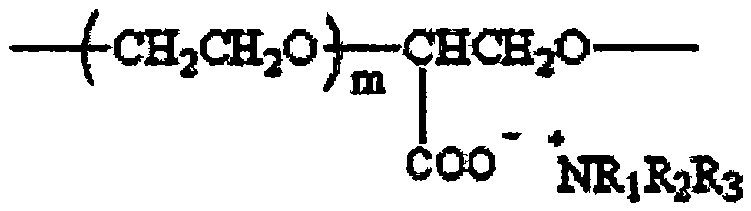

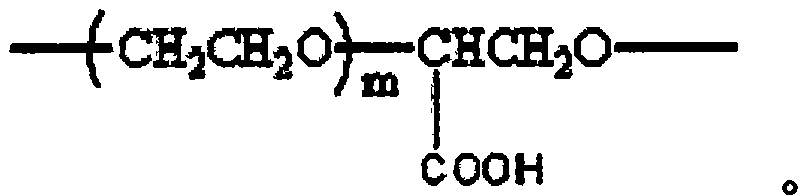

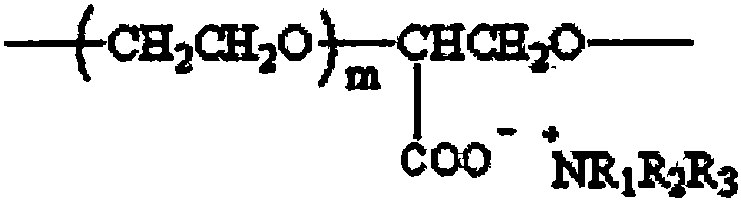

Water-based hydraulic fluid anti-wear additive, namely carboxylic acid amine salt modified polyethylene oxide

A polyethylene oxide water-based, polyethylene oxide technology, applied in the directions of additives, petroleum industry, lubricating compositions, etc., can solve the problems of serious, unable to form protective film, wear of vane pump stator and rotor, etc. The effect of improved service life, increased anti-wear performance, excellent anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 300 grams of carboxylic acid polyethylene oxide with a molecular weight of 300 and 28 grams of triethylamine into a 1L single-necked flask, stir, react at room temperature for 1 hour, heat to 45±5°C, and continue stirring for 1 hour to obtain a transparent light yellow color liquid, product 1 was obtained.

Embodiment 2

[0023] Add 500 grams of carboxylic acid polyethylene oxide with a molecular weight of 1500 and 35 grams of n-hexylamine into a 1L single-necked flask, stir, react at room temperature for 1 hour, heat to 45±5°C, and continue stirring for 1 hour to obtain a transparent light yellow liquid , get product 2.

Embodiment 3

[0025] Add 300 grams of carboxylic acid polyethylene oxide with a molecular weight of 2000 and 35 grams of triethylamine into a 1L single-necked flask, stir, react at room temperature for 1 hour, heat to 45±5°C, and continue stirring for 1 hour to obtain a transparent light yellow color liquid, product 3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com