High-thermal conductivity lubricating oil and preparation method thereof

A high thermal conductivity, lubricating oil technology, used in lubricating compositions, petroleum industry, additives, etc., can solve the problems of easy wear of friction pairs, easy deterioration of lubricating oil, shortened life, etc., and achieve low interface thermal resistance and friction coefficient. The effect of reducing, good carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

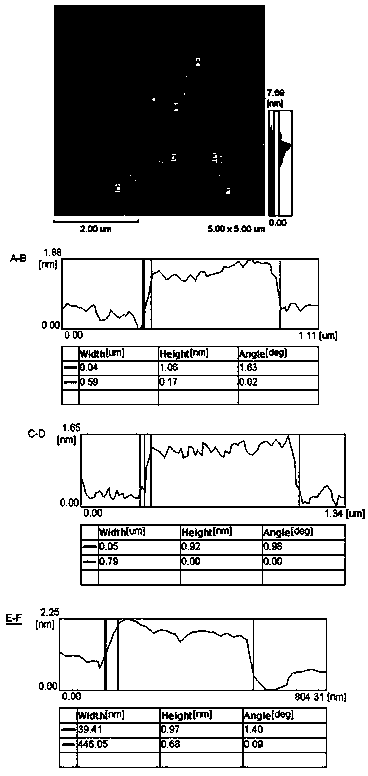

[0030] A lubricating oil with high thermal conductivity, comprising: 98% by weight of liquid paraffin oil and 2% by weight of fluorinated graphene nanosheets.

[0031] The preparation method of this lubricating oil is:

[0032] (1) Preparation of fluorinated graphene nanosheets by gas-phase fluorination: 1) Preparation of graphite oxide: In an ice bath, mix 10g of graphite powder and 5g of sodium nitrate with 230mL of concentrated sulfuric acid, and slowly add 30g of KMn0 while stirring 4 ;It was transferred to a 35°C water bath for 30 minutes, then gradually added 460mL of deionized water, and when the temperature rose to 98°C, the reaction was continued for 40 minutes, the mixture turned from brown to bright yellow, further diluted with water, and used for weight fraction 30% H 2 0 2 Solution treatment, neutralization of unreacted permanganate, centrifugal filtration and repeated washing of the filter cake, and finally vacuum drying to obtain graphite oxide. 2) Preparation...

Embodiment 2

[0035] A high thermal conductivity lubricating oil, comprising: 94.95% by weight of HVI150SN lubricating oil, 5% by weight of fluorinated graphene nanosheets and 0.05% by weight of sorbitan oil Ester Tween 80.

[0036] The preparation method of this lubricating oil is:

[0037] (1) Preparation of fluorinated graphene nanosheets by gas-phase fluorination: the preparation process is the same as in Example 1; (2) Preparation of lubricating oil containing fluorinated graphene nanosheets: 1) the fluorinated graphene nanosheets obtained by the method Graphene nanosheets are mixed with oil-soluble dispersant sorbitan oleate Tween 80 and gradually added to HVI150SN lubricating base oil, wherein the fluorinated graphene nanosheets are 5% by weight, and the weight of the dispersant The percentage content is 0.05%; 2) Under the condition of 60°C, the above mixture is firstly stirred by high-speed machinery for 30 minutes, then ultrasonicated for 30 minutes, and then the rubber mill tech...

Embodiment 3

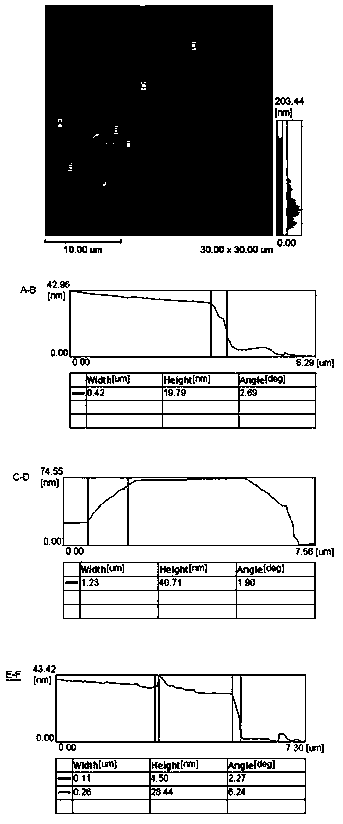

[0040] A lubricating oil with high thermal conductivity, comprising: 98.2% by weight of liquid paraffin oil and 1.8% by weight of fluorinated graphene nanosheets.

[0041] The preparation method of this lubricating oil is:

[0042] (1) Preparation of fluorinated graphene nanosheets by exfoliation of fluorinated graphite: 1) direct reaction of carbon and fluorine at 500 °C to generate fluorinated graphite, 2) solvent intercalation of fluorinated graphite: the intercalation solvent is N , N-dimethylformamide (DMF), dissolve 500mg fluorinated graphite in 500ml DMF, heat to reflux for 2 hours, 3) ultrasonic process of fluorinated graphite: put the suspension obtained in step 2) at a power of 200W , the ultrasonic frequency is 40HZ, the ultrasonic temperature is 25°C, and the ultrasonic time is 6 hours. 4) Separation and drying of fluorinated graphene nanosheets: use high-speed centrifugation to obtain wet powder of fluorinated graphene, and then use 60°C vacuum Dried to obtain fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com