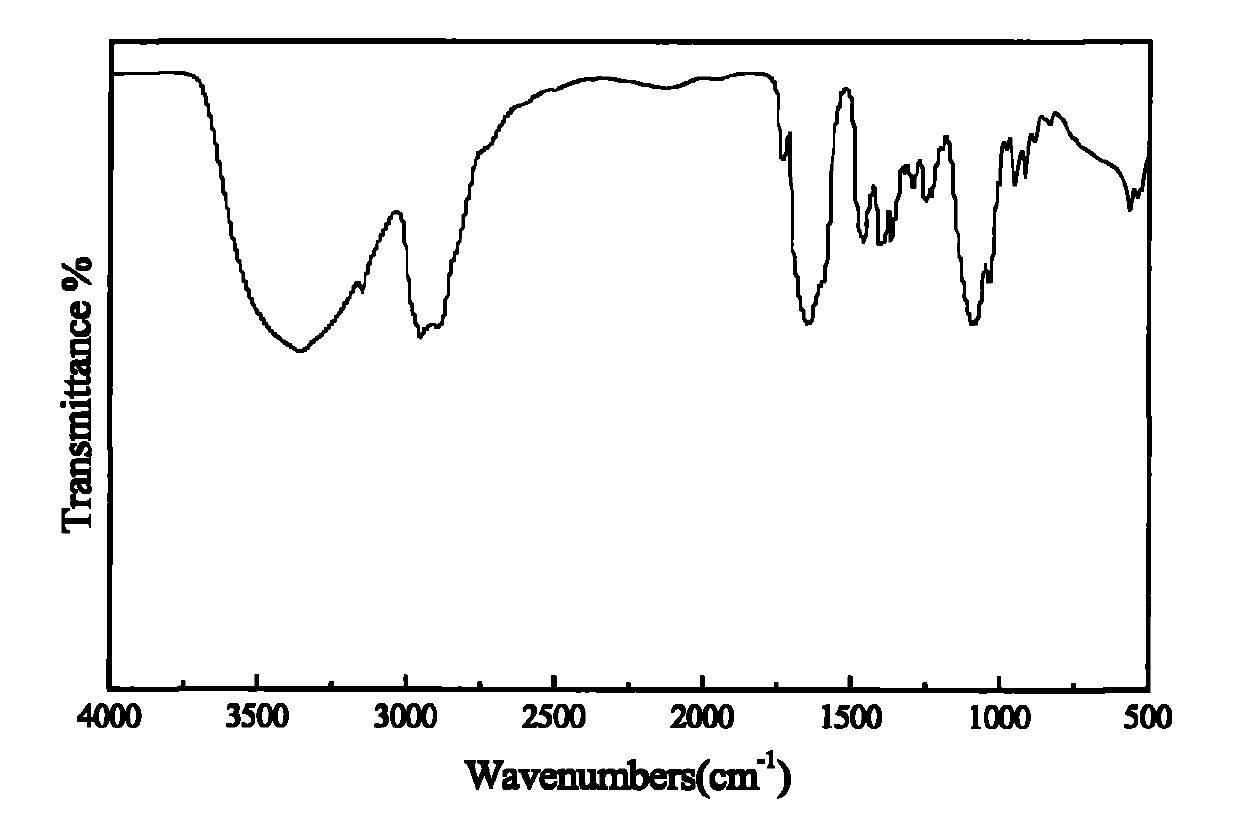

[0028] Wherein, R1 is triethanolamine. The synthesized product was analyzed by infrared spectrum (scanning range 4000~400cm -1 ),have figure 1 Characteristic peaks shown.

Embodiment 2

[0030] 1 mole C 71 Add long-chain alkenyl succinic anhydride and 0.5 mole of polyethylene glycol (PEG400) into the reaction vessel, install a reflux condenser, heat while stirring, and control the temperature at 35°C. After stirring evenly, heat to 100°C. React for 20 hours. After the above reaction mixture is cooled, add 0.5 mole of phosphorus pentasulfide, heat to 80°C, stir for 2 hours, add 2 moles of triethanolamine to the container, stir and react for 2 hours at 80°C, and the final product after cooling is as follows:

[0031]

[0032] Wherein, R1 is triethanolamine.

Embodiment 3

[0034]Add 1 mole of dodecenylsuccinic anhydride and 2 moles of polyethylene glycol (PEG200) into the reaction vessel, install a reflux condenser, heat while stirring, the temperature is controlled at 35 ° C, and then heat to 100 °C after stirring evenly °C, the reaction was maintained for 20 hours. After the above reaction mixture is cooled, add 0.5 mole of phosphorus pentoxide, heat to 80°C, stir for 2 hours, then add 1 mole of triethanolamine into the container, stir and react for 2 hours at 80°C, the final product after cooling is as follows:

[0035]

[0036] Wherein, R1 is triethanolamine. The synthesized product was analyzed by infrared spectrum (scanning range 4000~400cm -1 ),have figure 1 Characteristic peaks shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com