Carbon steel forming oil composition and preparation method thereof

A molding oil and composition technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of large wear spots, low-load wear, mixed fish and dragons, etc., to reduce metal surface wear, high extreme pressure anti-wear performance, and reduce friction The effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

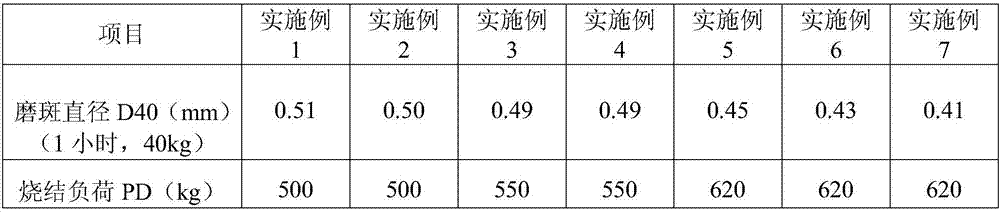

Examples

Embodiment 1

[0027] A carbon steel forming oil composition, comprising the following components in parts by weight: 1 part of extreme pressure agent, 60 parts of base oil, 1 part of friction reducer, 1 part of detergent, 1 part of dispersant , 1 part of antioxidant; extreme pressure agent is organic sulfide; friction reducer is sulfurized vegetable fatty acid hydrocarbon.

[0028] The preparation method of the carbon steel molding oil composition, according to the above ratio, at a temperature of 60 ° C, add the friction reducer, detergent, dispersant, and antioxidant to the base oil, stir for 1 hour, and make it evenly mixed to prepare A carbon steel forming oil composition was obtained.

Embodiment 2

[0030] A carbon steel forming oil composition, comprising the following components in parts by weight: 4.5 parts of extreme pressure agent, 90 parts of base oil, 2 parts of friction reducer, 10 parts of detergent, 15 parts of dispersant , 10 parts of antioxidant; extreme pressure agent is organic sulfide; antifriction agent is fatty acid.

[0031] Among them, the detergent is a sulfonate. The dispersant is dienyl succinimide. Antioxidants are phenolic antioxidants.

[0032] The preparation method of the carbon steel molding oil composition, according to the above ratio, at a temperature of 90 ° C, add the friction reducer, detergent, dispersant, and antioxidant to the base oil, stir for 5 hours, and make it evenly mixed to prepare A carbon steel forming oil composition was obtained.

Embodiment 3

[0034] A carbon steel forming oil composition, comprising the following components in parts by weight: 1.5 parts of extreme pressure agent, 84 parts of base oil, 10 parts of friction reducer, 3 parts of detergent, 3 parts of dispersant , 3 parts of antioxidant; the extreme pressure agent is an organic sulfide; the friction reducer is sulfurized vegetable fatty acid hydrocarbon and fatty acid with a mass ratio of 1:4.

[0035] The detergent is calcium sulfonate and calcium salicylate with a mass ratio of 2:1.

[0036] The dispersant is dienyl succinimide and boronated dispersant with a mass ratio of 2:1.

[0037] The antioxidant is a phenolic antioxidant and an amine antioxidant with a mass ratio of 2:1.

[0038] The preparation method of the carbon steel molding oil composition, according to the above ratio, at a temperature of 65 ° C, add the friction reducer, detergent, dispersant, and antioxidant to the base oil, stir for 2 hours, and make it evenly mixed to prepare A car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com