Automatic feeding and unloading device of laminated board hot press

An automatic feeding and hot press technology, which is applied to veneer presses, plywood presses, manufacturing tools, etc., can solve the problems of heavy physical exertion of feeding personnel, decline in product quality, and low feeding efficiency, and achieve efficiency improvement, The effect of low manpower consumption and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

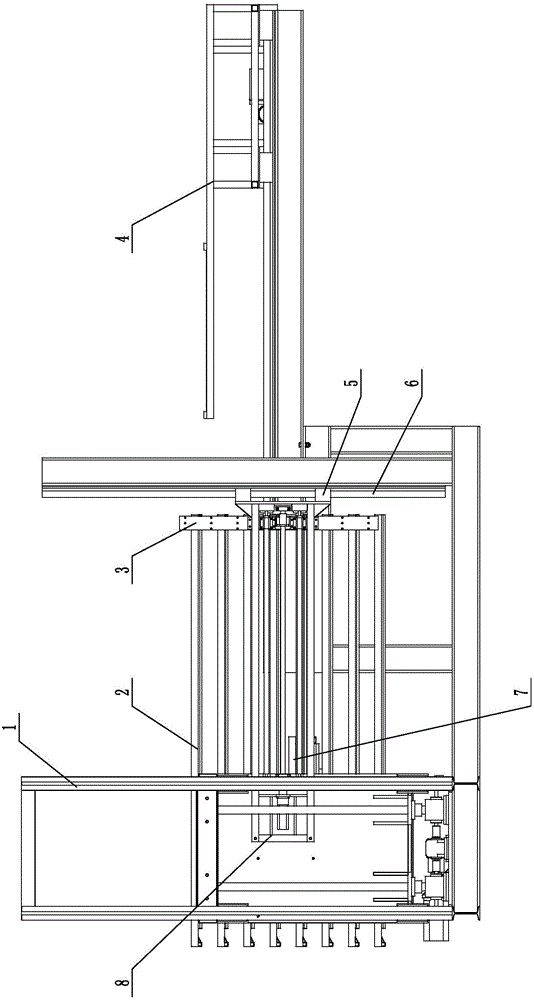

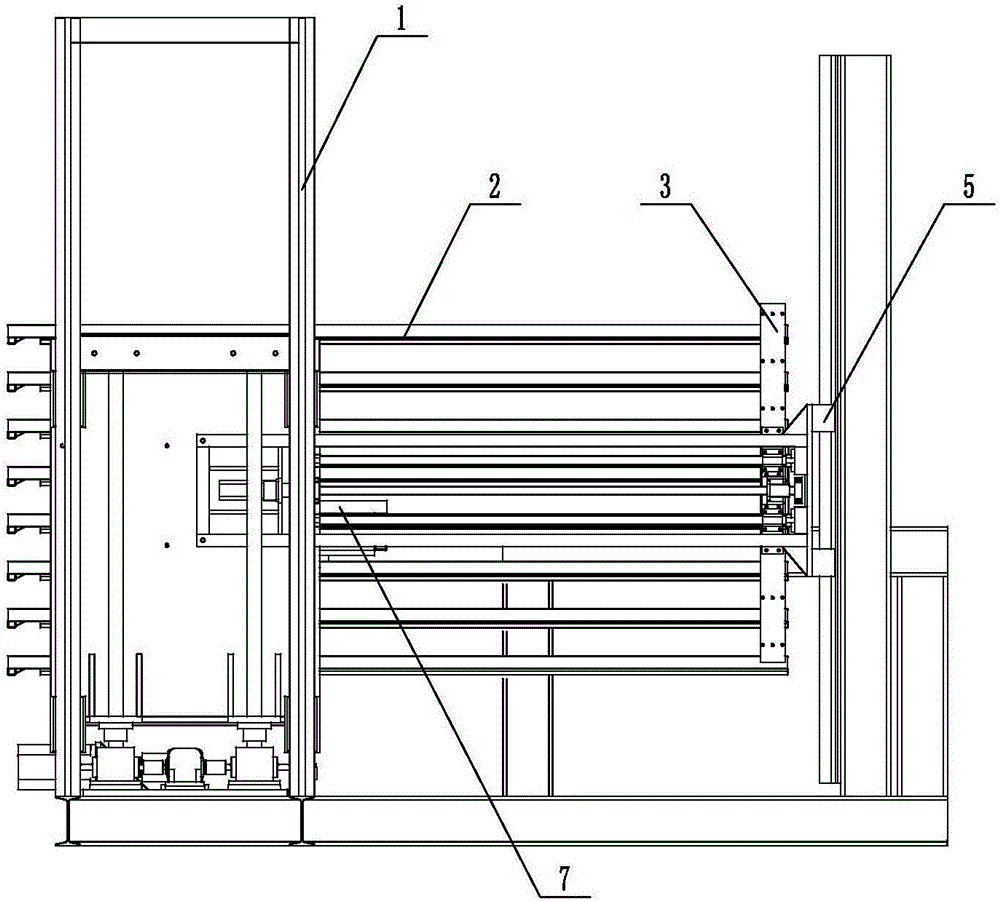

[0055] Such as Figure 1-8 , Shown in 12-20, a kind of automatic feeding and unloading equipment of veneer heat press, it comprises wooden board loading and unloading lifting assembly and conveying mechanism 4, wooden loading and unloading lifting assembly includes lifting mechanism 1, top Lifting mechanism 7, pushing mechanism 8 and 8 supporting mechanisms 2; Lifting mechanism 1 comprises lifting mechanism base 101, and the front end of lifting mechanism base 101 is respectively provided with a lifting mechanism support 105, and lifting mechanism support 105 is provided with lifting parts 106, The front end of the lifting mechanism base 101 is also provided with a lifting component driver 102, the lifting component driving component 102 is connected with the lifting component 106, and the lifting component driving component 102 drives the lifting component 106 to move up and down; The limit column 104 is provided with a vertical linear guide rail IV6 adjacent to the limit col...

Embodiment 2

[0057] Such as Figure 1-8 , 12-20, on the basis of Embodiment 1, sliders III 406 are provided on the left and right sides below the rear part of the material placement bracket 401 of the conveying mechanism 4, and the sliders III 406 are movably connected with the linear guide rail III 403, and the linear guide rail III 403 is located on On the conveying mechanism base 407, the middle part of the conveying mechanism base 407 is provided with a conveying mechanism rack 402, and the conveying mechanism driving part 405 is rollingly connected with the conveying mechanism rack 402; the front ends of the four material placement plates 4011 are respectively provided with barriers to prevent materials from slipping out. Section 404.

[0058] The driving part 405 of the conveying mechanism includes a stepping motor 4052 and a stepping motor gear 4051 , the power output of the stepping motor 4052 is to the stepping motor gear 4051 , and the stepping motor gear 4051 is rollingly connec...

Embodiment 3

[0060] Such as Figure 1-8 , 12-21, on the basis of Embodiment 1, the jacking mechanism 7 also includes a linear guideway V704, a linear bearing 708, a linear guideway V connecting rod 709 and a jacking mechanism rack 705, a linear guideway V704 and a linear bearing 708 Flexible connection, the linear bearing 708 is located on the support pad 707, one end of the linear guide V 704 is connected with the lifting platform 702, and the other end passes through the support pad 707 to connect with the linear guide V connecting rod 709; the jacking mechanism rack 705 is located on In the jacking mechanism frame 706 , one end passes through the support pad 707 and is connected to the lifting platform 702 , and the other end is connected to the bottom plate of the jacking mechanism frame 706 , and the lifting platform driver 703 is rollingly connected to the jacking mechanism rack 705 . Lifting table driver 703 includes servo motor gear 7031, reducer 7032 and jacking mechanism servo mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com