Lubricating oil additive based on modified nano alumina and preparation method of lubricating oil additive

A nano-alumina, lubricating oil technology, applied in additives, petroleum industry, lubricating compositions, etc., can solve problems affecting lubricating oil performance and stability, and achieve improved wear resistance, good performance stability, wear resistance Spot diameter reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

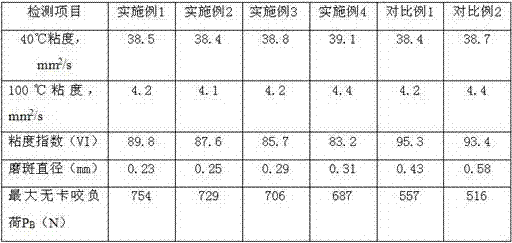

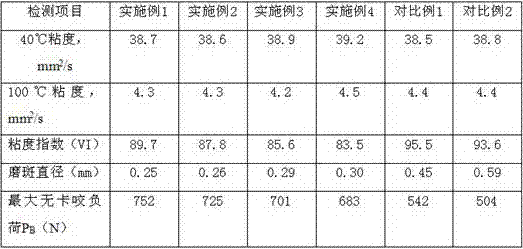

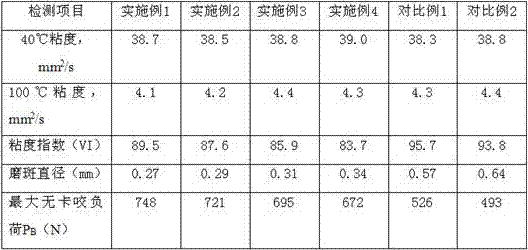

Examples

Embodiment 1

[0021] A preparation method of a lubricating oil additive based on modified nano-alumina, comprising the steps of:

[0022] (1) Add 40 parts of nano-alumina, isopropanol, polyethylene glycol, and polyvinylpyrrolidone into 120 parts of an aqueous solution, and after ultrasonic treatment for 15 minutes at room temperature, place it on a magnetic stirrer for stirring. Slowly add 2wt% aluminum-zirconium coupling agent, and stir the reaction system at 50°C for 30 minutes; adjust the pH of the reaction solution to 9.0-9.5 with dilute hydrochloric acid, and form a gel after stirring for 3-5 minutes ; Wash the gel product 3 times with ethanol solution, collect the solid precipitate, and add it to the autoclave for 2-4 hours to react to obtain modified nano-alumina; wherein, the nano-alumina is mixed with isopropanol, polyethylene The mass volume ratio g / mL of diol and polyvinylpyrrolidone is 20:1, 15:1, 15:1 respectively, and the mass volume ratio g / mL of the nano-alumina and aluminum...

Embodiment 2

[0027] A preparation method of a lubricating oil additive based on modified nano-alumina, comprising the steps of:

[0028] (1) Add 30 parts of nano-alumina, isopropanol, polyethylene glycol, and polyvinylpyrrolidone into 80 parts of an aqueous solution, and after ultrasonic treatment for 10 minutes at room temperature, place it on a magnetic stirrer for stirring. Slowly add 1wt% aluminum-zirconium coupling agent, and stir the reaction system at 40°C for 20 minutes; adjust the pH of the reaction solution to 9.0-9.5 with dilute hydrochloric acid, and form a gel after stirring for 3-5 minutes ; Wash the gel product 3-5 times with ethanol solution, collect the solid precipitate, and add it to a high-pressure reactor for 2 hours to obtain modified nano-alumina; wherein, the nano-alumina is mixed with isopropanol, polyethylene The mass volume ratio g / mL of diol and polyvinylpyrrolidone is 15:1, 10:1, 12:1 respectively, and the mass volume ratio g / mL of the nano-alumina and aluminum...

Embodiment 3

[0033] A preparation method of a lubricating oil additive based on modified nano-alumina, comprising the steps of:

[0034] (1) Add 50 parts of nano-alumina, isopropanol, polyethylene glycol, and polyvinylpyrrolidone into 150 parts of an aqueous solution, and after ultrasonic treatment at room temperature for 20 minutes, place it on a magnetic stirrer for stirring. Slowly add 3wt% aluminum-zirconium coupling agent, and stir the reaction system at 60°C for 40 minutes; adjust the pH of the reaction solution to 9.0-9.5 with dilute hydrochloric acid, and form a gel after stirring for 3-5 minutes ; Wash the gel product 3-5 times with ethanol solution, collect the solid precipitate, and add it to a high-pressure reactor for 4 hours to obtain a modified nano-alumina; wherein, the nano-alumina is mixed with isopropanol, polyethylene The mass volume ratio g / mL of diol and polyvinylpyrrolidone is 30:1, 20:1, 18:1 respectively, and the mass volume ratio g / mL of the nano-alumina and alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com