Rapid evaluation method for stress corrosion sensitivity of low-alloy structural steel in atmospheric environment

A stress corrosion and atmospheric environment technology, applied in the direction of weather resistance/light resistance/corrosion resistance, strength characteristics, using repetitive force/pulse force to test the strength of materials, etc. The effect of improving corrosion resistance, reducing defective product rate and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

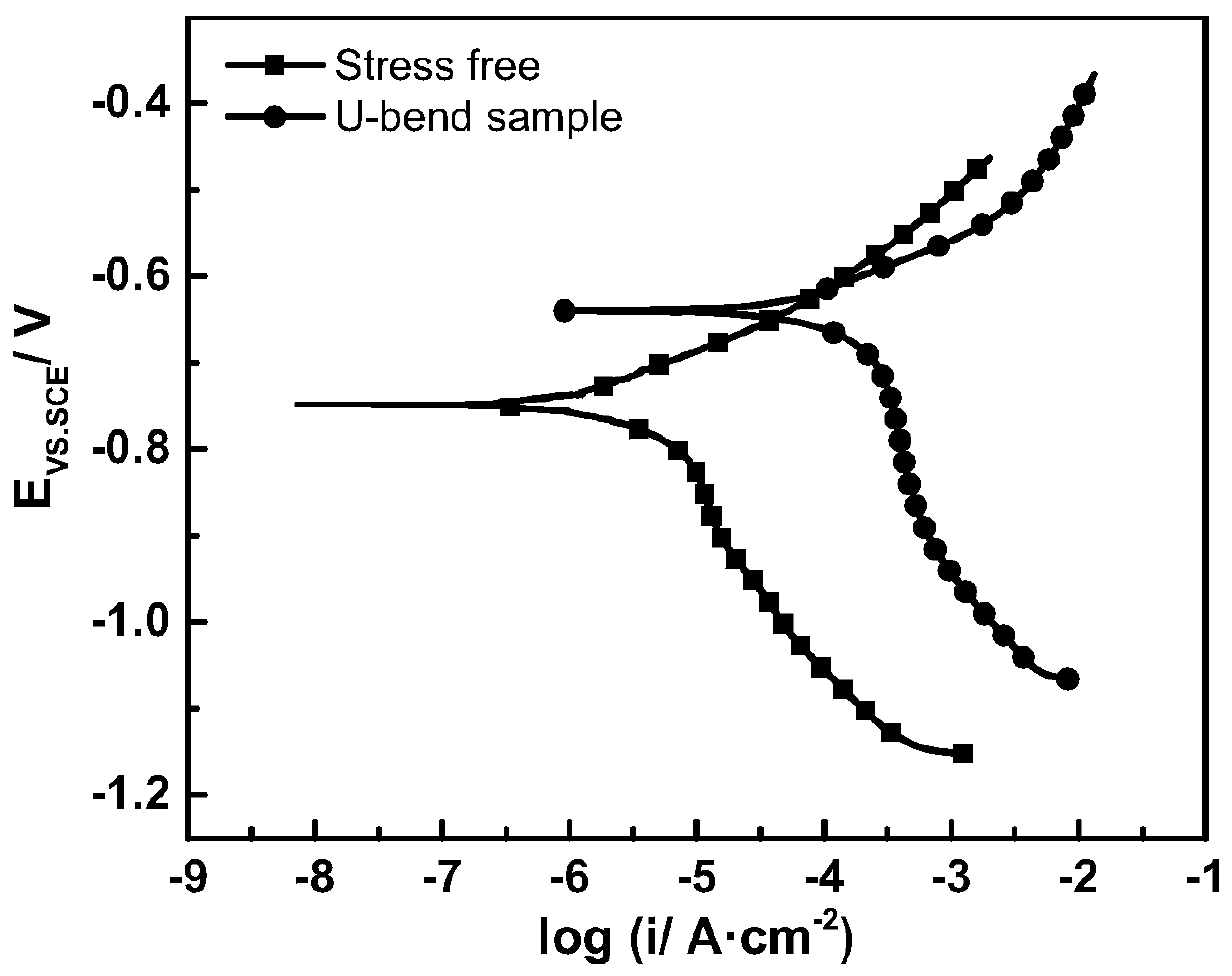

[0026] The sample undergoes plastic deformation under constant stress, and is prone to stress corrosion cracking under the promotion of anodic dissolution. Therefore, the U-bend sample is selected for stress loading to test its stress corrosion sensitivity in the Xisha marine atmospheric environment. Using 5% NaCl+0.05% CaCl 2 +0.05%Na 2 SO 4 After mixing, a solution adjusted to pH 4 with dilute hydrochloric acid was used as the accelerating medium. Taking the atmospheric corrosion environment spectrum (Table 2) of Xisha Test Station as a reference, the indoor environment spectrum is designed by using the equivalent calculation method.

[0027] Table 2 Ocean Atmospheric Environmental Spectrum of Xisha

[0028]

[0029] Equivalent conversion between Xisha atmospheric environment spectrum and standard humid air: 1) Convert the hours of humid air action at each temperature in Xisha atmospheric environment spectrum to the action hours of standard humid air with temperature T...

Embodiment 2

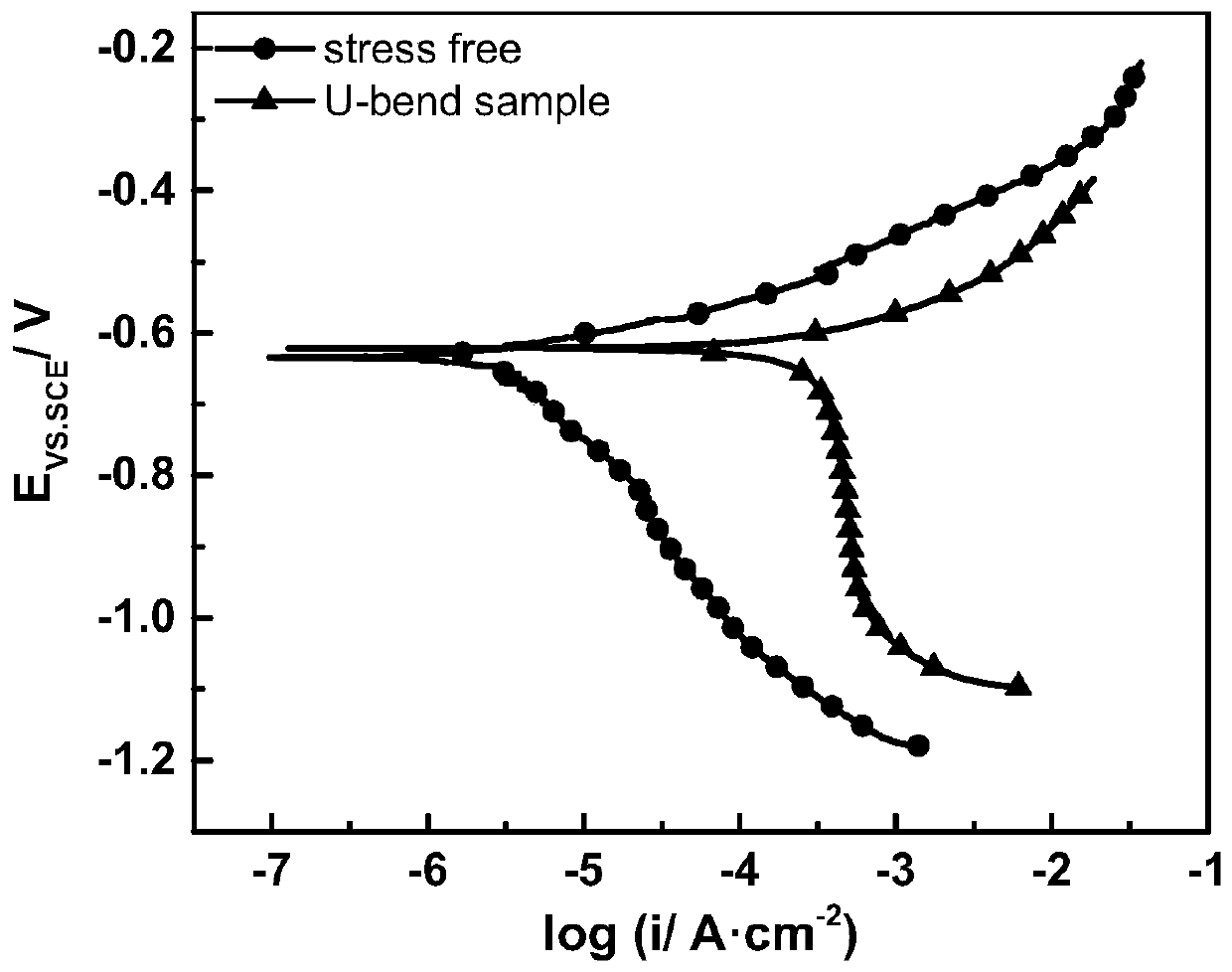

[0035] The sample undergoes plastic deformation under constant stress, and is prone to stress corrosion cracking under the promotion of anodic dissolution. Therefore, the U-bend sample is selected for stress loading to test its stress corrosion sensitivity in simulated seawater (3.5% NaCl solution). 3.5% NaCl solution is used as the simulated solution, and the U-bend sample is selected for the test. Before loading, the outer surface must be polished to 1000 mesh or above with metallographic sandpaper. The surface of the sample is degreased (for example, degreased with absolute ethanol and acetone), rinsed with distilled water, dried, and set aside.

[0036] The potentiodynamic polarization test was carried out in the prepared solution, and the results were as follows image 3 shown

[0037] Calculate R SCC =(I corr -I 0corr ) / I 0corr =(7.47e- 4 -1.05e- 5 ) / 1.05e- 5 =70.14, the stress corrosion sensitivity of low alloy structural steel in this atmospheric environment is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com