External rotor type dynamo of washing machine

An external rotor and washing machine technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/pattern/structure, etc., can solve the problems of decreased qualified product rate, increased operation procedures, complicated structure, etc., to simplify the structure and reduce the manufacturing cost. , The effect of reducing the rate of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

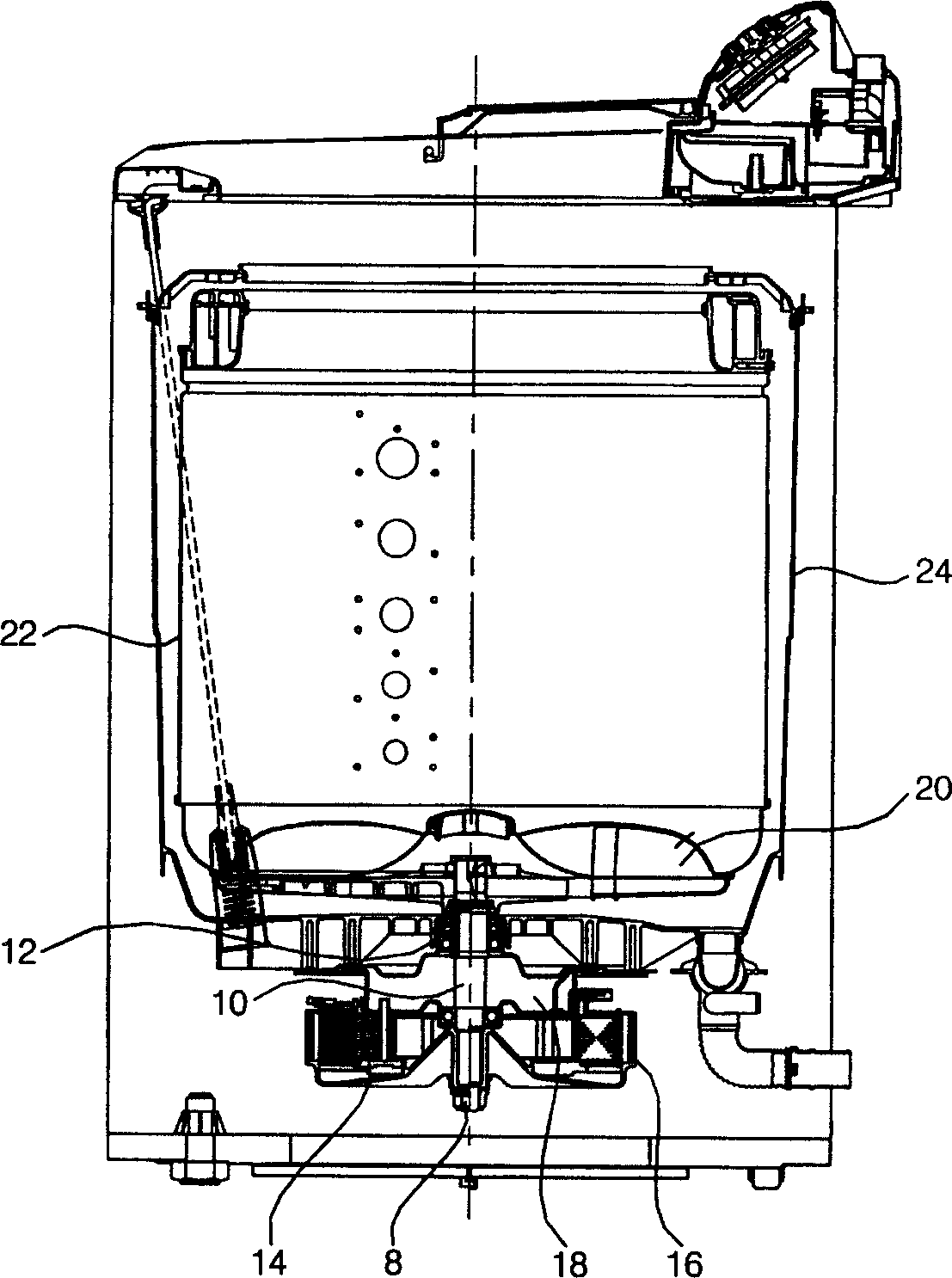

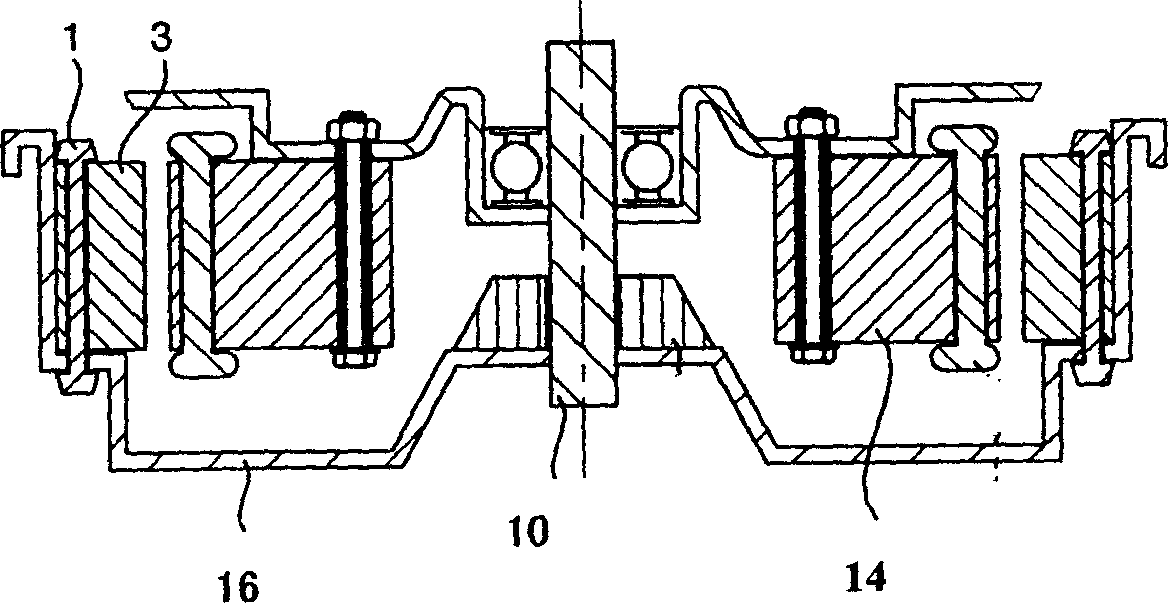

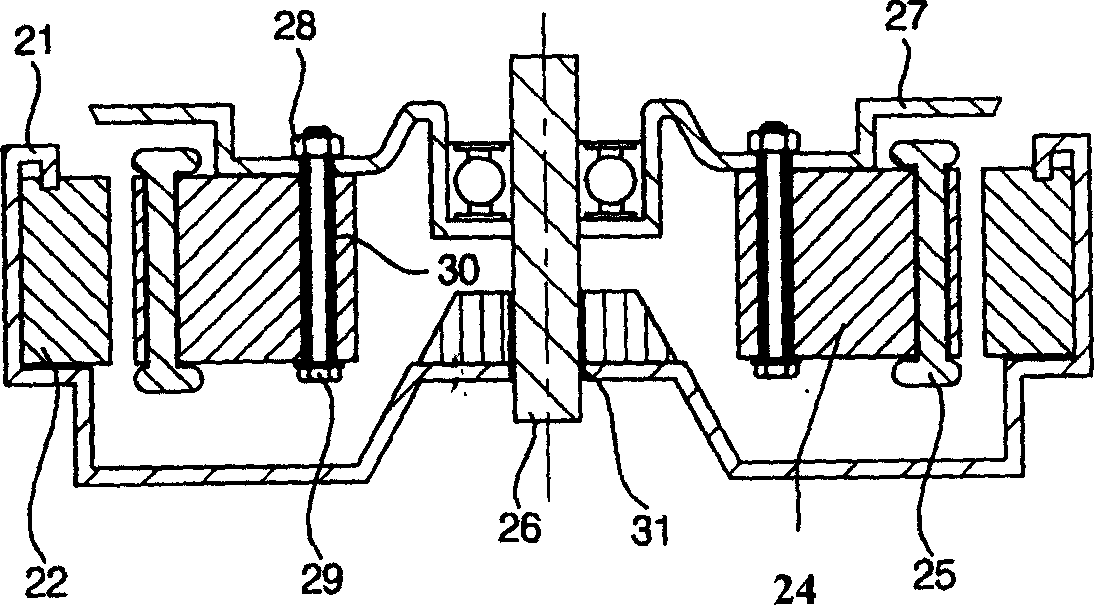

[0010] Such as image 3 As shown, the outer rotor type motor of the washing machine provided by the present invention includes: a rotating frame 21 connected to the drive shaft 26 at the center; a stator 24 located inside the rotating frame 21 and fixedly arranged on the lower side of the motor cover 27; and The rotor 22 is located on the inner side of the rotating frame 21, is arranged radially opposite to the stator 24, and is made of permanent magnets. Corresponding connecting holes 30 are respectively formed on the stator 24 and the motor cover 27 , and one end of the screw 28 is fastened with a nut 29 after passing through the connecting holes 30 , so that the stator 24 can be fixed on the lower side of the motor cover 27 . In addition, in order to fix the rotor 22 on the inner peripheral surface of the rotating frame 21, the upper end of the rotating frame 21 is inwardly The shape is bent to press the upper end of the rotor 22. A coil 25 is wound on the outer peripher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com