Preparation method of copper wire

A technology for copper wire and copper wire drawing liquid, applied in the field of bonding wire, can solve the problems of short liquid change cycle, extreme pressure and anti-wear, broken wire and wire shrinkage, etc., to prevent surface oxidation, extreme pressure and resistance to Good wearability and the effect of reducing the diameter of wear scars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

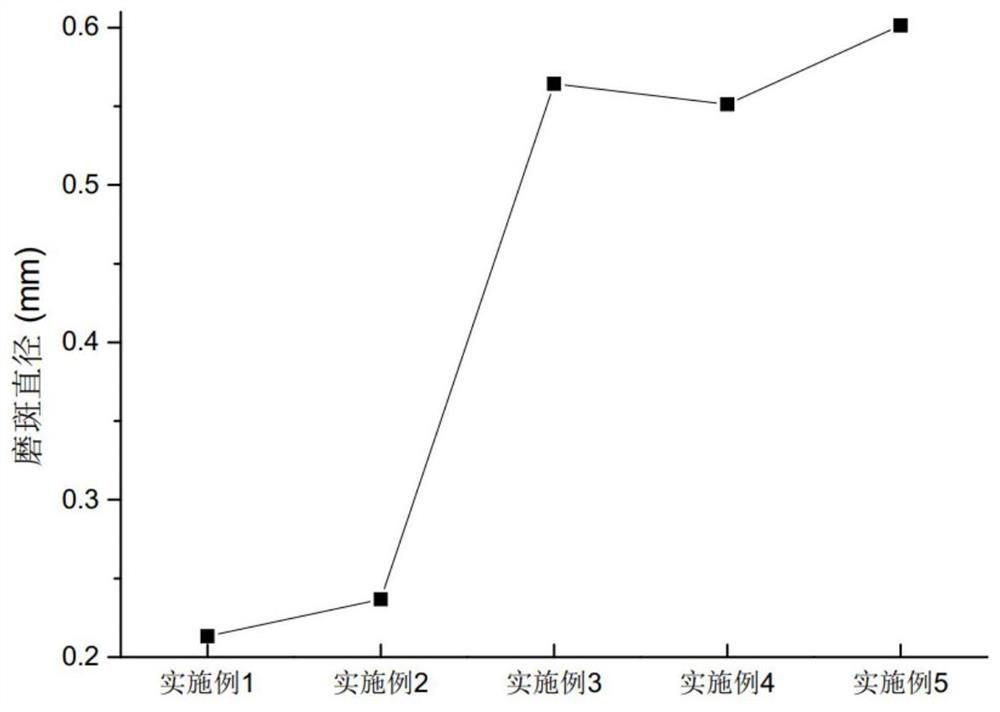

Embodiment 1

[0045] 1. a preparation method of tall oil acid emulsifier, comprising,

[0046] S1: Weigh tall oleic acid, isatoic anhydride, galactosamide, azobisisobutyronitrile, and sodium hydroxide in a molar ratio of 1:1.32:1.25:0.01:0.01.

[0047] S2: Put tall oil acid, isatoic anhydride, azobisisobutyronitrile and toluene at 67°C, 220r / min, N 2 Stirring and reacting for 3.5 hours under protection gave the intermediate compound;

[0048] S3: Add sodium hydroxide to the intermediate compound, keep it warm at 110°C for 45min, add galactosamide, and then heat it at 150°C, 220r / min, N 2 Stirring reaction under protection for 4h, to obtain tall oil acid emulsifier.

[0049] 2. A preparation method for copper wire drawing liquid, comprising,

[0050] S1: In parts by weight, take 15 parts of castor oil, 3 parts of sulfonated castor oil, 3 parts of pentaerythritol oleate, 9 parts of triethanolamine borate, 22 parts of tall oil acid emulsifier, and 1000 parts of deionized water;

[0051] S2...

Embodiment 2

[0059] 1. a kind of preparation method of tall oil acid emulsifier, with embodiment 1

[0060] 2. A preparation method for copper wire drawing liquid, comprising,

[0061] S1: In parts by weight, take 13 parts of castor oil, 5 parts of sulfonated castor oil, 5 parts of pentaerythritol oleate, 7 parts of triethanolamine borate, 15 parts of tall oil acid emulsifier, and 1000 parts of deionized water;

[0062] S2: Heat deionized water to 56°C, add castor oil, sulfonated castor oil, pentaerythritol oleate, triethanolamine borate, and tall oil acid emulsifier at a stirring speed of 1200r / min, and continue stirring for 90 minutes. The copper wire drawing liquid was obtained, and the HLB value of the copper wire drawing liquid was 13.8.

[0063] 3. A kind of preparation method of copper wire, with embodiment 1.

Embodiment 3

[0065] 1. a preparation method of tall oil acid emulsifier 1, comprising,

[0066] S1: Weigh tall oleic acid, isatoic anhydride, and azobisisobutyronitrile at a molar ratio of 1:1.32:0.01.

[0067] S2: Put tall oil acid, isatoic anhydride, azobisisobutyronitrile and toluene at 67°C, 220r / min, N 2 Stirred and reacted for 3.5 h under protection to obtain tall oil acid emulsifier 1.

[0068] 2. A preparation method of copper wire drawing liquid, same as embodiment 1, the HLB value of copper wire drawing liquid is 16.3.

[0069] 3. A kind of preparation method of copper wire, with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com