Bentonite-containing grease composition and preparation method thereof

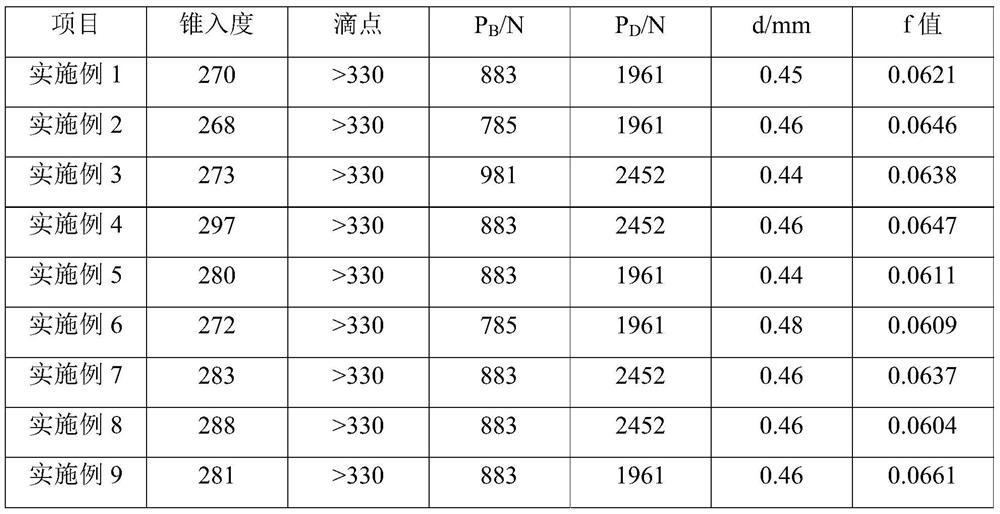

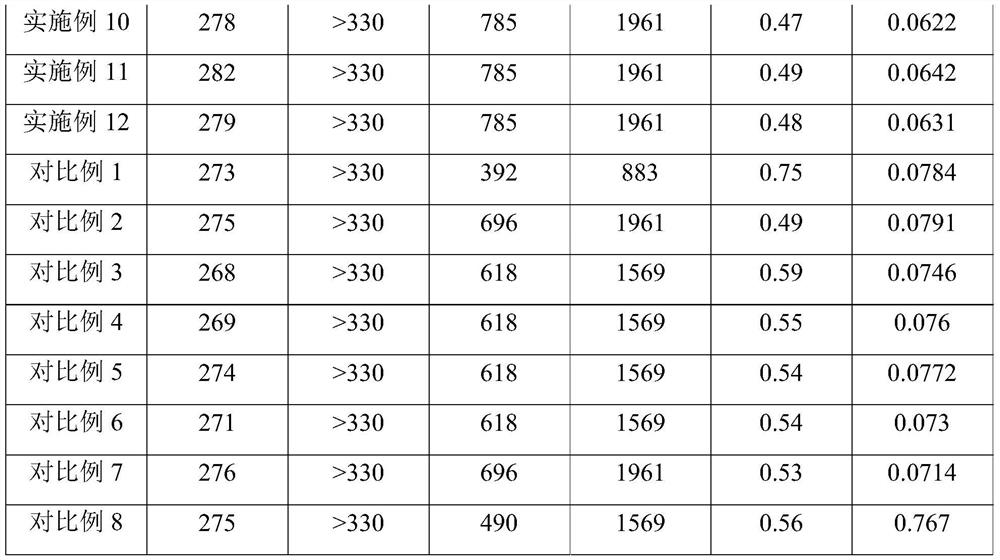

A grease composition and technology of bentonite, applied in the field of bentonite grease, can solve the problems of large addition amount and poor effect, and achieve the effect of improving anti-wear performance, small wear scar diameter and high sintering load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The method for preparing a lubricating grease composition provided by the present invention includes: mixing organic bentonite, inorganic metal salt, dispersant and part of the base oil, heating and heating, then mixing with the remaining base oil, and then mixing with optional additives.

[0024] More specifically, the method includes: mixing organic bentonite, inorganic metal salt, dispersant and part of base oil and heating to 120-130°C, then mixing with the remaining base oil, and then optionally mixing with additives . Generally, the finally obtained mixture should also be ground to make the material disperse more uniformly.

[0025] In the present invention, in order to further improve the performance of the resulting grease composition, preferably, the inorganic metal salt is introduced in the form of an aqueous solution of the inorganic metal salt. There is no special requirement on the concentration of the inorganic metal salt aqueous solution, for example, th...

Embodiment 1

[0034] In the reaction kettle, add 670g of mineral oil 1 (100 ℃ kinematic viscosity 10mm 2 / s), 100g organic bentonite (brand HFGEL-310) and 20g acetone, stir evenly, add 60g inorganic metal salt aqueous solution (30g sodium carbonate + 130g water), stir and heat up to 125±5°C, add 200g mineral oil 1, material A sample of the grease composition was prepared by three-wheel milling to uniformly disperse the material.

Embodiment 2

[0036] In the reactor, add 670g olefin oil 1 (100 ℃ kinematic viscosity 10mm 2 / s), 120g organic bentonite (brand HFGEL-310) and 20g acetone, stir evenly, add 40g inorganic metal salt aqueous solution (10g lithium carbonate+30g water), stir and heat up to 125±5℃, add 200g olefin oil 1, the material A sample of the grease composition was prepared by three-wheel milling to uniformly disperse the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com