High-hydrolysis stability organic ammonium borate extreme-pressure antiwear additive and preparation method thereof

A technology of hydrolytic stability and ammonium borate salt, which is applied in the fields of additives, organic chemistry, chemical instruments and methods, etc., and can solve the problems of poor hydrolytic stability of boron-containing additives and failure of product storage performance to meet requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

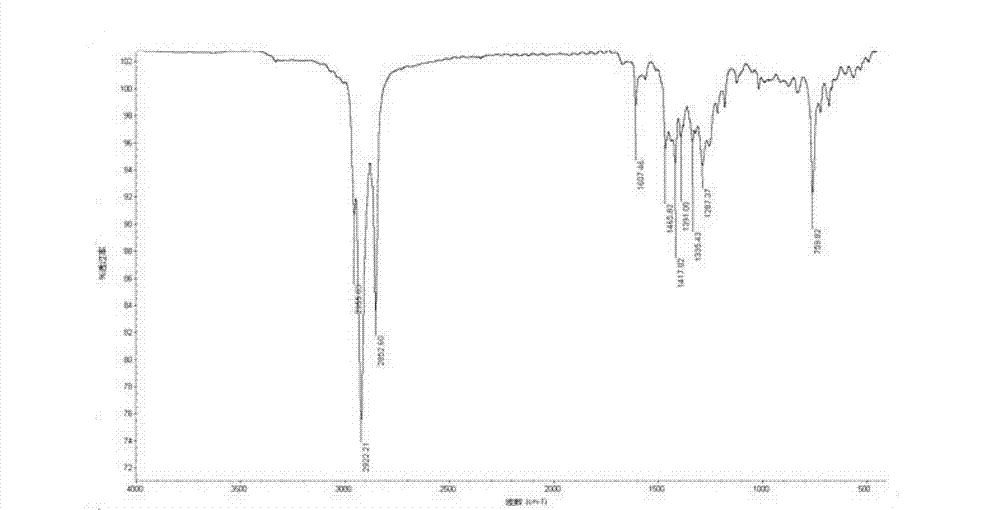

Embodiment 1

[0049] This embodiment relates to a highly hydrolytically stable ammonium organoborate extreme pressure anti-wear additive and a preparation method thereof, the method comprising the following steps:

[0050] Step 1, in the there-necked flask of the bromine of 24.6g 4-dodecylbenzene and 17.5g, add 2g catalyst, after reacting in ice-water bath for half an hour, add 2g acid-binding agent (potassium hydroxide) aqueous solution, heated to reflux for 12 hours, the organic layer was washed with sodium thiosulfate solution until the aqueous layer was transparent, dried over anhydrous magnesium sulfate, and the organic solvent was evaporated under reduced pressure to obtain a yellow oily intermediate (4-dodecylbromobenzene) 30.91 g, yield 95.2%;

[0051] Step 2: Add 0.1 g of catalyst to 30.91 g of 4-dodecylbromobenzene anhydrous tetrahydrofuran solution, cool to -78°C, add 5.9 g of n-butyllithium, and slowly add excess 43.73 g of boric acid after 0.5 h Tributyl ester, the reaction te...

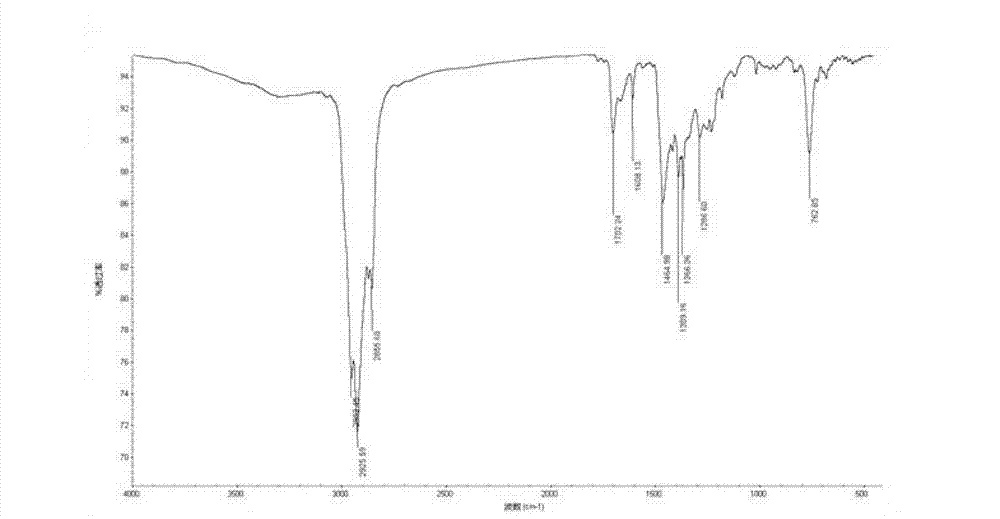

Embodiment 2

[0059] This example relates to a highly hydrolytically stable organic borate ammonium salt extreme pressure anti-wear additive and its preparation method.

[0060] Its method comprises the following steps:

[0061] Step 1, in the there-necked flask that 24.6g4-dodecylbenzene and 17.5g bromine are housed, add 2g catalyst, after reacting in ice-water bath for half an hour, add 2g acid-binding agent (potassium hydroxide) aqueous solution again, Heated to reflux for 12 hours, the organic layer was washed with sodium thiosulfate solution until the aqueous layer was transparent, dried over anhydrous magnesium sulfate, and the organic solvent was evaporated under reduced pressure to obtain 30.91 g of a yellow oily intermediate (4-dodecylbromobenzene). Yield 95.2%;

[0062] Step 2: Add 0.1 g of catalyst to 30.91 g of 4-dodecylbromobenzene anhydrous tetrahydrofuran solution, cool to -78°C, add 5.9 g of n-butyllithium, and slowly add excess 43.73 g of boric acid after 0.5 h Tributyl est...

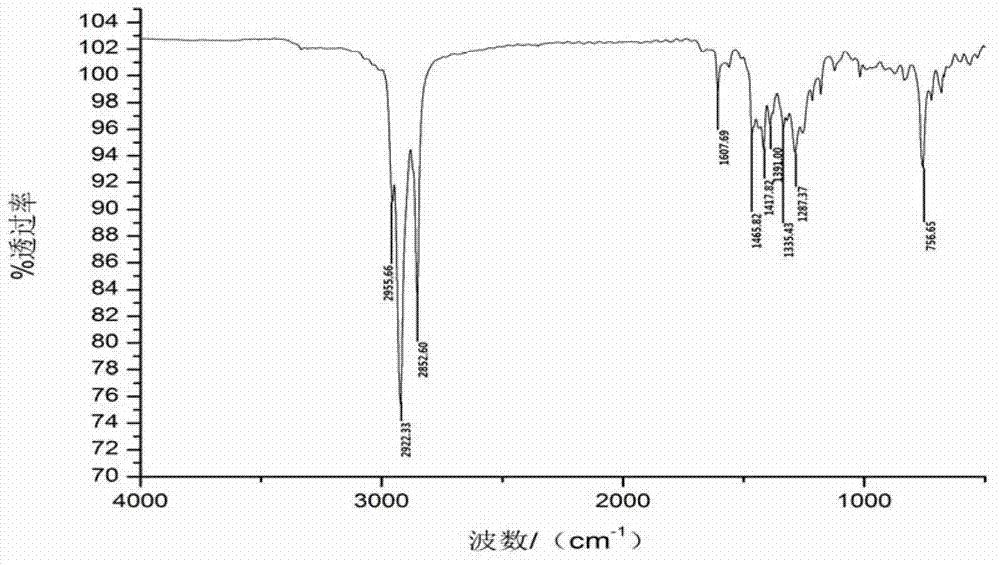

Embodiment 3

[0067] This embodiment relates to a highly hydrolytically stable ammonium organoborate extreme pressure anti-wear additive and a preparation method thereof, the method comprising the following steps:

[0068] Step 1, in the there-necked flask that 33g4-octadecylbenzene and 17.5g of bromine are housed, add 2g catalyst, after reacting in ice-water bath for half an hour, then add 2g acid-binding agent (potassium hydroxide) aqueous solution, heat Refluxed for 12 hours, the organic layer was washed with sodium thiosulfate solution until the aqueous layer was transparent, dried over anhydrous magnesium sulfate, and the organic solvent was evaporated under reduced pressure to obtain 38.9 g of a yellow oily intermediate (4-octadecylbromobenzene), which produced Rate 94.99%;

[0069] Step 2: Add 0.1 g of catalyst to 30 g of 4-octadecylbromobenzene anhydrous tetrahydrofuran solution, cool to -78°C, add 4.7 g of n-butyllithium, and slowly add excess 33.72 g of tributyl borate after 0.5 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com