Pad printing ink for elastic paint surface decoration

A technology of surface decoration and elastic paint, applied in the direction of ink, application, household utensils, etc., can solve the problems of poor adhesion fastness of ordinary ink, damaged pattern corners, coating peeling, etc., to achieve rich decoration scheme design and visual effects , Reduce the rate of unqualified products and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Under normal temperature and pressure, take 20 parts (weight) of ketone solvent, 35 parts (weight) of polyurethane resin, 24 parts (weight) of modified polyester resin and stir at 600-1200r / min for 15-30 minutes to dissolve completely, then add 1.5 parts (weight) of dispersant, 18 parts (weight) of pigment, after stirring evenly, pass through a three-roll machine and grind to below 10цm, then add 1.5 parts (weight) of defoamer, stir and disperse evenly, and then the finished product is obtained.

Embodiment 2

[0050] Under normal temperature and pressure, take 15 parts (weight) of ketone solvent, 30.5 parts (weight) of polyurethane resin, 28.5 parts (weight) of modified polyester resin and stir at 600-1200r / min for 15-30 minutes to dissolve completely, then add 1.5 parts (weight) of dispersant, 18 parts (weight) of pigment, after stirring evenly, pass through a three-roll machine and grind to below 10цm, then add 1.5 parts (weight) of defoamer, 5 parts (weight) of alcohol ether solvent, stir and disperse After uniformity, the finished product is obtained.

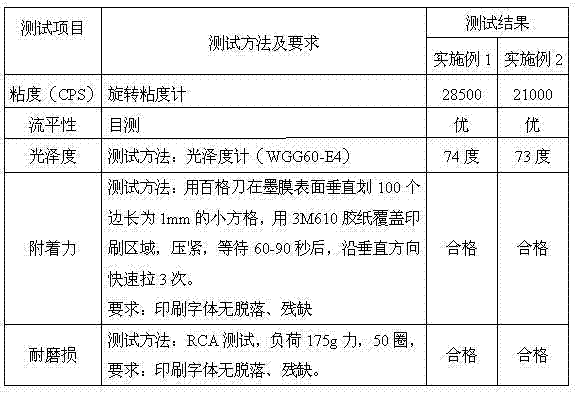

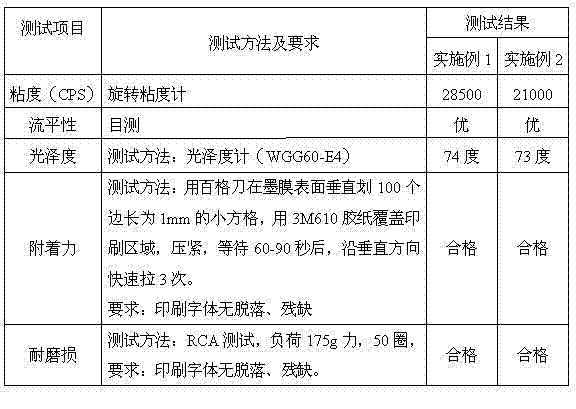

[0051] Above embodiment gained elastic varnish surface decoration with pad printing ink on elastic varnish surface, when pad printing thickness is 10μm, printing effect and physical and chemical index state of printing ink on material see figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com