Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

106results about How to "Reduce the rate of defective products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

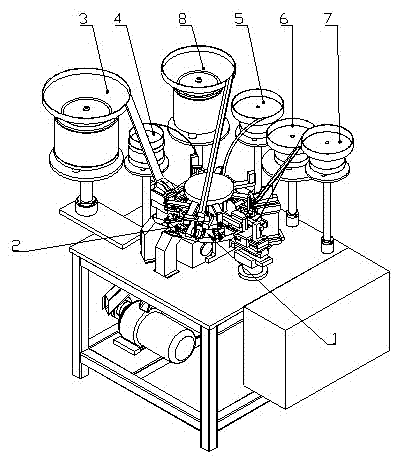

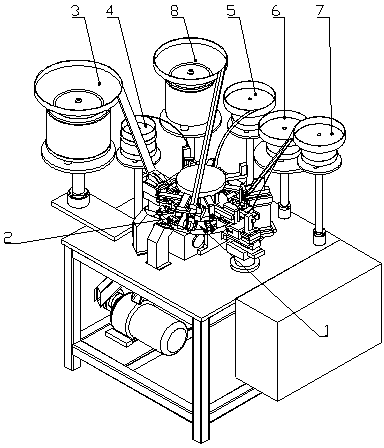

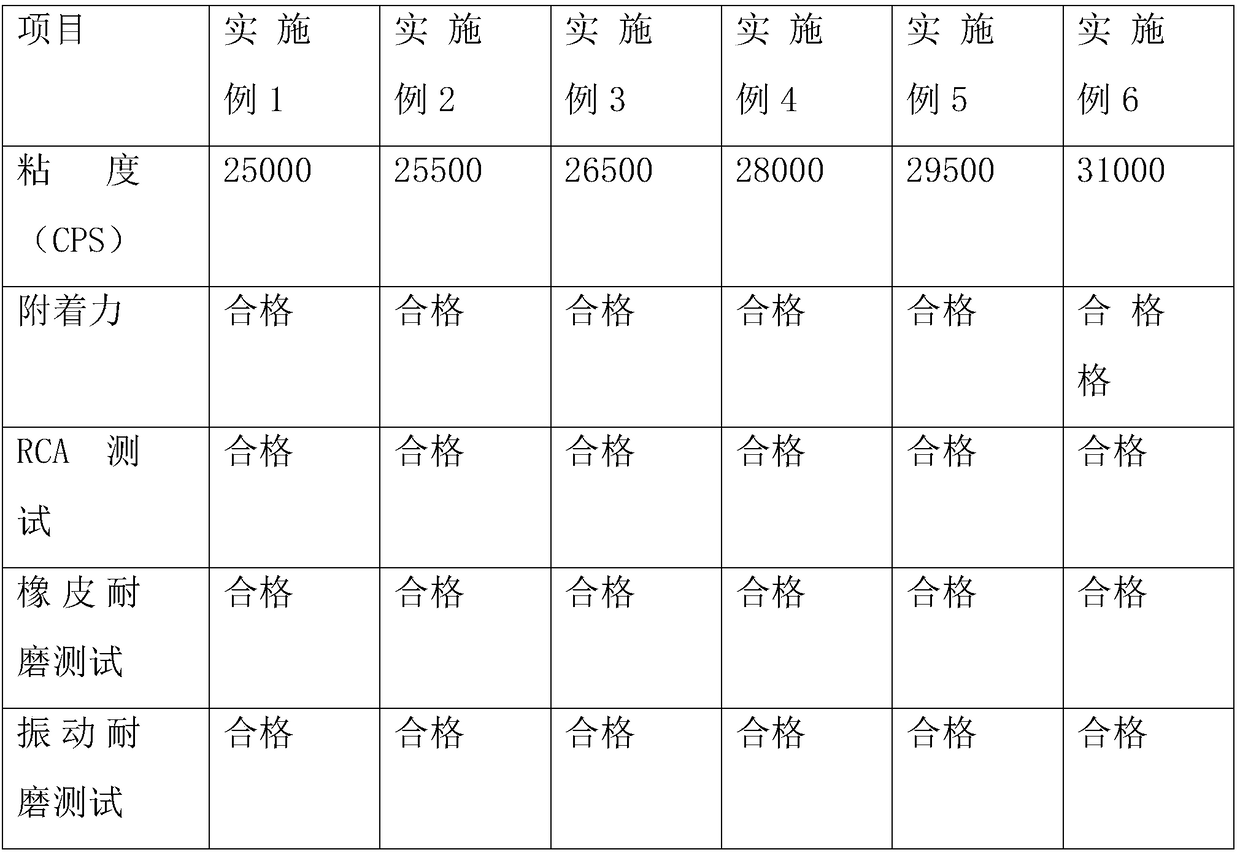

Six-part full-automatic assembly machine for invisible zipper puller

InactiveCN102525044AHigh degree of automationRealize automatic feedingSlide fastenersEngineeringStructural engineering

The invention discloses a six-part full-automatic assembly machine for invisible zipper puller and is characterized in that a moving assembly that is connected with a power device is arranged at the table top of a frame; twelve die cavities for fixing zipper pullers are arranged at equal intervals on the margin of the division main rotor plate of the moving assembly; and a zipper puller feeding mechanism, a zipper puller detection mechanism, a zipper puller spring feeding mechanism, a spring detection mechanism, a triangular collar feeding mechanism, a triangular collar detection mechanism, a horse hooker feeding mechanism, a copper pin feeding mechanism, a copper pin detection mechanism, a puller detection mechanism, a puller detection mechanism rejected puller discharge mechanism, and a qualified product discharge mechanism are arranged on the frame and used for assembling zipper pullers. The six-part full-automatic assembly machine integrates the functions of two machines, the detection mechanisms are arranged behind the corresponding feeding mechanism to automatically identify parts in the die cavities, and the start-up or shut-down of the assembly machine is automatically controlled according to the assembly information of parts, so as to prevent defected parts from entering the next procedure or prevent idle running of the assembly machine, as a result, the rate of rejected products is reduced and the assembly machine is guaranteed to run safely and reliably.

Owner:义乌市振宏机械科技有限公司

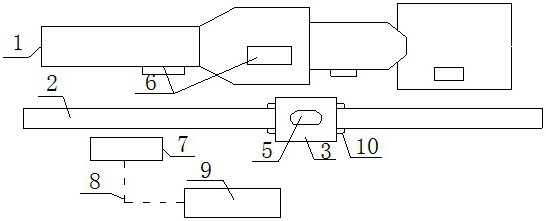

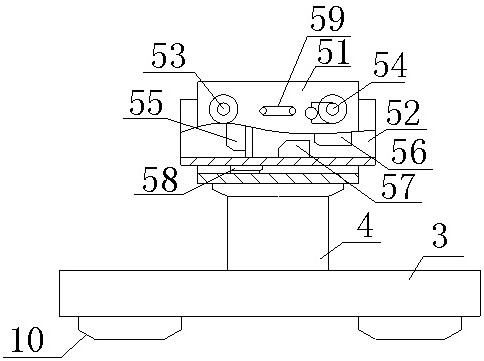

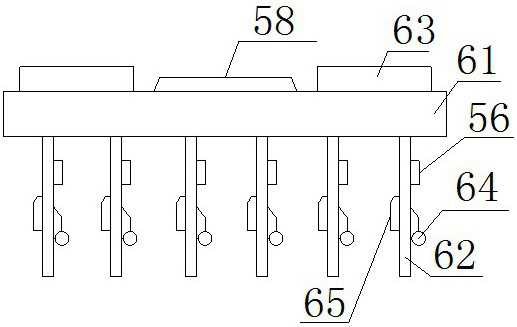

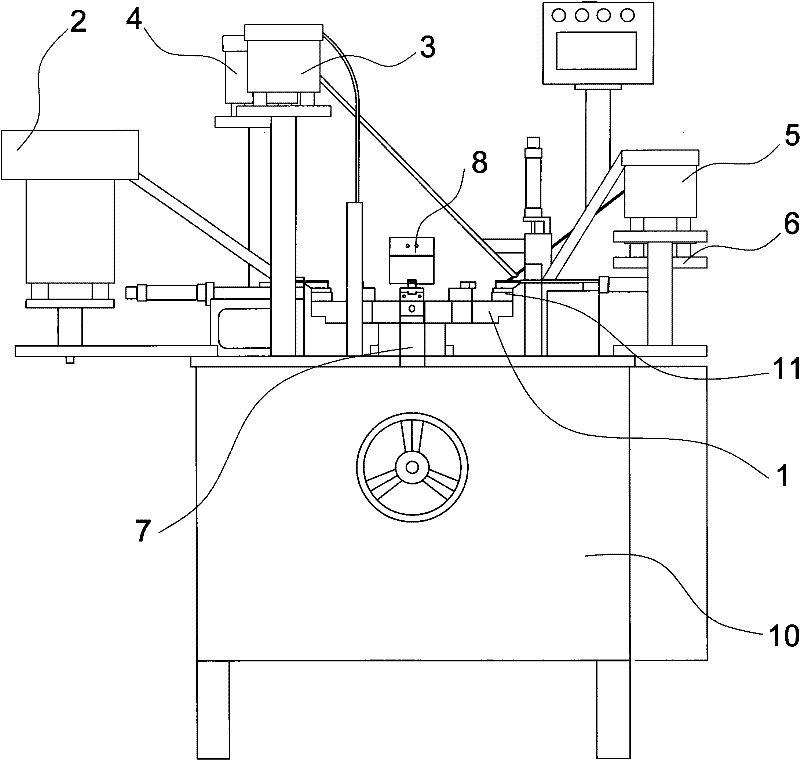

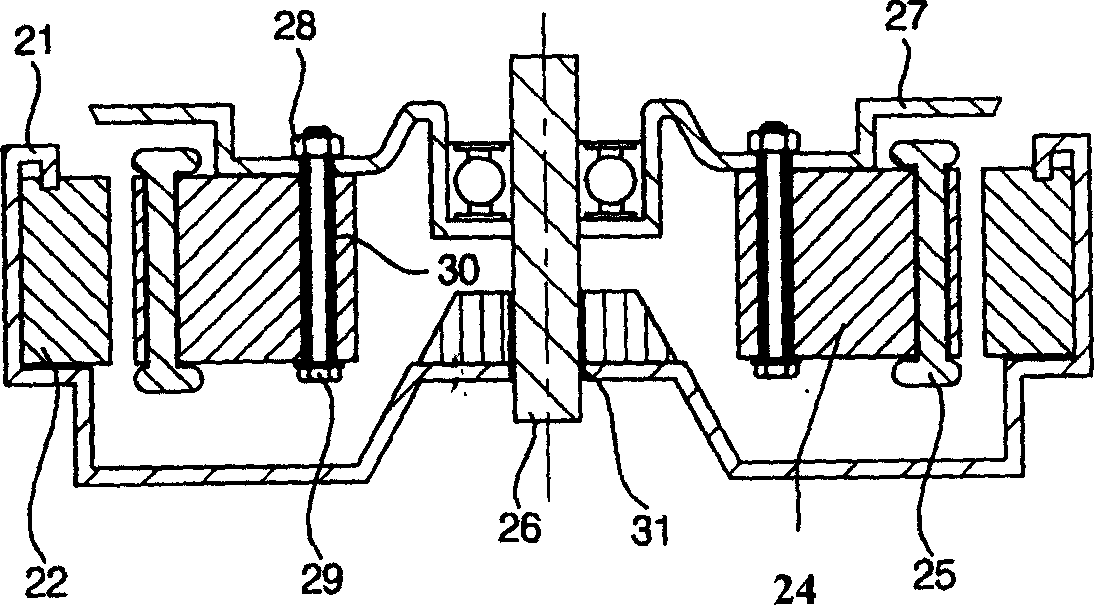

Full-automatic assembly machine for track type zipper head

InactiveCN102551281AGuaranteed uptimeAvoid idlingSlide fastenersControl engineeringProcess engineering

The invention discloses a full-automatic assembly machine for a track type zipper head. The full-automatic assembly machine comprises a rack and power mechanism, twelve die cavity assemblies with same structure, a track feeding mechanism, a zipper piece feeding mechanism, a zipper head feeding mechanism, a detection mechanisms and a finished product pull-out mechanism; twelve rectangular grooves are uniformly distributed on a turntable of the rack and power mechanism along the radial direction, and the twelve die cavity assemblies are respectively arranged in respective rectangular groove; and the track feeding mechanism, the zipper piece feeding mechanism, the zipper head feeding mechanism, the detection mechanisms and the finished product pull-out mechanism are respectively arranged on a panel by surrounding the turntable. The full-automatic assembly machine realizes automatic feeding, completes the assembly of finished products and has high automation degree; in addition, a detection mechanism is arranged behind each feeding mechanism to automatically distinguish parts in a die cavity and automatically control the operation or halt of the assembly machine according to the assembly information of the parts to prevent deficient parts from entering into the next procedure and prevent the assembly machine from idling so as to reduce the rate of rejected products, improve the product quality and ensure the safe and reliable running of the assembly machine.

Owner:义乌市振宏机械科技有限公司

Desktop-level polyether ether ketone high-temperature 3D printing device

ActiveCN106079444AStrive for structural stabilityStrive for structural integrityAdditive manufacturing apparatusTemperature controlEngineering

The invention discloses a desktop-level polyether ether ketone high-temperature 3D printing device. The desktop-level polyether ether ketone high-temperature 3D printing device is characterized by comprising a box body, a moving mechanism, a printing head, a driving mechanism and a temperature control mechanism; the moving mechanism comprises an X-axis moving mechanism, a Z-axis moving mechanism and two Y-axis moving mechanisms; the two Y-axis moving mechanisms are fixed into the box body; the X-axis moving mechanism is installed on the two Y-axis moving mechanisms; the printing head is installed on the X-axis moving mechanism; and the temperature control mechanism is fixed to the Z-axis moving mechanism. According to the desktop-level polyether ether ketone high-temperature 3D printing device, the problems of heating, cooling and quick forming of a high-temperature material in the printing process are solved; the 3D printing device is compact in structure, small in size, convenient to disassemble and assemble, high in applicability to materials with different models, capable of controlling printing and forming within an optimal temperature range and suitable for precise printing and forming of high-temperature polyether ether ketone.

Owner:拓凌机械(浙江)有限公司

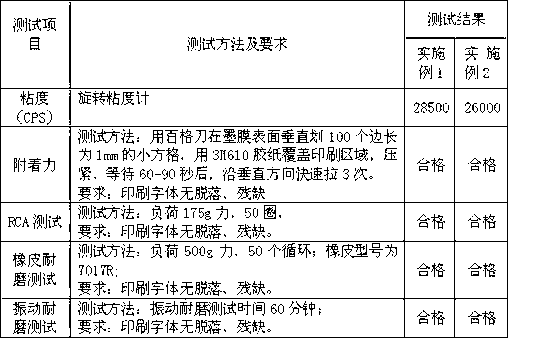

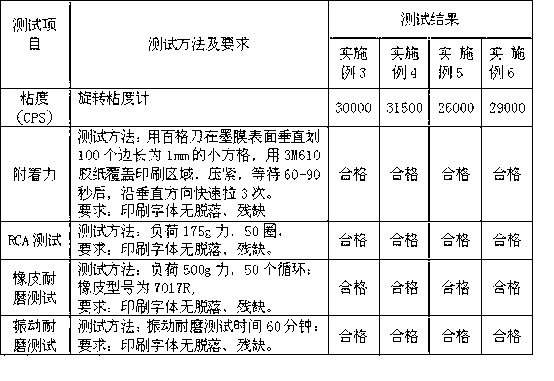

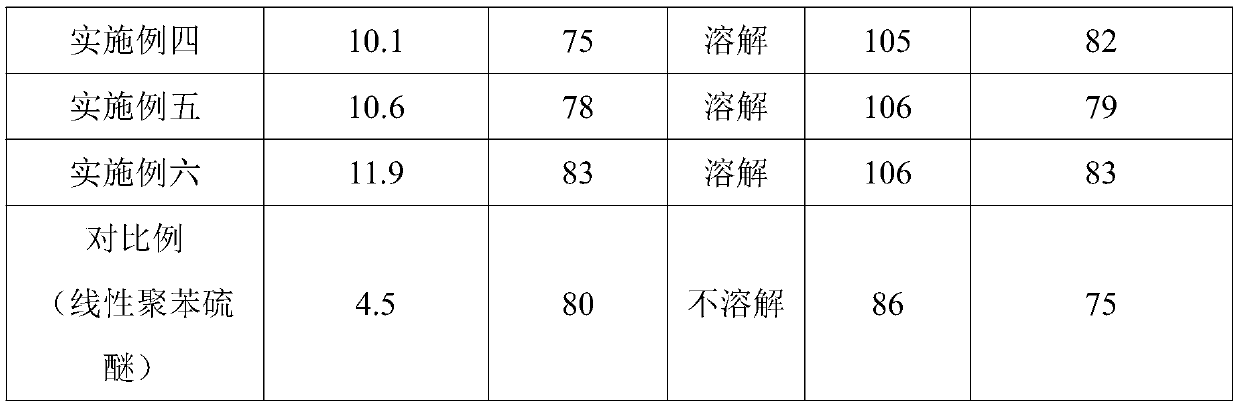

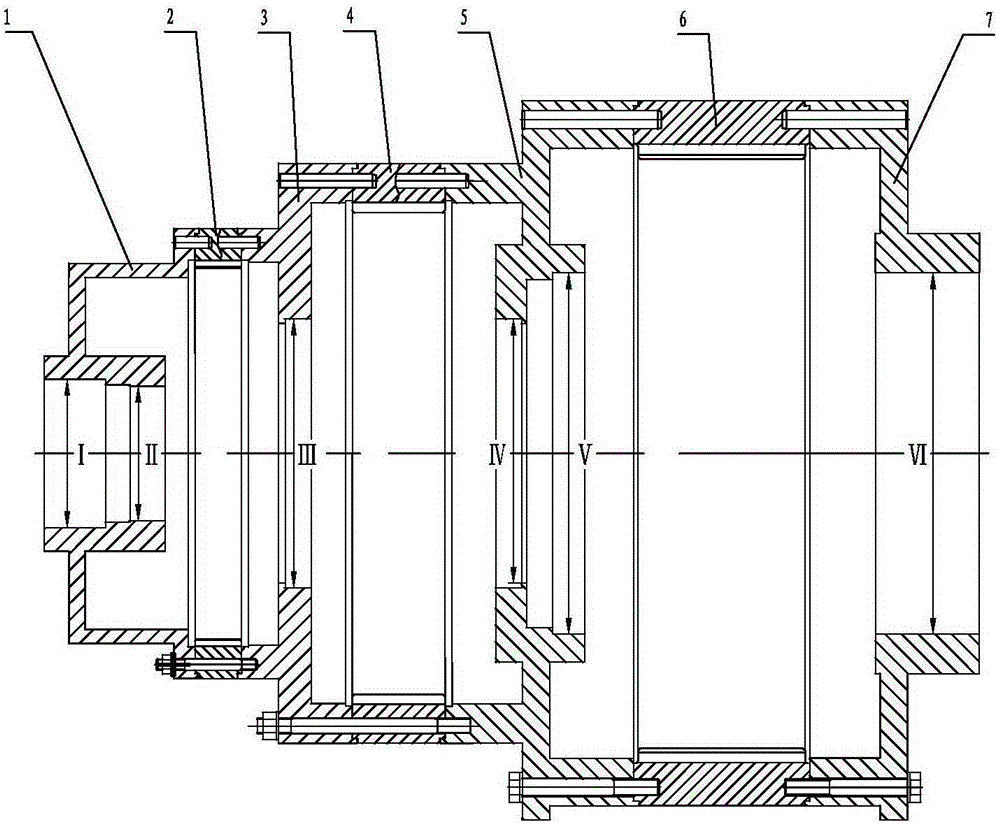

Ink for surface of finish paint and preparation method thereof

ActiveCN103254685AStrong adhesionImprove alcohol resistanceInksPolycyclic aromatic hydrocarbonScreen printing

The invention discloses ink for a surface of finish paint and a preparation method thereof. The ink is suitable for the surfaces of UV (ultraviolet) and PU (poly-urethane) paints, and has excellent RCA resistance, rubber resistance and chemical resistance. The ink comprises the following components by weight percent: 30-45% of modified acrylic resin, 10-20% of modified polyester resin, 20-30% of solvent, 0.1-5% of dispersing agent, and 0.1-5% of defoamer. The solvent used by the ink disclosed by the invention is environment-friendly, and free of PAHS (polycyclic aromatic hydrocarbons); the viscosity at room temperature of 25 DEG C is 25000-35000 CPS; and the solvent is baked for 60-90 minutes at 80 DEG C. The ink has excellent adhesive force, alcohol resistance, chemical resistance, abrasive resistance and the like on the products at the surfaces of various finish paints; and the problems of the traditional silk screen printing ink when being applied on various finish paints are effectively overcome.

Owner:深圳市美丽华科技股份有限公司

Pad printing ink for elastic paint surface decoration

The invention discloses pad printing ink for elastic paint surface decoration. The pad printing ink comprises: be weight, 20 to 40% of a polyurethane resin, 15 to 30% of a modified polyester resin, 20 to 35% of one or two solvents, 5 to 35% of pigment, 0.1 to 5% of a dispersant and 0.1 to 5% of a defoaming agent. The one or two solvents adopted in the invention do not contain polycyclic aromatic hydrocarbons (PAHS) thus are environmentally friendly. After being baked at a temperature of 80 DEG C for 30 to 60 minutes, the pad printing ink coated on a rubber paint product and the surface of elastic paint has the characteristics of excellent adhesiveness, scraping resistance, alcohol resistance, aging resistance and wear resistance. The pad printing ink simplifies a decoration processing technology for elastic paint surfaces, improves production efficiency, reduces an unqualified rate of products, and provides multiple choices for enriching decorative designs and visual effects of elastic paint surface materials.

Owner:深圳市美丽华科技股份有限公司

Remote monitoring type carbon black master batch production and preparation control system and method thereof

ActiveCN112255991AHigh degree of intelligenceHigh accuracy of data detectionTotal factory controlProgramme total factory controlProcess engineeringBatch production

The invention relates to a remote monitoring type carbon black master batch production and preparation control system and method. The system comprises a carbon black master batch production line and amonitoring system, and the monitoring system comprises a guide slide rail, a bearing base, a bearing column, a mobile detection terminal, an embedded detection terminal, a field controller and a remote production monitoring platform. The bearing base is in sliding connection with the guide sliding rail through a walking mechanism, the upper end face of the bearing base is connected with the bearing column, the upper end face of the bearing column is hinged to the mobile detection terminal through a rotary table mechanism, the embedded detection terminal is embedded outside a pipeline of the carbon black master batch production line, the mobile detection terminal and the embedded detection terminal are electrically connected with the field controller, and the field controller is connectedwith the remote production monitoring platform. The use method comprises two steps of system configuration, detection operation and the like. Data of all links of the production line can be comprehensively detected, and the data detection precision is high; moreover, the working efficiency and the control precision of the carbon black master batch production and processing control operation can begreatly improved.

Owner:江苏新鹏塑化科技有限公司

Automatic appearance detection device

InactiveCN105158261ASimple structureAvoid error checkingOptically investigating flaws/contaminationPlane mirrorEngineering

The invention discloses an automatic appearance detection device. The automatic appearance detection device comprises a device framework, an illumination system and a product table, wherein the illumination system and the product table are vertically arranged above the device framework by virtue of a fixed bracket, an LED light source a is arranged at one side of the product table, the bottom of the product table is provided with a plane mirror, the bottom of the device framework is provided with rollers, two sides of the device framework are respectively of a drawer structure, and the illumination system comprises an LED light source b and a multi-angle fixed bracket. The automatic appearance detection device is simple in structure; by adopting an automation technology, a rotation device can rotate in various angles to test the appearance of a tested product, the product is accurately positioned by virtue of a groove and a positioning sheet, the error in detection caused by manmade factors can be avoided, the defective percentage of the product and the production loss can be reduced, and the working efficiency can be improved.

Owner:TAICANG KAI LUN AUTOMATION EQUIP CO LTD

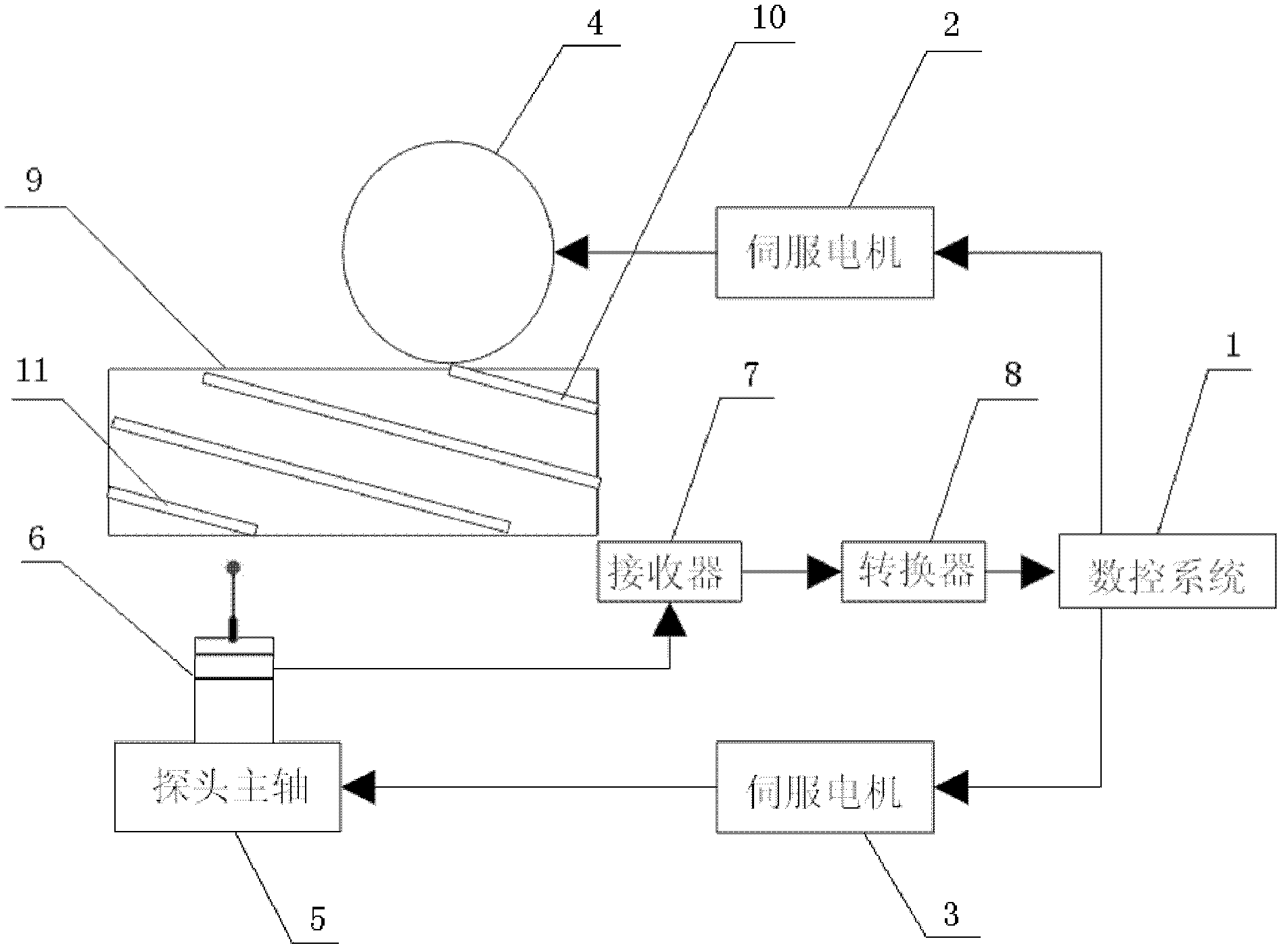

Online detection system and detection method for machining superhard cutters

ActiveCN102601683AIncrease productivityReduced operating requirementsMeasurement/indication equipmentsElectrical-based auxillary apparatusData signalEngineering

The invention relates to an online detection system and a detection method for machining superhard cutters. The system is characterized by comprising a numerical control system which is connected with two servo motors, an output end of one servo motor is connected with an electrical sparkle discharge electrode, and an output end of the other servo motor is connected with a measuring probe through a probe spindle. The measuring probe sends data to a receiver, and the receiver converts the data signals through a converter and then feeds the converted signals back to the numerical control system. The online detection system can detect whether machining parameters of a tooth are qualified or not when another opposite tooth of a superhard cutter is ground by an electrode, remachining procedures can be provided by the numerical control system, and all unqualified teeth can be repaired at once after machining of all teeth is completed. Therefore, once forming of the cutter is really achieved, cutter production efficiency is effectively improved, and mounting errors caused by repeated cutter mounting can be avoided.

Owner:TSINGHUA UNIV +2

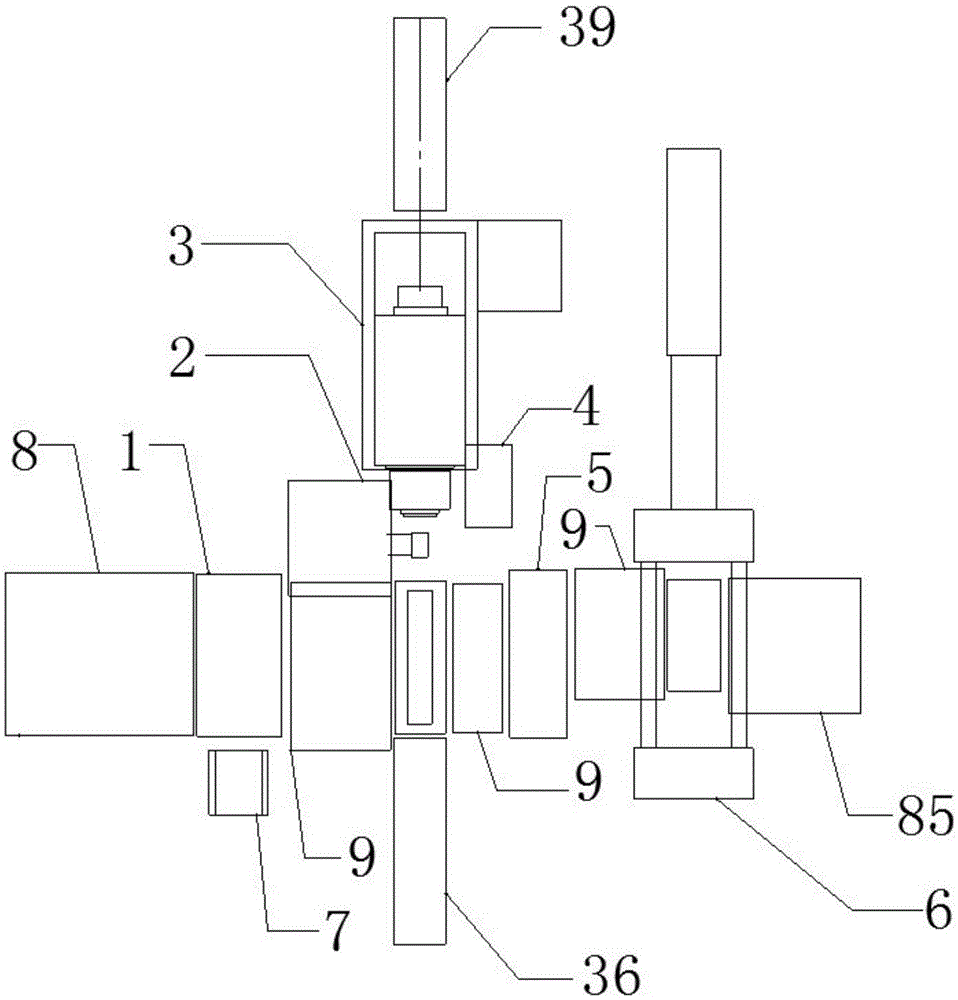

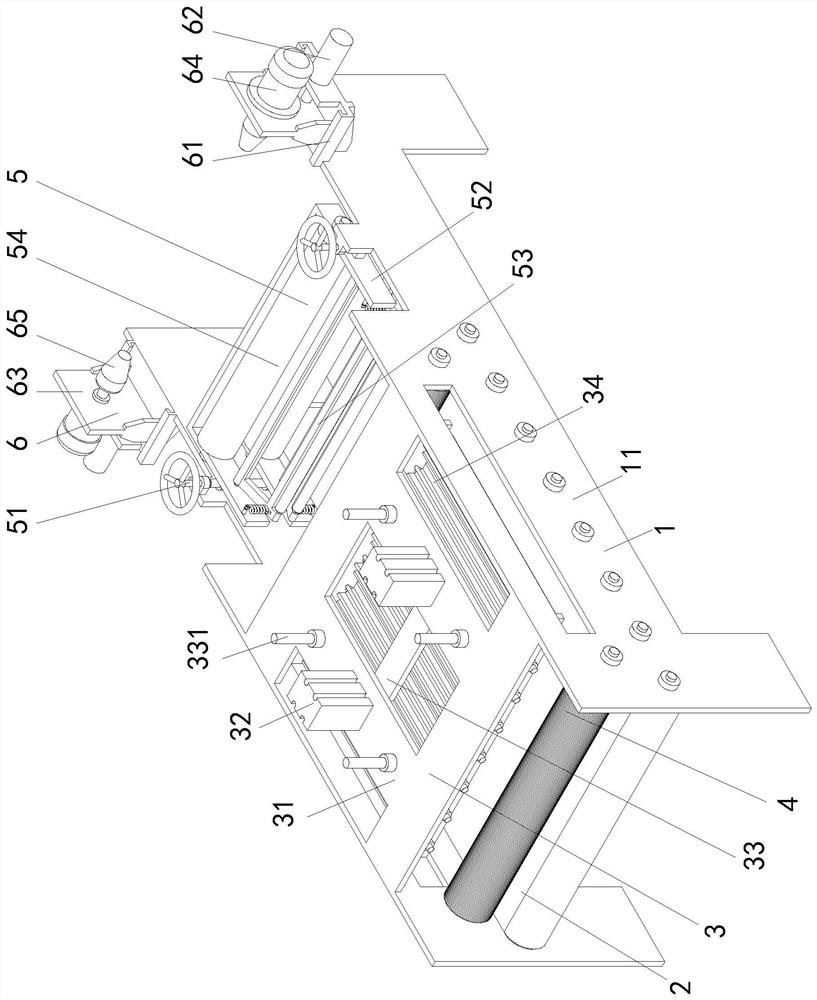

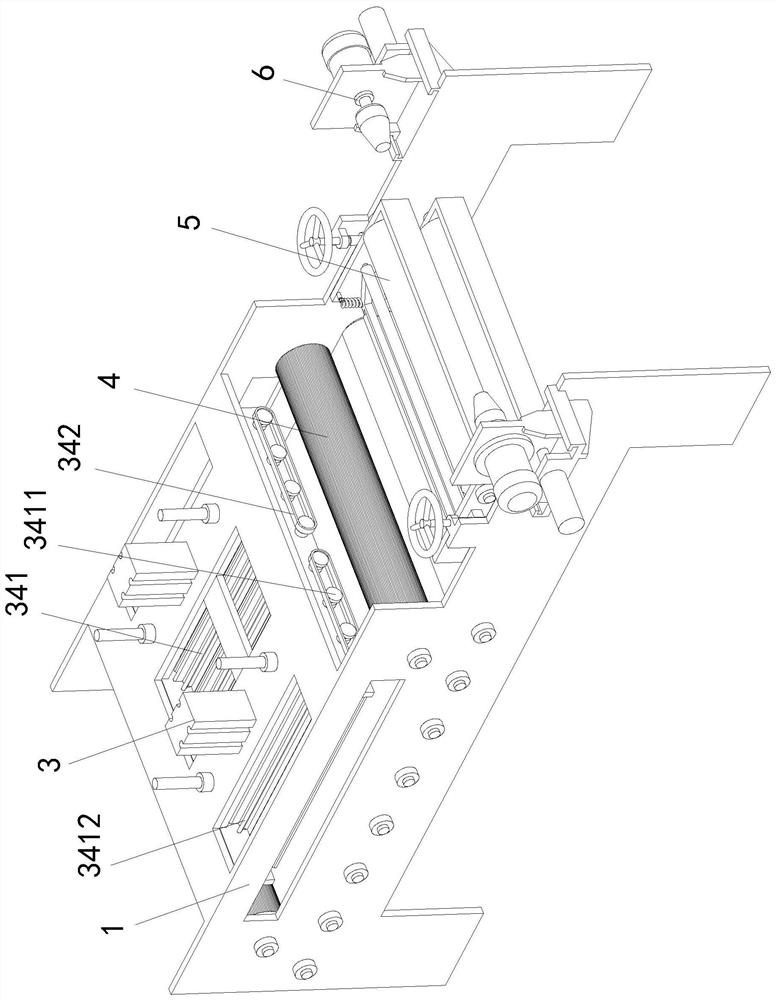

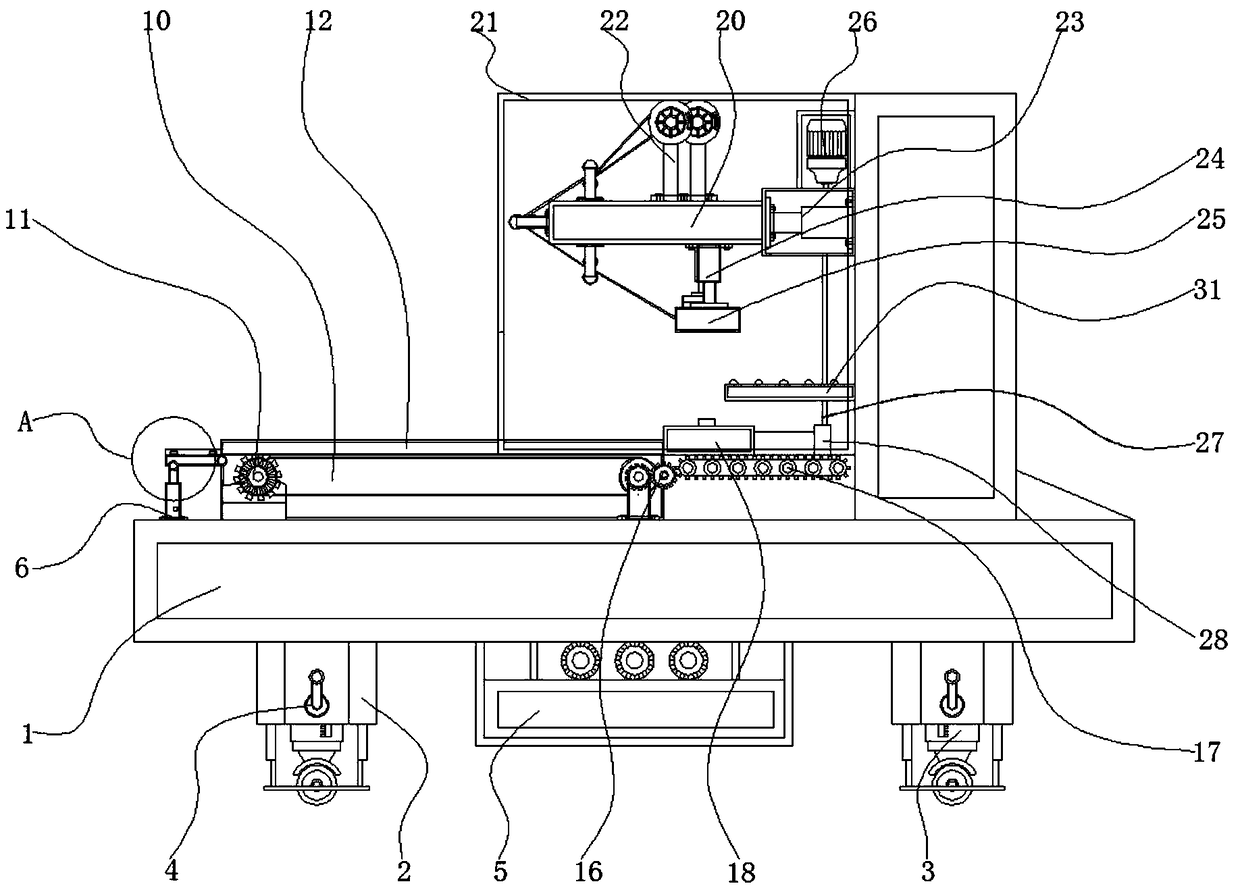

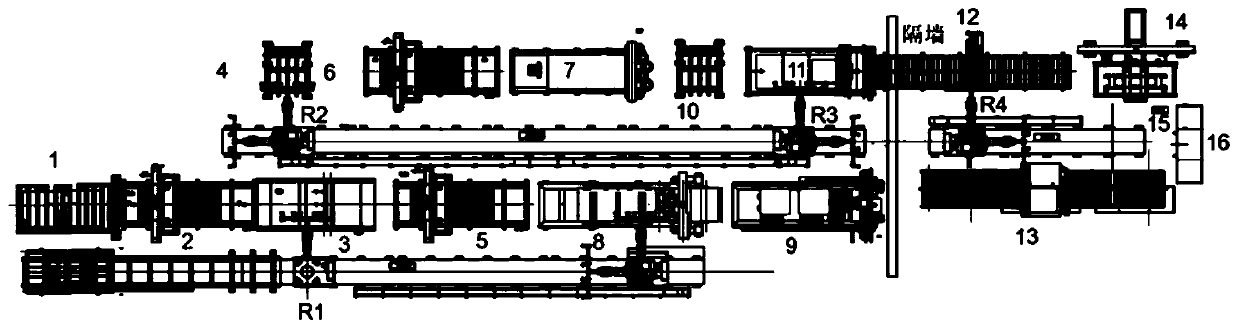

Full-automatic bottom hot-spinning and forming production line for steel cylinder

ActiveCN105537426ACompact structureEasy to useShaping toolsMetal-working feeding devicesProduction lineHigh volume manufacturing

The invention provides a full-automatic bottom hot-spinning and forming production line for a steel cylinder. The full-automatic bottom hot-spinning and forming production line for the steel cylinder sequentially comprises a heating and pushing device, a turning and receiving device, a clamping device, a gas auxiliary heating device, a deslagging device and a bottom pressing device in the machining sequence of the steel cylinder. The full-automatic bottom hot-spinning and forming production line for the steel cylinder is compact in structure, easy to use and convenient to operate; product forming is stable, the unqualified rate is decreased, and the production line is suitable for automatic volume production; the labor production cost is reduced, and the market competitiveness of products is improved.

Owner:潍坊泰克机械有限公司

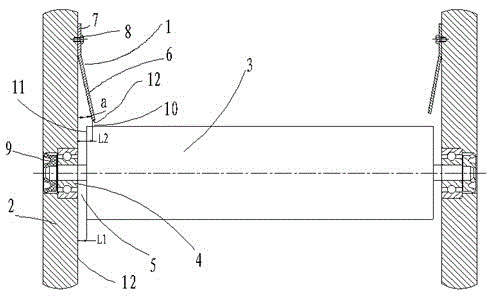

Preparation process for plate roller for printing

ActiveCN107020793AReduce surface roughnessSmooth surface roughnessPhotomechanical apparatusPlate printingCopper platingLaser engraving

The invention discloses a preparation process for a plate roller for printing. The process comprises the following steps that (1) manufacturing of a plate roller base body: the plate roller base body is manufactured from a specific formula of seamless steel tube; (2) copper plating treatment of the plate roller base body: the plate roller base body is subjected to copper plating in a plating tank containing a specific copper plating solution, and the thickness of a copper layer is 12-15 microns; (3) surface treatment of the plate roller base body: the copper surface is subjected to grinding treatment; (4) gumming of the plate roller: the plate roller subjected to copper plating and surface treatment is coated with a layer of glue solution with the thickness being 0.08-0.12mm and then is aired; (5) manufacturing of a laser image, laser engraving of the plate roller and developing of the plate roller; (6) corrosion to the plate roller: the plate roller is subjected to spray-type corrosion treatment with specific corrosive liquid; (7) cleaning of the plate roller: the plate roller is subjected to spray-type cleaning with specific cleaning fluid; and (8) chromium plating of the plate roller: the plate roller is subjected to chromium plating treatment in a plating tank containing a specific chromium plating solution, the thickness of a chromium layer is 5-8 microns. The preparation process has the advantage that the difference of the surface flatness of different positions of the same plate roller is reduced.

Owner:ZIBO YUNCHENG PLATE MAKING

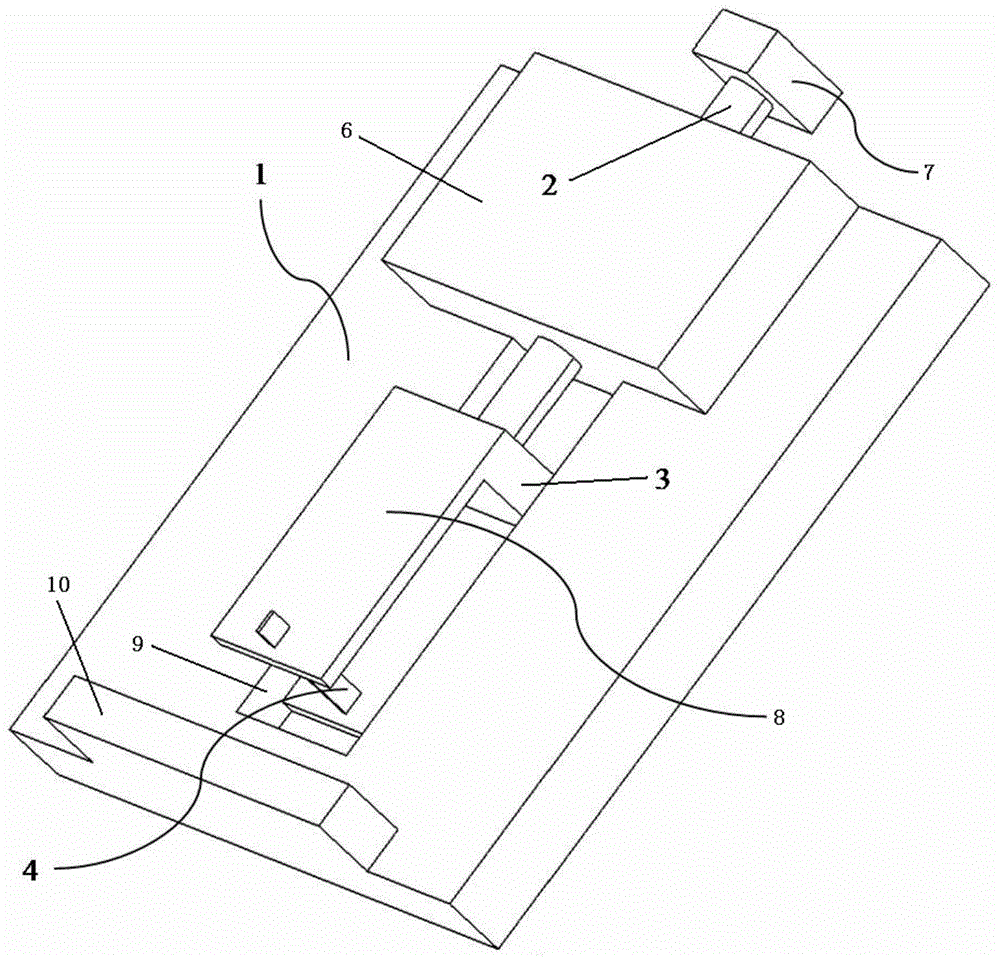

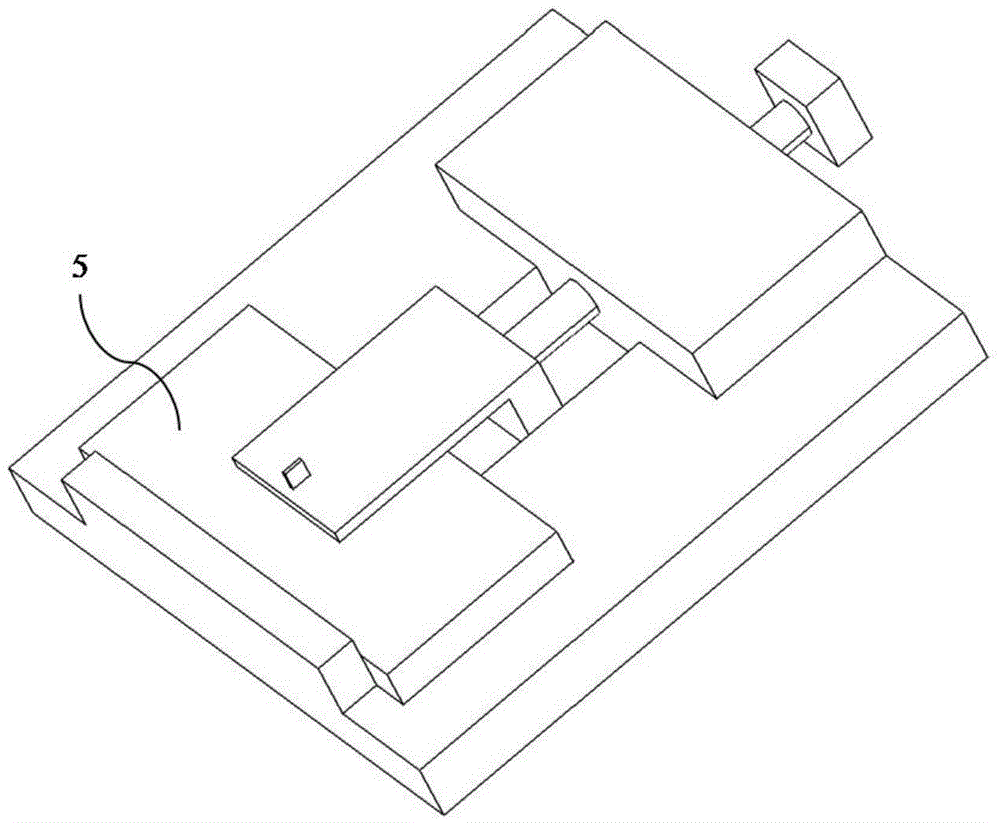

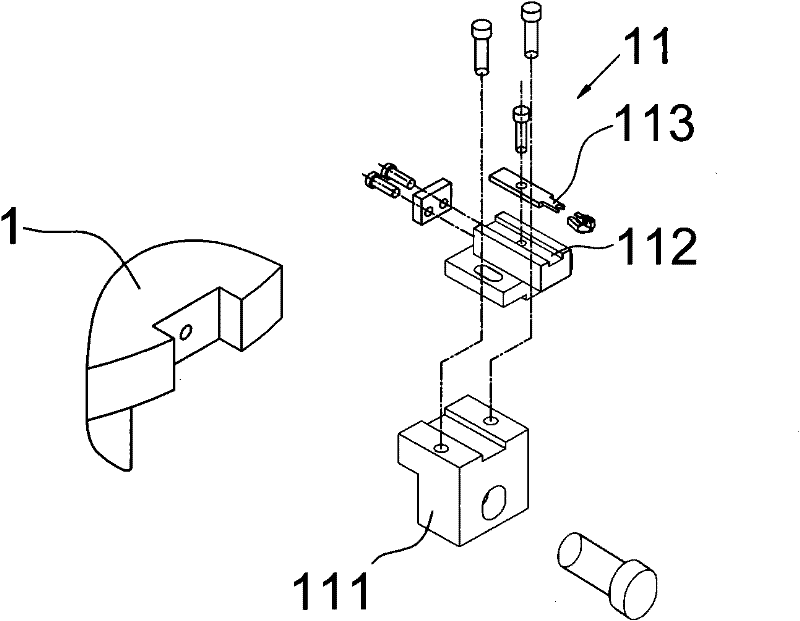

Crack prefabricating device of non-metal material fracture toughness test

InactiveCN104535386AControl lengthReduce the rate of defective productsPreparing sample for investigationTest sampleMetallic materials

The invention provides a crack prefabricating device of a non-metal material fracture toughness test. The device can be used for carrying out crack prefabricating in the non-metal material fracture toughness test; a blade position is controlled by utilizing a manner of manually rotating an adjusting screw rod, so that the length of prefabricated cracks can be effectively controlled and the reject ratio of a prefabricated test sample is reduced. By virtue of the device, the crack prefabricating time of a sample can be greatly shortened and the testing speed is improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

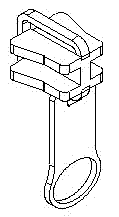

Outer shuttle of sewing machine and its making process

The present invention is outer shuttle of sewing machine and its making process. The outer shuttle includes one shuttle body, one rotating shaft and one mesh element. The shuttle body made of metal material includes one side wall around some axis, one notch in one end of the side wall, one bottom wall on the other end of the side wall, and one axial hole in the bottom wall. The rotating shaft includes one first end in the hole, one opposite second end far from the hole and one material jetting hole extending from the first end to the outer ring face. The mesh element around the rotating shaft is formed with plastic and through jetting molding and has one locating part stretched into the material jetting hole. The outer shuttle of the present invention has high strength and light weight.

Owner:YUAN FONG PRECISION TECH

Volume-weight control system for mineral wool production line

The invention discloses a volume-weight control system for a mineral wool production line. The system comprises a centrifugal machine, a weighing controller, a trapping belt motor, a pendulum bob motor, a cotton forming belt motor, a pleating motor, and a main line driving motor. The fiber forming quantity is changed along with the melt flow of a smelting furnace. The system is characterized in that the quantity of cotton flowing into a trapping belt along with the change of the fiber forming quantity is also changed, the volume-weight control system focuses on adjusting the speed of each conveying belt to keep the volume weight within a certain range, the power of the centrifugal machine is used for measuring the current fiber flow, firstly, the fiber flow is estimated according to the power of the centrifugal machine, and then the volume-weight control system modifies the estimated fiber flow according to the weighing controller under a pendulum bob. According to the corrected fiberflow, the volume-weight control system decides to accelerate or decelerate each conveying belt.

Owner:吉林省梓楗新型建材股份有限公司

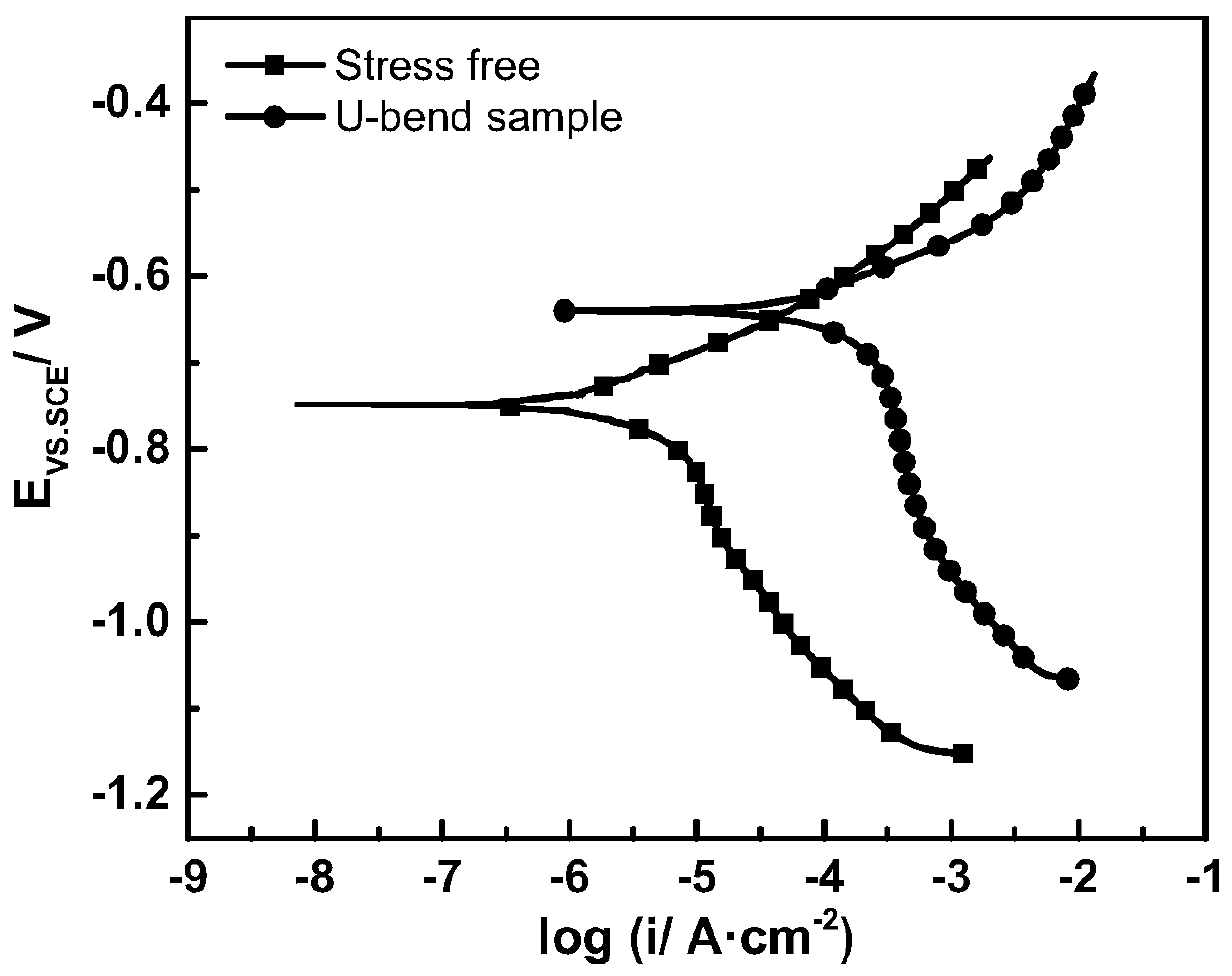

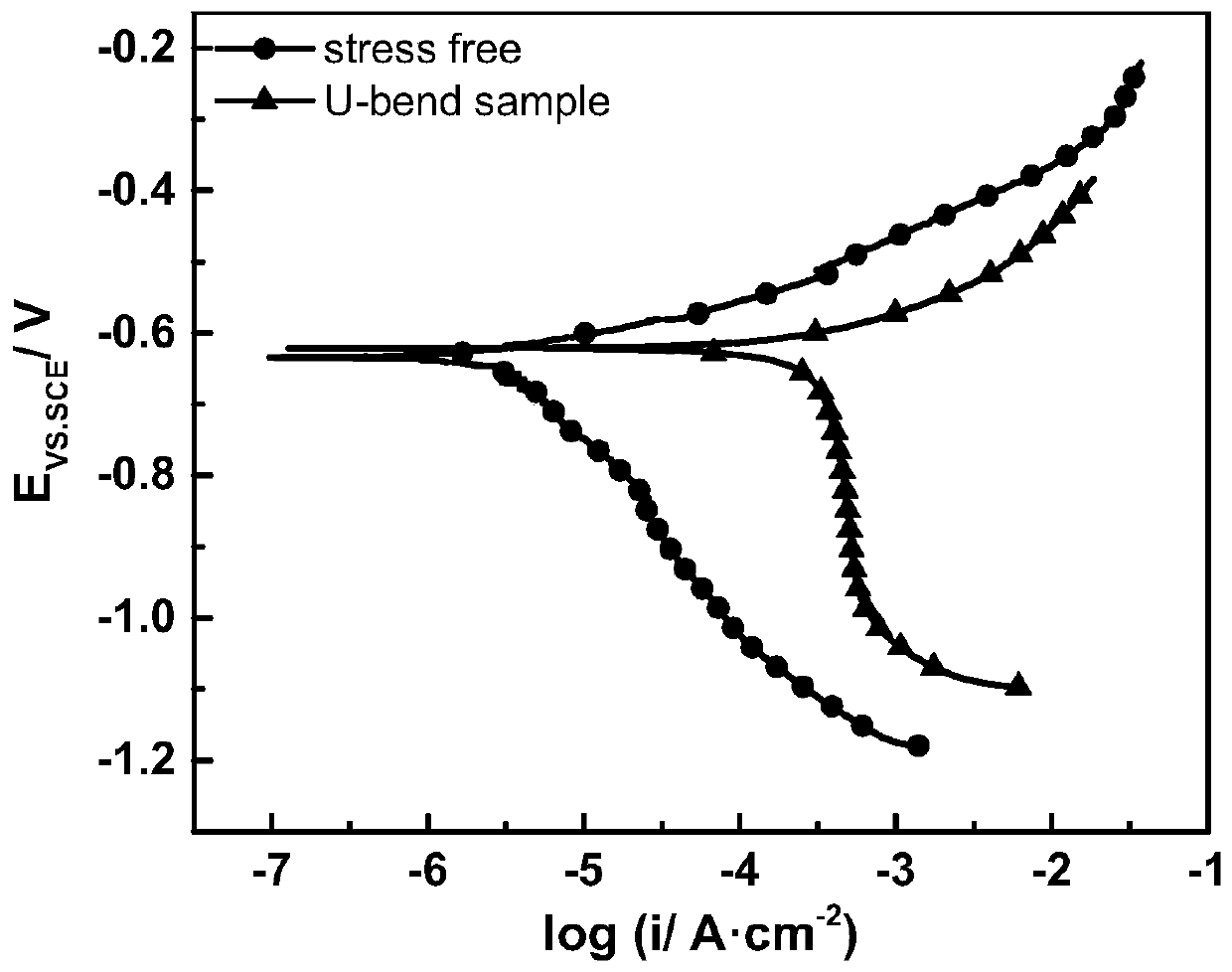

Rapid evaluation method for stress corrosion sensitivity of low-alloy structural steel in atmospheric environment

PendingCN110823690AEasy to operateImprove surface qualityWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesResearch dataPhysical chemistry

The invention discloses a rapid evaluation method for stress corrosion of low-alloy structural steel in an atmospheric environment. The rapid evaluation method is a stress corrosion sensitivity evaluation method constructed based on electrochemical tests and based on atmospheric environment stress corrosion indoor and outdoor simulation and acceleration research data and a stress corrosion electrochemical mechanism thereof. Compared with a traditional outdoor atmospheric exposure test method, the rapid evaluation method has high operability in indoor tests and short test time, the evaluation of stress corrosion performance of the low-alloy steel can be realized, and the rapid evaluation method can be further used for the research and development, production and relevant evaluation and testing in the material selection process of the low-alloy structural steel. The rapid evaluation method has the characteristics of simulation, acceleration and effectiveness, a new method is provided forthe evaluation study of the stress corrosion sensitivity of the low-alloy structural steel in the atmospheric environment, and thus an advantageous basis is provided for the use and protection of materials.

Owner:NANJING IRON & STEEL CO LTD

Process for processing sand outlets of engine cylinder

InactiveCN102430896AReduce processing stepsShorten the processing cycleReaming toolsReaming devicesPulp and paper industryMachine tool

The invention relates to a process for processing sand outlets of an engine cylinder, aiming to solve the problems that the prior process for processing the sand outlets of the engine cylinder is complex, the production cycle is long and the coaxiality of the rough processing hole and the fine processing hole is not consistent so that the fine boring hole has a black skin and poor roughness. The process comprises the following steps: (1) enlarging the front sand outlet and the rear sand outlet in a semi-finishing way by controlling the cutting speed of a lathe at 200-300m / min, the feeding amount at 0.3-0.4mm / r, the Ra at 6.3 and the cutting depth at 2.4-2.6mm; and (2) hinging the front sand outlet and the rear sand outlet by controlling the cutting speed of the lathe at 200-300m / min, the feeding amount at 0.3-0.4mm / r, the Ra at 2.5 and the cutting depth at 0.30-0.32mm until the sand outlets are processed to have the required apertures. The process for processing the sand outlets of the engine cylinder is simple and easy to operate, has short processing cycle and can ensure all the processing procedures can be finished on the same processing lathe, the production cost is low, the hole has no black skin and the roughness of the hole meets the requirements.

Owner:DONGFENG AUTOMOBILE COMPANY

Plastic woven bag producing, manufacturing and processing system

ActiveCN111923500AAvoid foldingAvoid the hassle of manual finishingBag making operationsPaper-makingManufacturing engineeringForming processes

The invention relates to a plastic woven bag producing, manufacturing and processing system. The plastic woven bag producing, manufacturing and processing system comprises a rack, a belt conveyor, a lateral pulling and flattening mechanism, a flexible guide roll, a leveling mechanism and rolling mechanisms. The rack comprises two supporting side frames, and the belt conveyor, the leveling mechanism and the rolling mechanisms are sequentially arranged between the two supporting side frames in the conveying direction of the belt conveyor. The lateral pulling and flattening mechanism is arrangedbetween the two supporting side frames and located above the belt conveyor. The rolling mechanisms are arranged on the two supporting side frames, and are oppositely arranged in a mirrored manner. Theprocessing system is suitable for leveling and rolling material strips in the producing and forming process of the plastic woven bag barrel-shaped material strips, and therefore the flattened and smooth barrel-shaped material strips are obtained for subsequent bag manufacturing, folding deformation of the produced and rolled material strips is avoided through effective leveling, the trouble of subsequent manual settling is avoided, the subsequent automatic bag manufacturing process is convenient, and the fraction defective is reduced.

Owner:儋州伟达化工有限公司

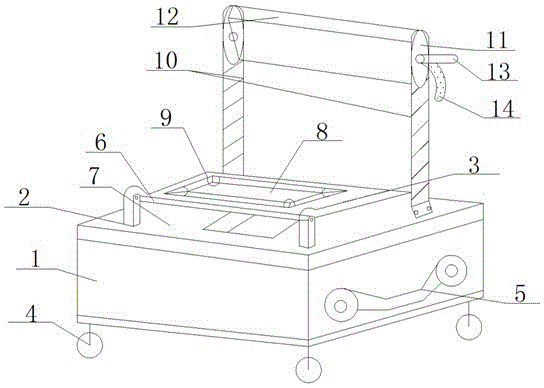

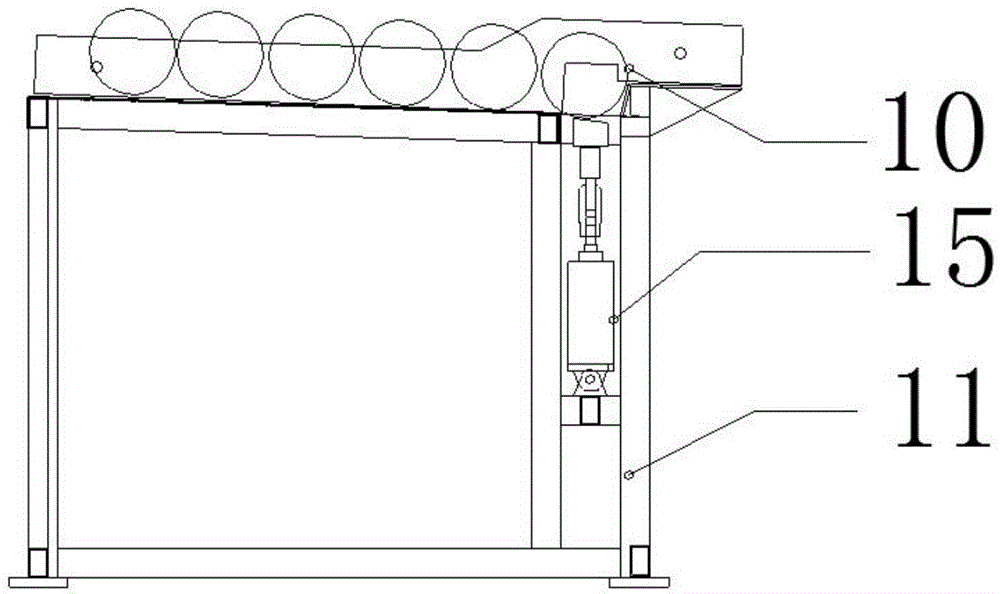

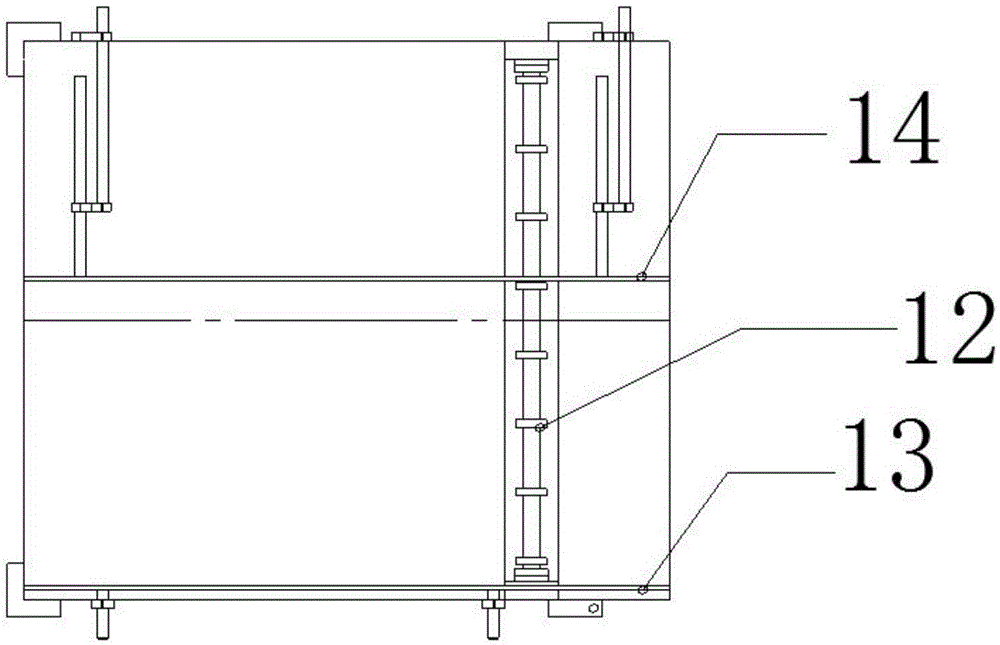

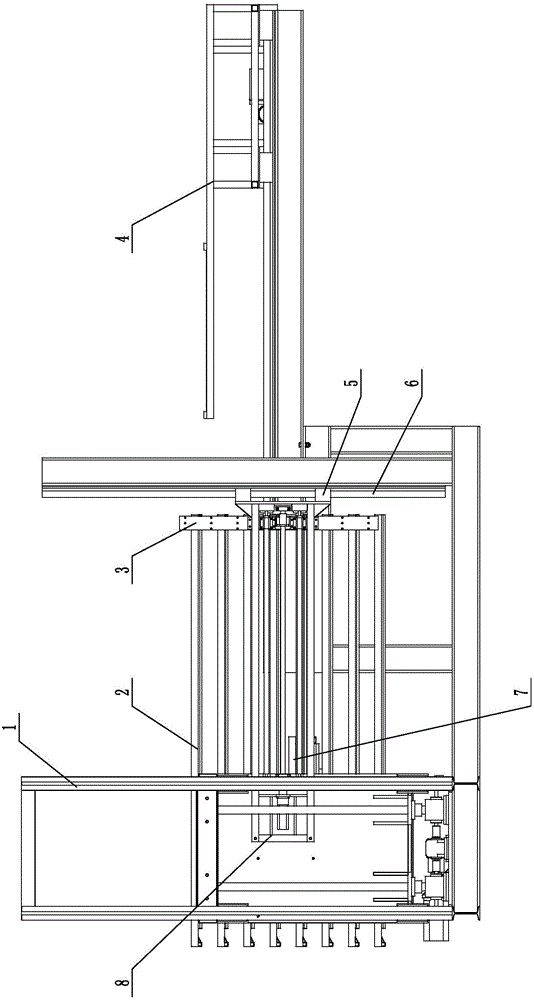

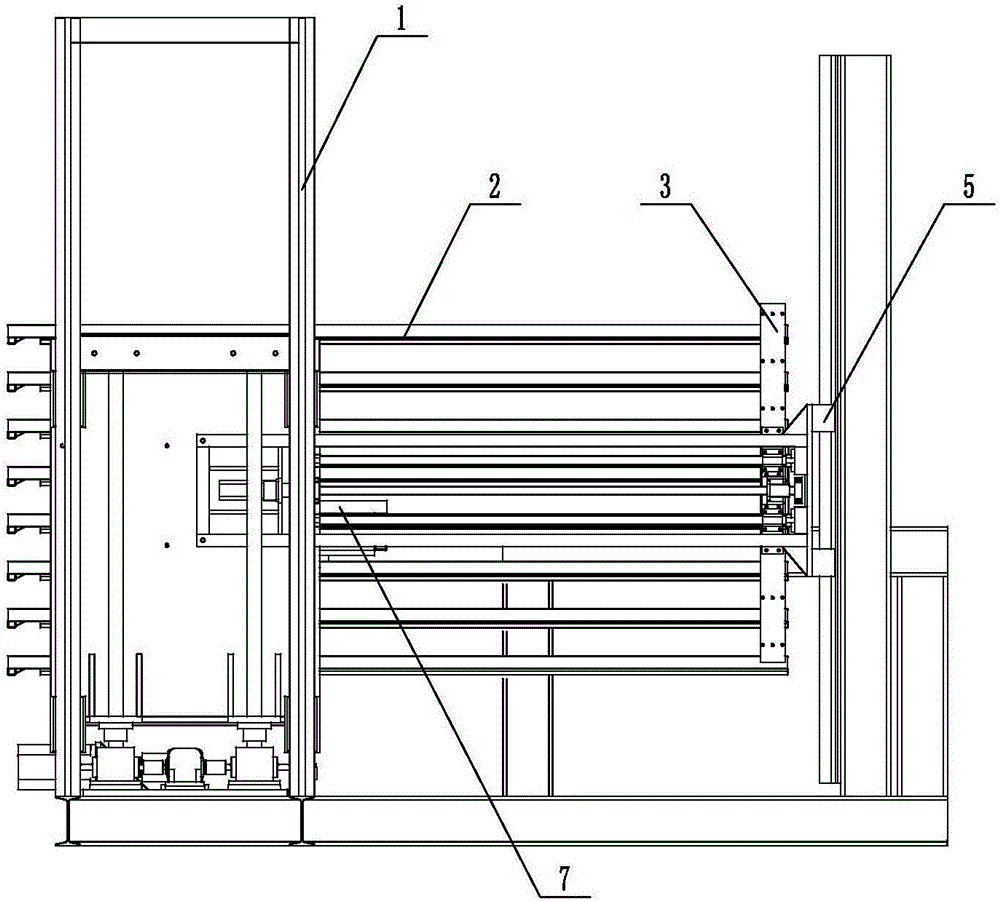

Automatic feeding and unloading device of laminated board hot press

ActiveCN106808537AHigh degree of automationReduce manpower consumptionPlywood pressesVeneer pressesWood plankEnergy consumption

The invention discloses an automatic feeding and unloading device of a laminated board hot press. The device comprises a plank loading and unloading lifting assembly and a conveying mechanism (4). The plank loading and unloading lifting assembly comprises a lifting mechanism (1), a jackingmechanism (7), a pusher mechanism (8), and a plurality of holding mechanisms (2). The automatic feeding and unloading device of the laminated board hot press has the advantages of being high in work efficiency and conveyingprecision, reducing energy consumption, saving manpower, and hot-pressing two sides through the hot pressat the same time.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

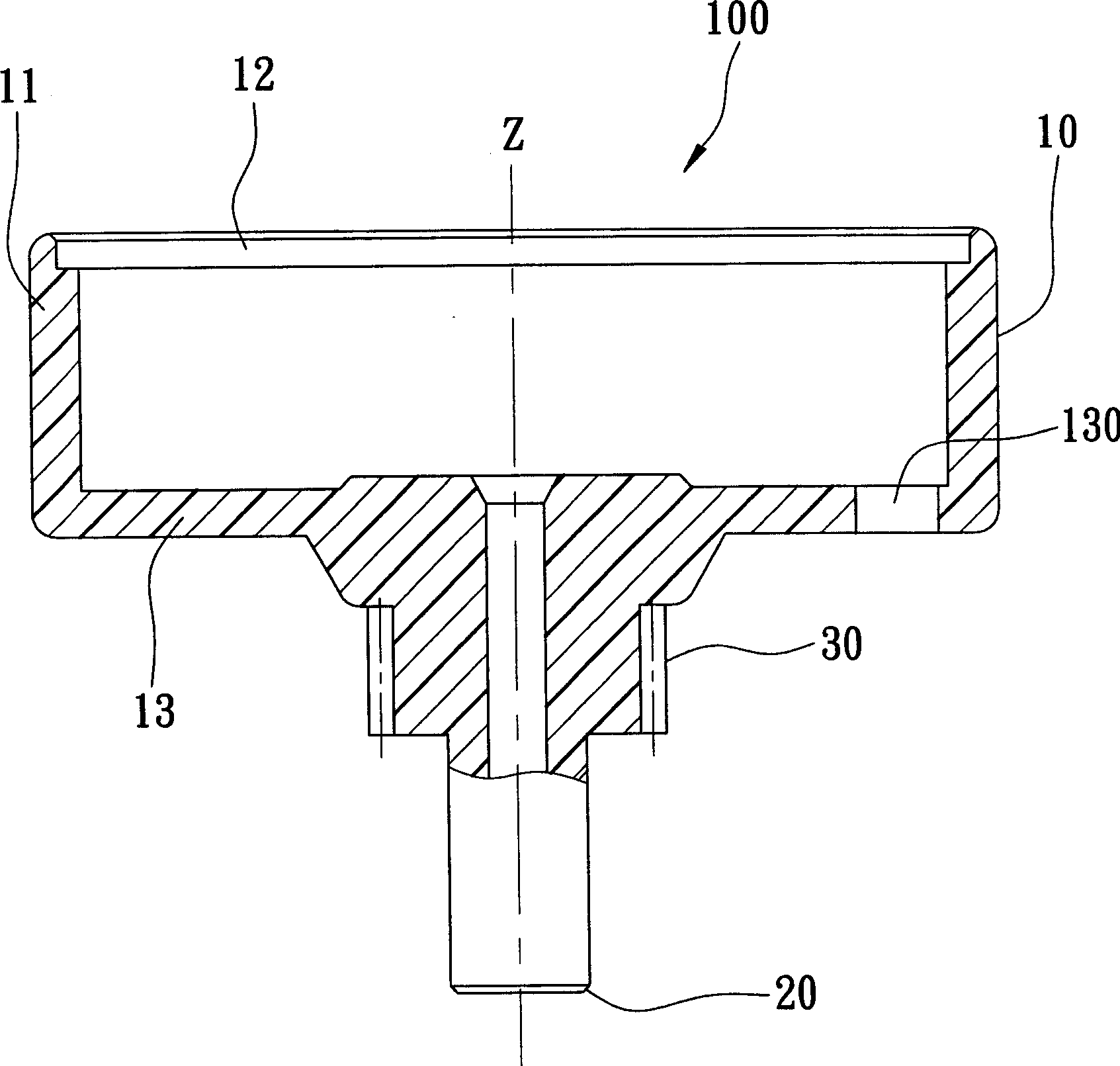

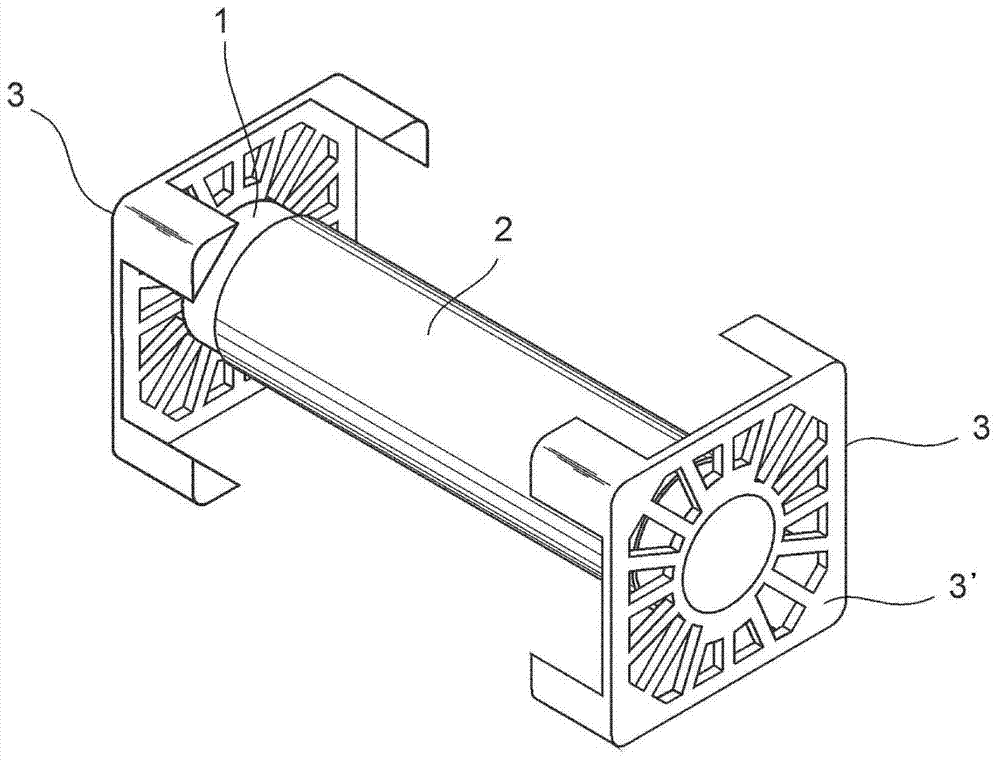

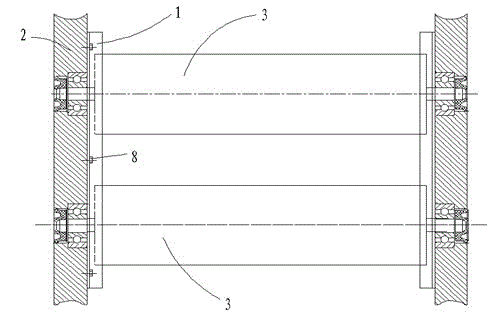

Roll-like polyelectrolyte film packaging body, and manufacturing method thereof, and packed object

ActiveCN104852063AInhibits wrinkling or damageReduce the rate of defective productsFinal product manufactureSolid electrolyte fuel cellsWrinklePolyelectrolyte

The purpose of the invention is to provide a roll-like polyelectrolyte film packaging body, and a manufacturing method of the packaging body, and a packed object. When a roll-like polyelectrolyte film is stored or transported, the packaging body can prevent defects, such as wrinkles or damage, from generation, so that the unqualified rate of the polyelectrolyte film can be reduced. The roll-like polyelectrolyte film packaging body of the invention has a roll core, the roll-like polyelectrolyte film being wound round the roll core, and two protectors arranged at two end surfaces of the roll core. Each protector has a side plate, the size of which is larger than the outer diameter of the roll-like polyelectrolyte film. The side plates of the two protectors arranged at two end surfaces of the core and the core can maintain the roll-like polyelectrolyte film wound round the core in a suspension state.

Owner:ASAHI KASEI KK

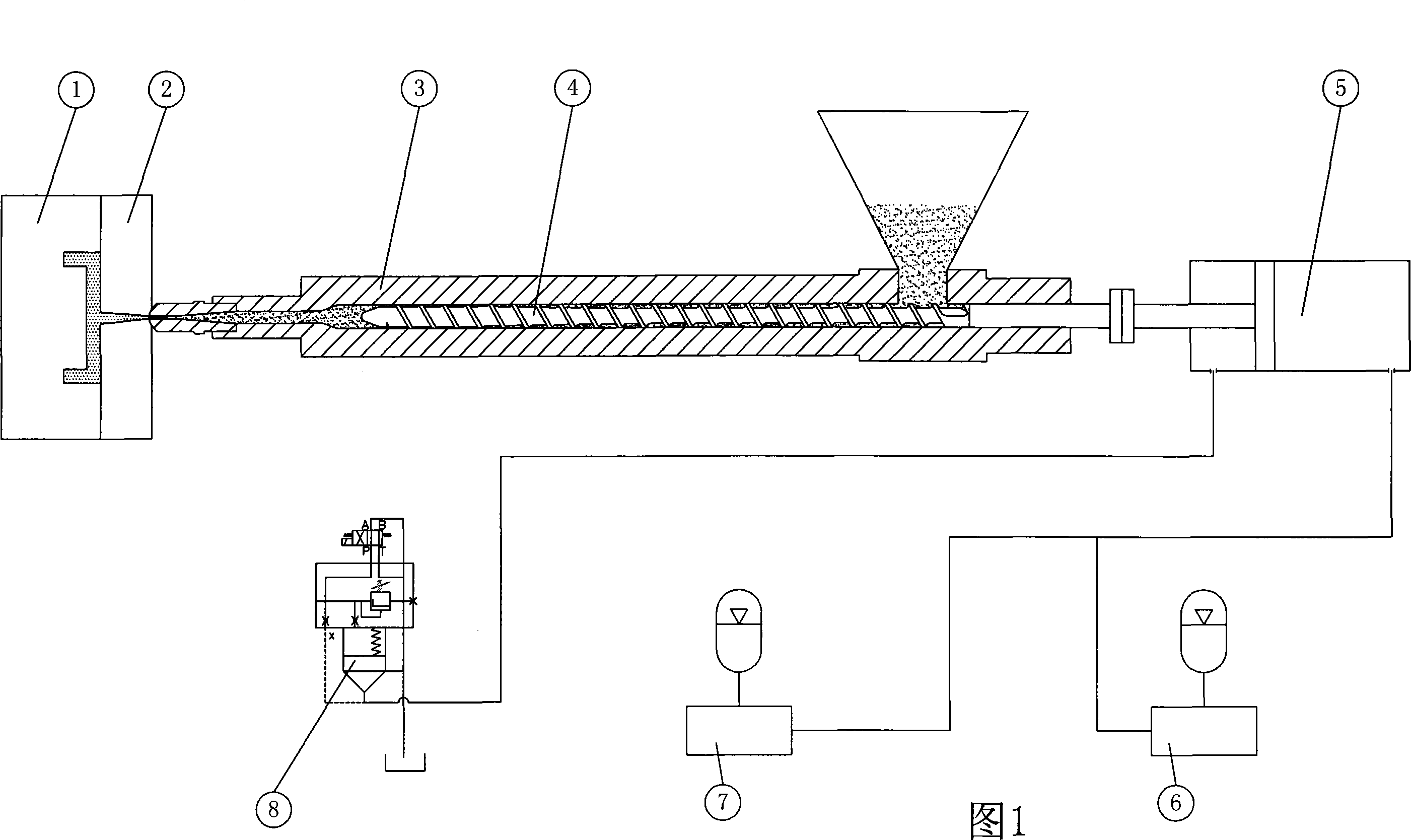

High-speed plastic-injecting dump energy pressure maintaining injection molding of plastic method

The invention relates to a method of high-speed glue injection to energy storage pressure preserving plastic injection modeling. First of all, the energy storage glue injection generator of a glue injection energy storage tank and the energy storage pressure preserving generator of a pressure preserving energy storage tank are used to accumulate, then plasticizing is carried out in feed hopper components plasticizing screw bat; a moving half moves towards a fixed half; molds for plasticizing the screw bat move forward at a high speed and a low pressure; and glue stock quickly fills the molds. At the moment, the screw bat plasticized stops moving, the energy storage pressure preserving generator quickly switches to be opened to transfer higher injection pressure to accumulating pressure at a given speed. The glue stock in the mold cavity made by the above steps freezes the modeling through cooling down. The invention adopting the technics of the high-speed glue injection to energy storage pressure preserving plastic injection modeling, thus the reaction rate of the pressure preserving is over twice than that of general oil passages, thereby not only reducing the forming period of plastic products, but also decreasing the probability of failure products, and the method has high economic and social benefits.

Owner:DONGHUA MACHINERY

Multi-bin cotton feed roller flaw preventing device

The invention discloses a multi-bin cotton feed roller flaw preventing device which comprises bin plates and a cotton feed rollers. Two ends of each cotton feed roller are supported in the bearing holes of the bin plates on two sides. The inner side of the roller plate above the rollers is provided with a anti-winding retaining plate. The anti-winding retaining plate is a bending plate which comprises an upper connecting plate and a lower retaining plate face. The included angle between the retaining plate face and the bin plates is acute. The axial clearance between the outer working face of each roller and the inner surface of each bin plate is smaller than the minimum vertical distance between one end, closest to the bin plates, of the retaining plate face and the inner surface of the bin plates. The multi-bin cotton feed roller flaw preventing device has the advantages that the bearings are small in friction resistance and good in radiation, normal machine operation is guaranteed, fiber blocking and winding can be avoided, fiber flaws can be reduced, rejection rate can be reduced, economical benefits are increased, and shut down caused by fiber blocking is reduced.

Owner:SHANDONG PROVINCE WINSON NON WOVEN MATERIALS

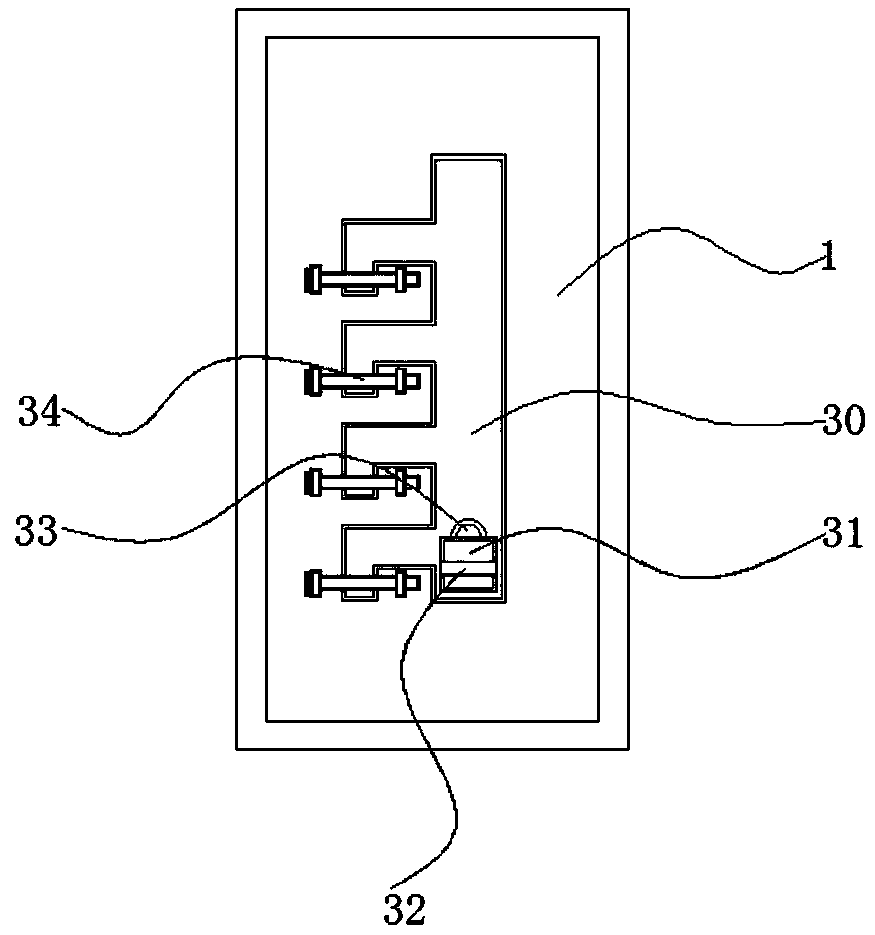

Safety type corner edge sealing machine capable of preventing hands from being clamped

ActiveCN109366682AShorten the timePrevent movementWood working apparatusDomestic articlesEngineeringEdge banding

The invention relates to a safety type corner edge sealing machine capable of preventing hands from being clamped. The machine comprises a main body, an extending-out rotating arm, an air pump and a material pushing air rod, a support is arranged below the main body, and a moving wheel is arranged in the support, the main body and the support are connected through screws, the support is movably connected with the moving wheel, the extending-out rotating arm penetrates through the front end of the support, and extends out of the rotating arm and is movably connected with the bracket, the air pump is arranged on the inner side of the support, and the air pump is connected with the main body through the screw, the pushing air rod is arranged above the main body, and a discharging plate is arranged above the pushing air rod, and the pushing air rod is connected with the main body through the screw. The safety type corner edge banding machine has the advantages of being capable of preventing hands from being clamped, an anti-collision layer is arranged, so that the possibility of collision between the sealed object and the material clamping plate can be prevented, so that the possibility that the cut-out of the object to be sealed is expanded is reduced, and the sealing opening of the glue is reduced, and the probability of defective products produced by the device is also reduced.

Owner:杨辉

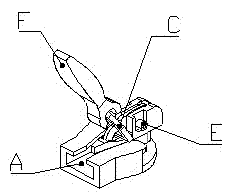

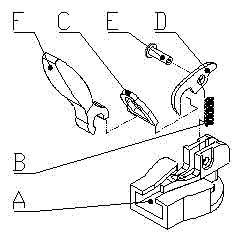

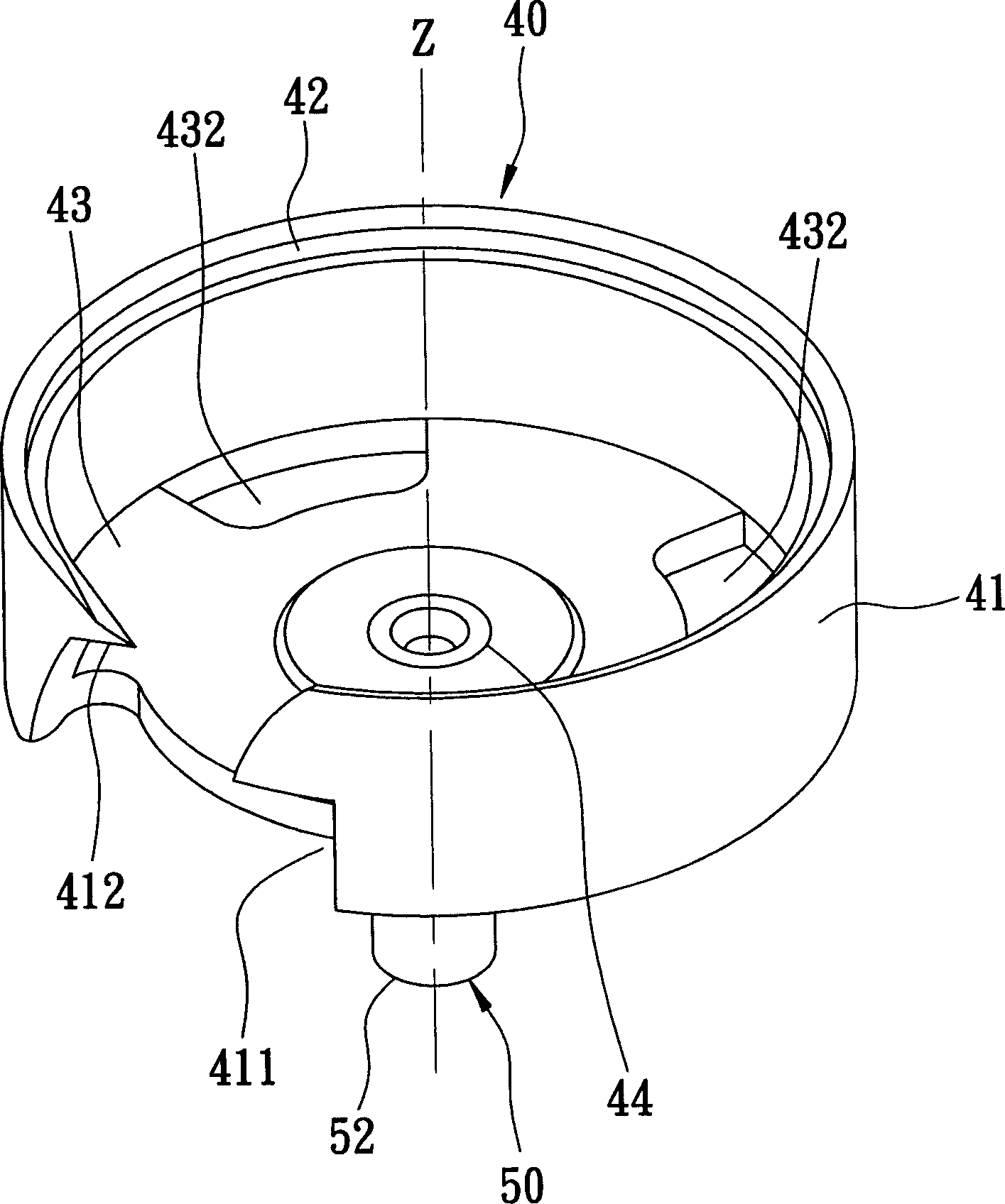

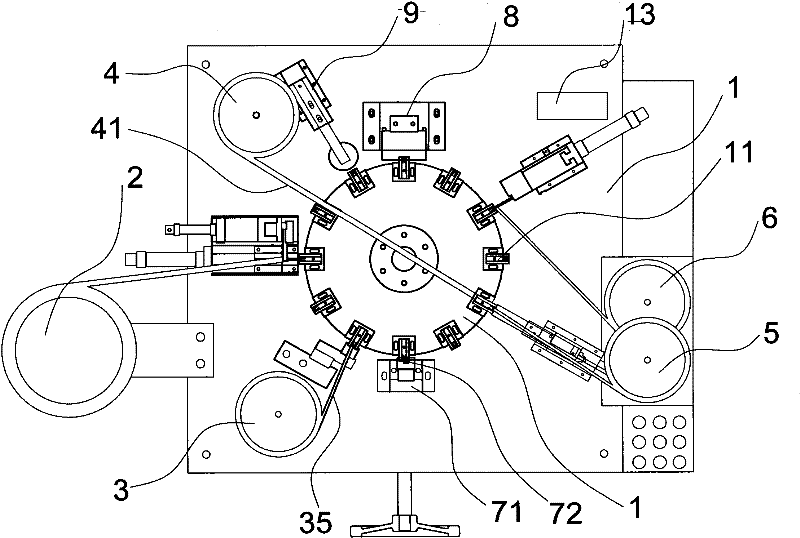

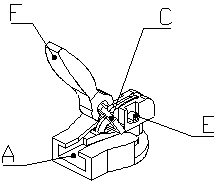

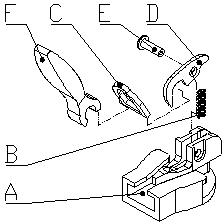

Automatic assembling machine of invisible zipper head

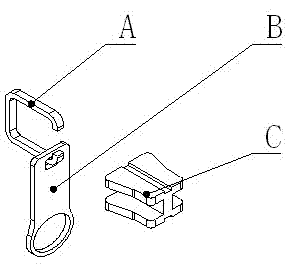

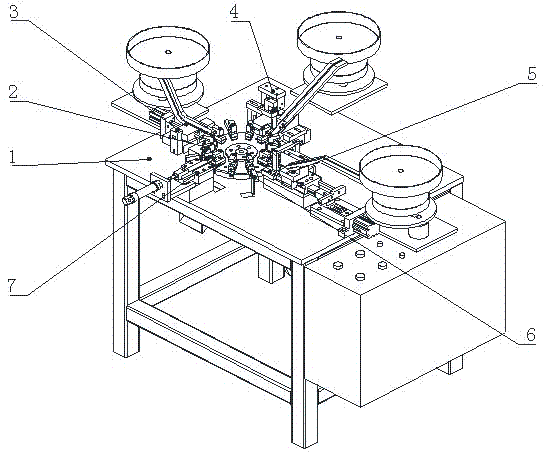

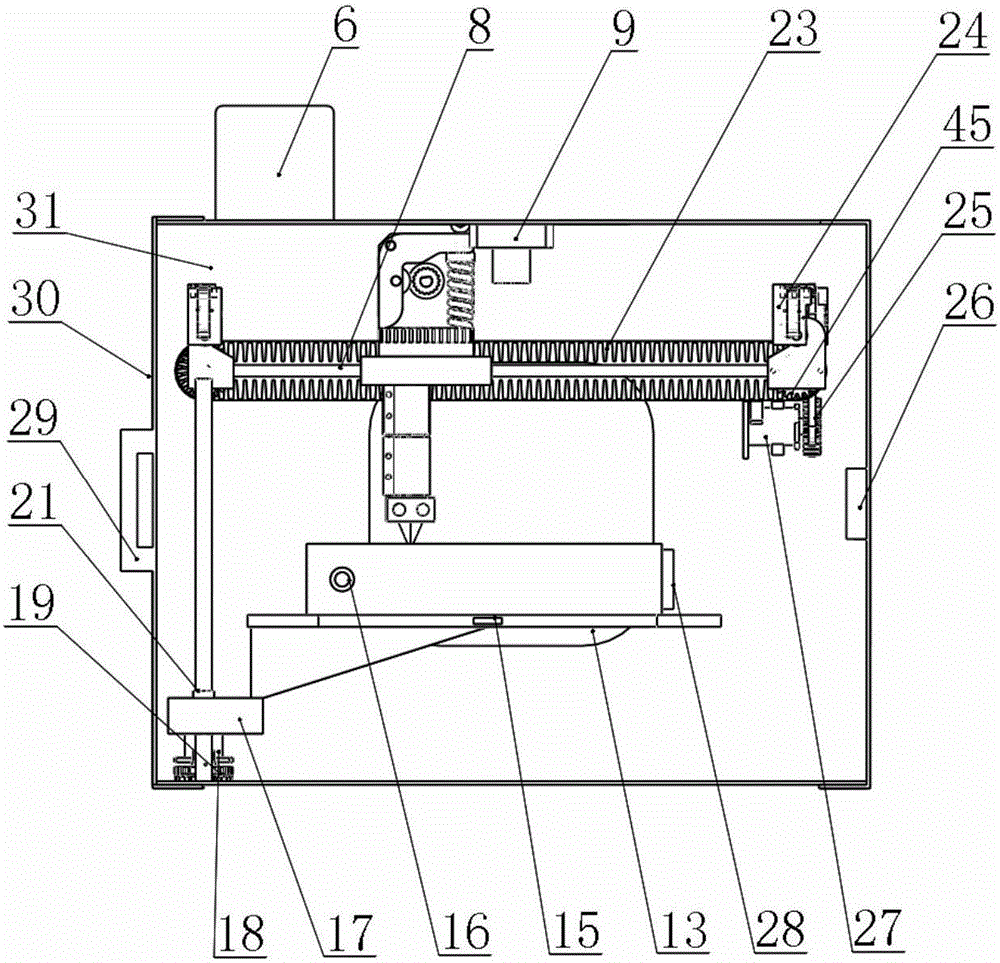

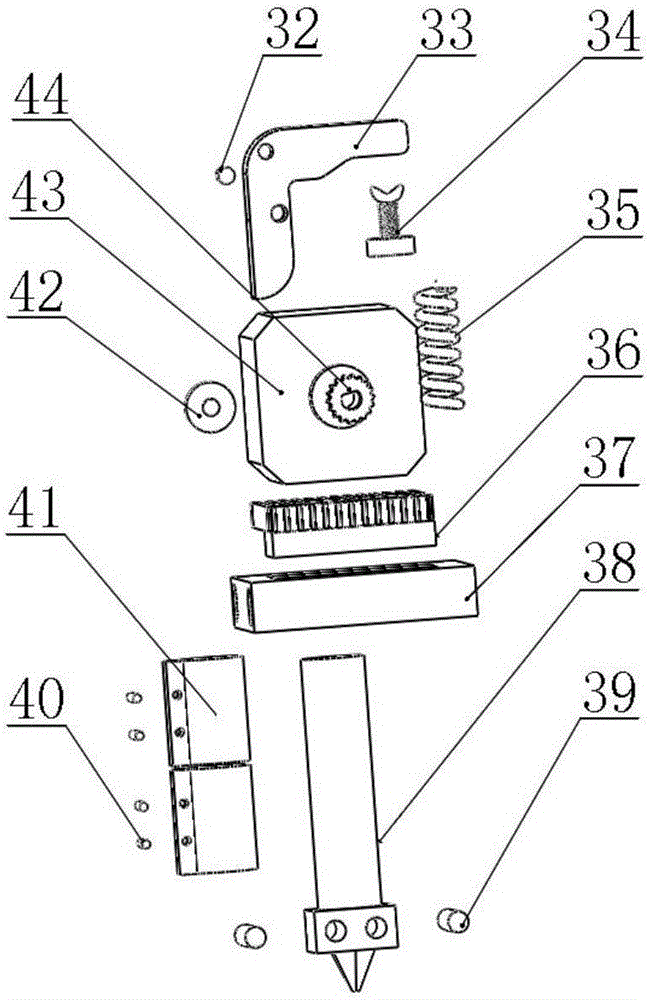

InactiveCN101766375BImprove assembly efficiencyImprove assembly qualitySlide fastenersEngineeringAutomation

The invention discloses an automatic assembling machine of an invisible zipper head. The automatic assembling machine has the following characteristics: the structure is simple, the automation degree is high, the assembling quality of a part can be automatically identified, and the automatic running of the assembling machine can be regulated as well as controlled so as to increase the assembling efficiency and ensure stable as well as reliable product quality. The automatic assembling machine solves the technical problems in the prior art that the product quality is poor and the production efficiency is low due to that the assembling automation degree of the zipper head is low and the assembling quality can only be manually identified. The automatic assembling machine comprises a machine seat. An assembling disc connected with a power device is horizontally arranged on a tabletop of the machine seat, and an assembling mould used for fixing a pull head is arranged on the assembling disc. A charging mechanism used for assembling the zipper head, a riveting mechanism and a discharging mechanism are arranged on the machine seat. The charging mechanism comprises a pull head feeding mechanism, a spring feeding mechanism, a triangular feeding mechanism, a hook feeding mechanism and a copper pin feeding mechanism which are respectively connected with a vibrating disc. A detecting control mechanism is arranged between the charging mechanism and the riveting mechanism.

Owner:义乌市华大压铸有限公司

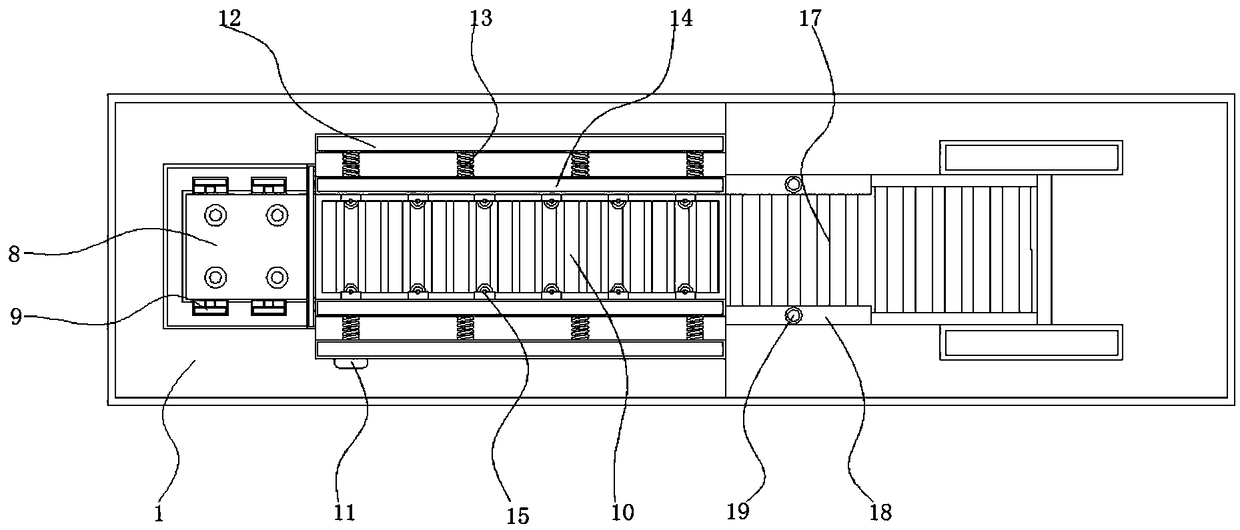

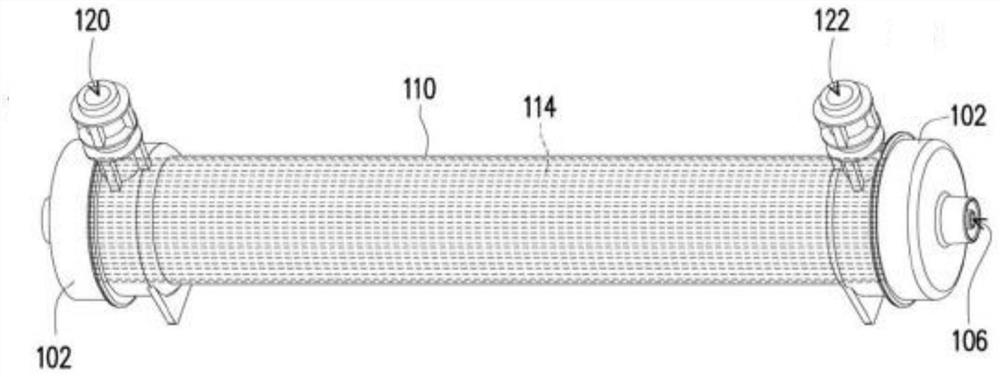

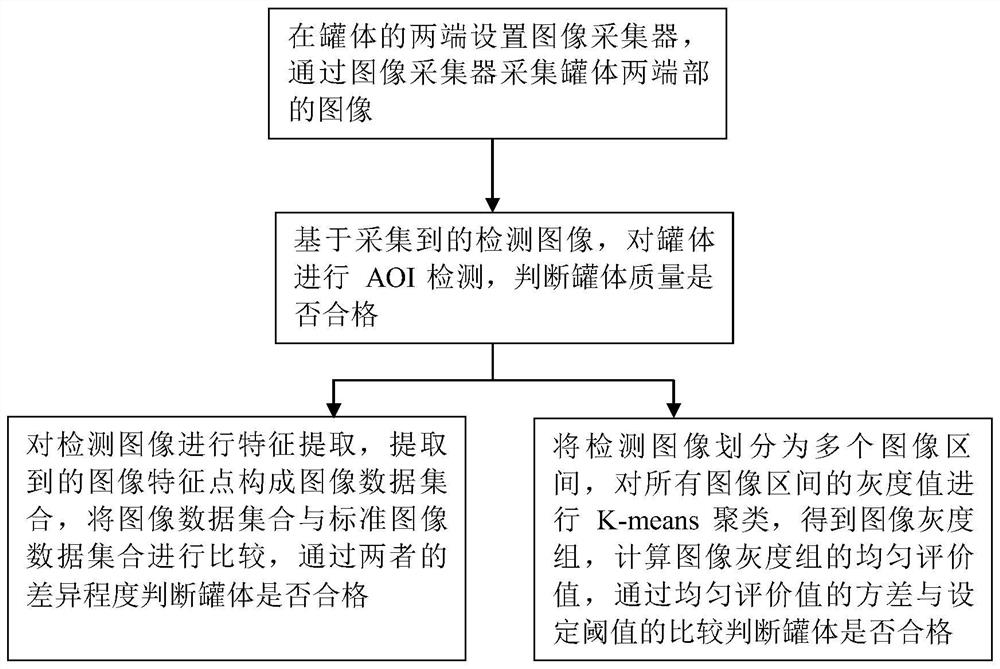

Quality inspection method and assembling method of dialyzer

ActiveCN113577422AQuality EvaluationEliminate the effects ofNuclear energy generationDialysis systemsHollow fibreFiber bundle

The invention discloses a quality inspection method and an assembling method of a dialyzer. The dialyzer comprises a tank body and end cover assemblies arranged at the two ends of the tank body; a hollow fiber bundle is arranged in the tank body and filled with sealant, the hollow fiber bundle comprises a plurality of hollow fiber membranes, and each end cover assembly comprises an end cover and a sealing ring; before the tank body and the end cover assembly are assembled, AOI detection is carried out on the tank body, and the method comprises the following steps that images of the two end portions of the tank body are collected through an image collector; and according to the collected detection image, performing AOI detection on the tank body, and judging whether the quality of the tank body is qualified or not. In the process of assembling the dialyzer, the quality inspection method of the dialyzer is applied to the assembling process so as to accurately identify the defects of the tank body, eliminate defective products in the production process of the tank body and reduce the production failure rate of the dialyzer in time, so the aim of considering the safety and the efficiency in the production process of the dialyzer is fulfilled.

Owner:JAFRON BIOMEDICAL +1

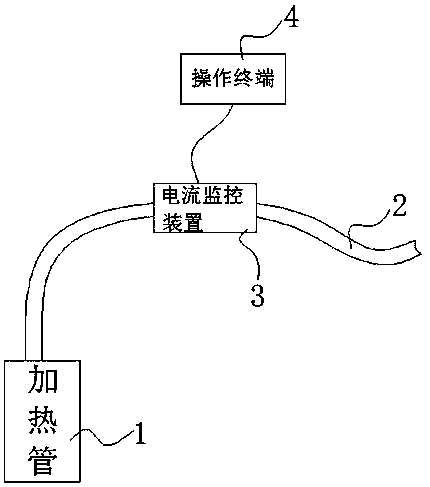

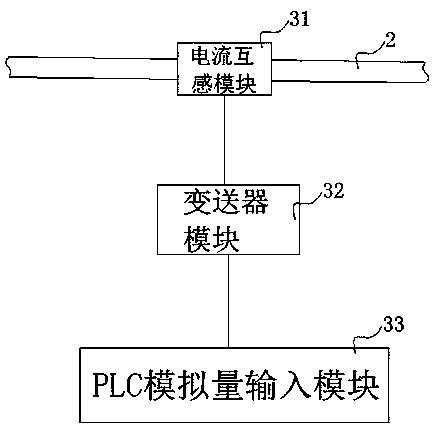

Current monitoring and reforming device for heating pipe of annealing furnace

PendingCN109471405ASolve the uninformedAvoid batch quality accidentsFurnace typesHeat treatment process controlElectricityCurrent limiting

The invention discloses a current monitoring and reforming device for a heating pipe of an annealing furnace, which comprises the heating pipe arranged at the bottom of the annealing furnace, whereinthe heating pipe is connected with a power supply cable; a current monitoring device is arranged on the power supply cable; the current monitoring device is composed of a current mutual inductance module, a transmitter module and a PLC analog quantity input module; the input end of the current mutual inductance module is electrically connected with the power supply cable; the output end of the current mutual inductance module is connected with the input end of the transmitter module; the output end of the transmitter module is connected with the input end of the PLC analog quantity input module; the output end of the PLC analog quantity input module is in communication connection with an operation terminal. According to the current monitoring and reforming device for the heating pipe of the annealing furnace, the fault problem can be found at the first time, the alarm can be fed back, the reliability is good, the response speed is high, the accident incidence rate is reduced, the rateof unqualified products is obviously reduced, and a large amount of cost is saved for enterprises.

Owner:CHONGQING LONGYU PRECISION COPPER TUBE CO LTD

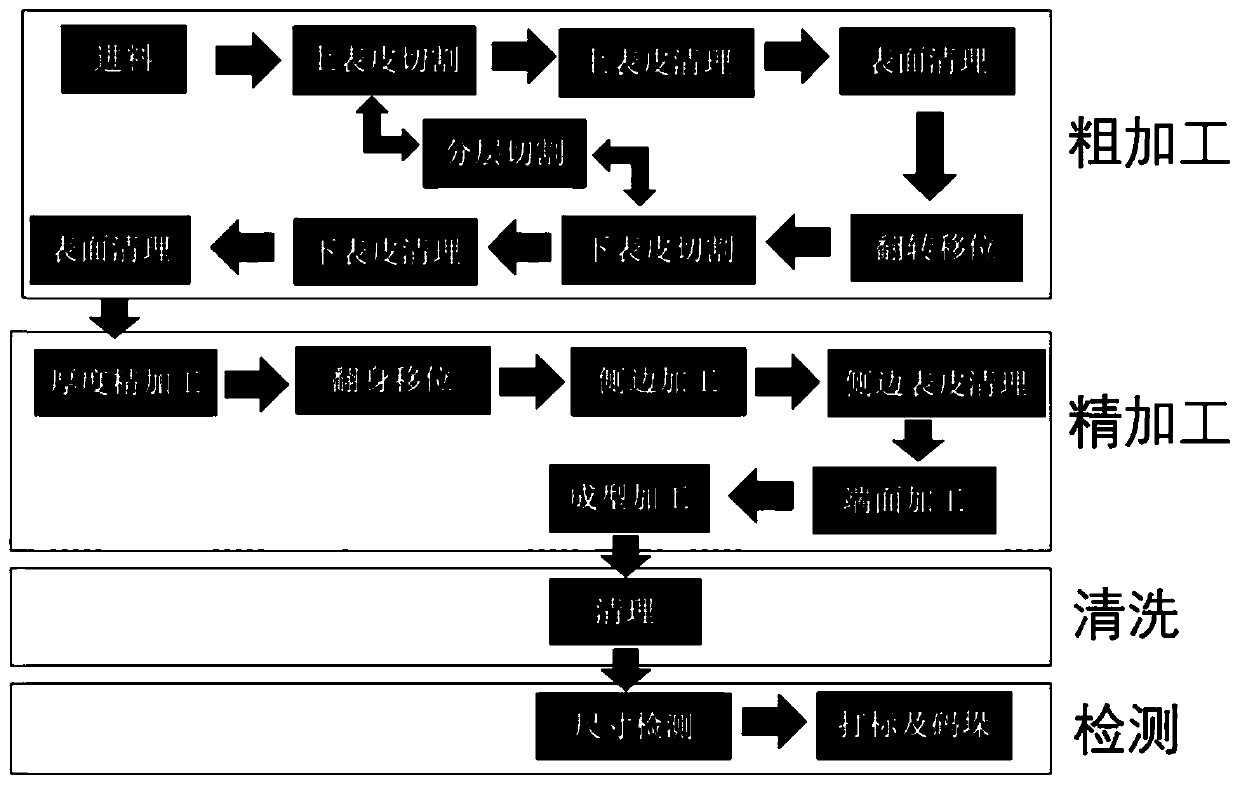

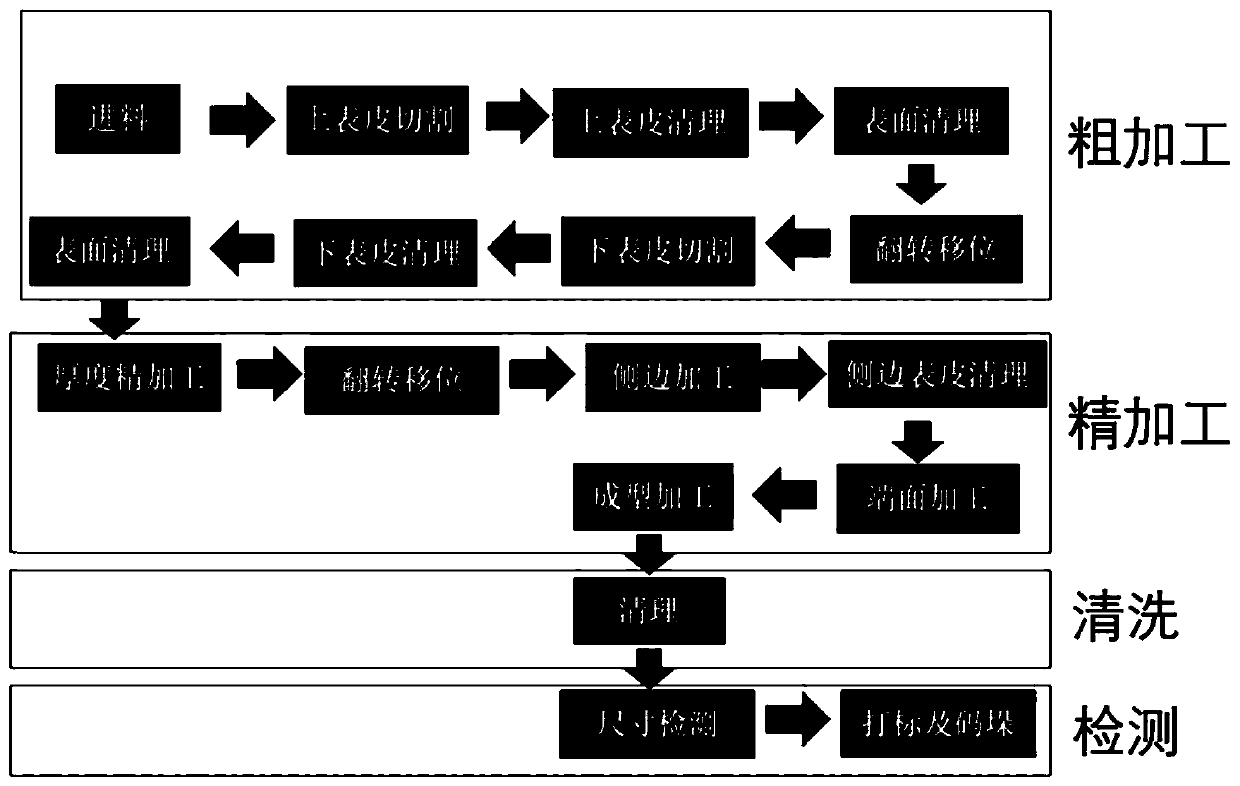

Non-rigid material hexahedron precise automatic processing technology and system

ActiveCN110948241AAffect normal operationOvercome deficienciesOther manufacturing equipments/toolsProcess engineeringMachining process

The invention relates to a non-rigid material hexahedron precise automatic processing technology and system for an insulation box foam board used for an LNG ship. The technology includes a foam boardrough processing stage, a foam board fine processing stage, a cleaning stage, and a detection stage, wherein the foam board rough processing stage, the foam board fine processing stage, the cleaning stage, and the detection stage are performed in sequence, and the foam board fine processing stage includes a thickness fine processing process, a side edge processing process, an end surface processing process, and a forming processing process, wherein the thickness fine processing process, the side edge processing process, the end surface processing process, and the forming processing process aresequentially performed. Compared with the prior art, the non-rigid material hexahedron precise automatic processing technology and system have innovative automatic processes, all carrying and overturning processes are completed by robots, all devices have communication functions, the unmanned requirement is met, manual participation is greatly reduced, safety of the production process is improved, and at the same time, the production efficiency and the stability of the size of a finished product are improved.

Owner:SHANGHAI JIAO TONG UNIV +1

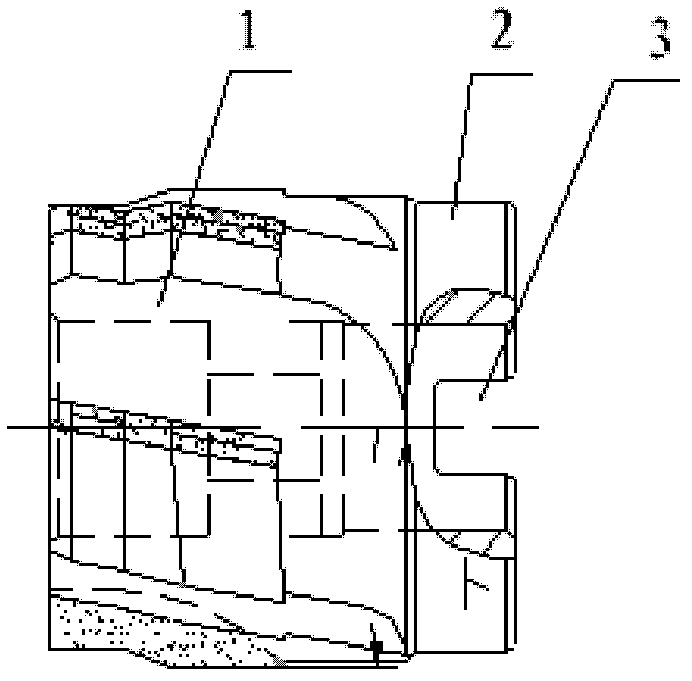

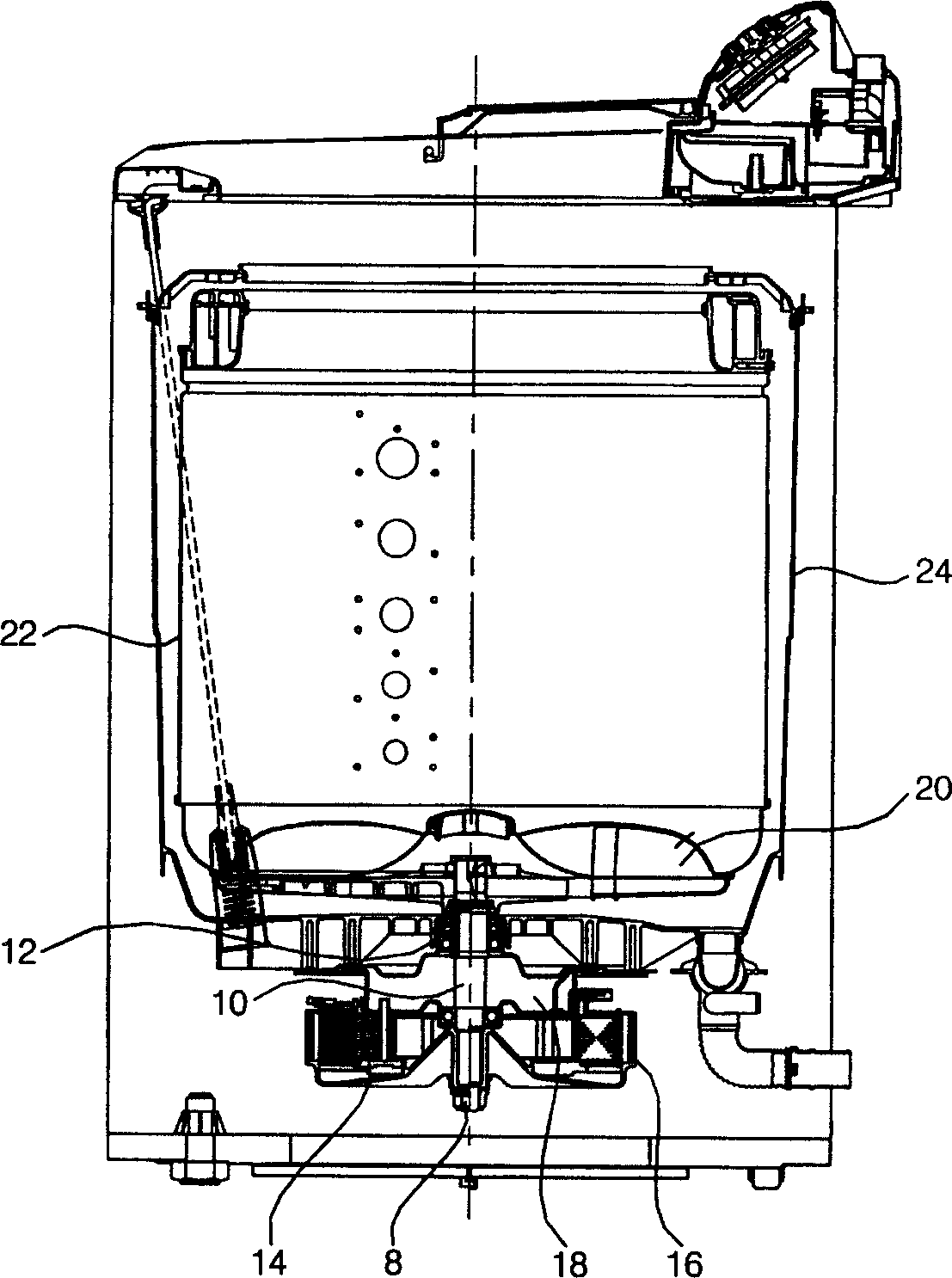

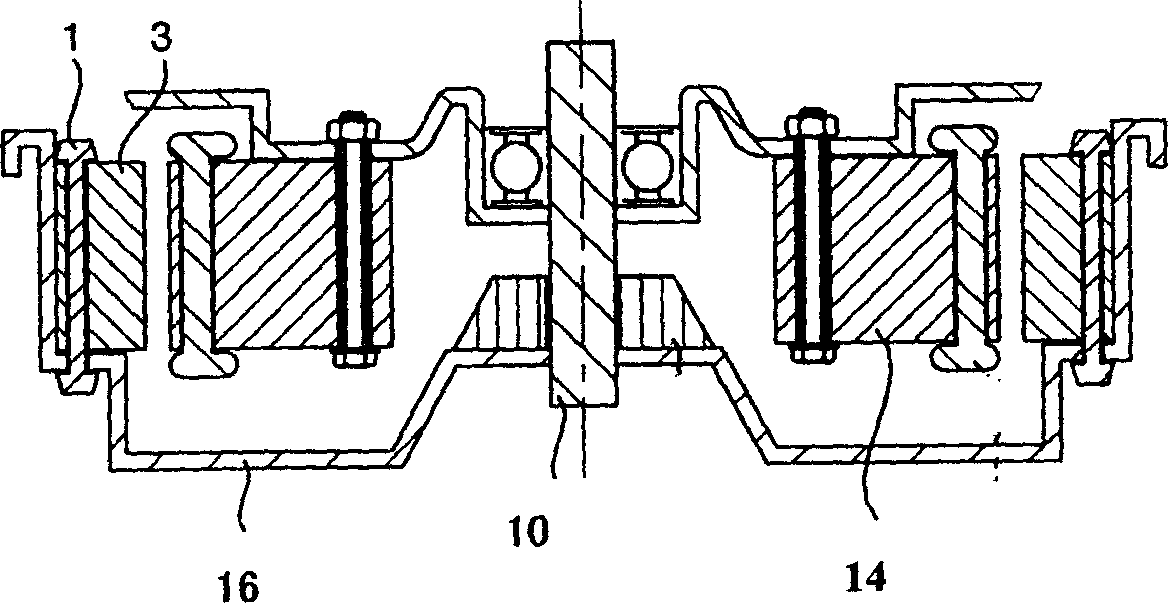

External rotor type dynamo of washing machine

InactiveCN1601853ASimple structureReduce assembly processMagnetic circuit rotating partsManufacturing cost reductionElectric machine

The motor includes following parts: stator enwound wire of making current passing through; rotor setup outer side of the stator, and keeping up a certain internal between rotor and stator, rotor is rotated when stator is connected to power source; rotative frame connected to rotor, the frame including an integrated connection part for fixing the rotor. In the invention, rotor is fixed on internal side face of rotative frame without need of individual connection part. Thus, structure of the motor is simplified, and assembling steps and time are reduced. The invention reduces defective rate.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Six-part full-automatic assembly machine for invisible zipper puller

InactiveCN102525044BHigh degree of automationRealize automatic feedingSlide fastenersStructural engineeringMachine

The invention discloses a six-part full-automatic assembly machine for invisible zipper puller and is characterized in that a moving assembly that is connected with a power device is arranged at the table top of a frame; twelve die cavities for fixing zipper pullers are arranged at equal intervals on the margin of the division main rotor plate of the moving assembly; and a zipper puller feeding mechanism, a zipper puller detection mechanism, a zipper puller spring feeding mechanism, a spring detection mechanism, a triangular collar feeding mechanism, a triangular collar detection mechanism, a horse hooker feeding mechanism, a copper pin feeding mechanism, a copper pin detection mechanism, a puller detection mechanism, a puller detection mechanism rejected puller discharge mechanism, and a qualified product discharge mechanism are arranged on the frame and used for assembling zipper pullers. The six-part full-automatic assembly machine integrates the functions of two machines, the detection mechanisms are arranged behind the corresponding feeding mechanism to automatically identify parts in the die cavities, and the start-up or shut-down of the assembly machine is automatically controlled according to the assembly information of parts, so as to prevent defected parts from entering the next procedure or prevent idle running of the assembly machine, as a result, the rate of rejected products is reduced and the assembly machine is guaranteed to run safely and reliably.

Owner:义乌市振宏机械科技有限公司

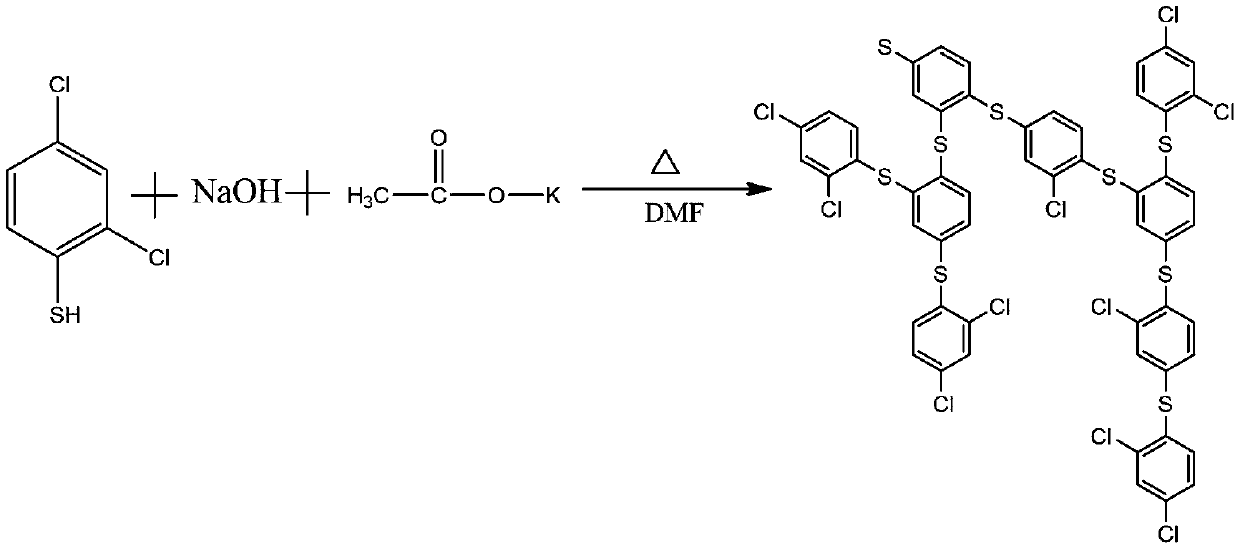

Preparation method of hyperbranched polyphenylene sulfide

The invention belongs to the field of high polymer materials, and particularly discloses a preparation method of hyperbranched polyphenylene sulfide. The preparation method comprises the following steps: (1) adding 2,4-dichlorothiophenol, sodium hydroxide and potassium acetate into an N,N-dimethylformamide solvent, and carrying out oil bath heating under the protection of high-purity nitrogen; (2) increasing the temperature of the system to 255-275 DEG C, and carrying out constant-temperature treatment on the system for 150-210 minutes; (3) cooling the system to 80-90 DEG C, adding distilled water, and continuously stirring the system for 30-60 minutes; (4) adding the system into a hydrochloric acid solution, and continuously stirring the system for 180-240 minutes; (5) filtering the system, and adding a filtered-out substance into an acetone solution for elution; (6) filtering the system after elution, and adding a filtered-out substance into distilled water for elution; and (7) filtering the system after elution, and drying a filtered-out substance to obtain the hyperbranched polyphenylene sulfide powder product. The preparation method is low in raw material price, simple in reaction process and short in reaction time, the synthesis process is easy to control, the reaction yield is high, and the rate of unqualified products is greatly reduced.

Owner:YIBIN TIANYUAN GRP CO LTD

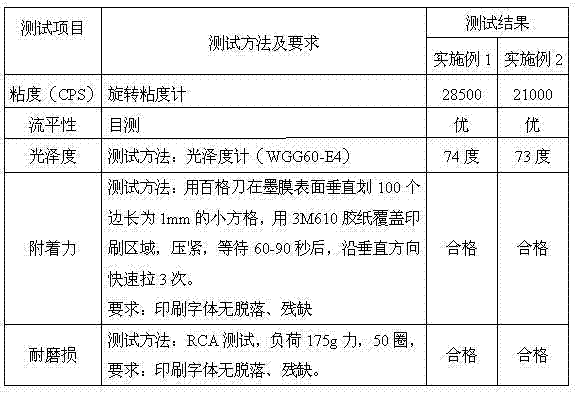

Screen printing ink and preparation method thereof

The invention provides screen printing ink and a preparation method thereof. The screen printing ink is prepared from the following components in parts by weight: 30 to 42 parts of polyester resin, 32to 42 parts of modified polyester resin, 22 to 25 parts of vinyl chloride-vinyl acetate resin, 26 to 32 parts of acrylic resin, 28 to 32 parts of a Cytec acrylate active monomer, 40 to 45 parts of asolvent, 0.5 to 1.5 parts of a dispersant and 0.5 to 1.3 parts of a de-foaming agent. The screen printing ink provided by the invention has the advantages of more stable adhesive force and more excellent wear resistance and chemical resistance.

Owner:ZHONGSHAN BRITE DAY COATING RAW MATERIALS

Method for machining box body assemblies of three-level planetary reducer

The invention discloses a method for machining box body assemblies of a three-level planetary reducer. The method comprises the steps that firstly reference tapes are lathed on the outer circle of a first-level inner gear ring, the outer circle of a second-level inner gear ring and the outer circle of a third-level inner gear ring respectively; secondly, the corresponding reference tapes serve as aligning bases, inner gears and spigots of the first-level inner gear ring, inner gear and spigots of the second-level inner gear ring and inner gears and spigots of the third-level inner gear ring are machined; thirdly, a front box body, the first-level inner gear ring and a first middle box body are assembled, the corresponding reference tape serves as the aligning base, and a first bearing hole and a second bearing hole are machined in the front box body; thirdly, a second middle box body, the third-level inner gear ring and a rear box body are assembled, the corresponding reference tapes serve as the aligning bases, and a fifth bearing hole in the second middle box body and a sixth bearing hole in the rear box body are machined; and finally, the first middle box body, the second-level inner gear ring and the second middle box body are assembled, the corresponding reference tapes serve as the aligning bases, and a third bearing hole in the first middle box body and a fourth bearing hole in the second middle box body are machined. In this way, the coaxiality of the bearing holes is improved remarkably, and the nonconforming rate is reduced.

Owner:CHONGQING GEARBOX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com