Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "Atmospheric exposure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

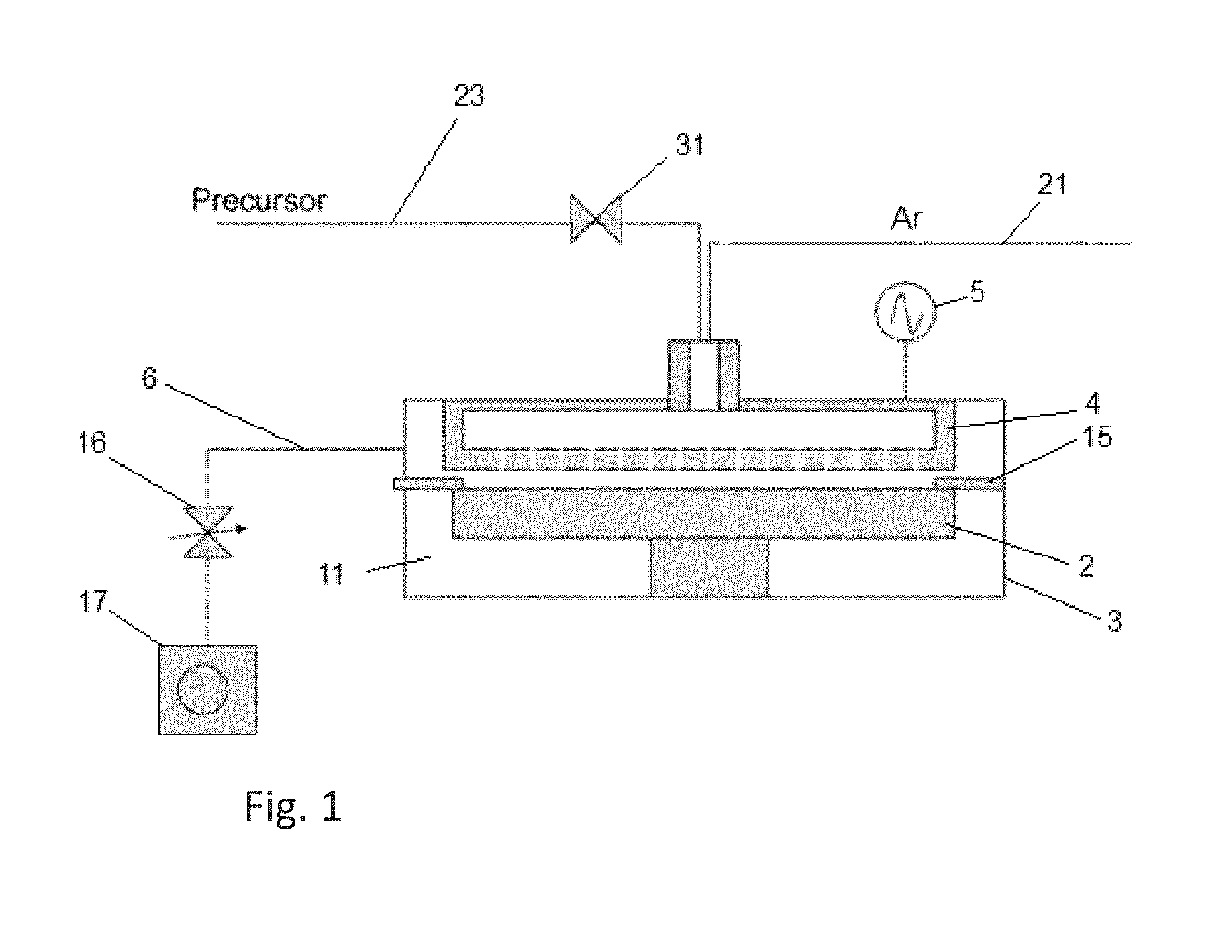

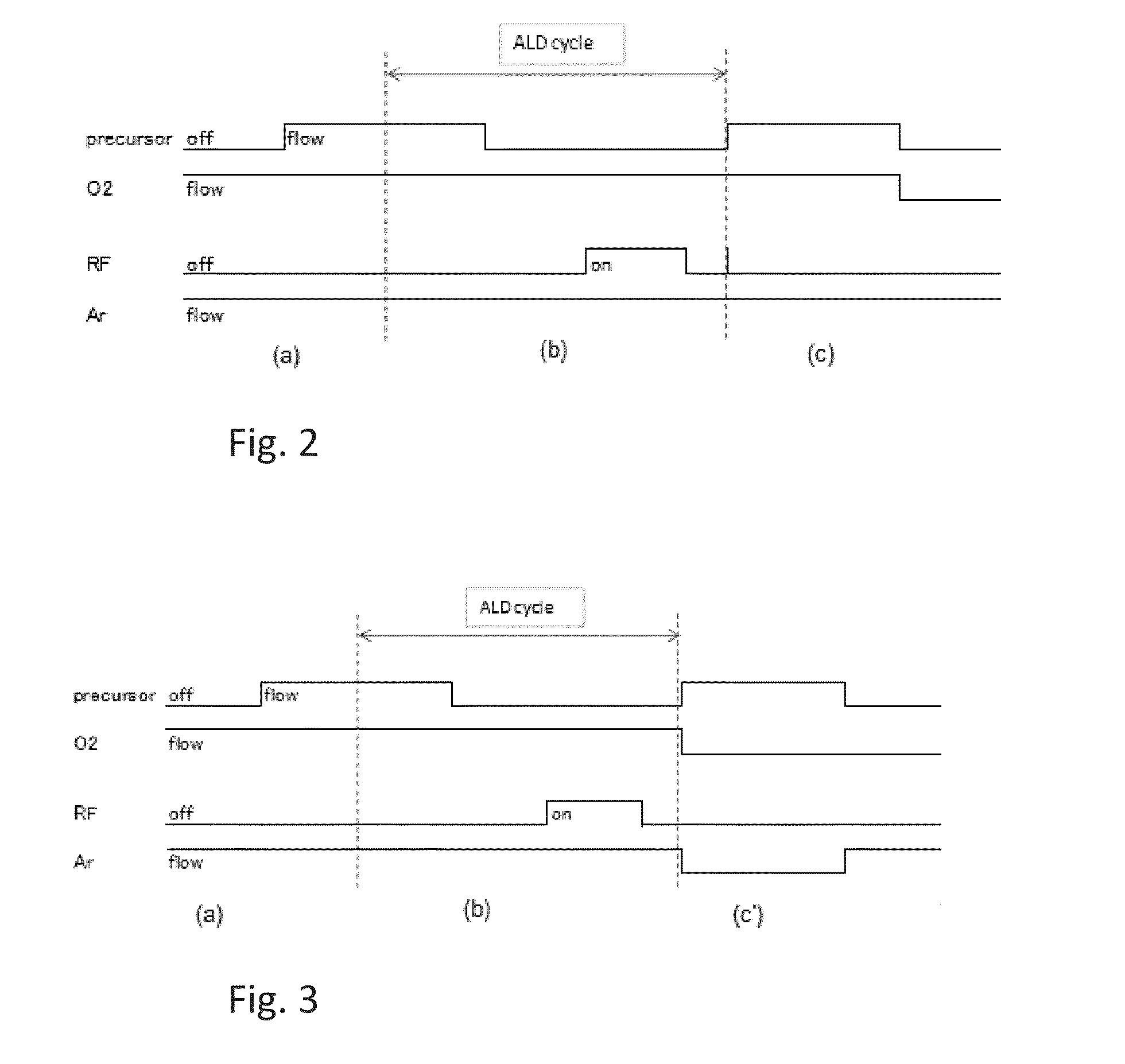

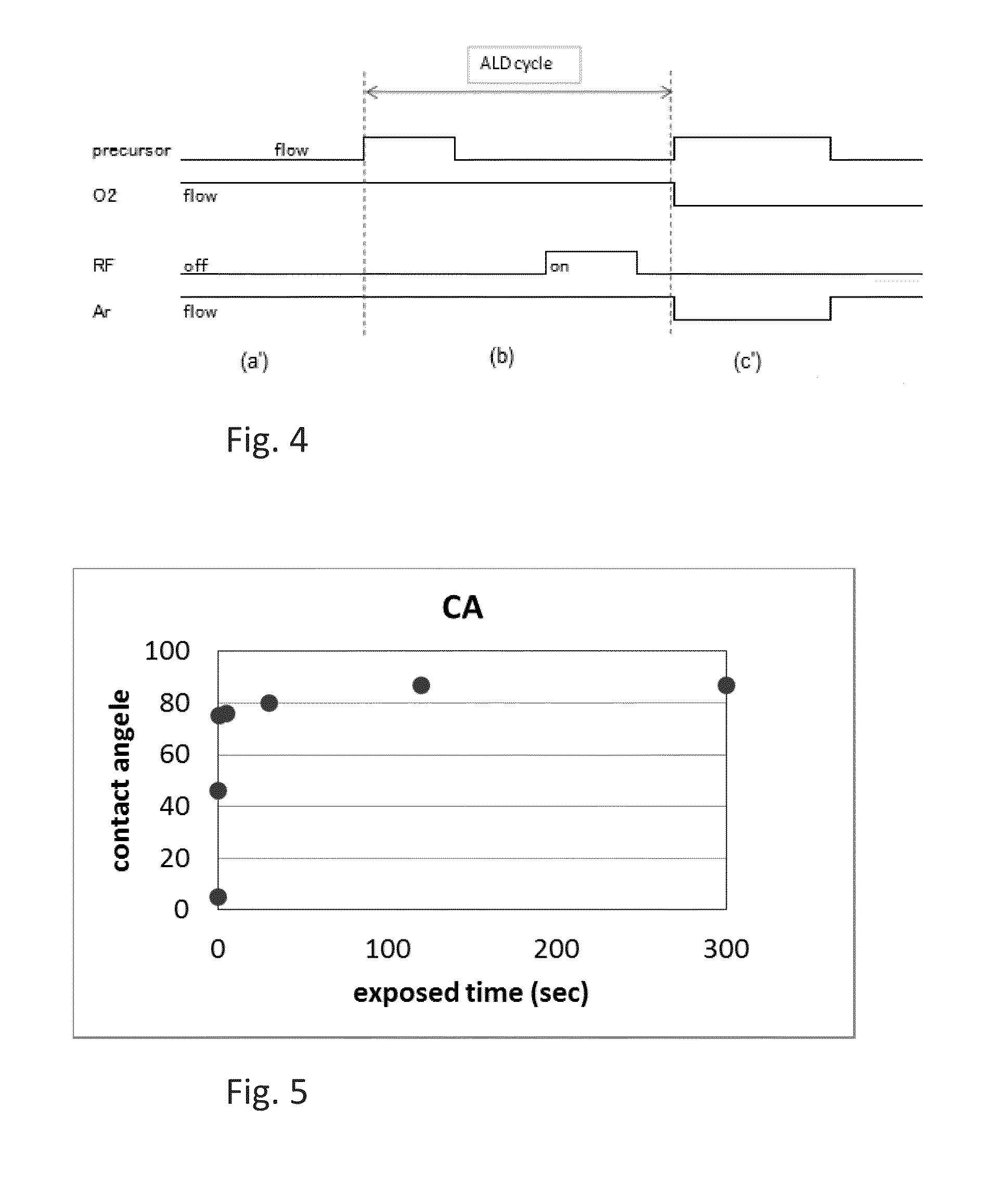

Method for hydrophobization of surface of silicon-containing film by ALD

ActiveUS9478414B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingAtmospheric airChemical adsorption

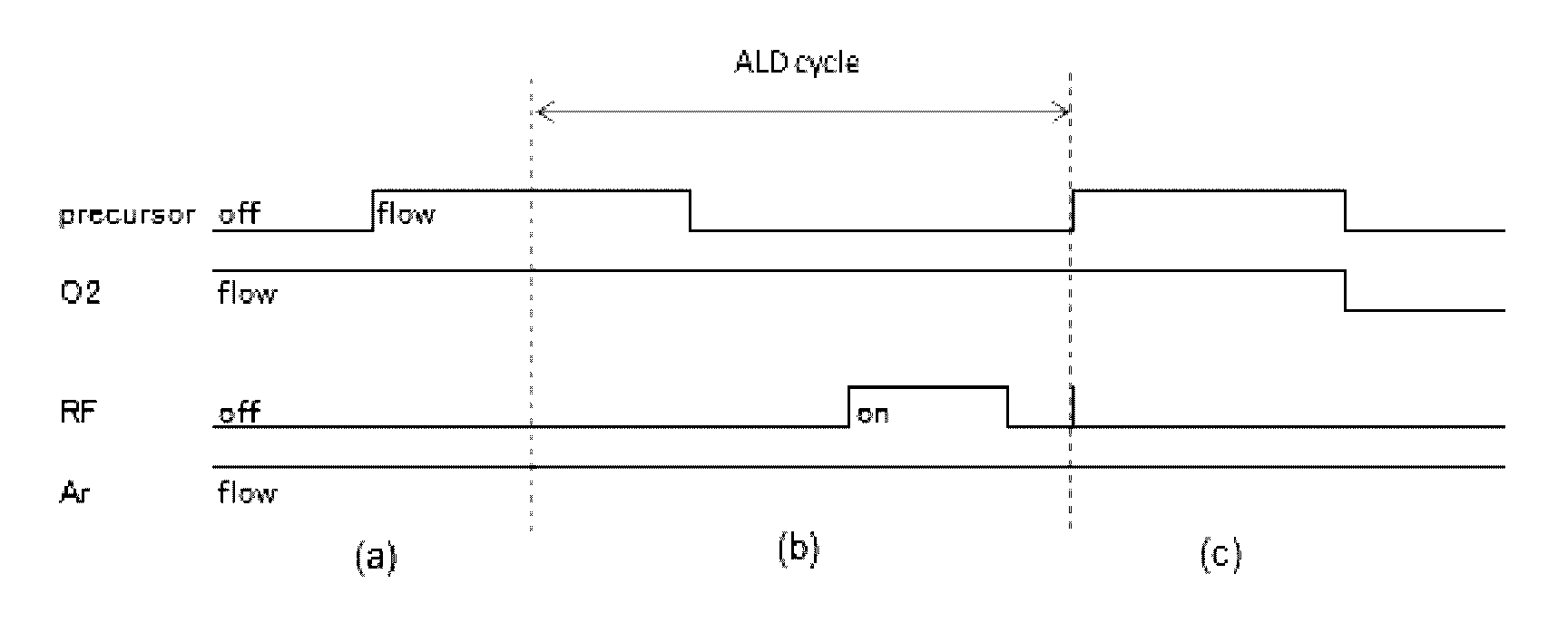

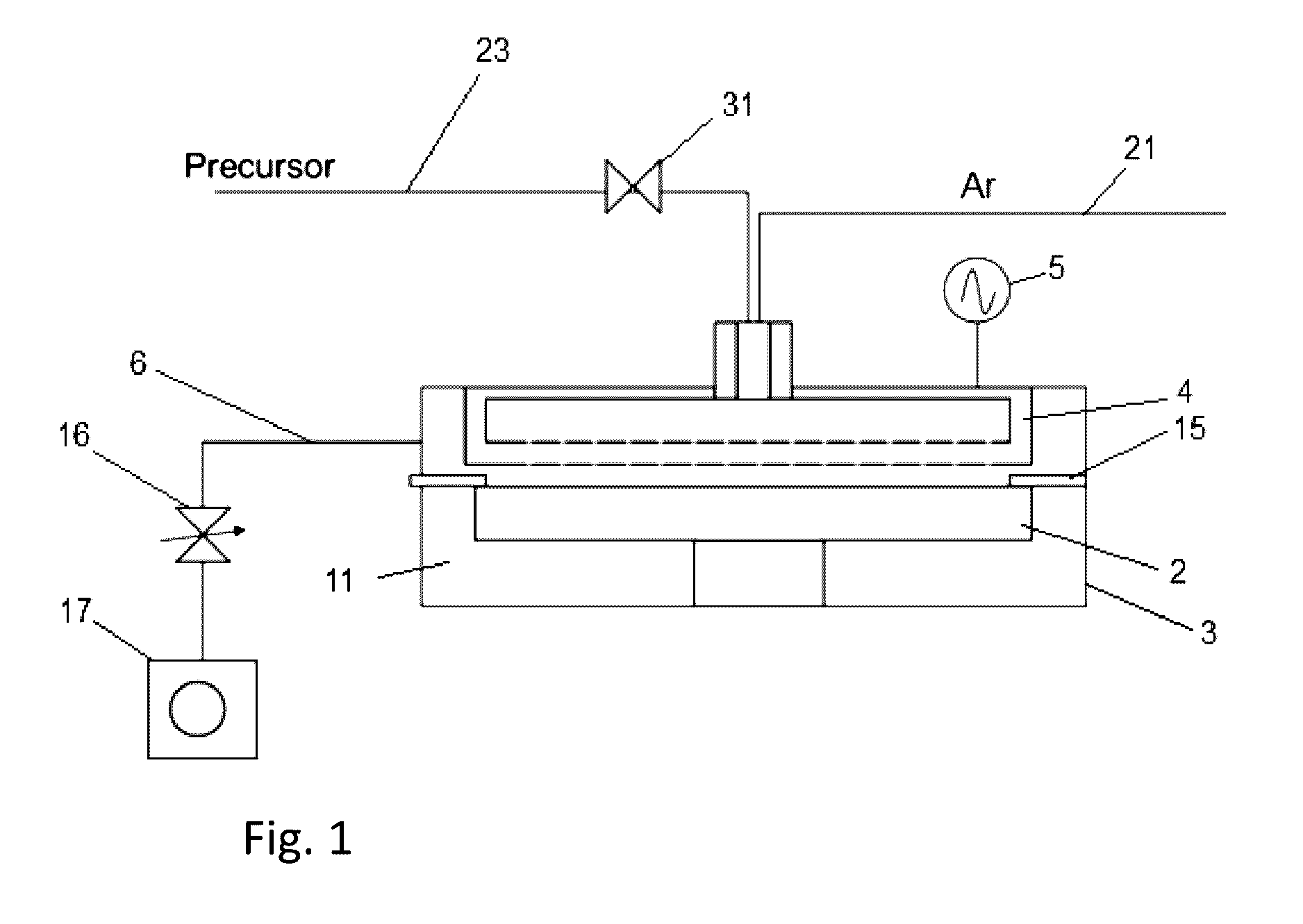

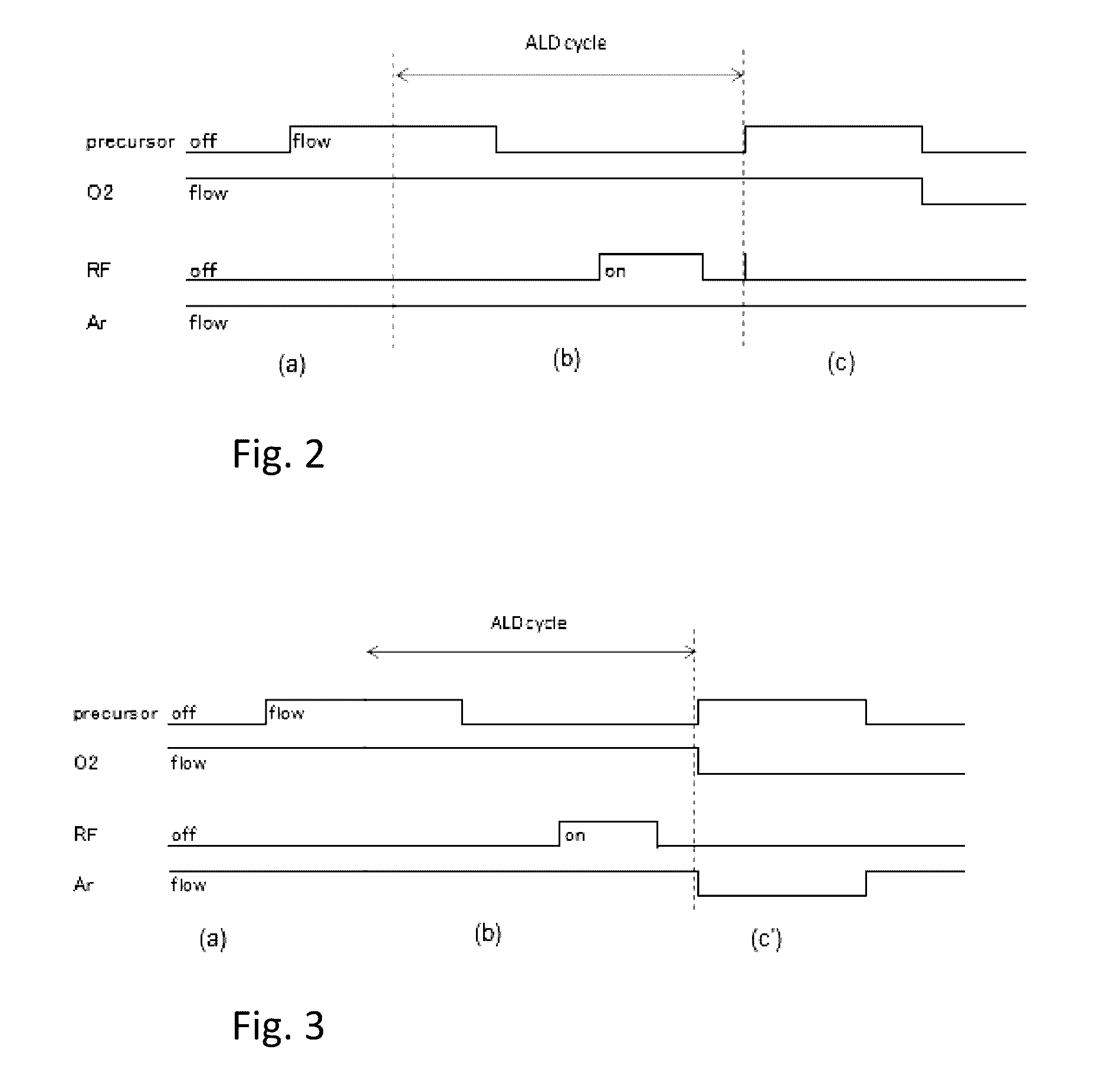

A method is for hydrophobization of a surface of a silicon-containing film by atomic layer deposition (ALD), wherein the surface is subjected to atmospheric exposure. The method includes: (i) providing a substrate with a silicon-containing film formed thereon; and (ii) forming on a surface of the silicon-containing film a hydrophobic atomic layer as a protective layer subjected to atmospheric exposure, by exposing the surface to a silicon-containing treating gas without exciting the gas. The treating gas is capable of being chemisorbed on the surface to form a hydrophobic atomic layer thereon.

Owner:ASM IP HLDG BV

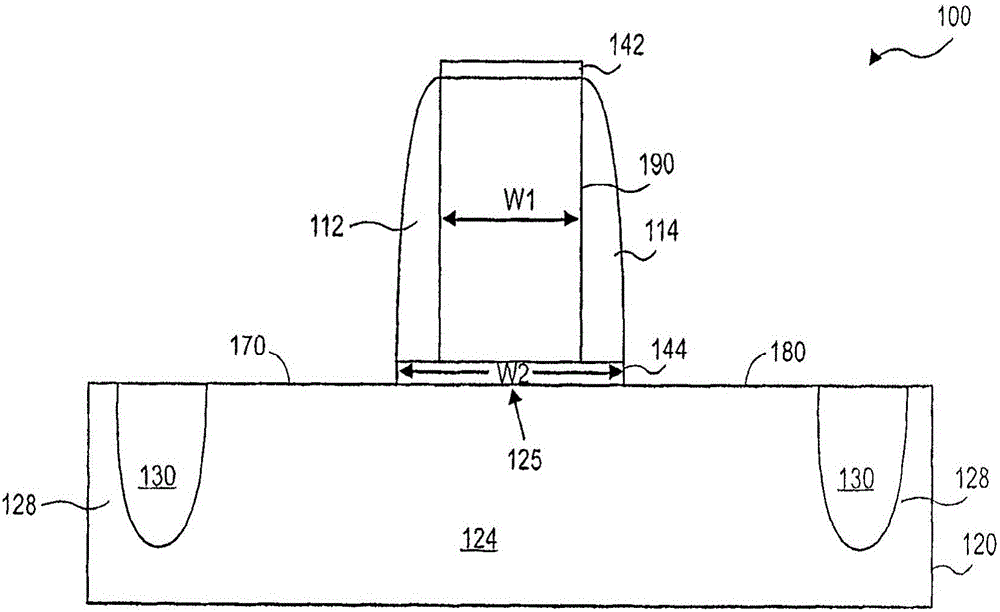

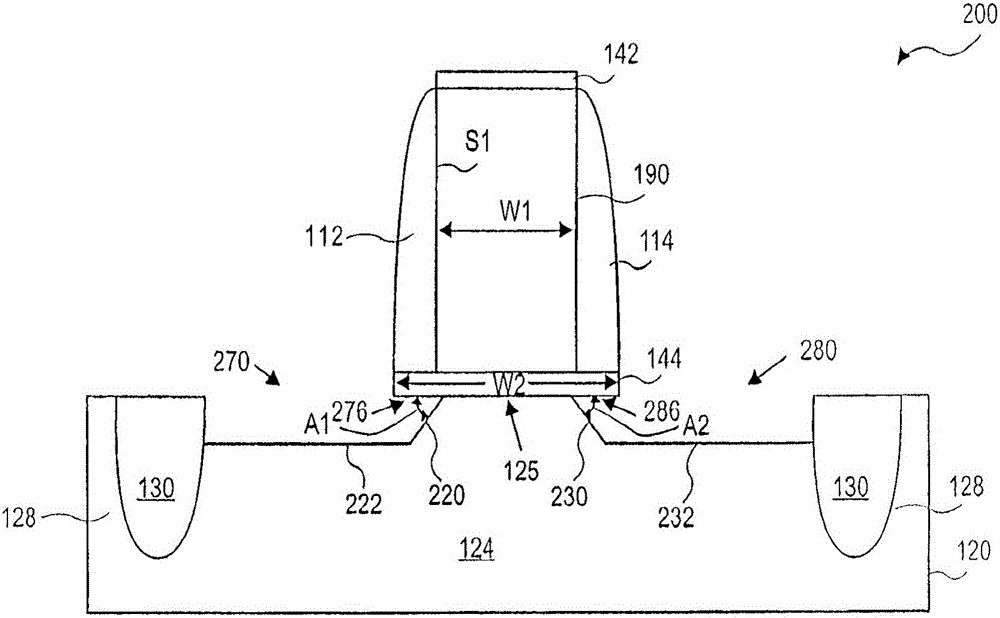

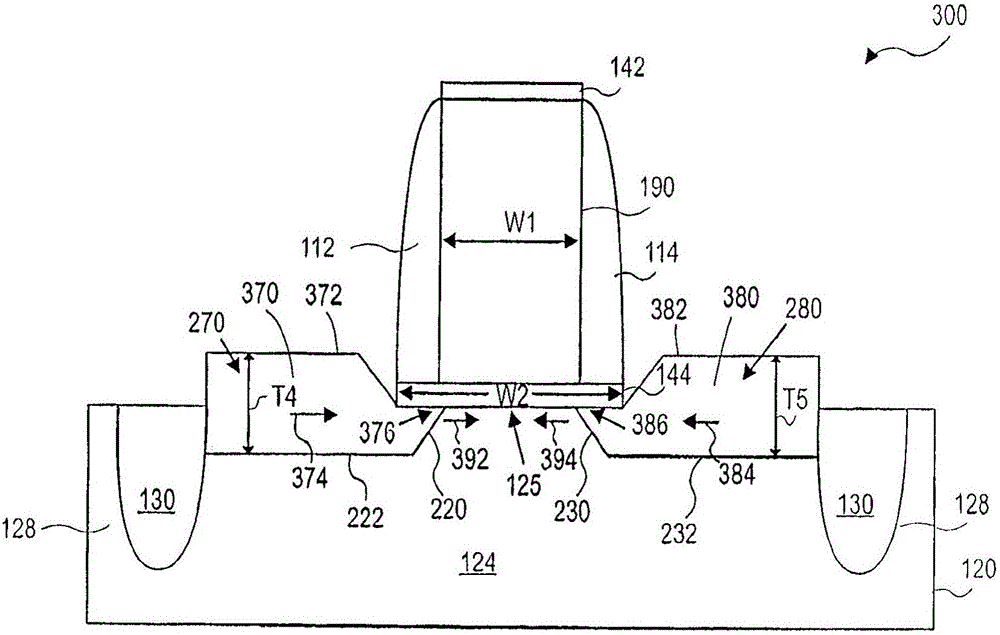

CMOS transistor junction regions formed by a CVD etching and deposition sequence

ActiveUS20070105331A1Semiconductor/solid-state device manufacturingNanotechnologyCMOSDriving current

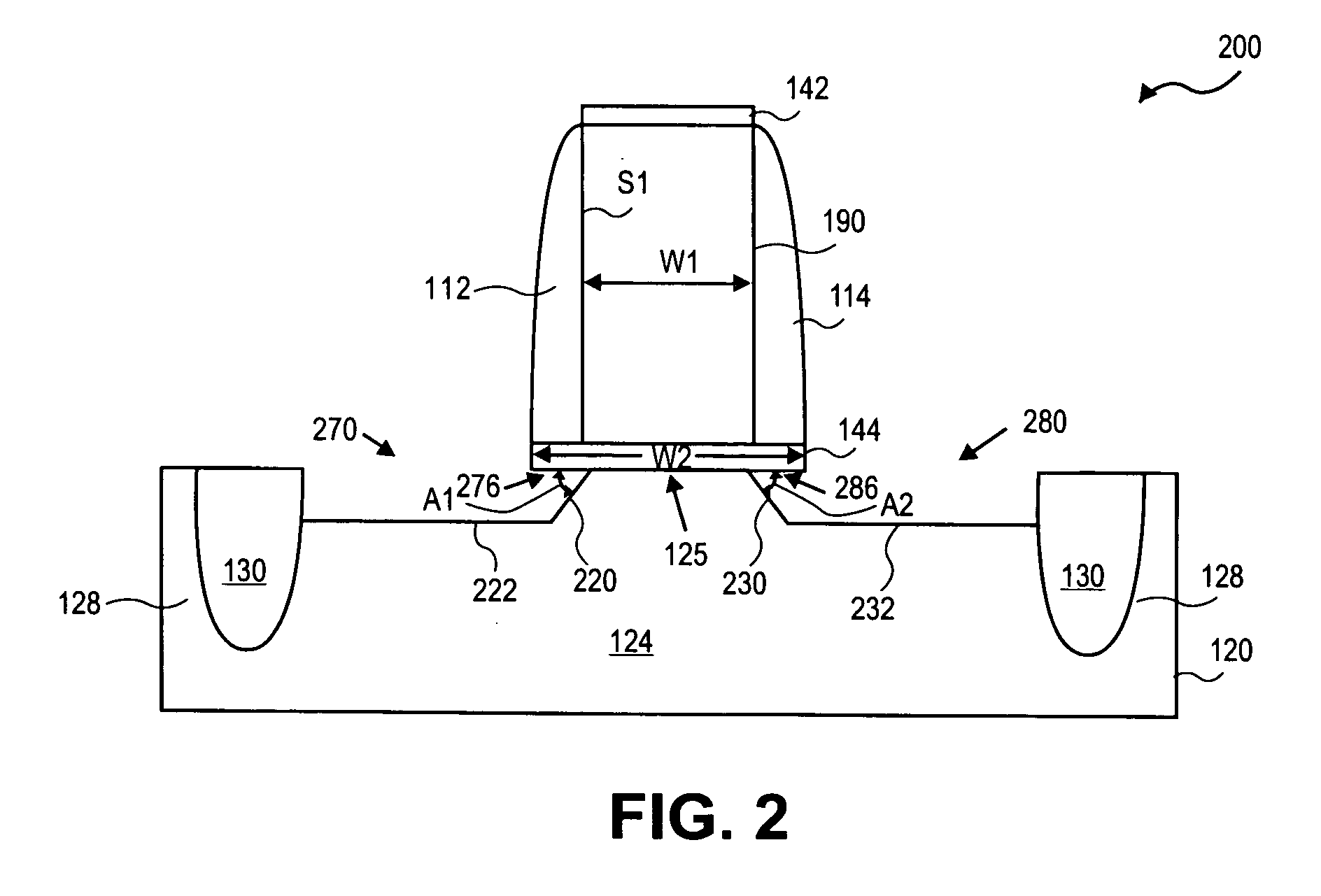

This invention adds to the art of replacement source-drain cMOS transistors. Processes may involve etching a recess in the substrate material using one equipment set, then performing deposition in another. Disclosed is a method to perform the etch and subsequent deposition in the same reactor without atmospheric exposure. In-situ etching of the source-drain recess for replacement source-drain applications provides several advantages over state of the art ex-situ etching. Transistor drive current is improved by: (1) Eliminating contamination of the silicon-epilayer interface when the as-etched surface is exposed to atmosphere and (2) Precise control over the shape of the etch recess. Deposition may be done by a variety of techniques including selective and non-selective methods. In the case of blanket deposition, a measure to avoid amorphous deposition in performance critical regions is also presented.

Owner:DAEDALUS PRIME LLC

Method for Hydrophobization of Surface of Silicon-Containing Film by ALD

ActiveUS20160093485A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon membraneChemical adsorption

A method is for hydrophobization of a surface of a silicon-containing film by atomic layer deposition (ALD), wherein the surface is subjected to atmospheric exposure. The method includes: (i) providing a substrate with a silicon-containing film formed thereon; and (ii) forming on a surface of the silicon-containing film a hydrophobic atomic layer as a protective layer subjected to atmospheric exposure, by exposing the surface to a silicon-containing treating gas without exciting the gas. The treating gas is capable of being chemisorbed on the surface to form a hydrophobic atomic layer thereon.

Owner:ASM IP HLDG BV

Antiperspirant formulations

The invention anhydrous antiperspirant cream composition which comprises:a) a particulate aluminum / zirconium astringent salt in an amount of from 5 to 30% by weight;b) a wax in an amount of from 4 to 20% by weight, said wax comprising an aliphatic ester or monohydric alcohol wax; andc) a water-immiscible carrier having a refractive index that is less than 0.1 below the refractive index of the aluminum / zirconium astringent salt and comprising an aromatic ester having a melting point of below 25° C. and / or a non-volatile silicone oil having a refractive index of at least 1.5 in an amount of from 45 to 80% by weight,has excellent avoidance of visible deposits on topical application, both initially and also after leave-on, i.e. after prolonged atmospheric exposure.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

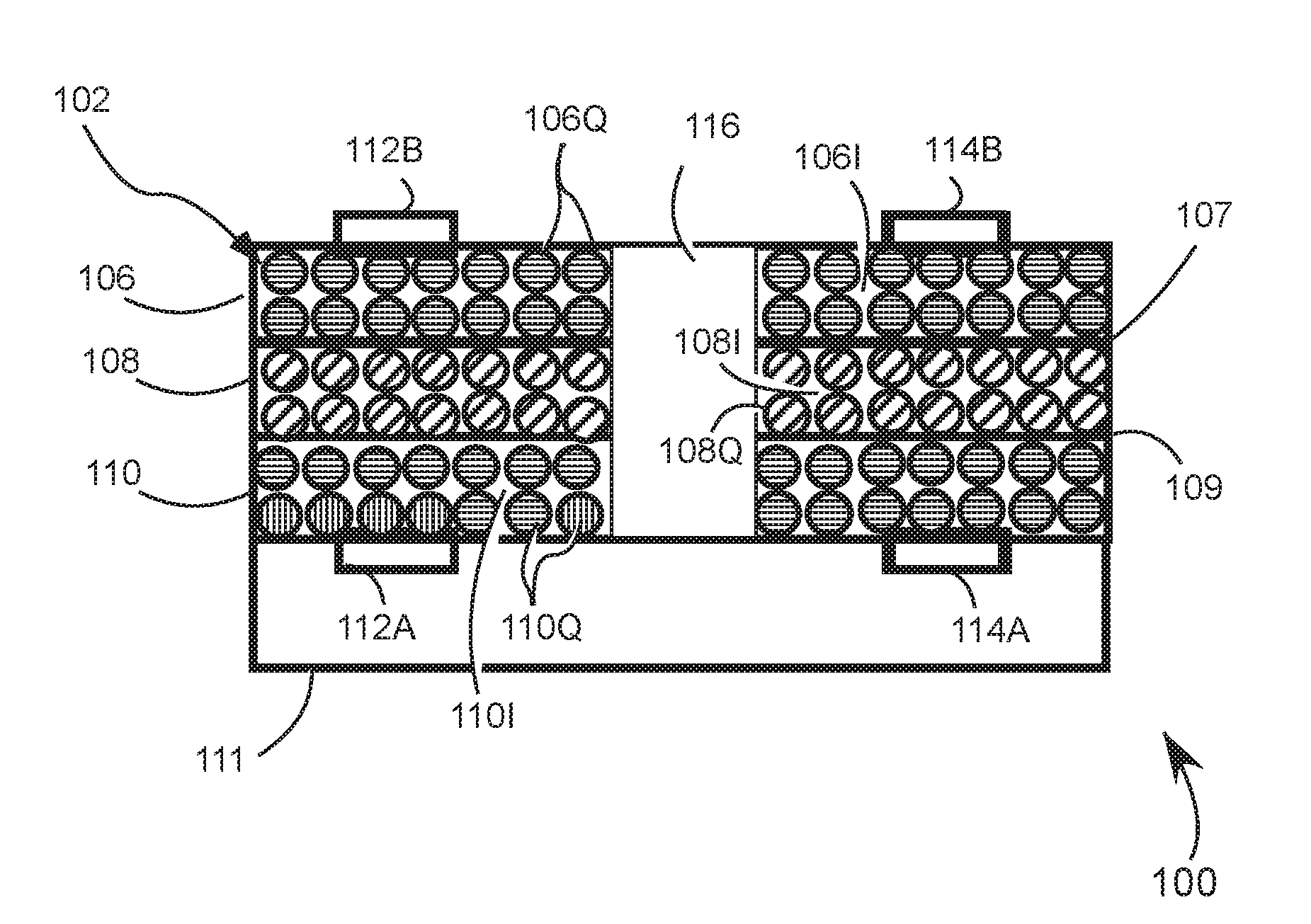

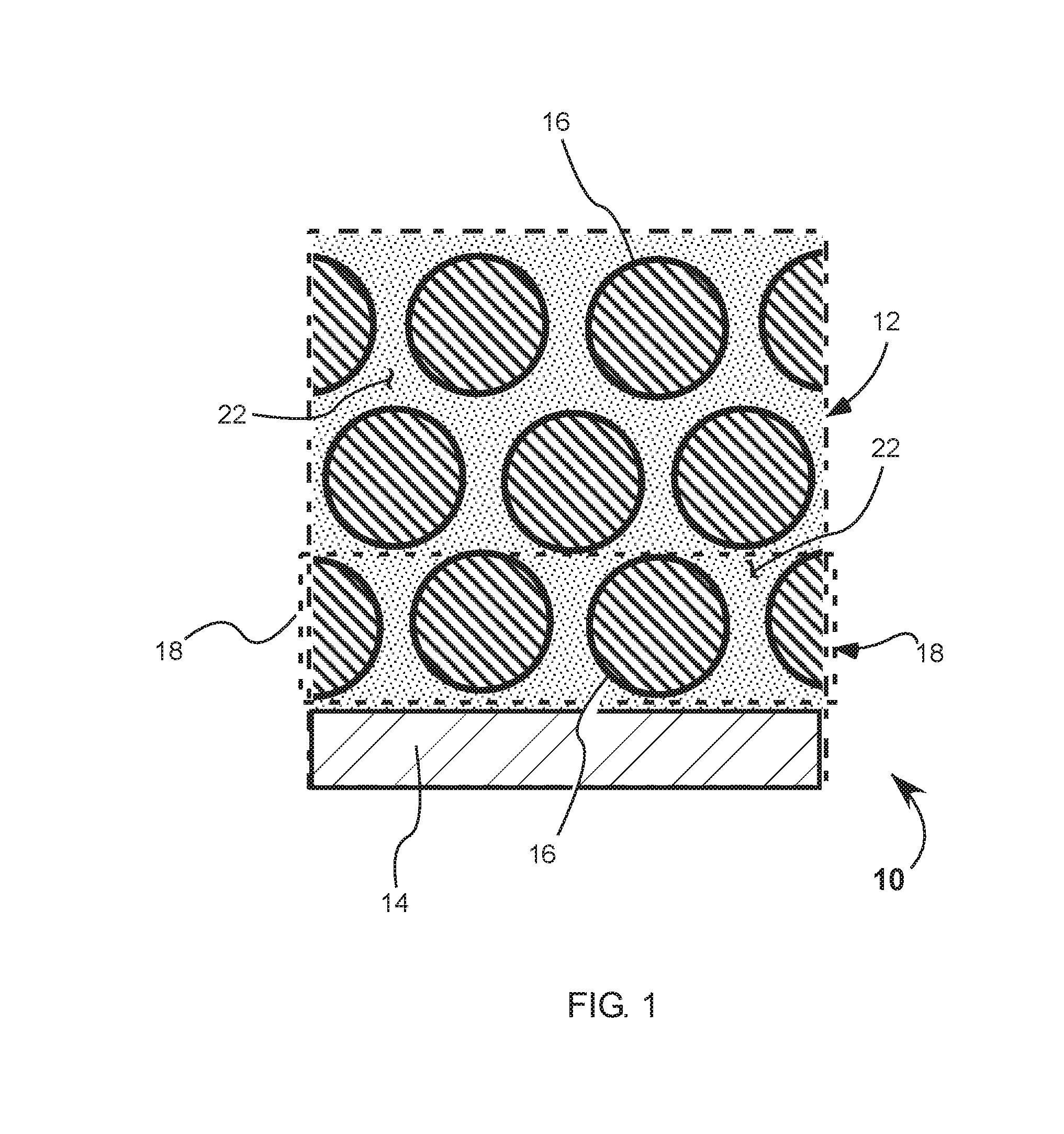

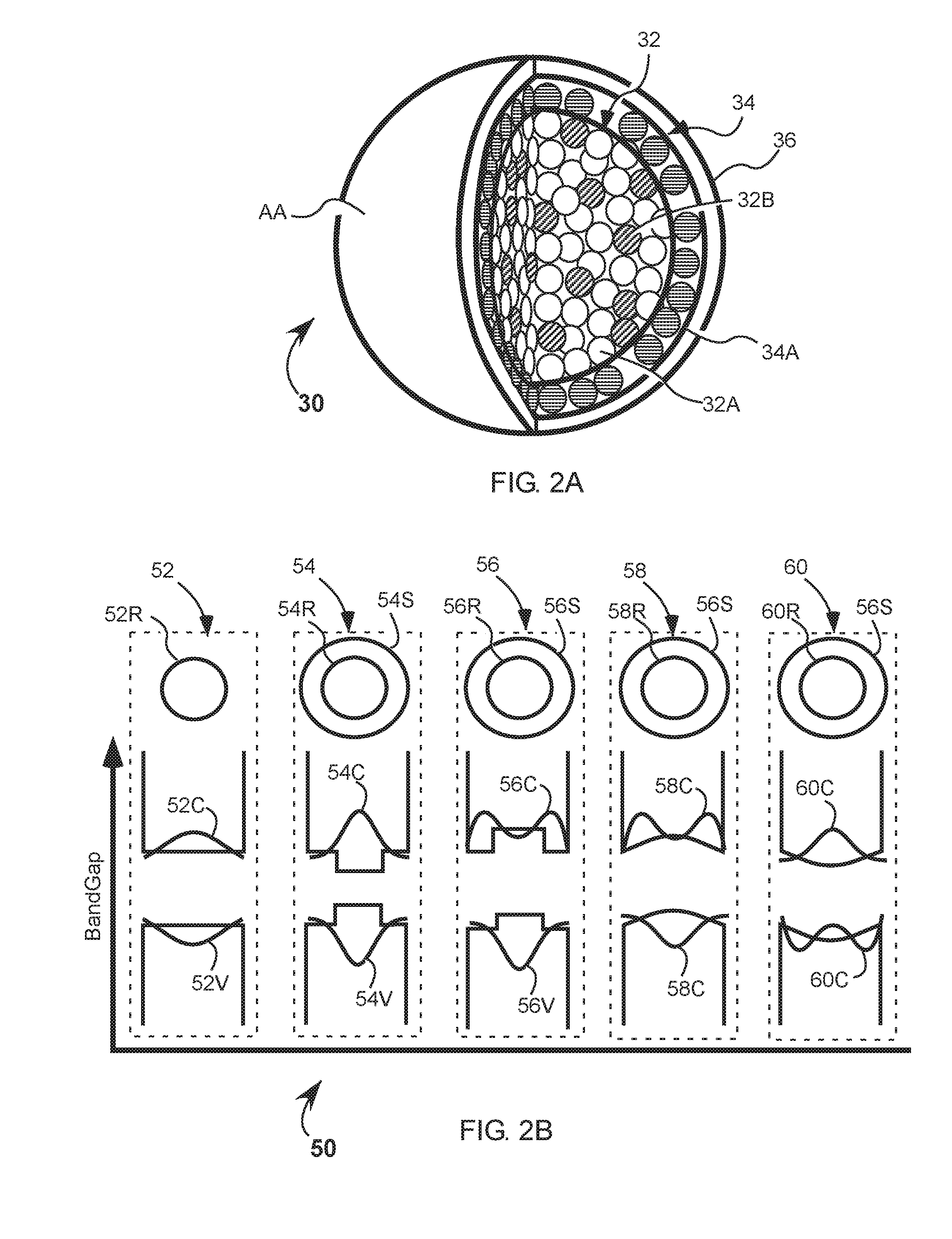

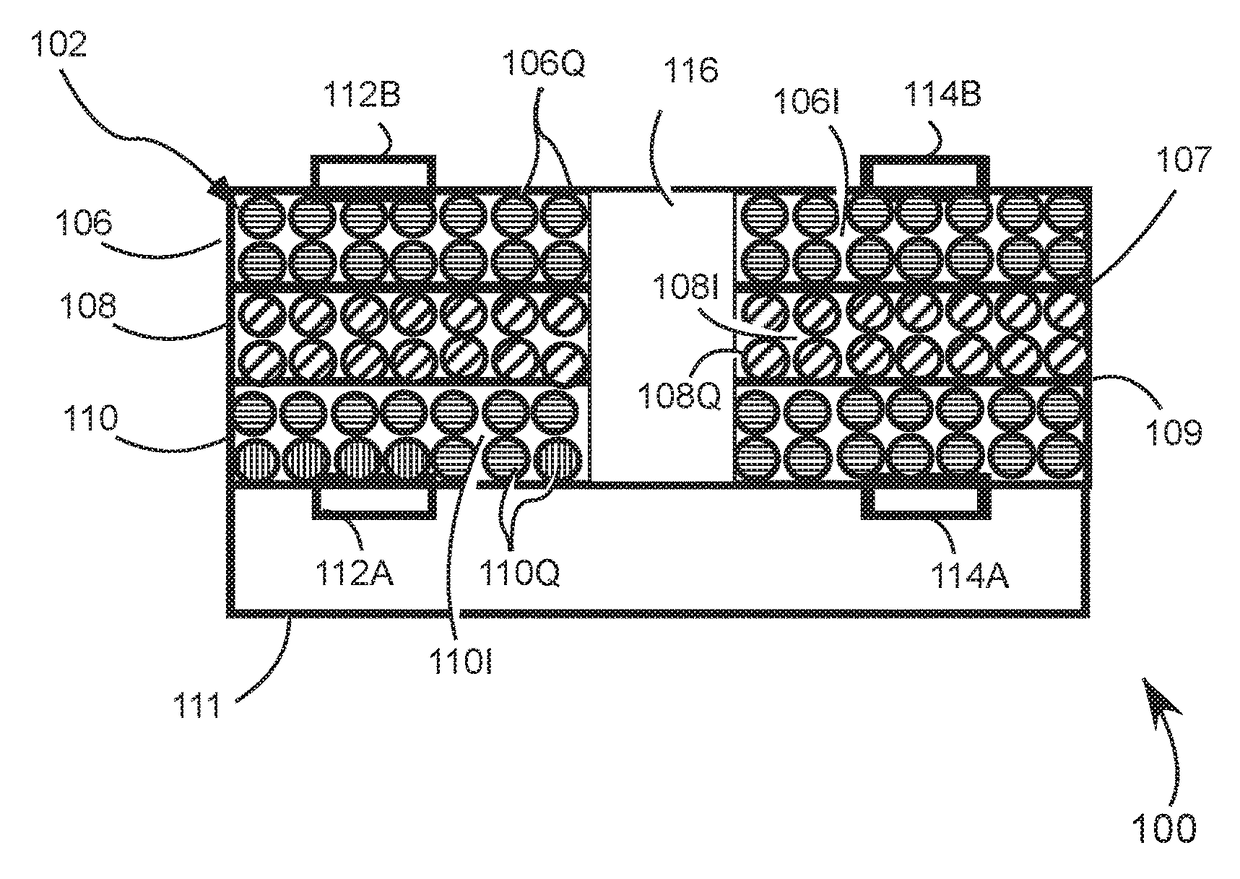

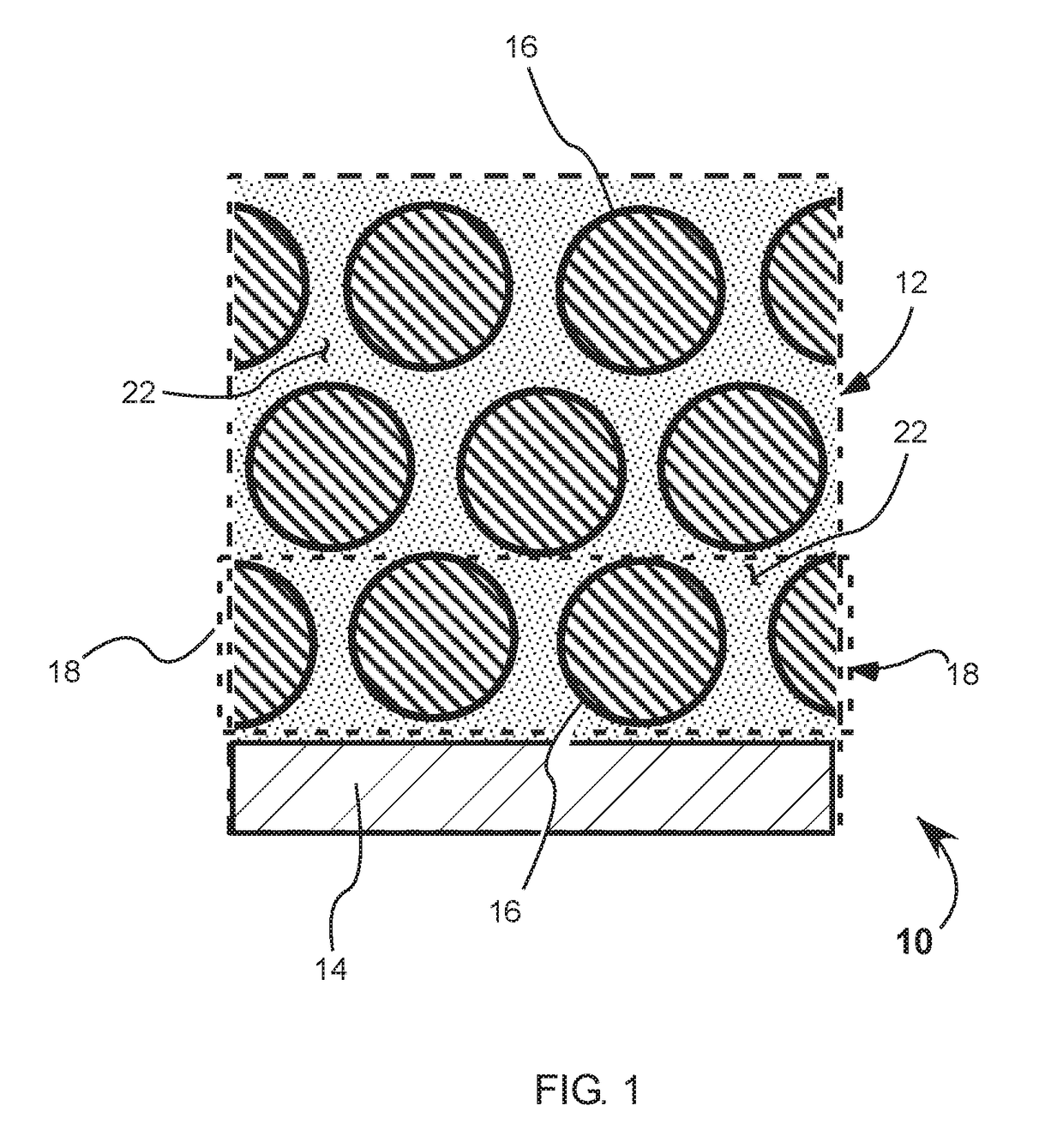

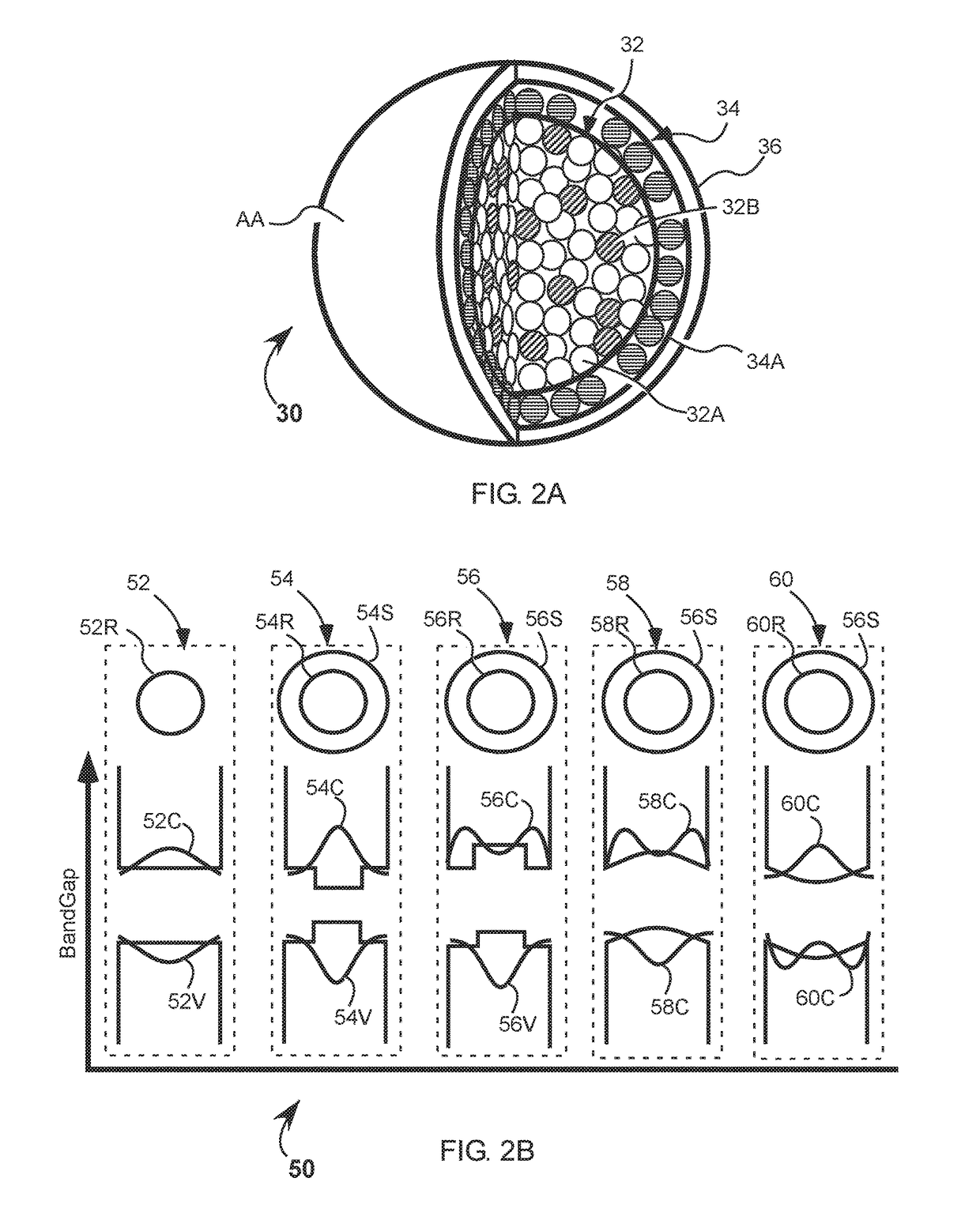

Composite quantum-dot materials for photonic detectors

ActiveUS20170018669A1Reduce probabilityStabilizing electrical property of deviceSolid-state devicesNanoopticsPhotodetectorFilling materials

A composite quantum-dot photodetector comprising a substrate with a colloidally deposited thin film structure forming a photosensitive region, the thin film containing at least one type of a nanocrystal quantum-dot, whereby the nanocrystal quantum dots are spaced by ligands to form a lattice, and the lattice of the quantum dots has an infill material that forms an inorganic matrix that isolates the nanocrystal quantum dots from atmospheric exposure.

Owner:LADARSYST INC

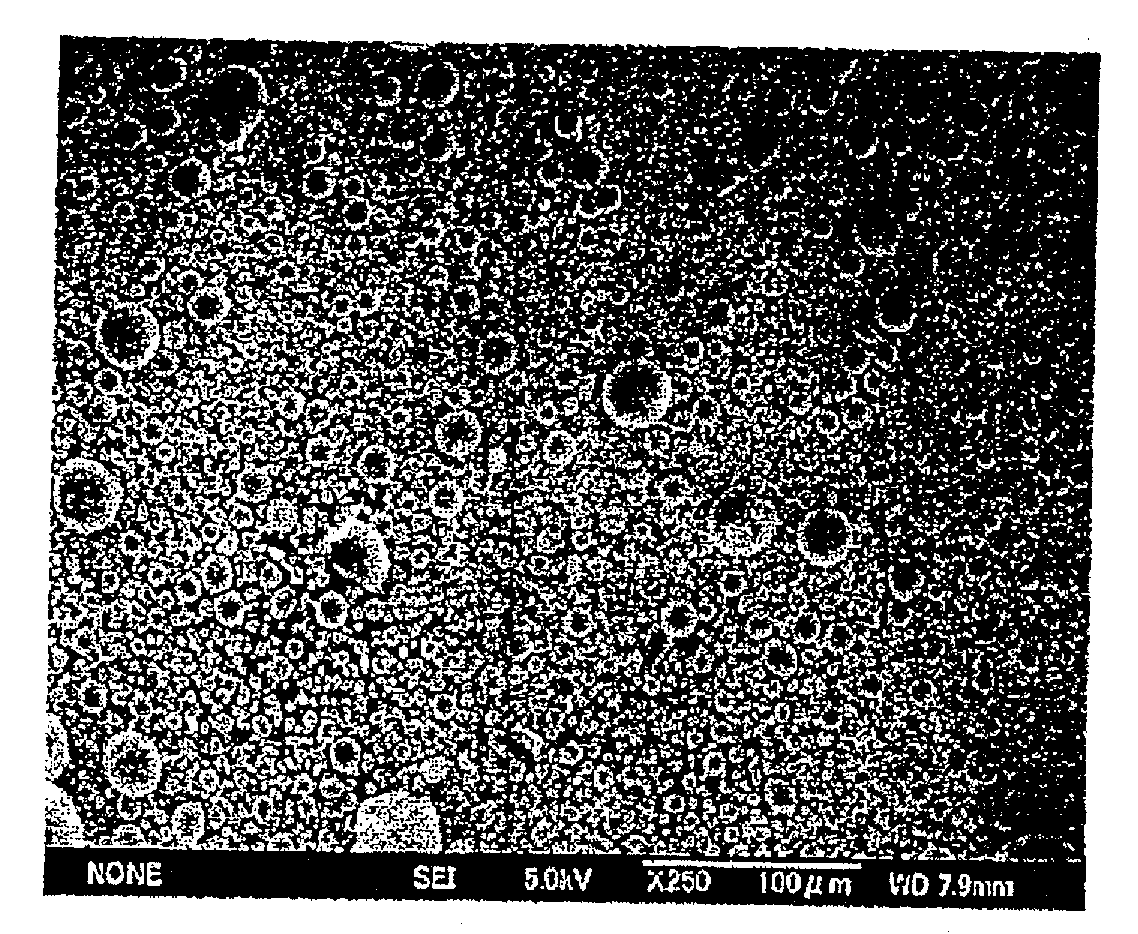

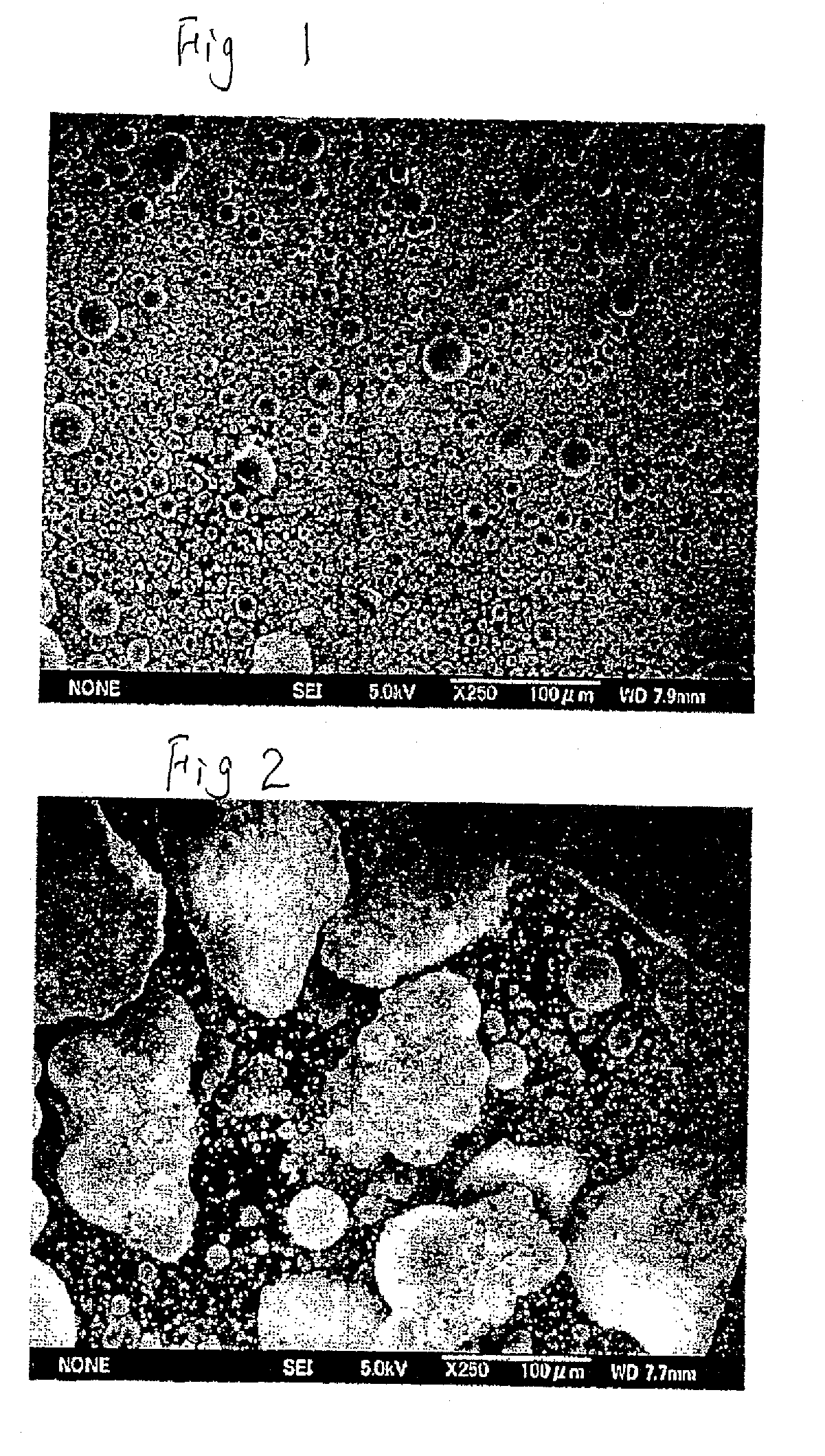

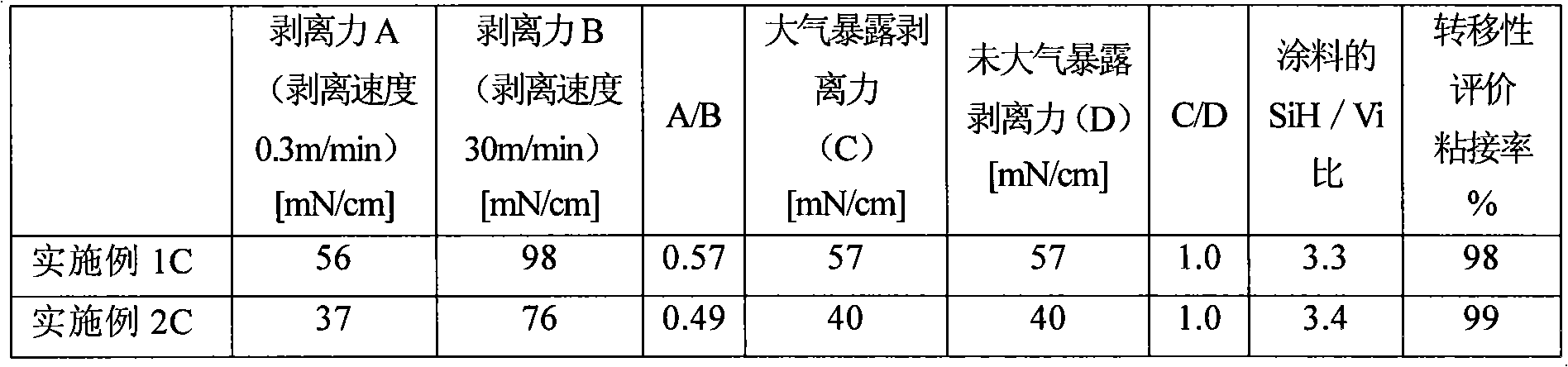

Sb-Te Alloy Powder for Sintering, Sintered Compact Sputtering Target Obtained by Sintering said Powder, and Manufacturing Method of Sb-Te Alloy Powder for Sintering

ActiveUS20090071821A1Good effectInhibit the generation of cracksCellsVacuum evaporation coatingSputteringSurface roughness

Provided is Sb—Te alloy powder for sintering in which the maximum grain size of the powder obtained by subjecting gas atomized powder of an Sb—Te alloy to mechanical pulverization is 90μm or less, and a sintered compact sputtering target obtained by sintering this powder. Further provided is a manufacturing method of Sb—Te alloy powder for a sintered compact sputtering target including the steps of dissolving an Sb—Te alloy, thereafter subjecting this to gas atomization to obtain atomized powder, and further subjecting this to mechanical pulverization in an inert atmosphere without any atmospheric exposure so as to manufacture powder having a maximum grain size of 90 μm or less and reduced oxygen content. Thus, the Sb—Te alloy sputtering target structure can be uniformalized and refined, generation of cracks in the sintered target can be inhibited, and generation of arcing during sputtering can be inhibited. Further, surface ruggedness caused by sputter erosion can be reduced in order to obtain a high quality Sb—Te alloy sputtering target.

Owner:JX NIPPON MINING& METALS CORP

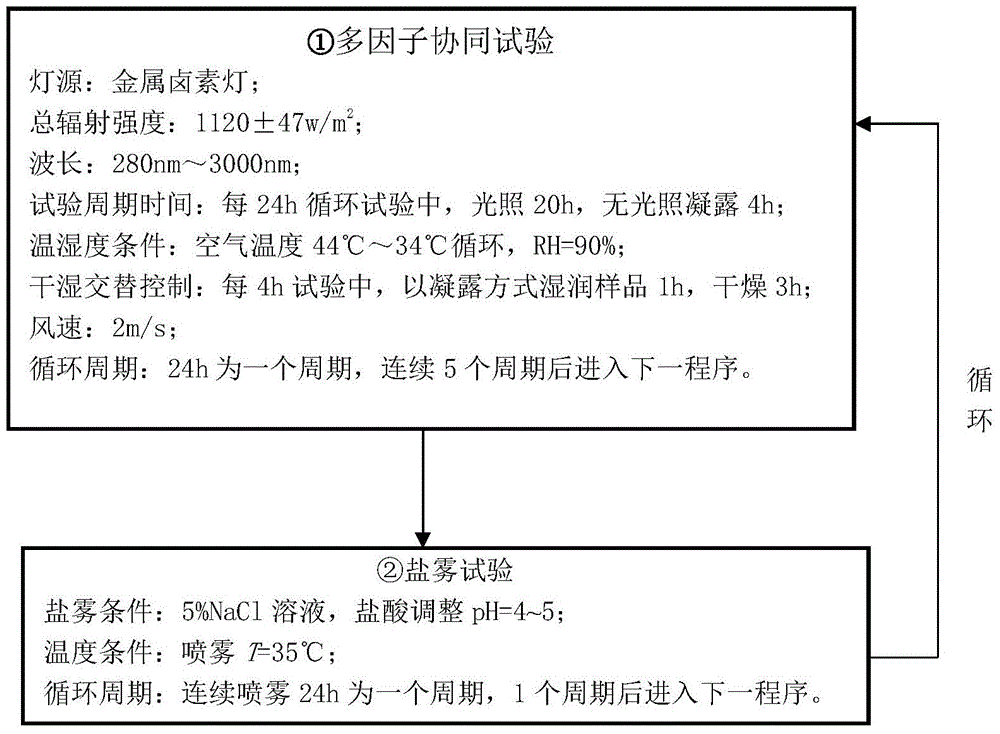

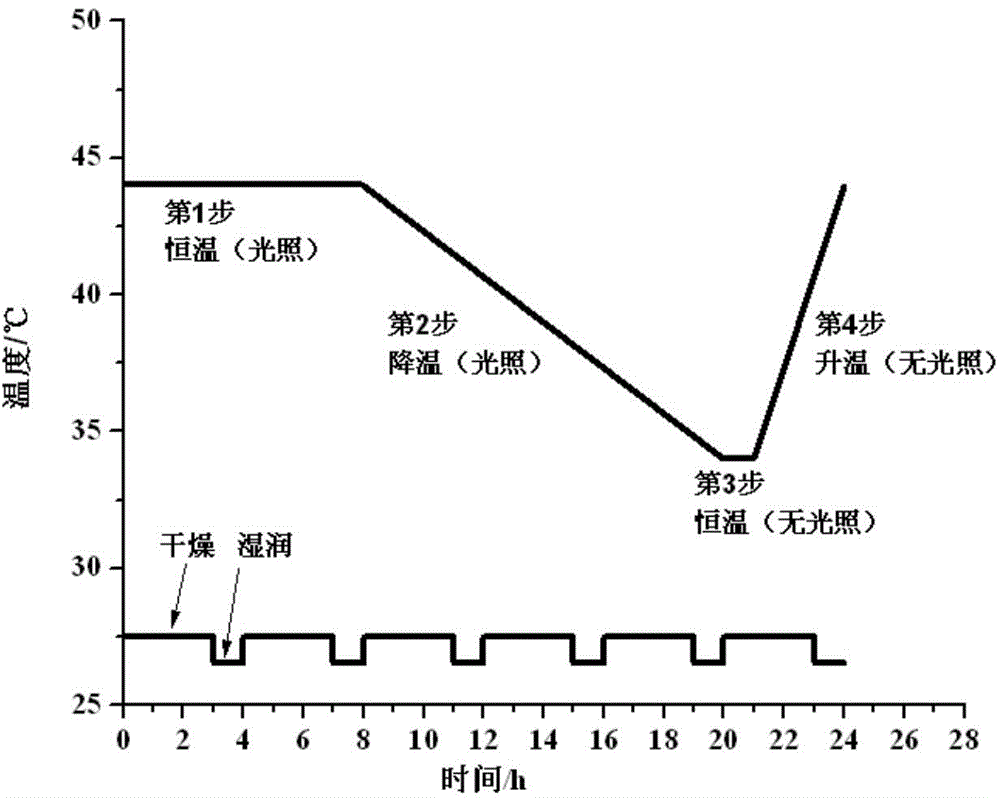

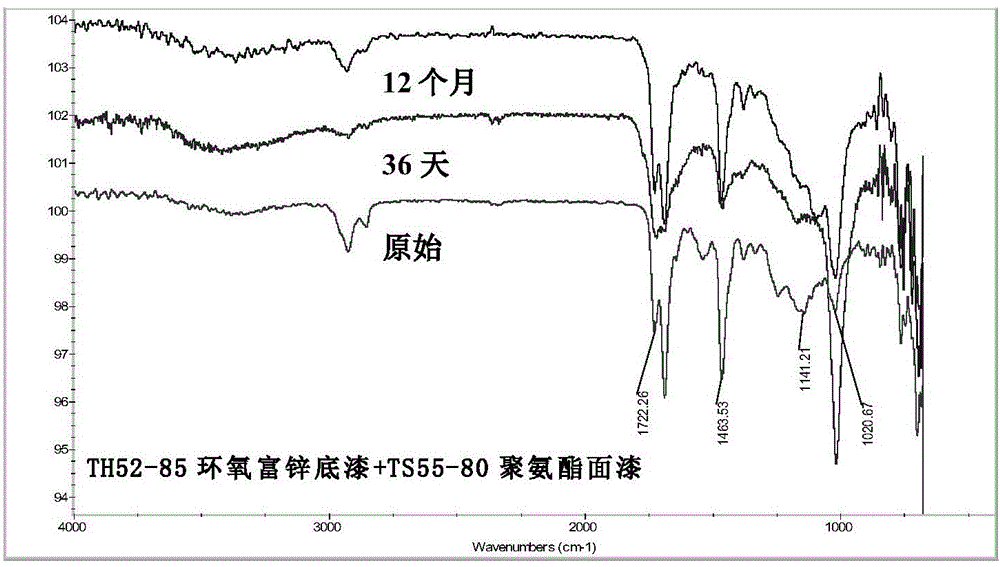

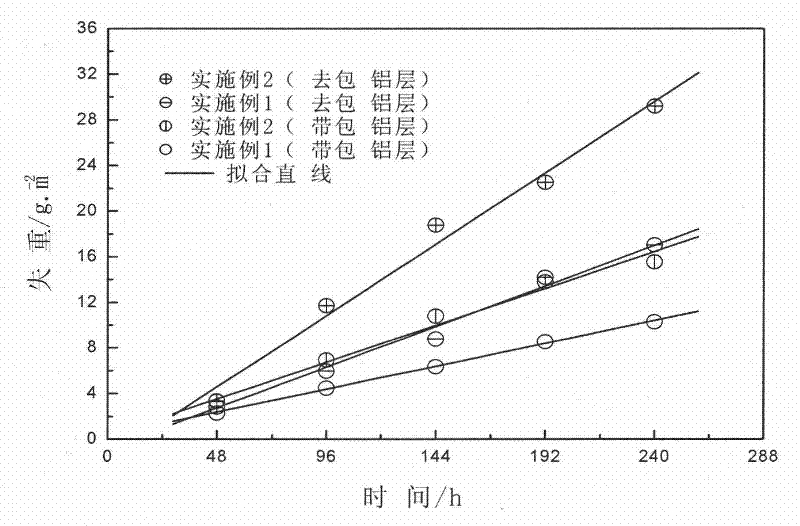

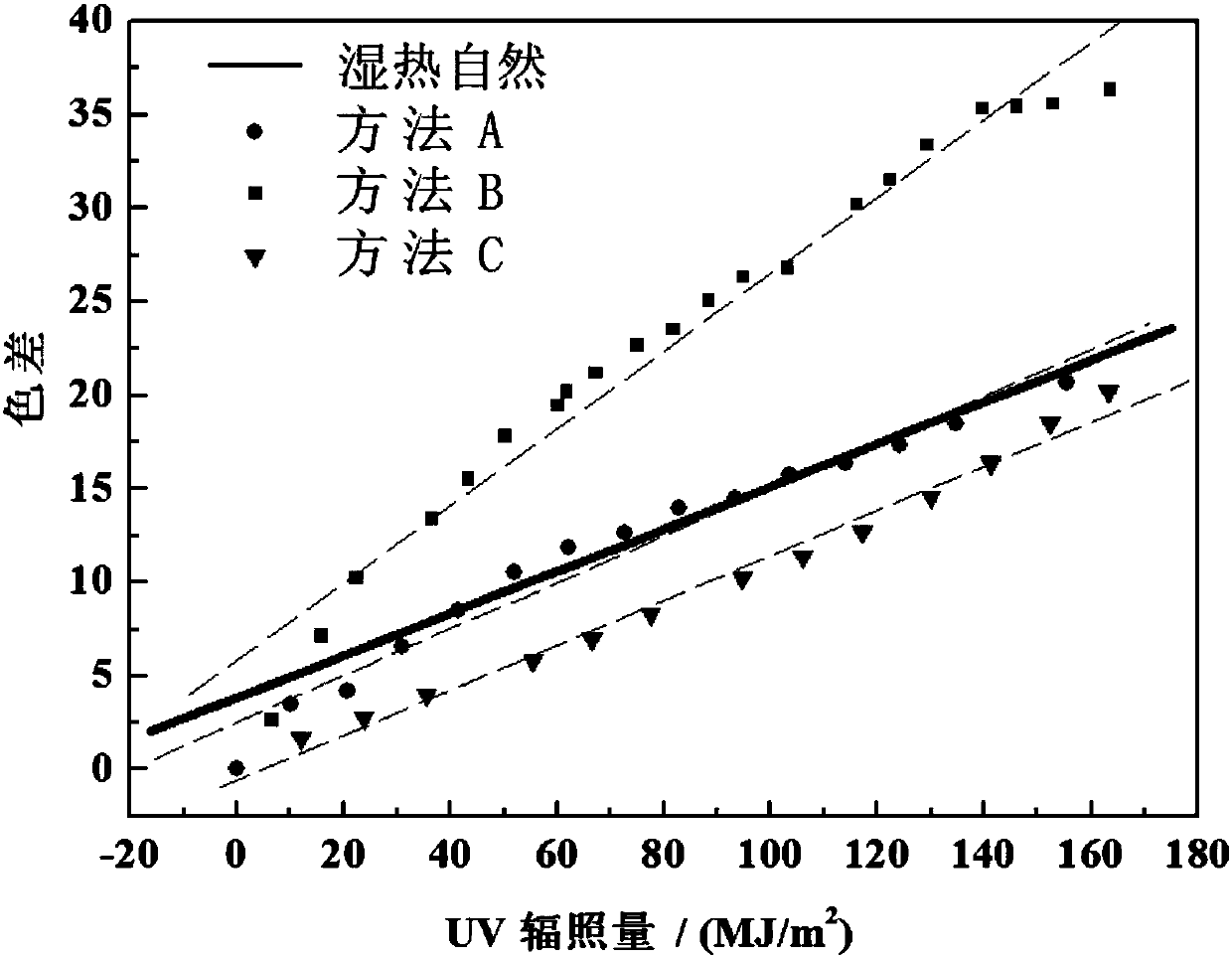

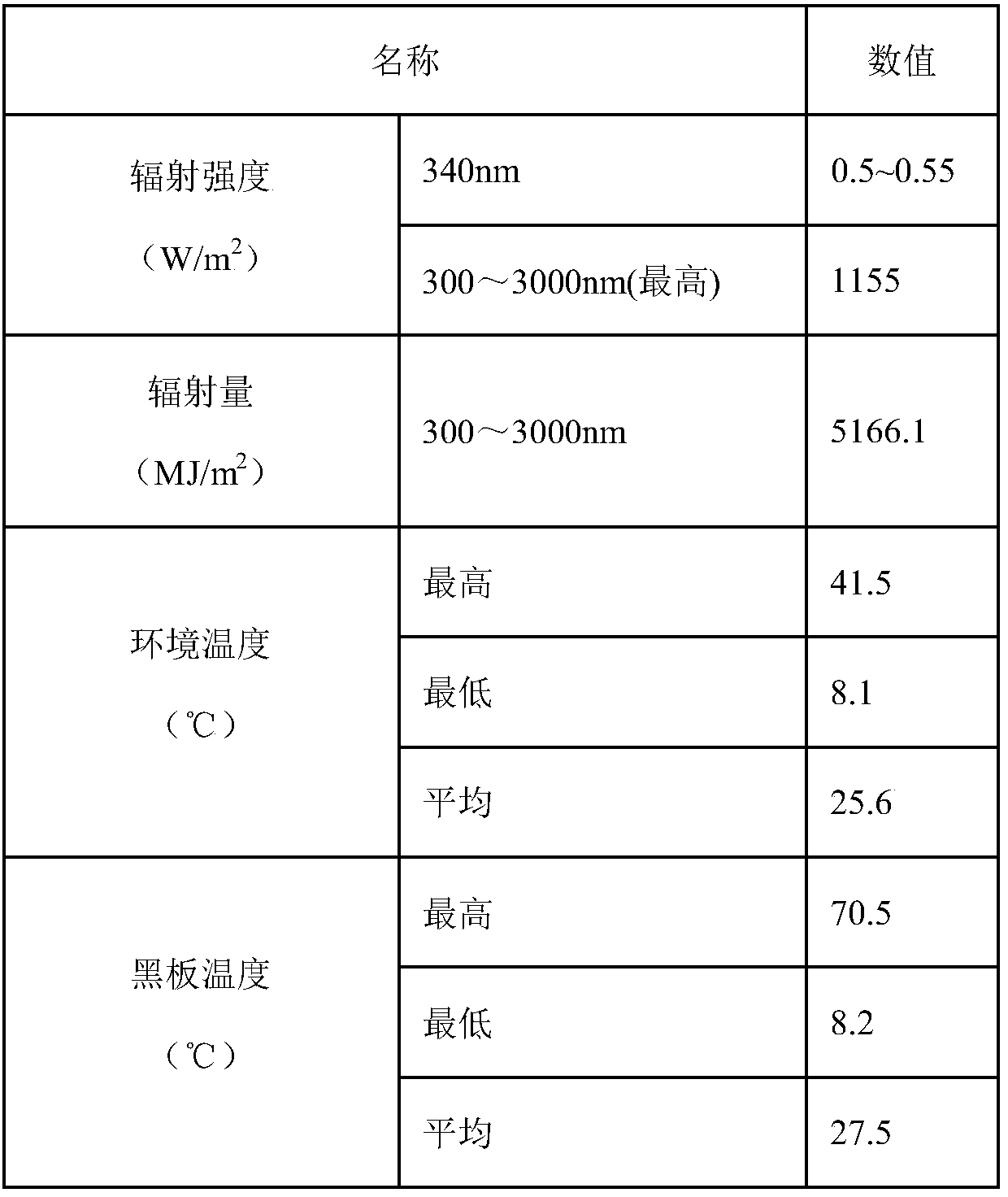

Acceleration test and equivalence estimation method of simulation coating under marine atmospheric environment

InactiveCN104568721AOvercome the defect of poor simulationReduce mistakesWeather/light/corrosion resistanceLoss rateSalt spray test

The invention discloses an acceleration test and equivalence estimation method of a simulation coating under marine atmospheric environment. The method comprises the following steps: sequentially performing multi-factor synergy test and salt spray test, and performing combined circulation. One test circulation cycle is 6 days, wherein one cycle of the multi-factor synergy test is 5 days and one cycle of the salt spray test is 1 day. The method is characterized in that conversion coefficients of the coating color difference or the light loss rate between the combined acceleration test in a laboratory and the marine atmospheric environment test are established, when the coating ageing mechanisms are essentially consistent under acceleration test and marine atmospheric environment, the color difference or the light loss rate during the marine atmospheric test is equivalently estimated by the acceleration test data in the laboratory under the same coating and the solar radiation, and the acceleration ratio can reach more than 8 times; the estimation result of the coating performance change is compared with the atmospheric exposure test result, and the error is less than 15%.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Composite quantum-dot materials for photonic detectors

ActiveUS9941433B2Reduce probabilityStabilizing electrical property of deviceSolid-state devicesNanoopticsPhotodetectorFilling materials

A composite quantum-dot photodetector comprising a substrate with a colloidally deposited thin film structure forming a photosensitive region, the thin film containing at least one type of a nanocrystal quantum-dot, whereby the nanocrystal quantum dots are spaced by ligands to form a lattice, and the lattice of the quantum dots has an infill material that forms an inorganic matrix that isolates the nanocrystal quantum dots from atmospheric exposure.

Owner:LADARSYST INC

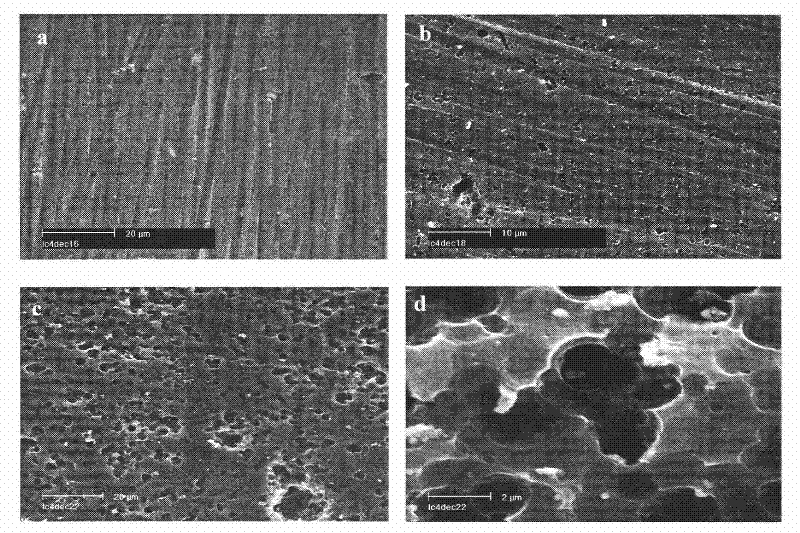

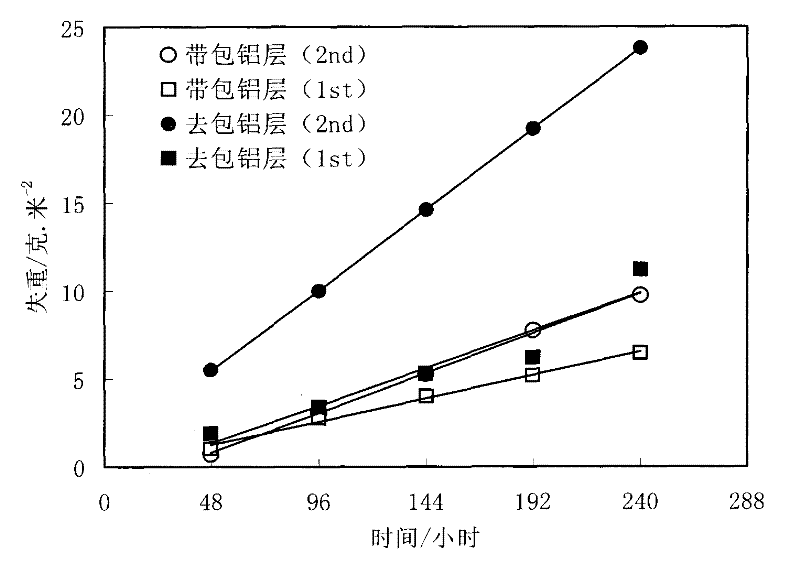

Test method for simulating corrosion process of aluminum and aluminum alloy in industrially polluted atmospheric environment

InactiveCN102128781ARapid evaluation of atmospheric corrosion resistanceHigh magnificationWeather/light/corrosion resistanceTested timeTest material

The invention relates to aluminum and aluminum alloy atmospheric corrosion simulation technique, in particular to a test method for simulating the corrosion process of aluminum and aluminum alloy in an industrially polluted atmospheric environment. In the method, aluminum or aluminum alloy is used as a tested material; aqueous solution containing NaHSO3 at a concentration of 0.02mol / L and NaCl at a concentration of 0 to 0.006mol / L is used as corrosive liquid; and soaking, drying and wetting are carried out in turn and are circulated every 10 to 20 minutes, wherein soaking is performed at 45 to 50 DEG C for 1 to 2 minutes, drying is performed at 50 to 60 DEG C for 8 to 15 minutes, wetting is performed at 40 to 50 DEG C for 1 to 3 minutes, and the test time is 48 to 240 hours. The method has simulating performance, accelerating performance and repeatability, can be used in study on the corrosion behaviors of the aluminum and aluminum alloy in the industrially polluted atmospheric environment to evaluate and predict the atmospheric corrosion of the aluminum and aluminum alloy quickly, and can solve the problems of long test period, high cost, difficult environmental factor control and the like of the conventional atmospheric exposure test.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

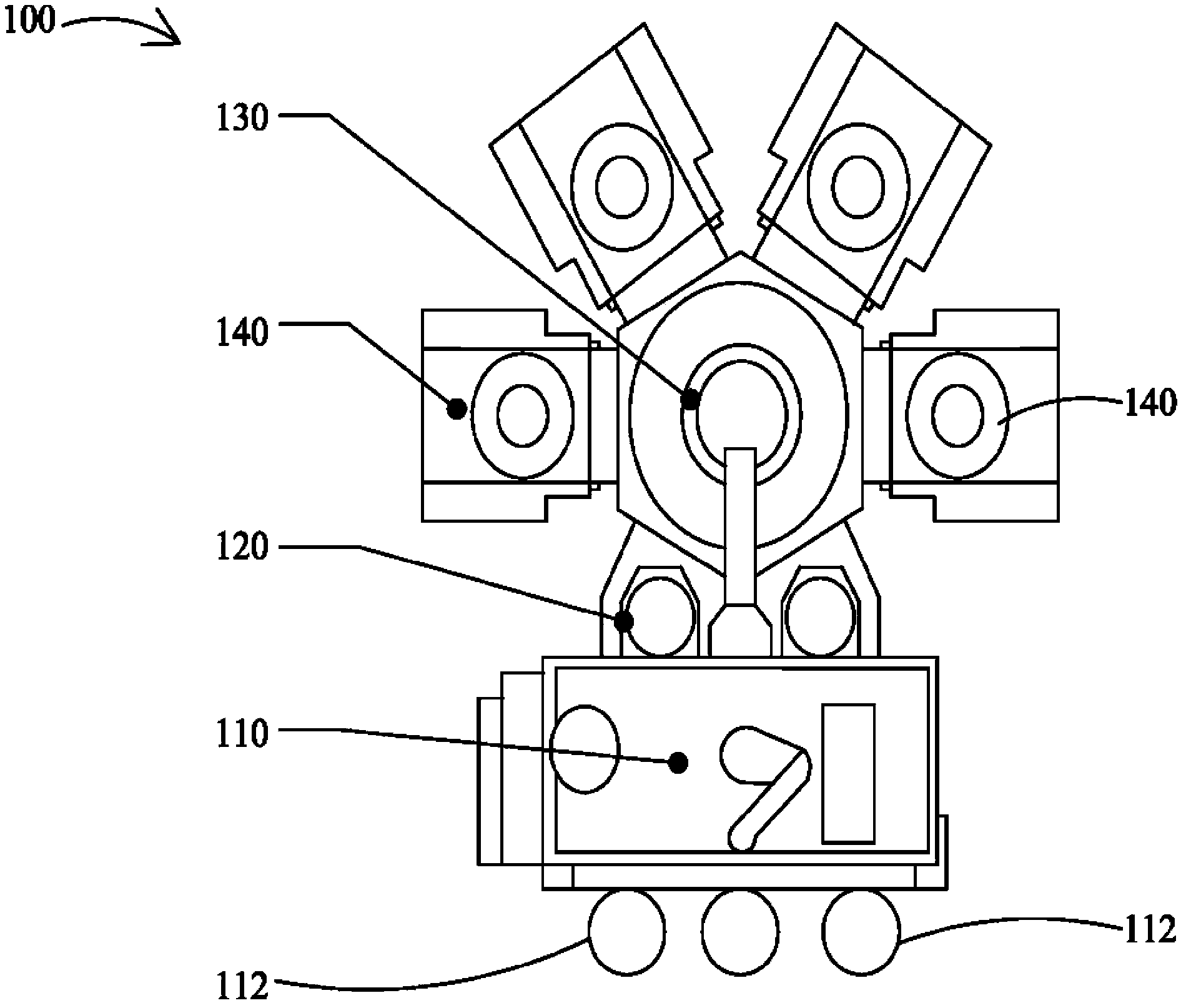

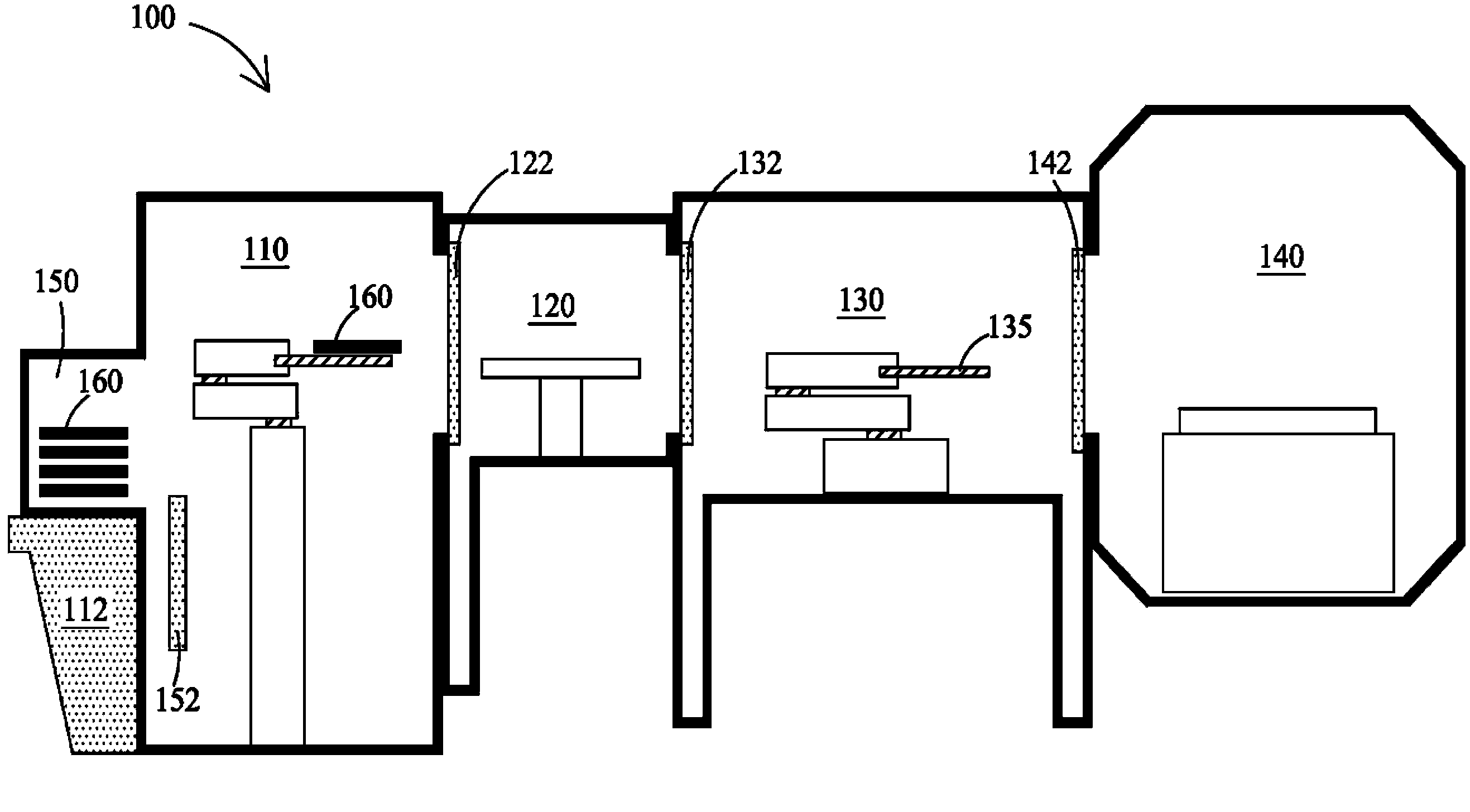

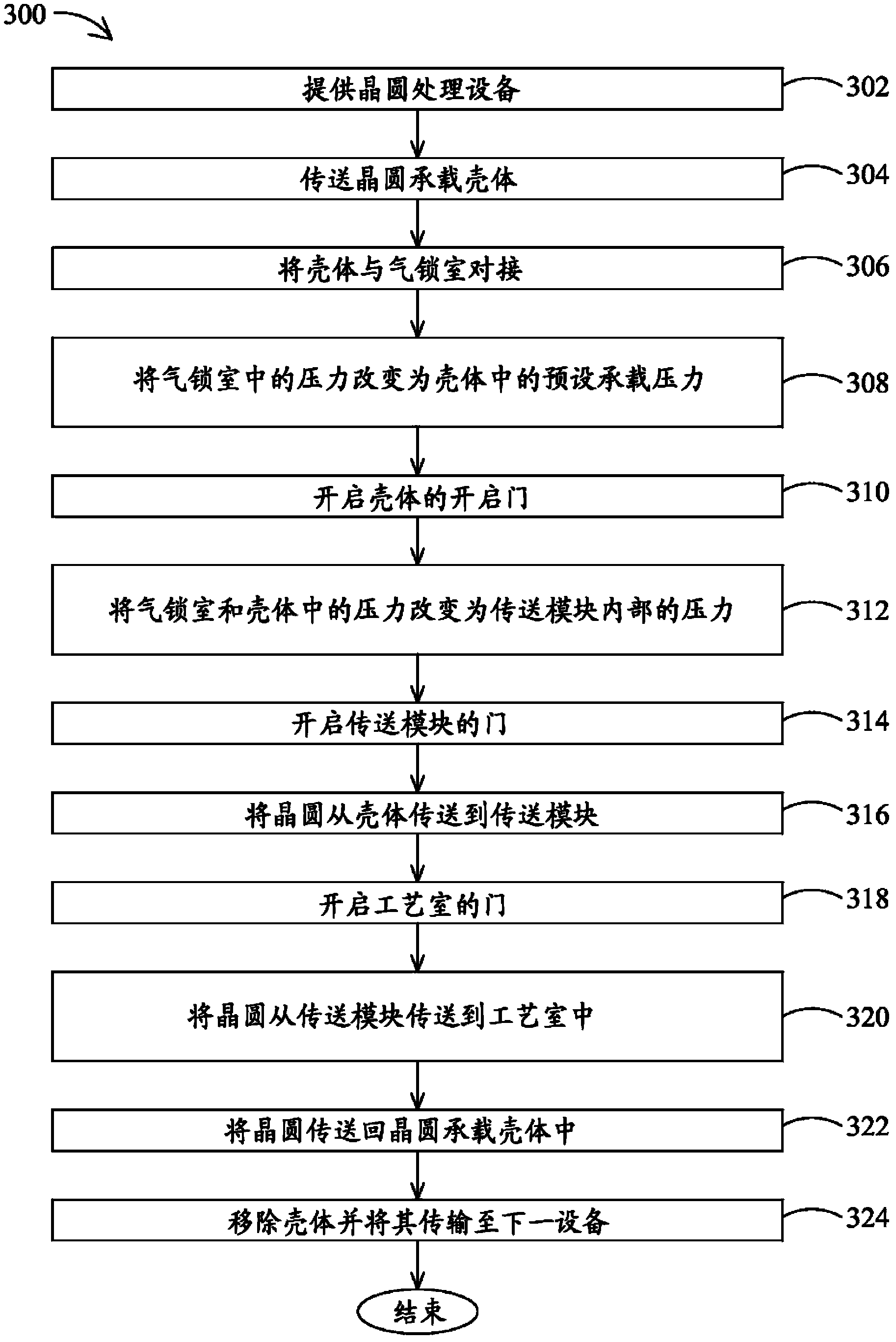

Pressure-controlled wafer carrier and wafer transport system

ActiveCN104051310ASemiconductor/solid-state device manufacturingConveyor partsInternal pressureTransport system

Disclosed are a wafer carrier that keeps wafers under a constant pressure, at any preset value below or above the atmospheric pressure, to prevent wafer contaminations arising from atmospheric exposure in conventional wafer carriers, and also, a wafer transport system and method utilizing the same wafer carrier. The wafer carrier charged with a preset carrier pressure is transported and docked with an airlock of a wafer processing tool comprising the airlock, a vacuum transfer module, and a process chamber. The airlock adjusts, by a gas pump, inner pressure to equate successively with, first, the carrier pressure before opening the carrier door, and next, the vacuum transfer module pressure before opening the latter's door. The wafers are then transferred into the process chamber. After processing, the wafers are transferred back into the wafer carrier and charged with the preset carrier pressure before undocked and transported to the next wafer processing tool.

Owner:TAIWAN SEMICON MFG CO LTD

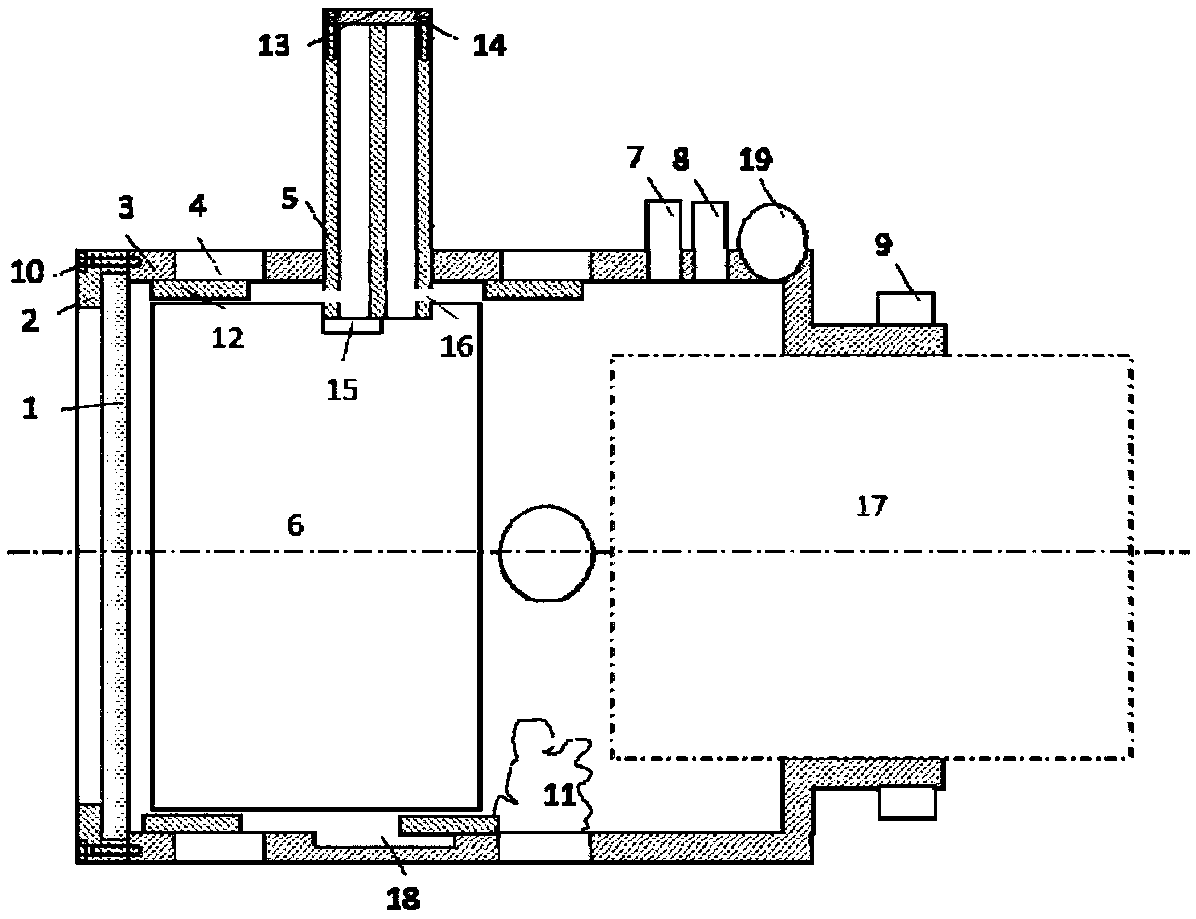

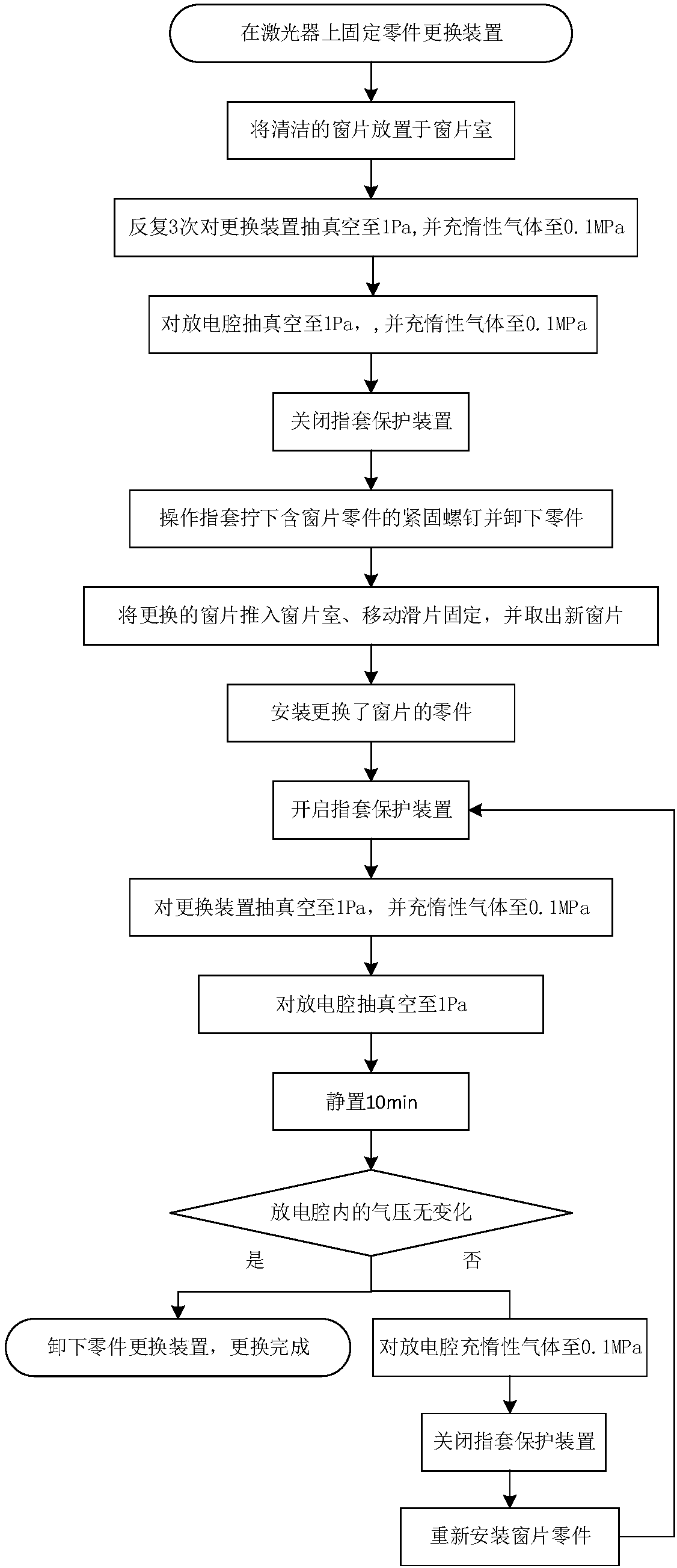

Replacement device and replacement method of excimer laser window

InactiveCN108183382APrevent proliferationHarm reductionGas laser constructional detailsEngineeringAtmospheric pressure

The invention relates to a replacement device and replacement method of an excimer laser window. The device comprises a replacement main cavity with an opening at one end. A cavity wall of the replacement main cavity is provided with multiple observation windows for observing the internal part of the replacement main cavity, a barometer for detecting the internal air pressure in the replacement main cavity, a vacuuming passage, an inflation passage, a plurality of finger sleeve holes and a window chamber. Both the vacuuming passage and the inflation passage communicate with the internal part of the replacement main cavity, and the finger sleeve holes are equipped with operation finger sleeves which facilitate the window replacement in the replacement main cavity. According to the replacement device and the replacement method, a diffusion phenomenon of a halogen medium in the process of replacing an excimer laser window can be significantly reduced, the contamination of parts in atmospheric exposure can be effectively avoided, the number of times of cleaning a discharge chamber and the harm to an operator can be effectively reduced, the passivation process is avoided or the passivation time is significantly reduced, and the use efficiency of a laser and the utilization rate of energy sources are improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

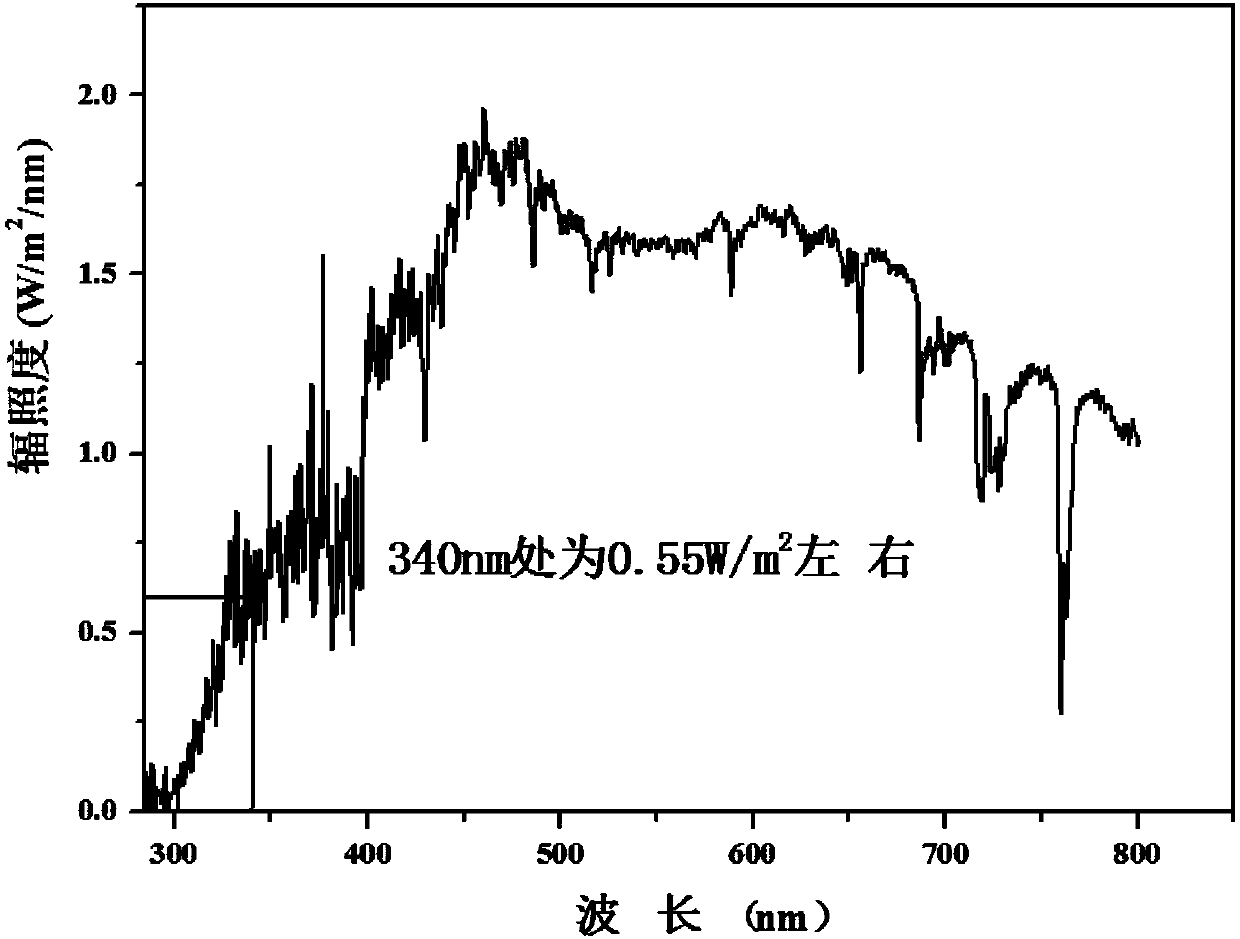

Climate environment simulating design method for accelerated aging test of xenon lamp made from high molecular material

InactiveCN107843545APredict natural agingAccurately Predict Service LifeWeather/light/corrosion resistanceAccelerated agingMolecular materials

The invention discloses a climate environment simulating design method for an accelerated aging test of a xenon lamp made from a high molecular material. The method comprises the following steps: (1)monitoring and analyzing climate environment conditions of some region where a high molecular material aging test is to be carried out; (2) designing at least three groups of accelerated aging test parameters of an xenon lamp based on a principle that the parameters are similer to the climate environment condition data of the region; (3) selecting a material, the structural property of which is similar to the to-be-tested high molecular material, as a reference material, and obtaining the accelerated aging test data of the xenon lamp of the reference material; (4) acquiring data of a natural atmospheric exposure test of the reference material; and (5) comparing the natural atmospheric exposure test of the reference material with the accelerated aging test data of the xenon lamp and determining the accelerated aging test condition, the relevance of which to the natural atmospheric exposure test is the best. The method is suitable for a high molecular material aging test.

Owner:CHINA NAT ELECTRIC APP RES INST

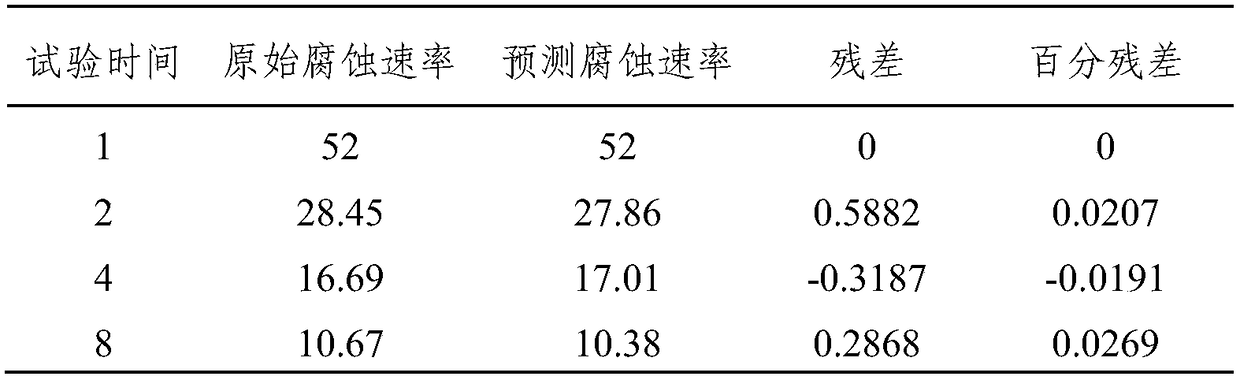

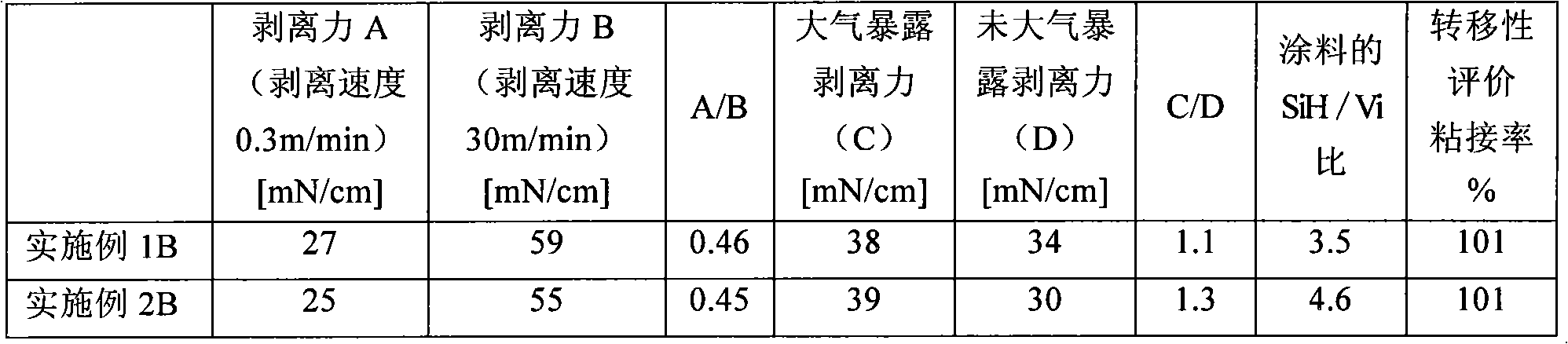

Release film

InactiveUS20110059322A1Improve retentionImprove the immunityLayered productsSolid-state devicesPolyesterPeel force

The present invention provides a release film which can be peeled off with a light peel force and can exhibit an excellent retention force upon storage as well as an excellent resistance to atmospheric exposure and an excellent anti-migration property. The release film comprises a polyester film and a coating material applied onto at least one surface of the polyester film which comprises a curing type silicone as a main component, wherein the curing type silicone in the coating material comprises a vinyl group-containing polysiloxane chain in which a content of the vinyl group is not less than 3% in terms of siloxane units; and wherein a ratio of SiH to Vi (SiH / Vi) in the coating material is 2.5 to 7.

Owner:MITSUBISHI PLASTICS INC

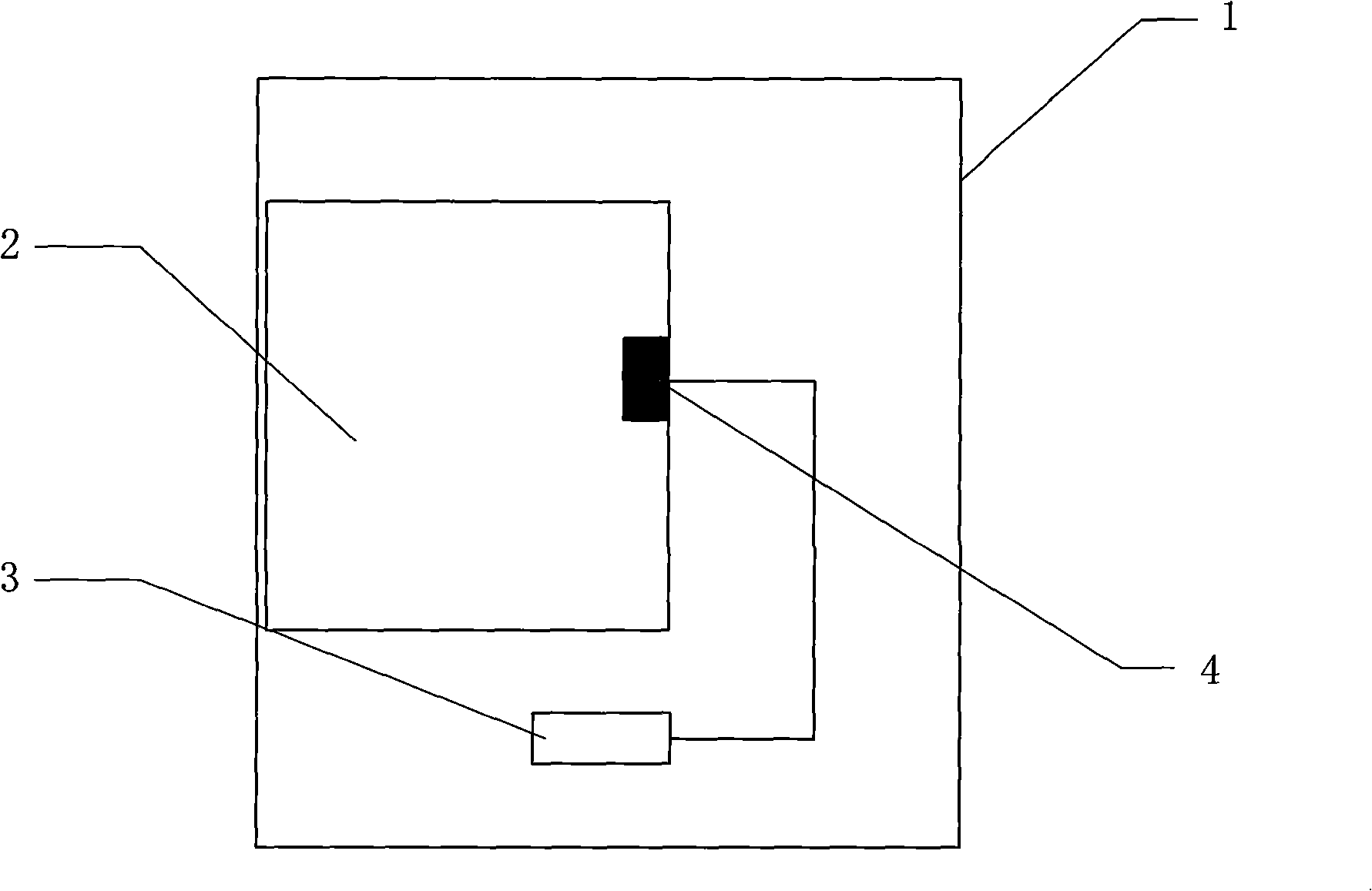

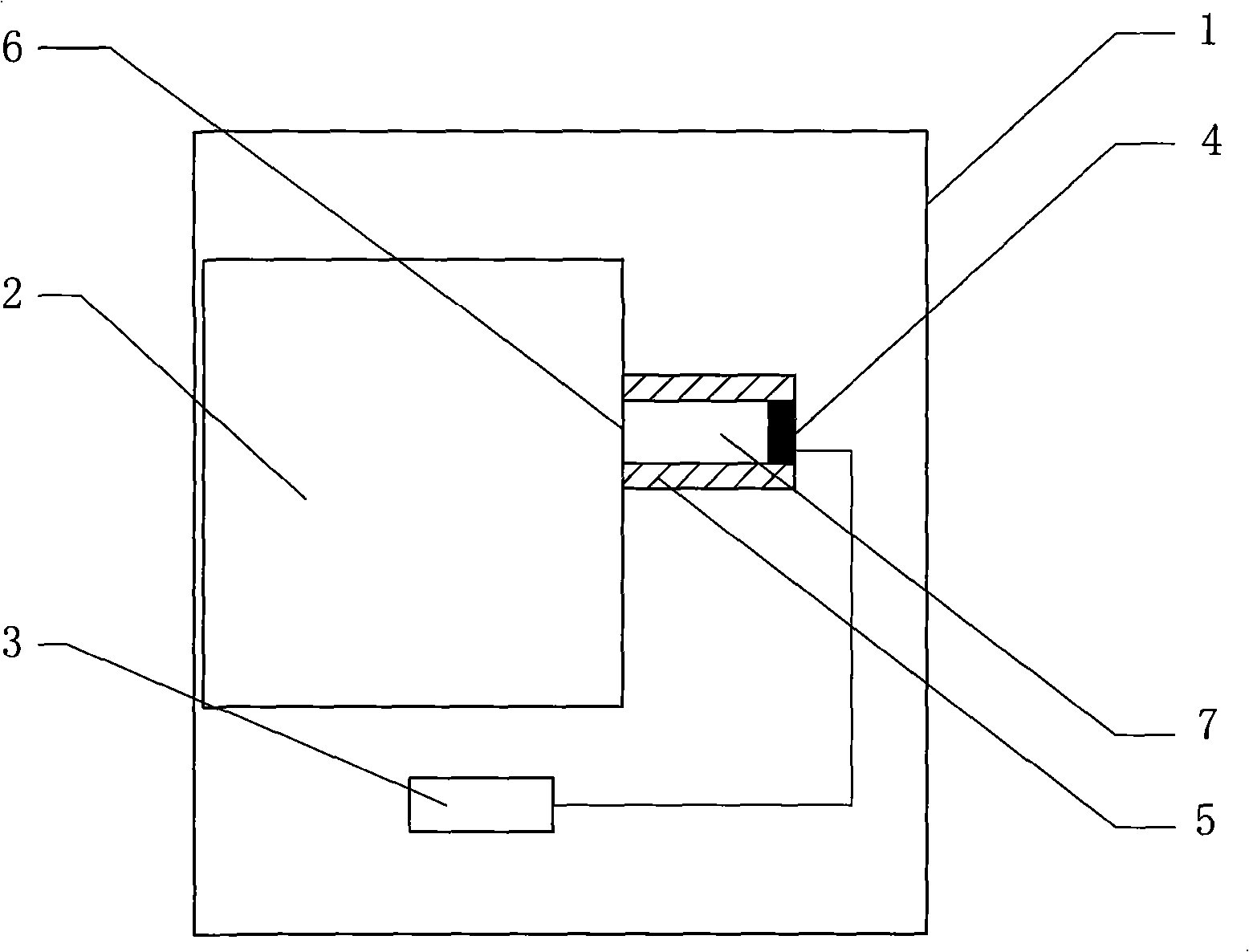

Xenon lamp weather resistance test box

InactiveCN101344477AExtended service lifeImprove accuracyWeather/light/corrosion resistanceWeather resistanceTest chamber

The invention provides an improved atmospheric exposure test chamber of xenon lamps, which has better testing accuracy and longer service life, comprises a case body with a working chamber and a controlling chamber arranged inside, and is characterized in that an irradiation sensor is arranged outside the working chamber.

Owner:孙国伟

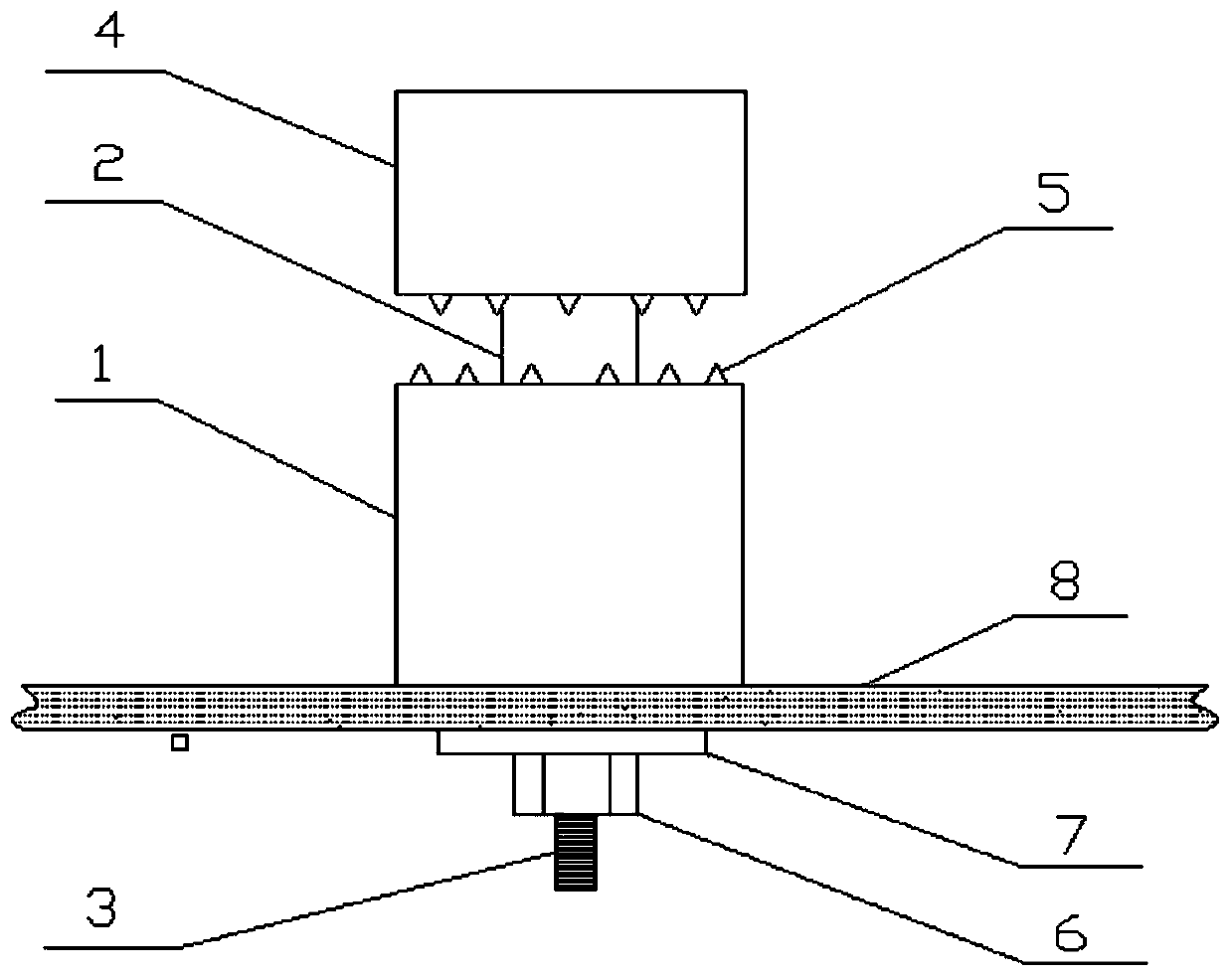

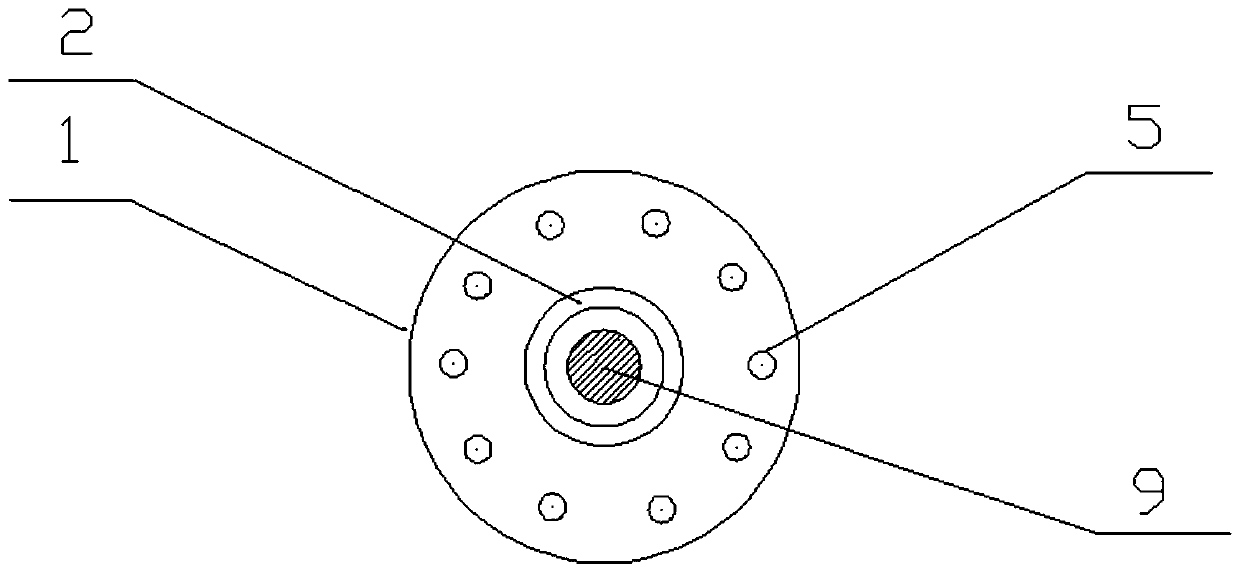

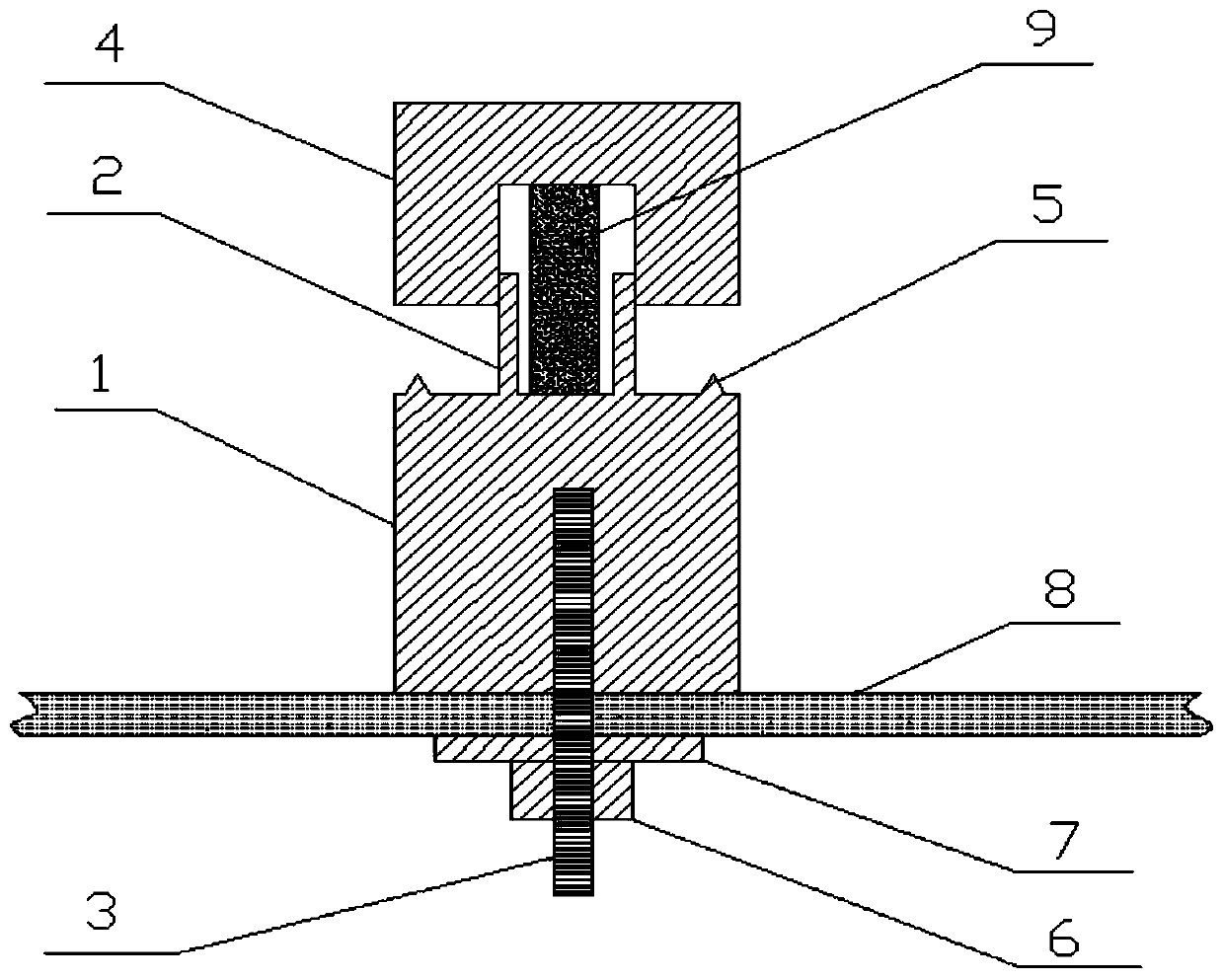

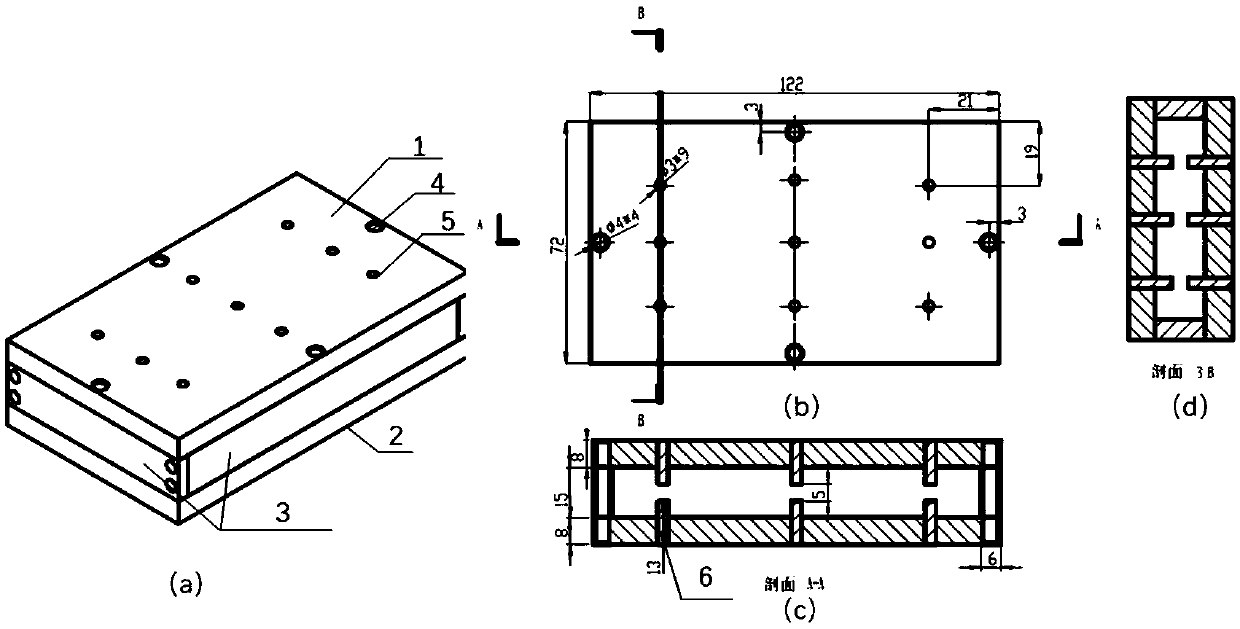

Corrosion coupon clamp for atmospheric exposure environment test

PendingCN111521550AEasy to holdEasy to operateWeather/light/corrosion resistanceWork holdersEngineeringBatten

The invention provides an atmospheric exposure environment test corrosion coupon clamp and belongs to the technical field of natural environment test devices. The clamp structurally comprises a base,an upright post on the base, a connecting part and a top cover, wherein the base is insulated from the upright post, the upright post is cylindrical and is positioned in the center of an upper surfaceof the base, the top cover is insulated, the bottom of the top cover is hollow corresponding to the upright post, a screw rod is fixedly connected in the base, extends out of the center of a lower surface of the base, and is matched with a nut to be fixed on an exposure rack sample fixing batten, the base and the top cover are connected through an elastic contraction part or are in threaded connection through an outer extension end of the screw rod in the base in the other direction, and protrusions with uniform sizes are distributed on a contact surface of the base and the top cover in a staggered mode. The clamp is advantaged in that the clamp is simple in structure, convenient to operate and capable of stably clamping corrosion hanging pieces with different thicknesses, meanwhile, thedesign of the convex points effectively reduces the contact area of the clamp and the corrosion hanging piece and avoids crevice corrosion.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

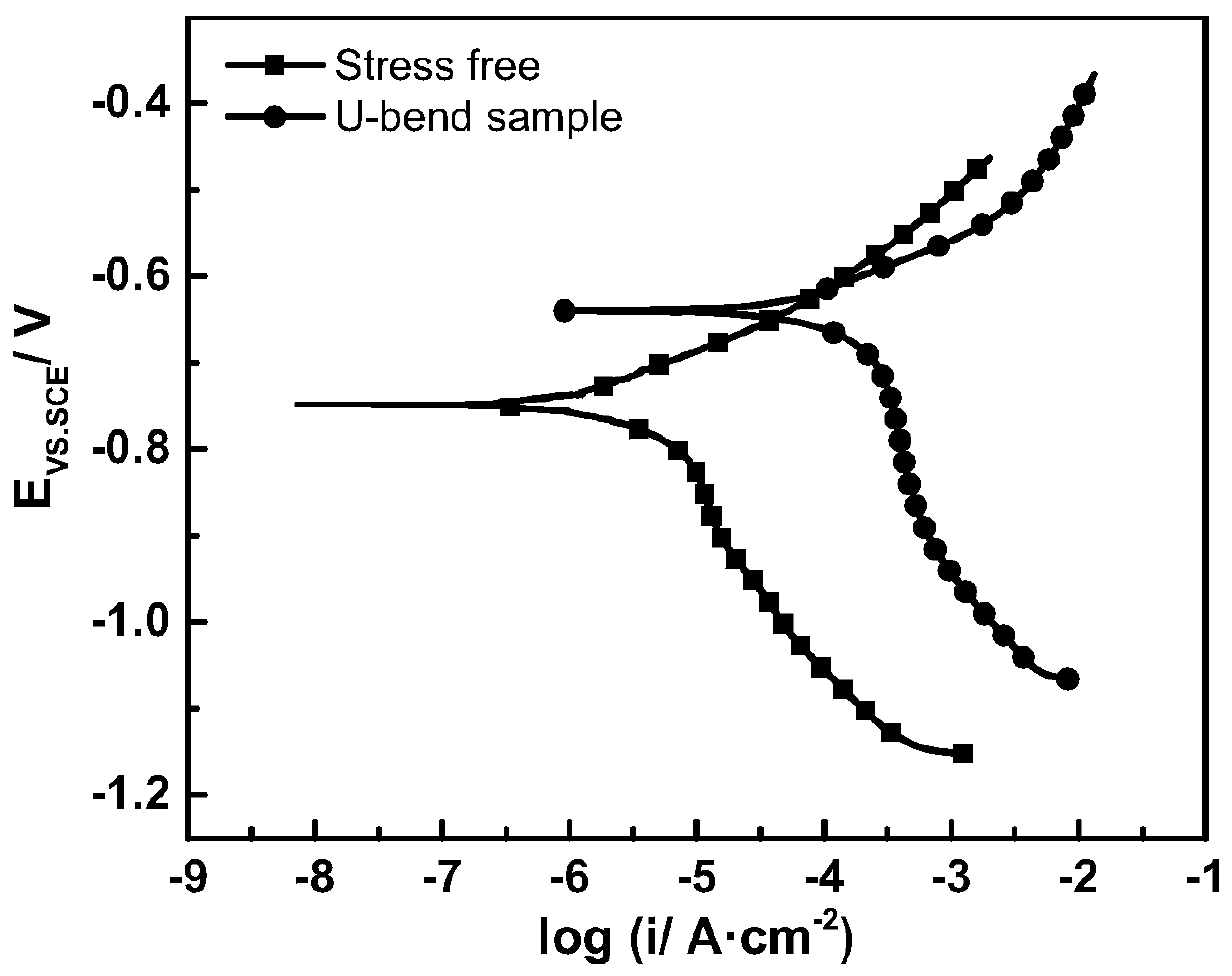

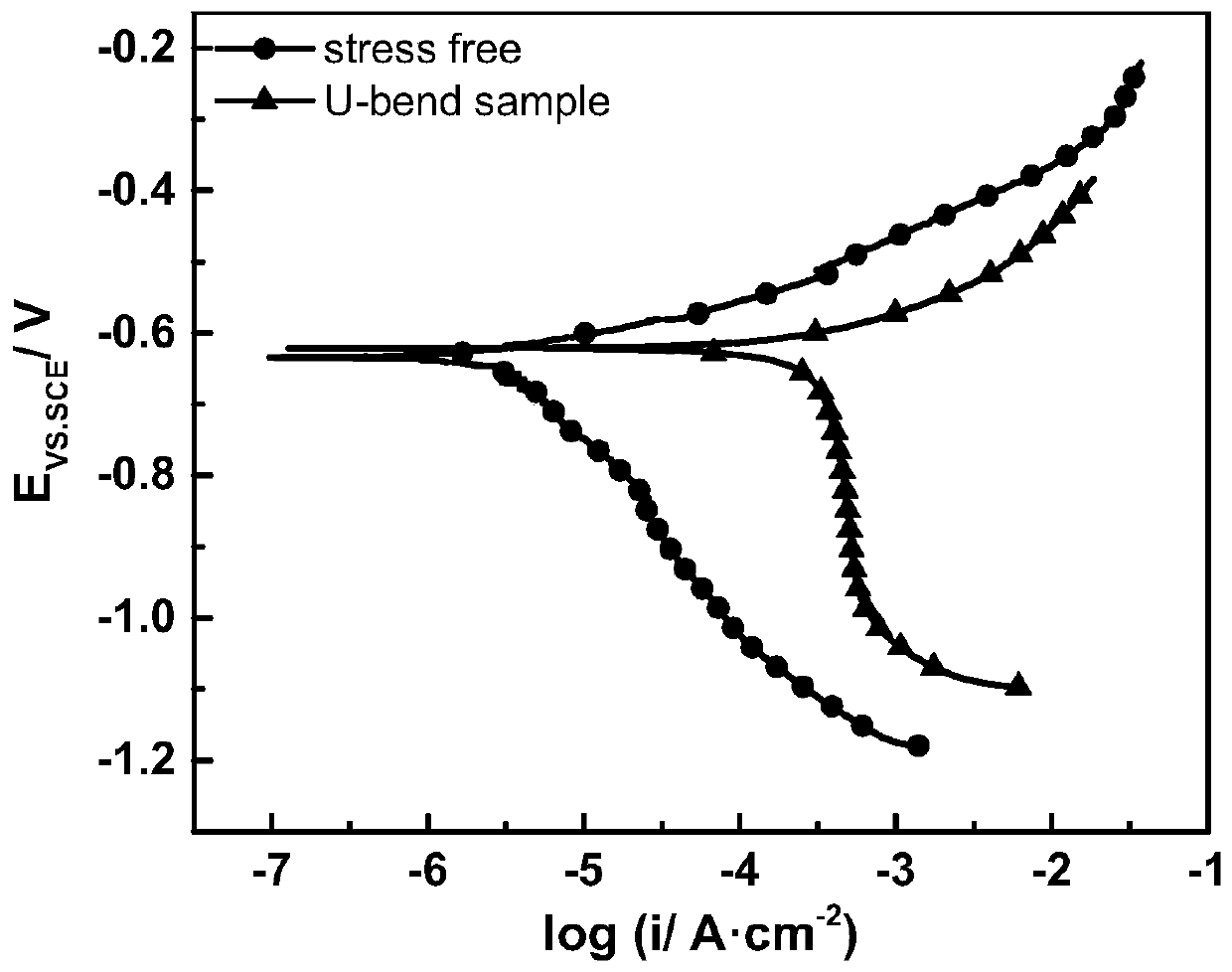

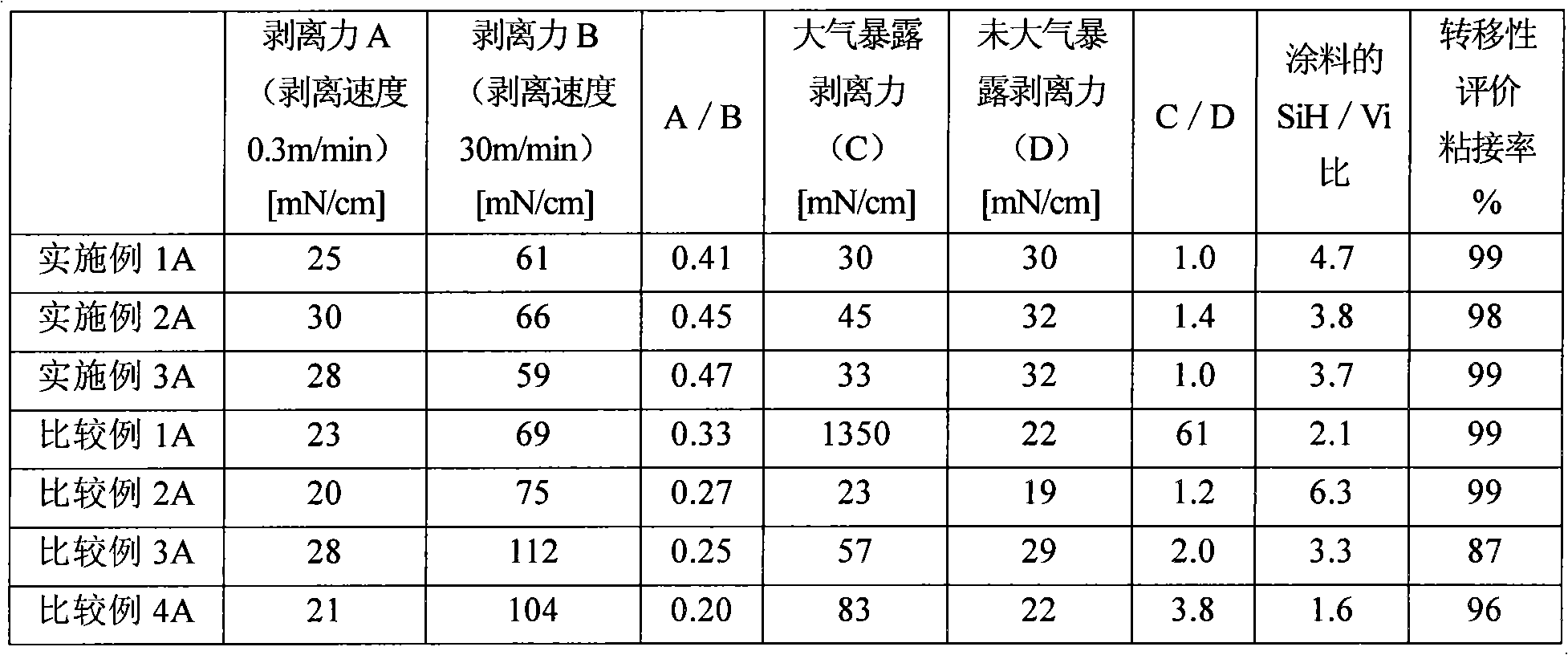

Rapid evaluation method for stress corrosion sensitivity of low-alloy structural steel in atmospheric environment

PendingCN110823690AEasy to operateImprove surface qualityWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesResearch dataPhysical chemistry

The invention discloses a rapid evaluation method for stress corrosion of low-alloy structural steel in an atmospheric environment. The rapid evaluation method is a stress corrosion sensitivity evaluation method constructed based on electrochemical tests and based on atmospheric environment stress corrosion indoor and outdoor simulation and acceleration research data and a stress corrosion electrochemical mechanism thereof. Compared with a traditional outdoor atmospheric exposure test method, the rapid evaluation method has high operability in indoor tests and short test time, the evaluation of stress corrosion performance of the low-alloy steel can be realized, and the rapid evaluation method can be further used for the research and development, production and relevant evaluation and testing in the material selection process of the low-alloy structural steel. The rapid evaluation method has the characteristics of simulation, acceleration and effectiveness, a new method is provided forthe evaluation study of the stress corrosion sensitivity of the low-alloy structural steel in the atmospheric environment, and thus an advantageous basis is provided for the use and protection of materials.

Owner:NANJING IRON & STEEL CO LTD

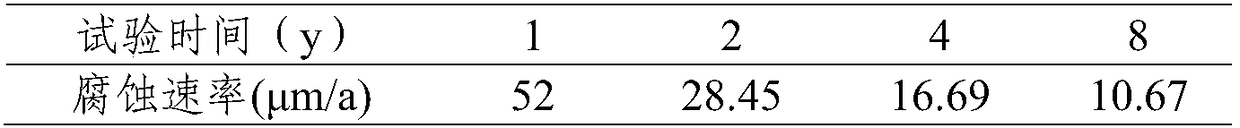

Predication method for corrosion service life of metal material

InactiveCN108106986ALife expectancyPredicting Corrosion LifeWeighing by removing componentWeather/light/corrosion resistanceTest sampleOriginal data

The invention belongs to the technical field of corrosion predication of metal materials and in particular relates to a predication method for the corrosion service life of a metal material. The predication method comprises the following steps: carrying out an atmospheric exposure test; calculating the corrosion weight loss of a test sample after the test sample is exposed for different exposure periods; establishing a predication model by utilizing original data, wherein an established differential equation is as follows: dX1 / dt+aX1=b; determining parameters a and b by utilizing least-squaresalgorithm linear fitting; finally, obtaining a solution of the equation, i.e. X1(m)=[X0(1)-b / a]e-a(m-2)+b / a. By adopting the predication method provided by the invention, predicated precision is checked by utilizing a residual testing method and a posterior variance testing method; the corrosion service life of the metal material in a long period under an actual application environment can be accurately predicated.

Owner:武汉钢铁有限公司

Mold release film

ActiveCN101965262ALight PeelingStrong retentionSynthetic resin layered productsSolid-state devicesPolyesterPeel force

Disclosed is a mold release film which has such a peel force as to permit light peeling and exerts excellent holding power in storage and which has excellent atmospheric exposure resistance and excellent migration resistance. A mold release film produced by coating at least one side of a polyester film with a curable silicone-based coating material, wherein the vinyl-containing polysiloxane chain of the curable silicone constituting the coating material has a vinyl content of 3% or above in terms of siloxane unit and the SiH / Vi ratio of the coating material is 2.5 to 7.

Owner:MITSUBISHI CHEM CORP

Sb-Te alloy powder for sintering, sintered compact sputtering target obtained by sintering said powder, and manufacturing method of Sb-Te alloy powder for sintering

ActiveUS7947106B2Avoid it happening againLow oxygenCellsVacuum evaporation coatingSputteringSurface roughness

Provided is Sb—Te alloy powder for sintering in which the maximum grain size of the powder obtained by subjecting gas atomized powder of an Sb—Te alloy to mechanical pulverization is 90 μm or less, and a sintered compact sputtering target obtained by sintering this powder. Further provided is a manufacturing method of Sb—Te alloy powder for a sintered compact sputtering target including the steps of dissolving an Sb—Te alloy, thereafter subjecting this to gas atomization to obtain atomized powder, and further subjecting this to mechanical pulverization in an inert atmosphere without any atmospheric exposure so as to manufacture powder having a maximum grain size of 90 μm or less and reduced oxygen content. Thus, the Sb—Te alloy sputtering target structure can be uniformalized and refined, generation of cracks in the sintered target can be inhibited, and generation of arcing during sputtering can be inhibited. Further, surface ruggedness caused by sputter erosion can be reduced in order to obtain a high quality Sb—Te alloy sputtering target.

Owner:JX NIPPON MINING & METALS CORP

Experimental method for corrosion resistance of steel bar used in concrete structure in tropical marine atmospheric environment

ActiveCN109557017AReflect corrosionTruly reflect the corrosion situationWeather/light/corrosion resistancePreparing sample for investigationSurface oceanReinforced concrete

The invention provides an experimental method for corrosion resistance of a steel bar used in a concrete structure in a tropical marine atmospheric environment. The method comprises the following steps of: counting and analyzing climatic and environmental conditions and changing laws of coastal areas of Thailand, establishing a load spectrum of environmental corrosion parameters; formulating various concrete proportions and concrete thickness, designing different experimental schemes, preferably setting a concrete proportion and determining the concrete thickness according to the load spectrumof the environmental corrosion parameters, and designing a mold according to the size of a steel bar sample and the concrete thickness; fixing the steel bar sample inside the mold, pouring the concrete slurry into the mold, and removing the mold after the slurry is solidified to obtain a reinforced concrete sample; and fixing the reinforced concrete sample to a sample holder for outdoor atmospheric exposure test, and evaluating the corrosion resistance of the steel bar sample by analyzing corrosion kinetics and macroscopic morphology of the steel bar sample in different sampling periods. According to the experimental method for the corrosion resistance of the steel bar used in the concrete structure in the tropical marine atmospheric environment, the corrosion resistance of the steel barcan be evaluated in a short period of time, the steel bar with good corrosion resistance are preferred.

Owner:UNIV OF SCI & TECH BEIJING

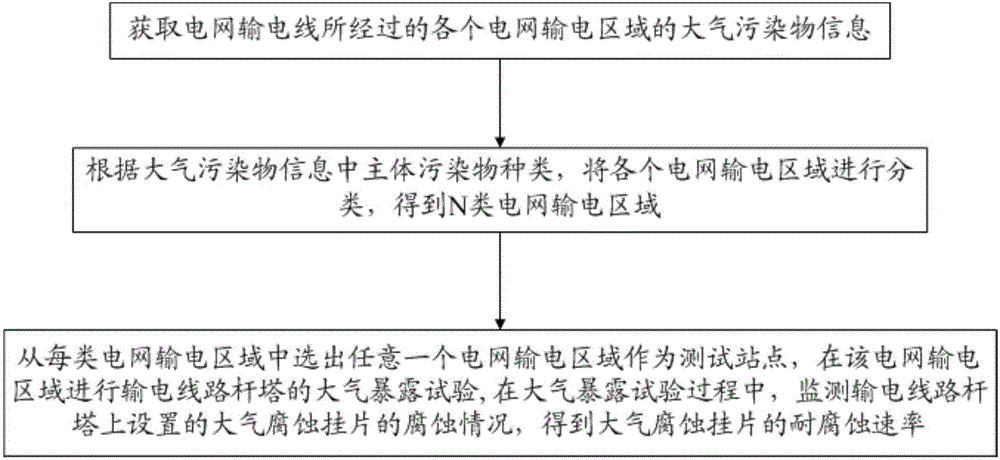

Measuring method for corrosion resistance rate of atmospheric corrosion hanging piece

InactiveCN105973788AReduced Atmospheric Corrosion Rate TimeReduce in quantityWeather/light/corrosion resistanceAir pollutantsPower grid

The invention discloses a method for measuring the corrosion resistance rate of atmospheric corrosion coupons, relates to the technical field of corrosion resistance, and aims to reduce the number of test stations for conducting atmospheric exposure tests on power transmission line poles. The measurement method includes obtaining the air pollutant information of each grid transmission area that the grid transmission line passes through; classifying each grid transmission area according to the main pollutant types in the air pollutant information, and obtaining N types of grid transmission areas, from each type Select any transmission area of the grid in the transmission area of the grid as the test site, and conduct the atmospheric exposure test of the transmission line tower in the transmission area of the grid, and obtain the corrosion resistance rate of the atmospheric corrosion coupon. The method for measuring the corrosion resistance rate of the atmospheric corrosion coupons provided by the invention is used in the atmospheric exposure test of transmission line towers.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +2

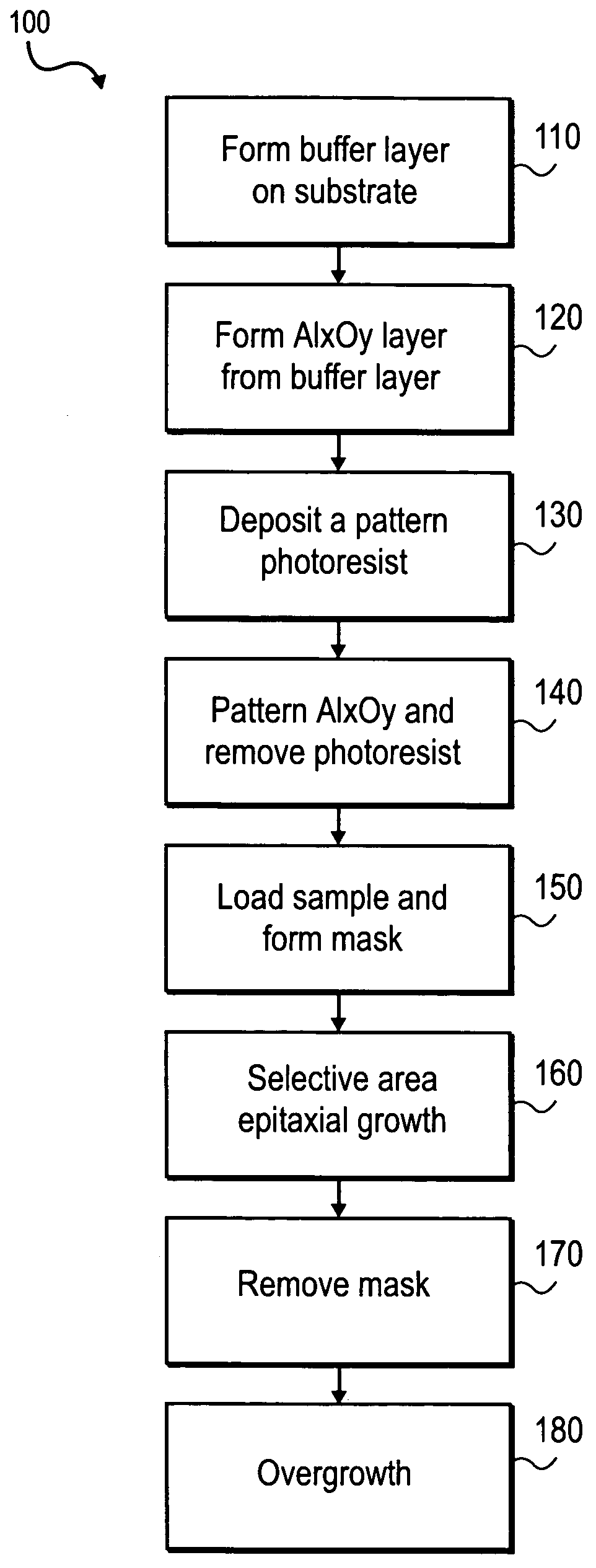

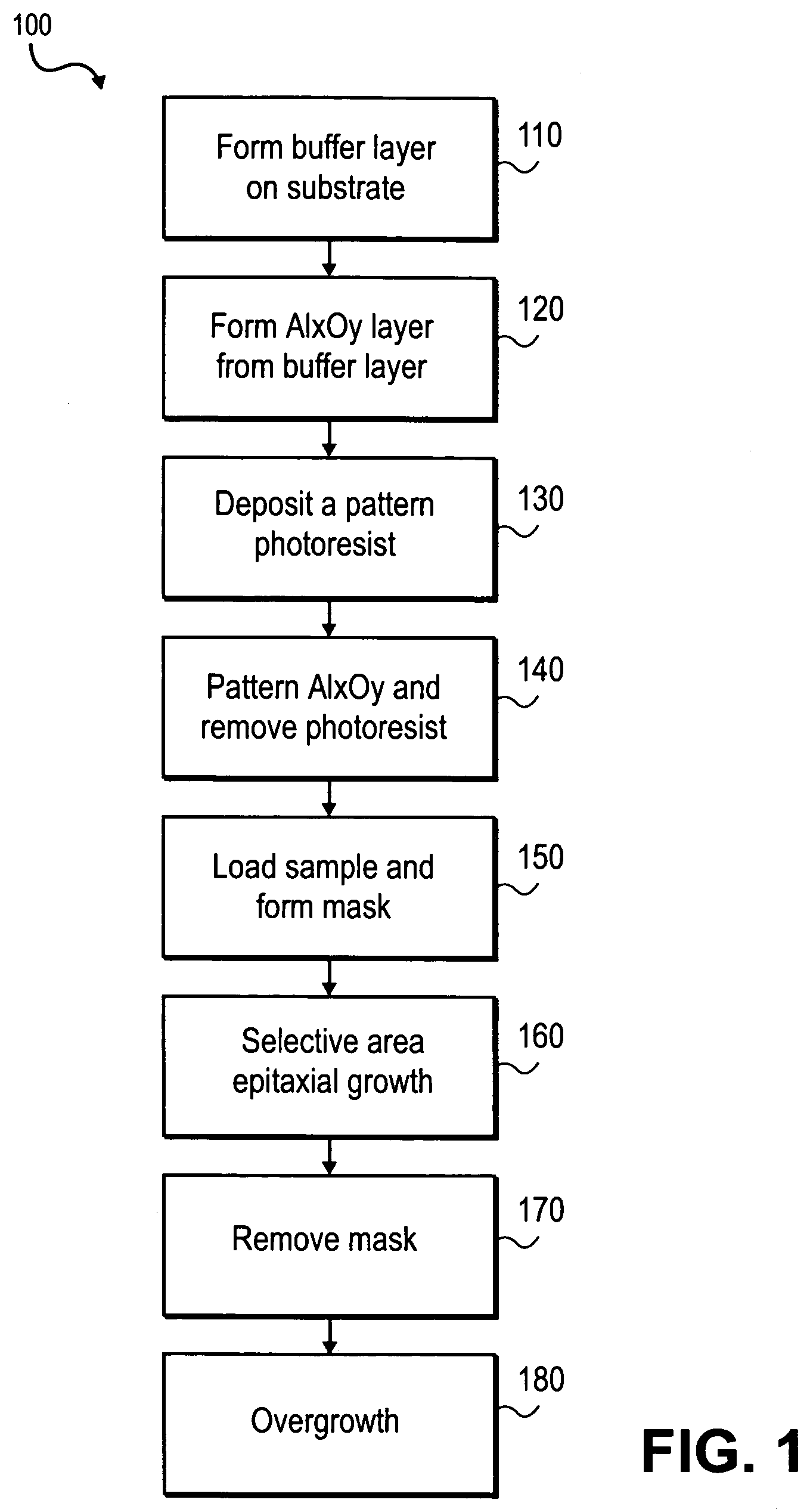

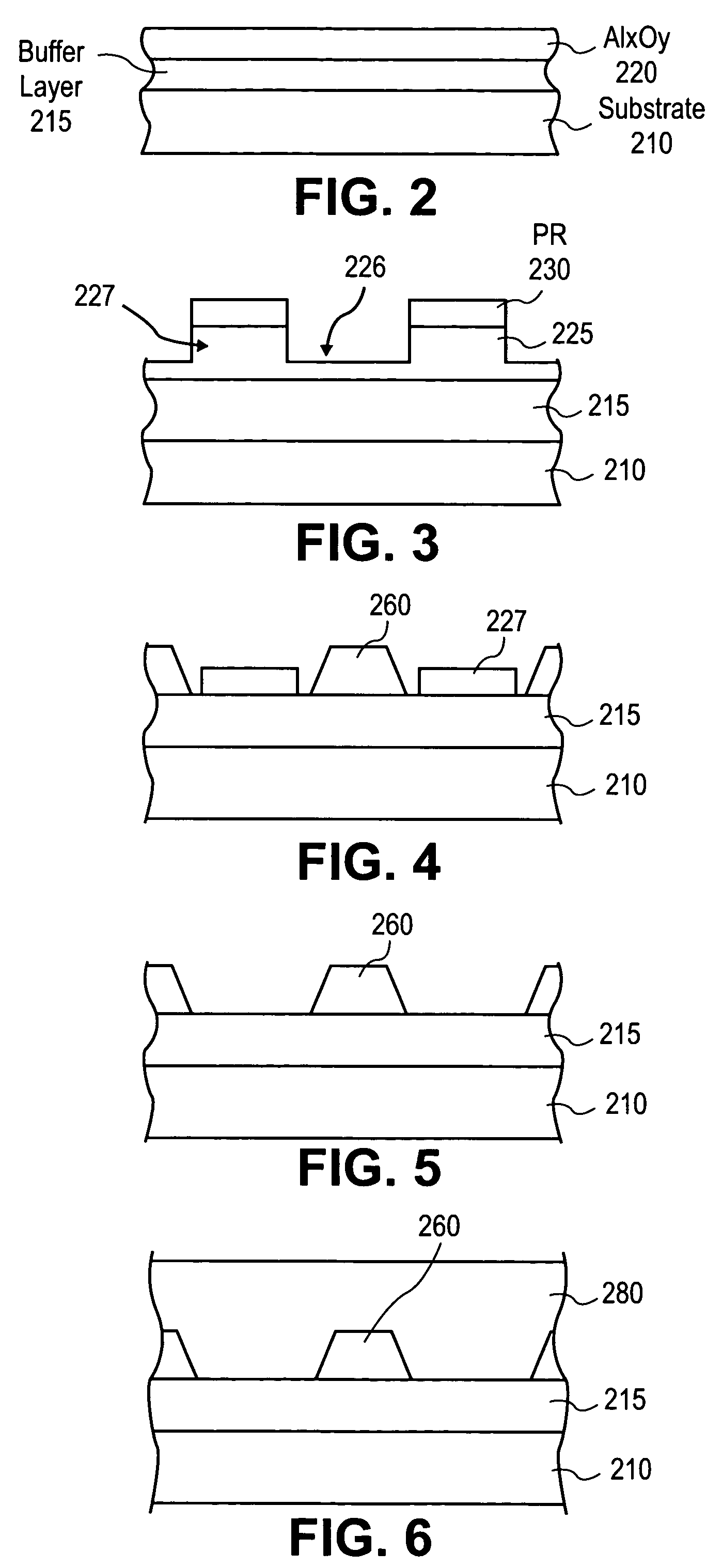

In-situ mask removal in selective area epitaxy using metal organic chemical vapor deposition

InactiveUS7288423B2Semiconductor/solid-state device manufacturingSemiconductor devicesChemical beam epitaxyPartial oxidation

A method for removing a mask in a selective area epitaxy process is provided. The method includes forming a first layer on a substrate and oxidizing the first layer. A patterned photoresist can be formed on the oxidized first layer. A portion of the oxidized first layer can then be removed using a wet chemical etch to form a mask. After removing the patterned photoresist a second layer can be epitaxially grown in a metal organic chemical vapor deposition (MOCVD) chamber or a chemical beam epitaxy (CBE) chamber on a portion of the first layer exposed by the mask. The mask can then be removed the mask in the MOCVD / MBE chamber. The disclosed in-situ mask removal method minimizes both the atmospheric exposure of a growth surface and the number of sample transfers.

Owner:STC UNM

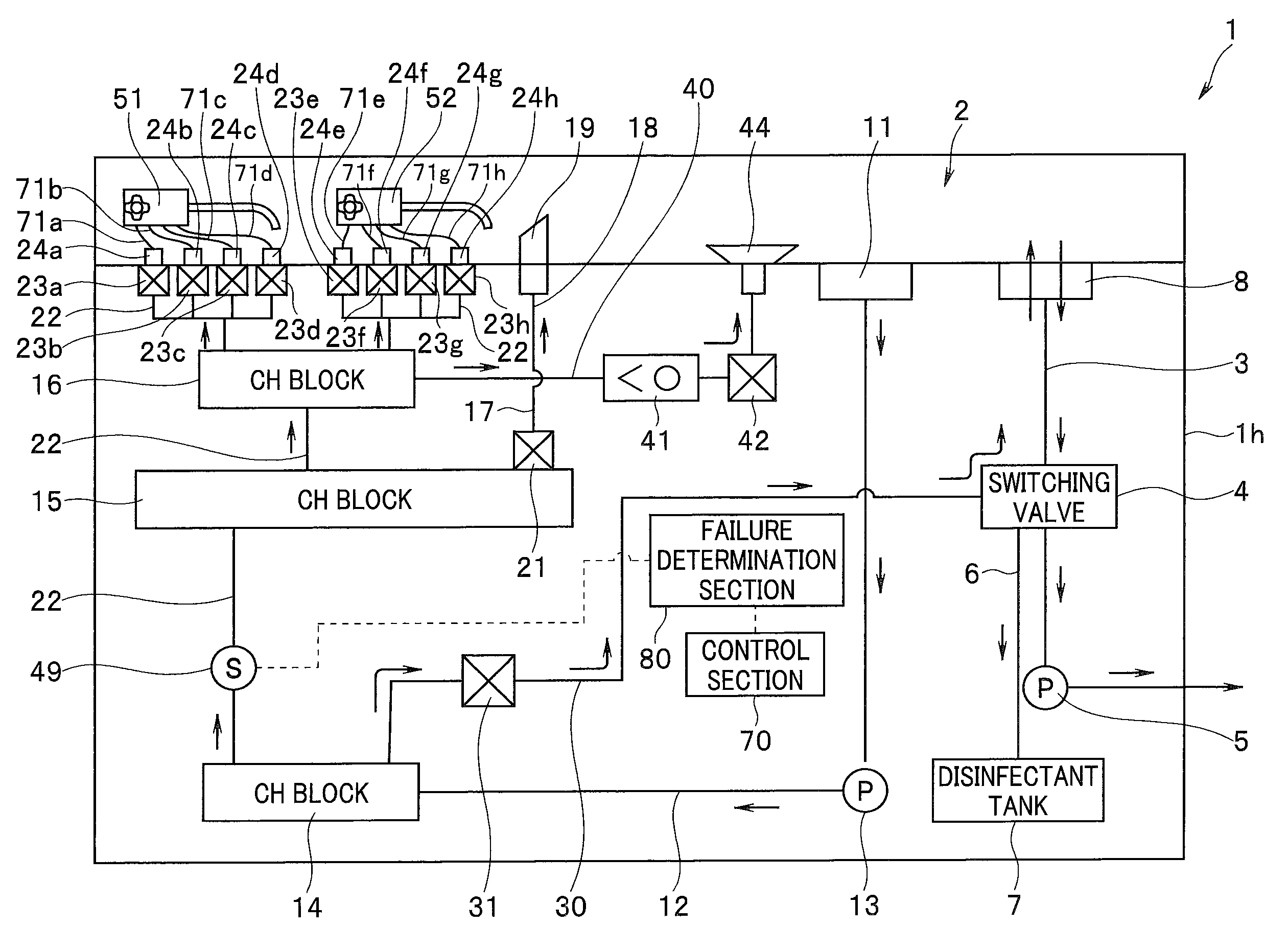

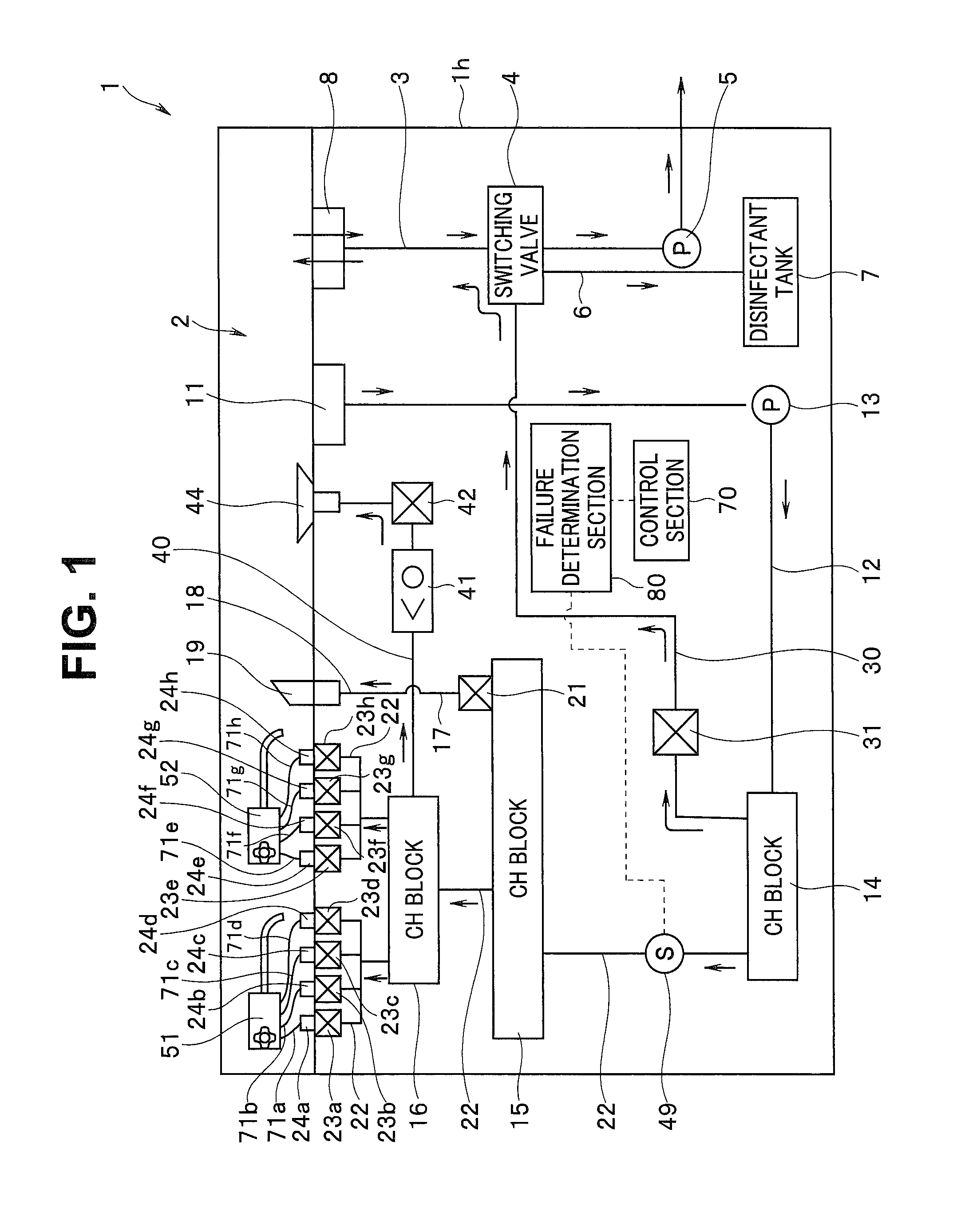

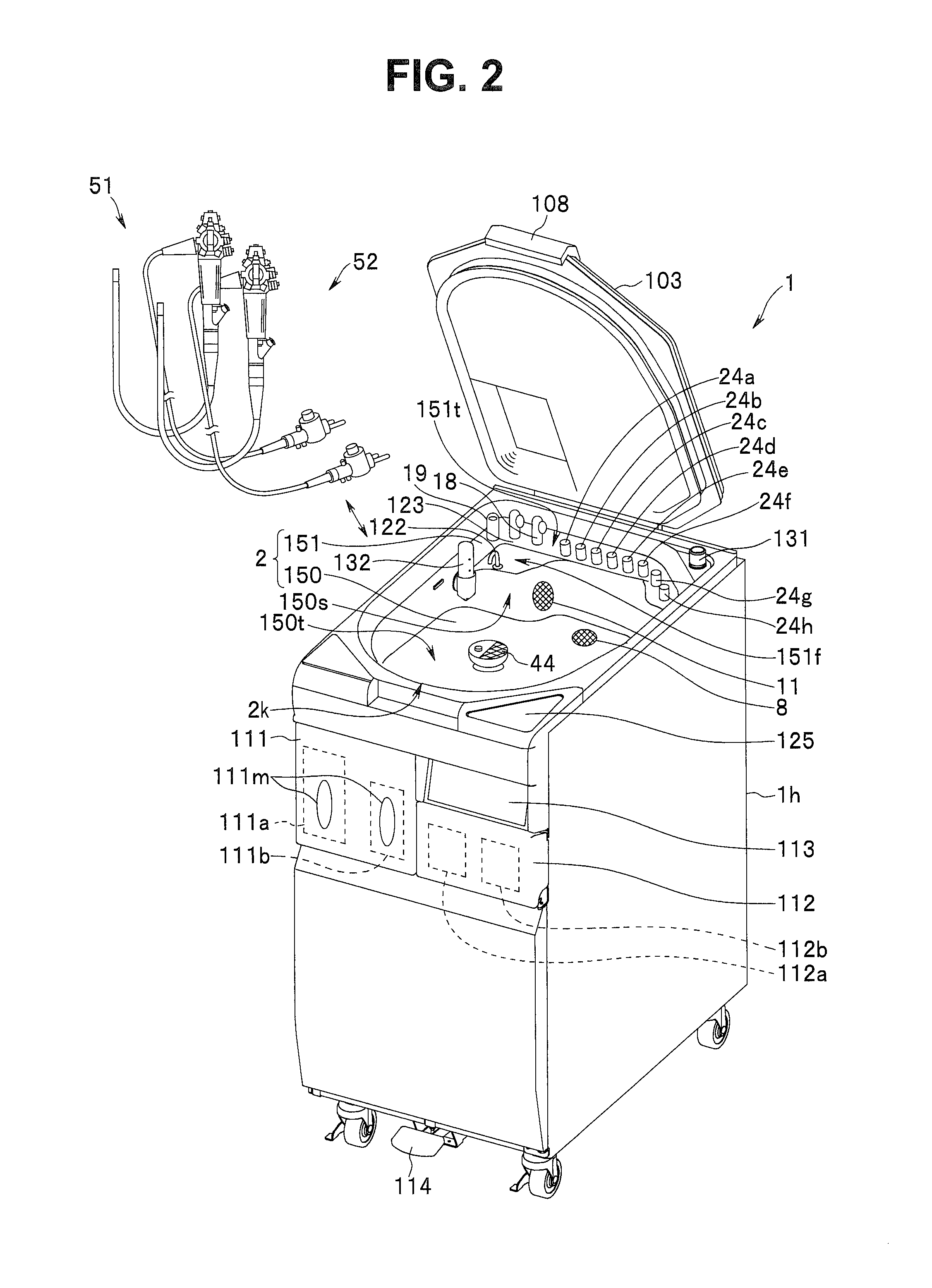

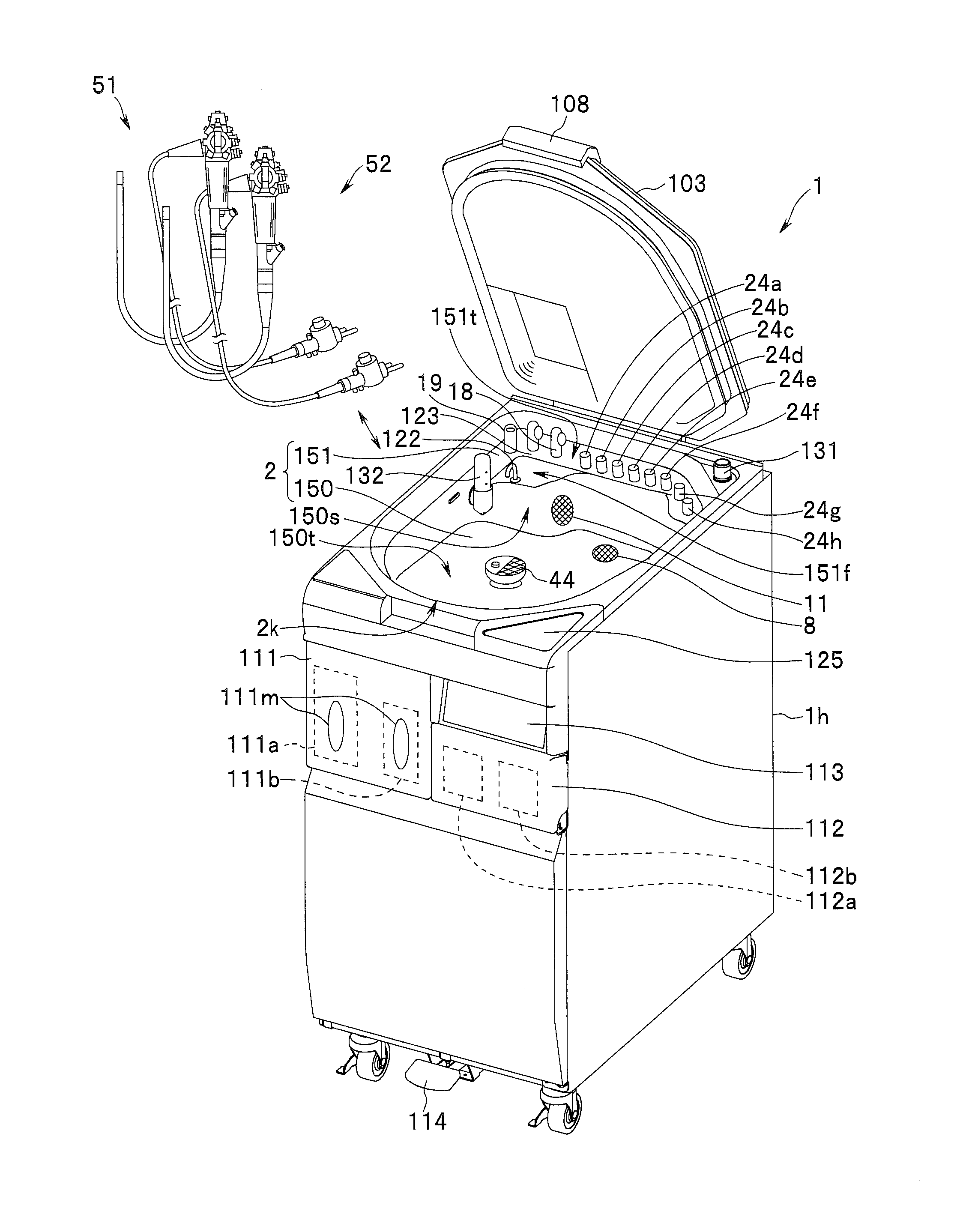

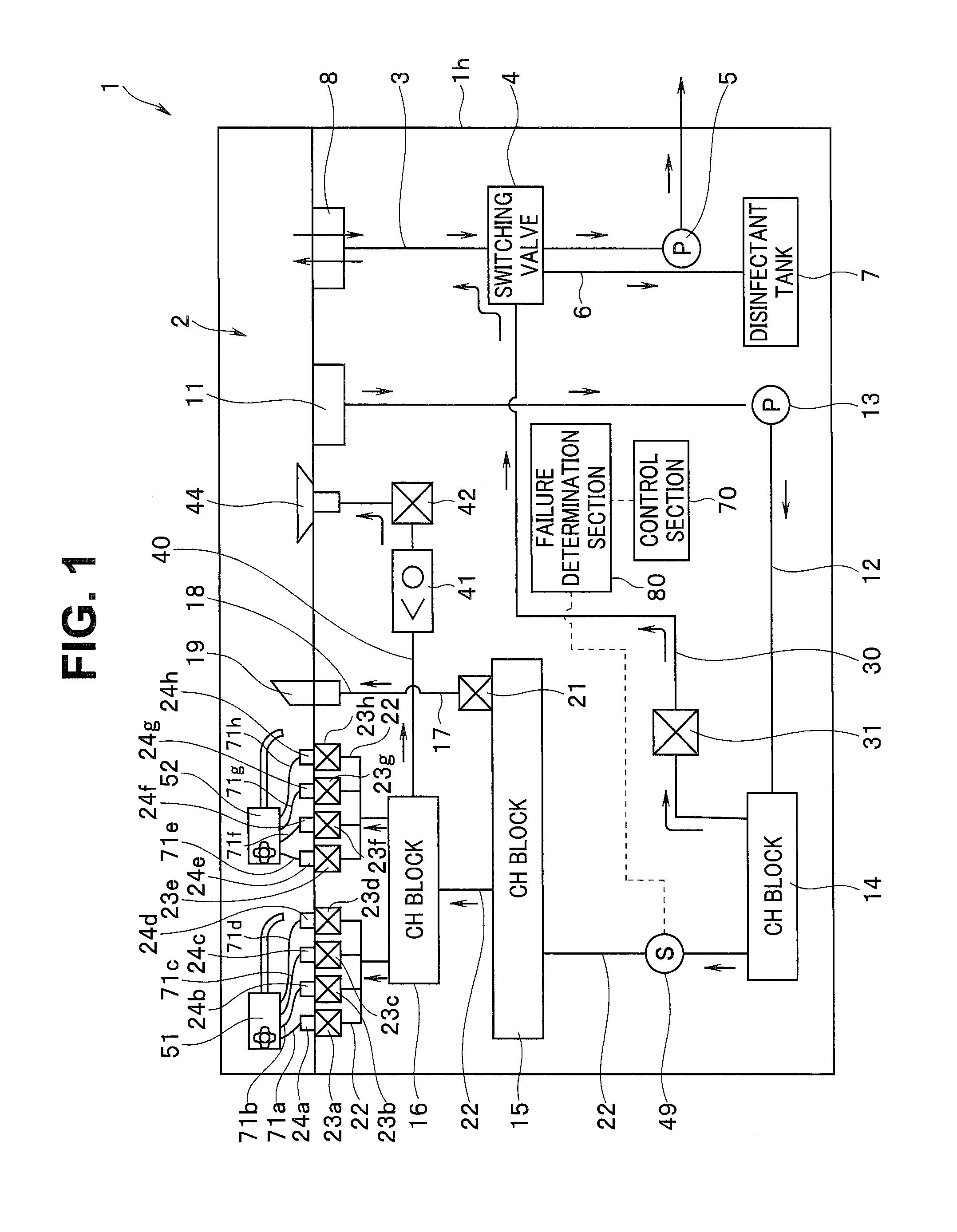

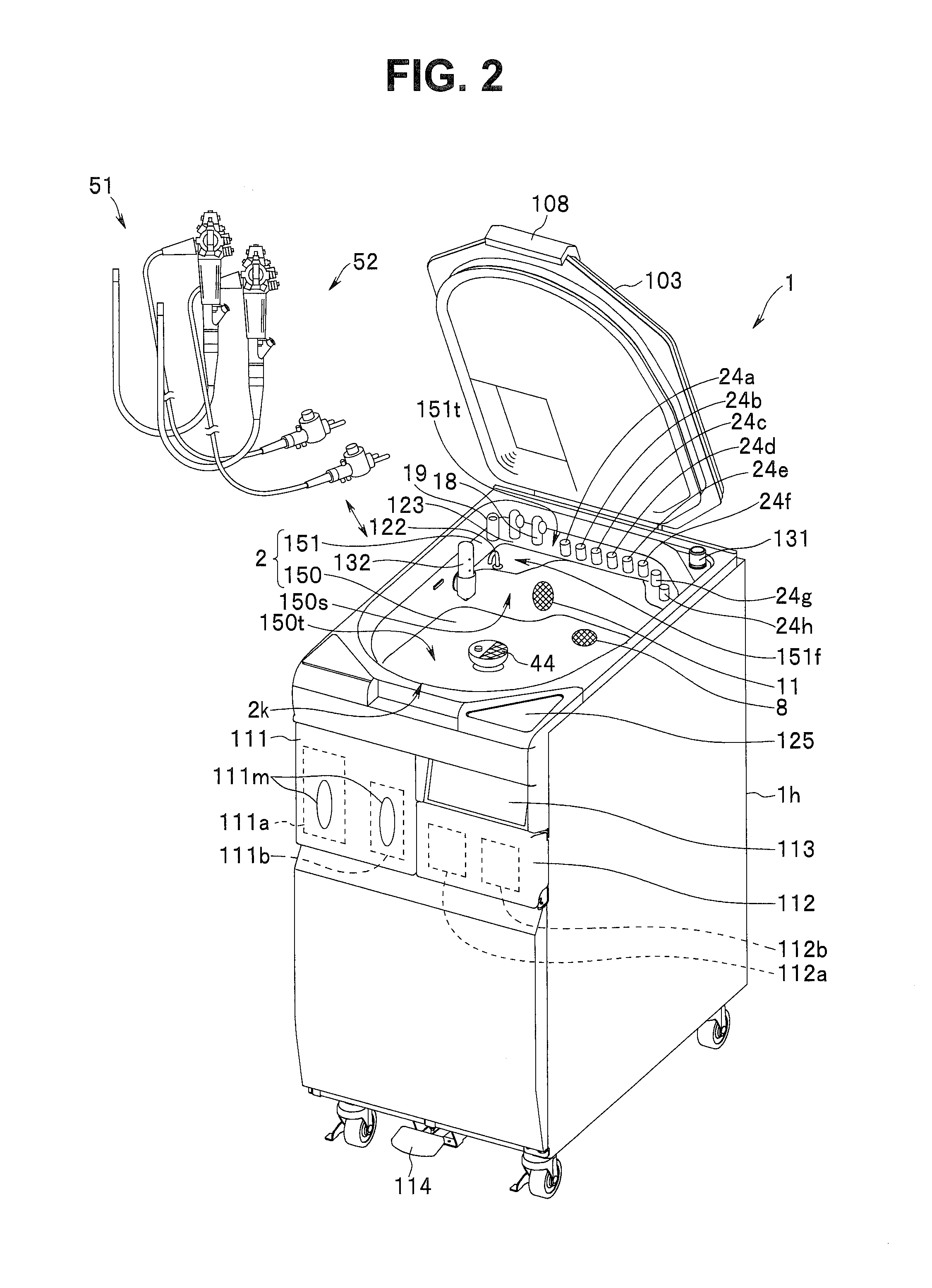

Endoscope cleaning/disinfecting apparatus

Endoscope connection portions, a fluid feeding duct, a liquid supply duct, a pump, a first atmospheric exposure duct including one end connected to the fluid feeding duct and the other end exposed to atmosphere, a relief valve disposed at an intermediate position of the first atmospheric exposure duct, a first stop section disposed at an intermediate position of the first atmospheric exposure duct, and a control section that performs control to supply a liquid to ducts of endoscopes and controls at least opening / closing operation of the first stop section are included.

Owner:OLYMPUS CORP

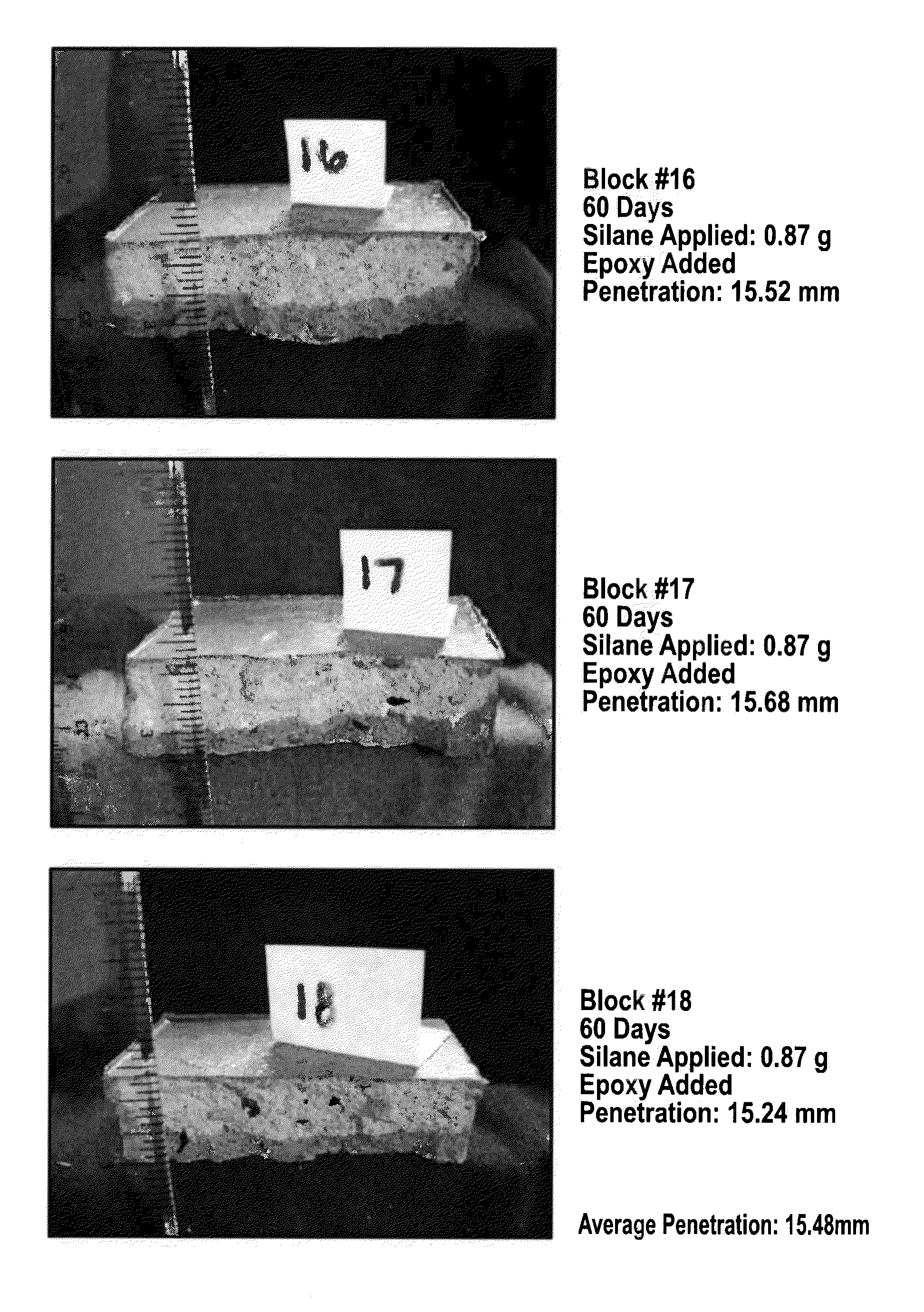

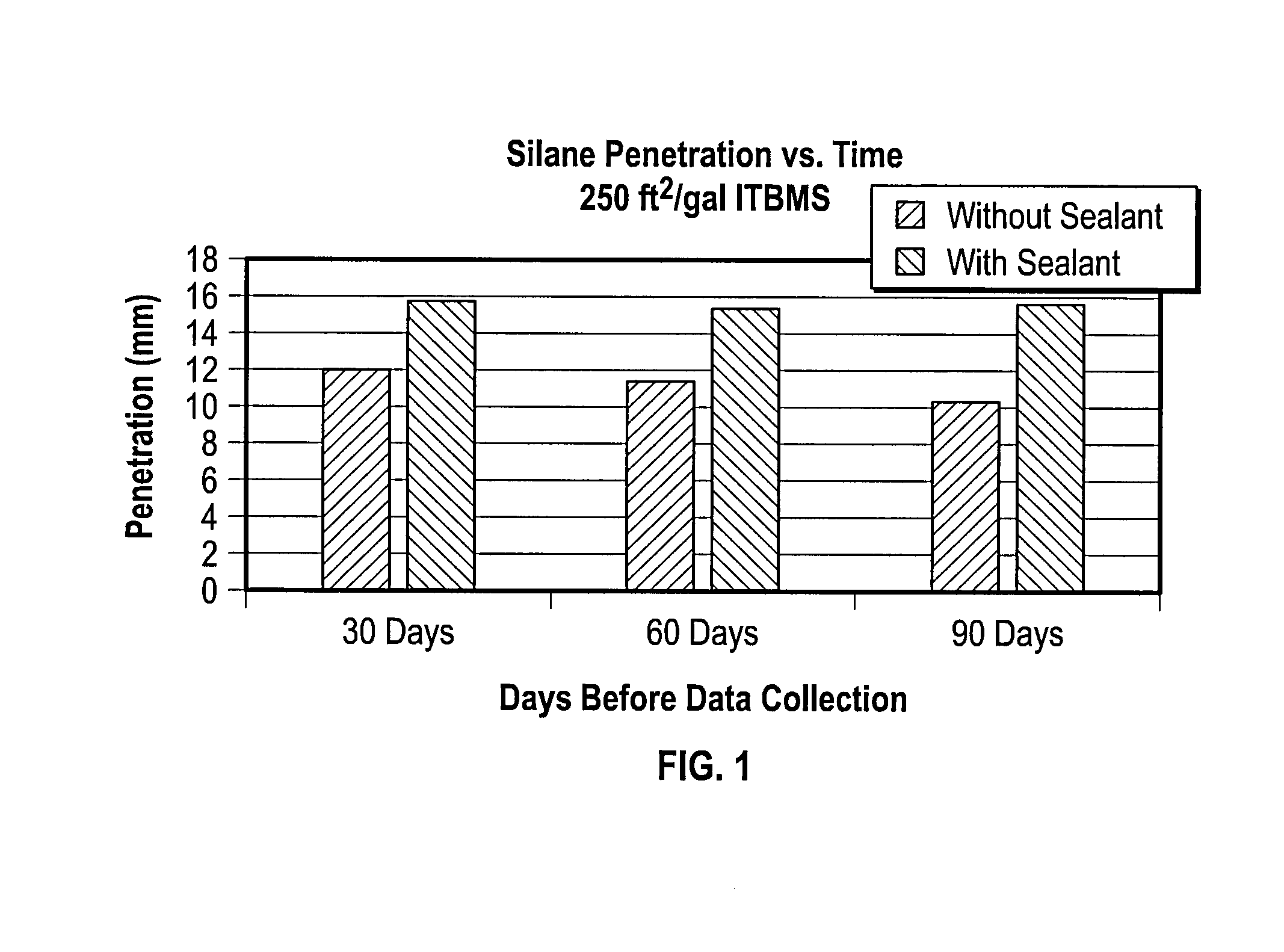

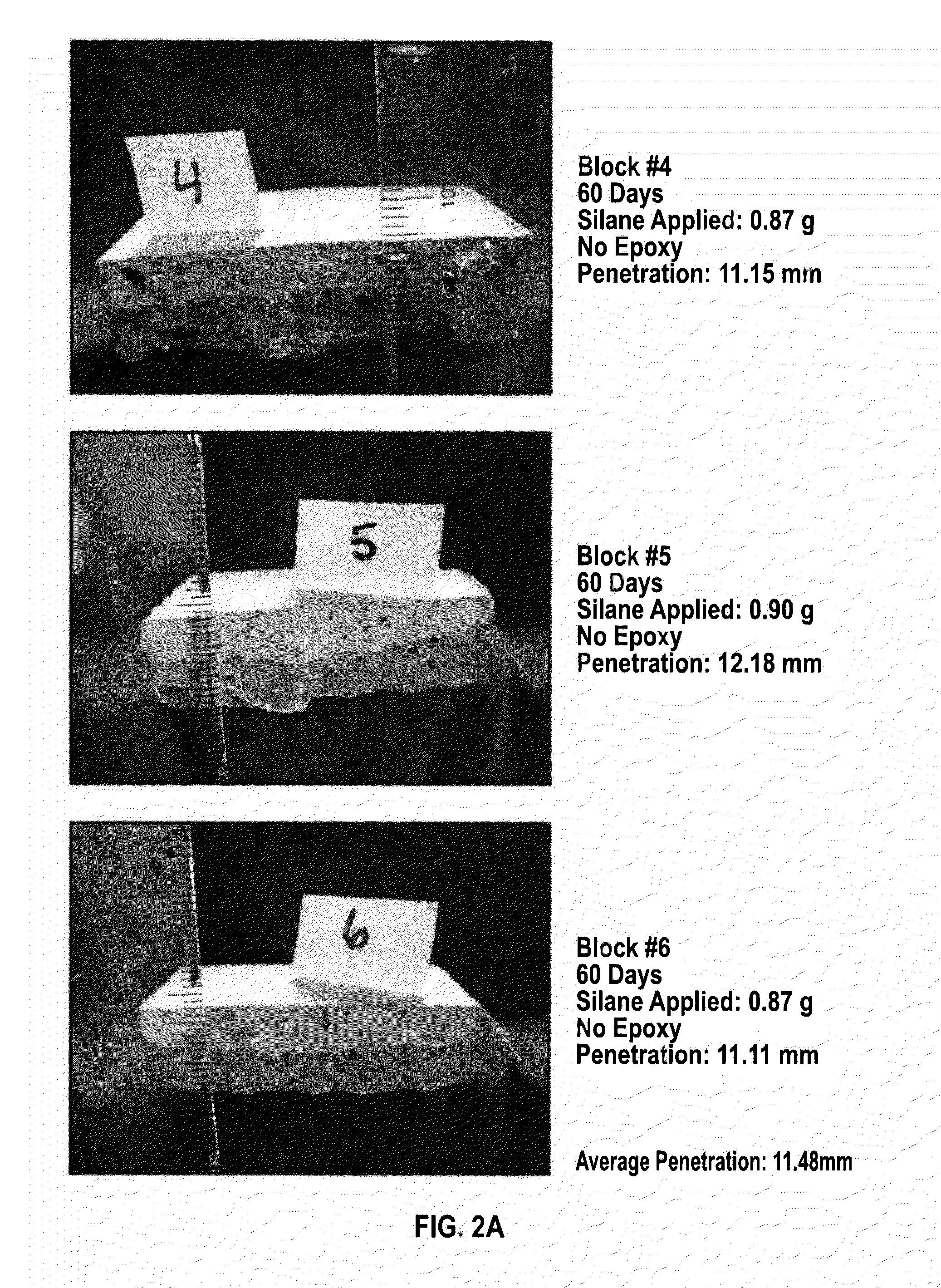

System And Method For Extending The Service Life Of Concrete Structures

ActiveUS20140314961A1Reduce atmospheric exposureCost-effectiveAnti-corrosive paintsSpecial surfacesCoated surfaceSilicon

A cost-effective process for treating a concrete structure includes the following steps. A surface of the concrete structure is coated with an organo-silicon compound and the organo-silicon coated surface is covered so as to reduce atmospheric exposure of the organo-silicon compound while the organo-silicon compound migrates into the concrete structure.

Owner:ADVANCED CHEM TECH

Preparation method of filaments for weather-resistant plastic woven bags

InactiveCN107973982AImprove physical performanceImprove compatibilityConjugated synthetic polymer artificial filamentsArtifical filament manufacturePolymer scienceFiltration

The invention belongs to the technical field of materials for plastic woven bags, and in particular relates to a preparation method of filaments for weather-resistant plastic woven bags. The method comprises the steps of preparing raw materials, preparing mixed powder, carrying out melt filtration on the raw materials, extruding to obtain a film, cooling with water, splitting into filaments, drawing the filaments and winding. Compared with the prior art, the preparation method provided by the invention has the advantages that the physical properties of the obtained woven bags can be better improved by proportioning the raw materials with different molecular weights; the compatibility of the materials can be improved due to the use of silane-grafted polyethylene; wollastonite powder is processed, and other raw materials are cooperatively used, so that the weather resistance of the material can be improved; in outdoor atmospheric exposure tests, the physical properties are maintained well; the plastic woven bags made by using the filaments have better oxidation resistance and anti-sunburn property, and are solid, durable and long in service life.

Owner:太和县亚美达塑业有限公司

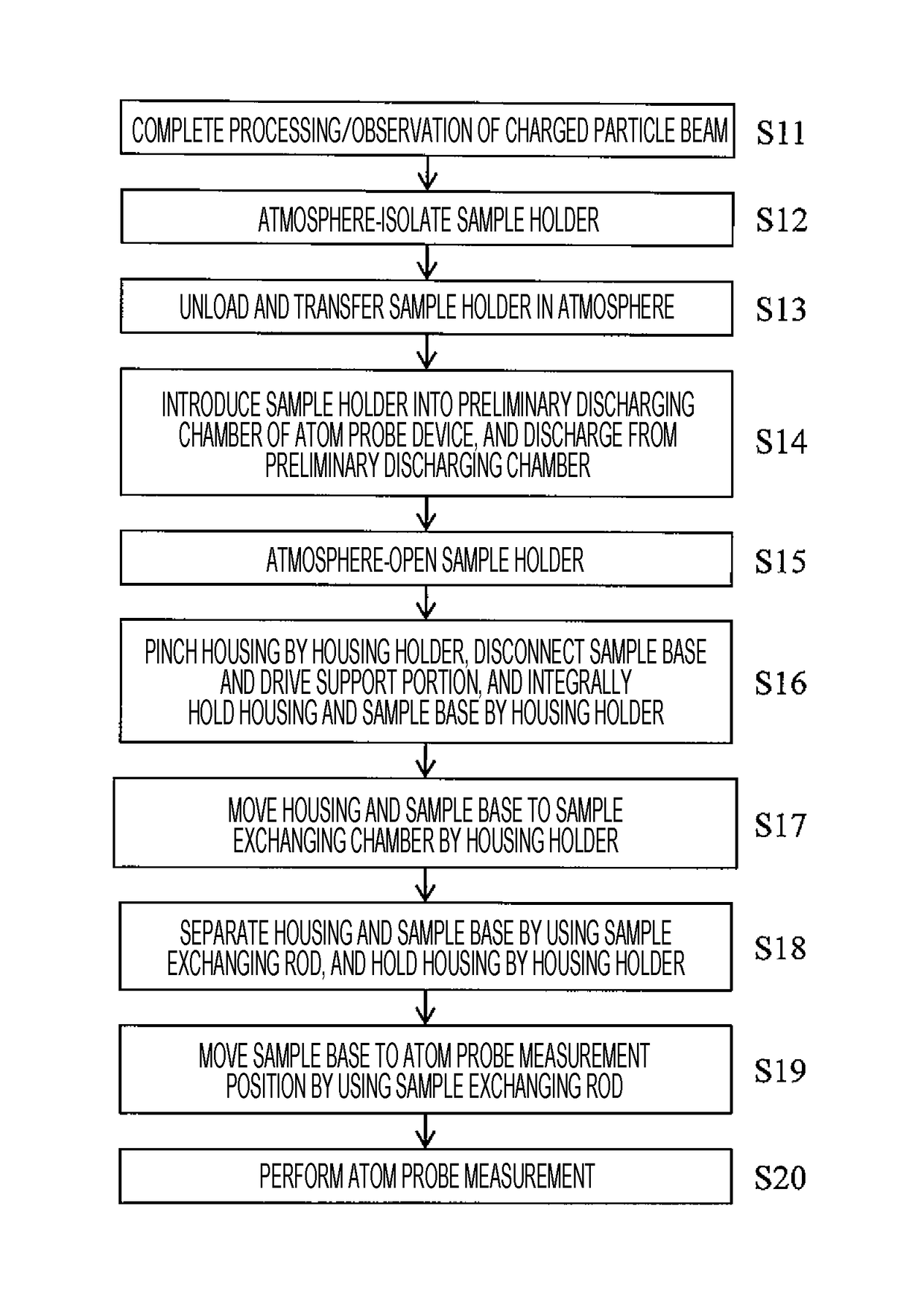

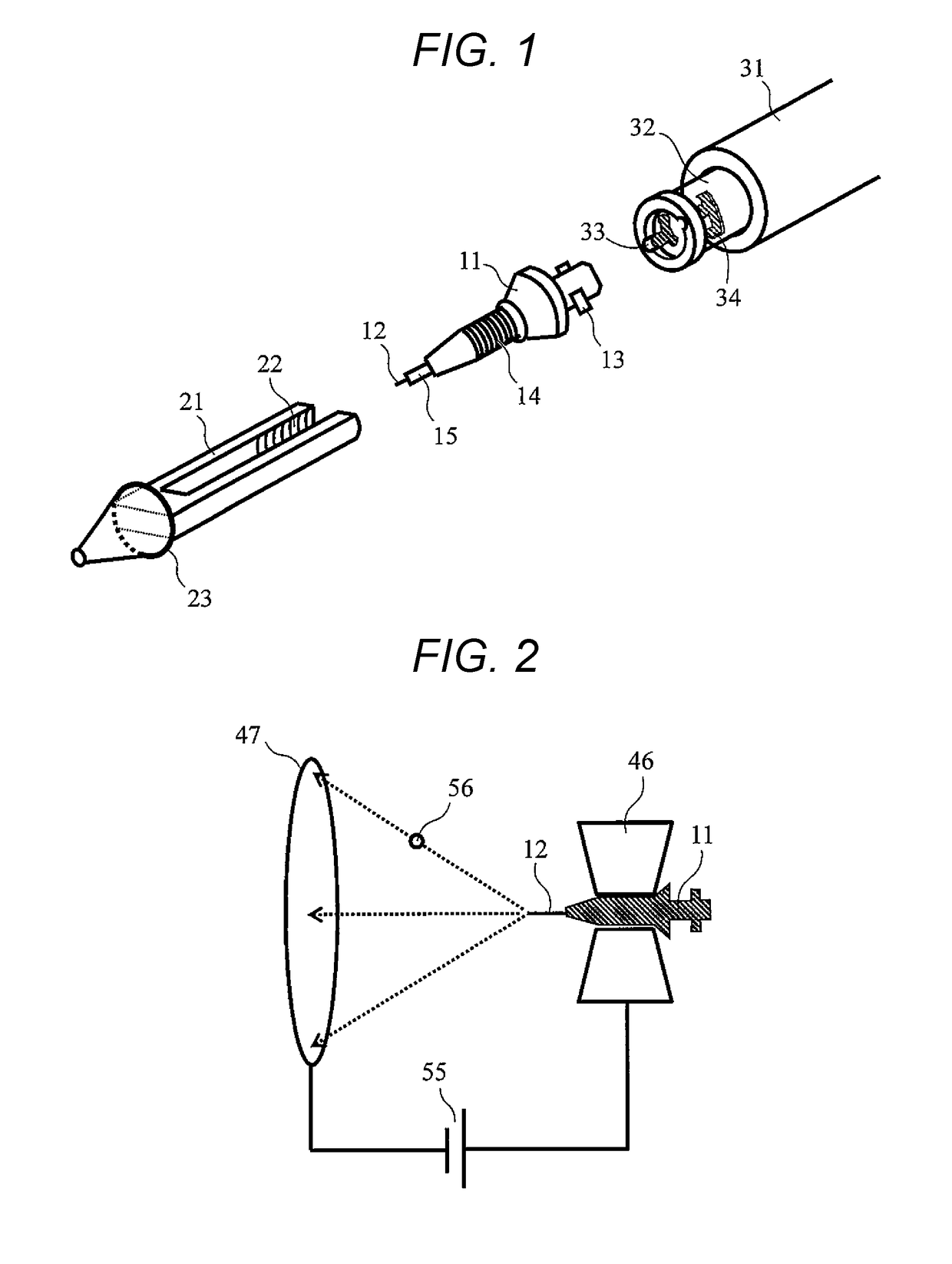

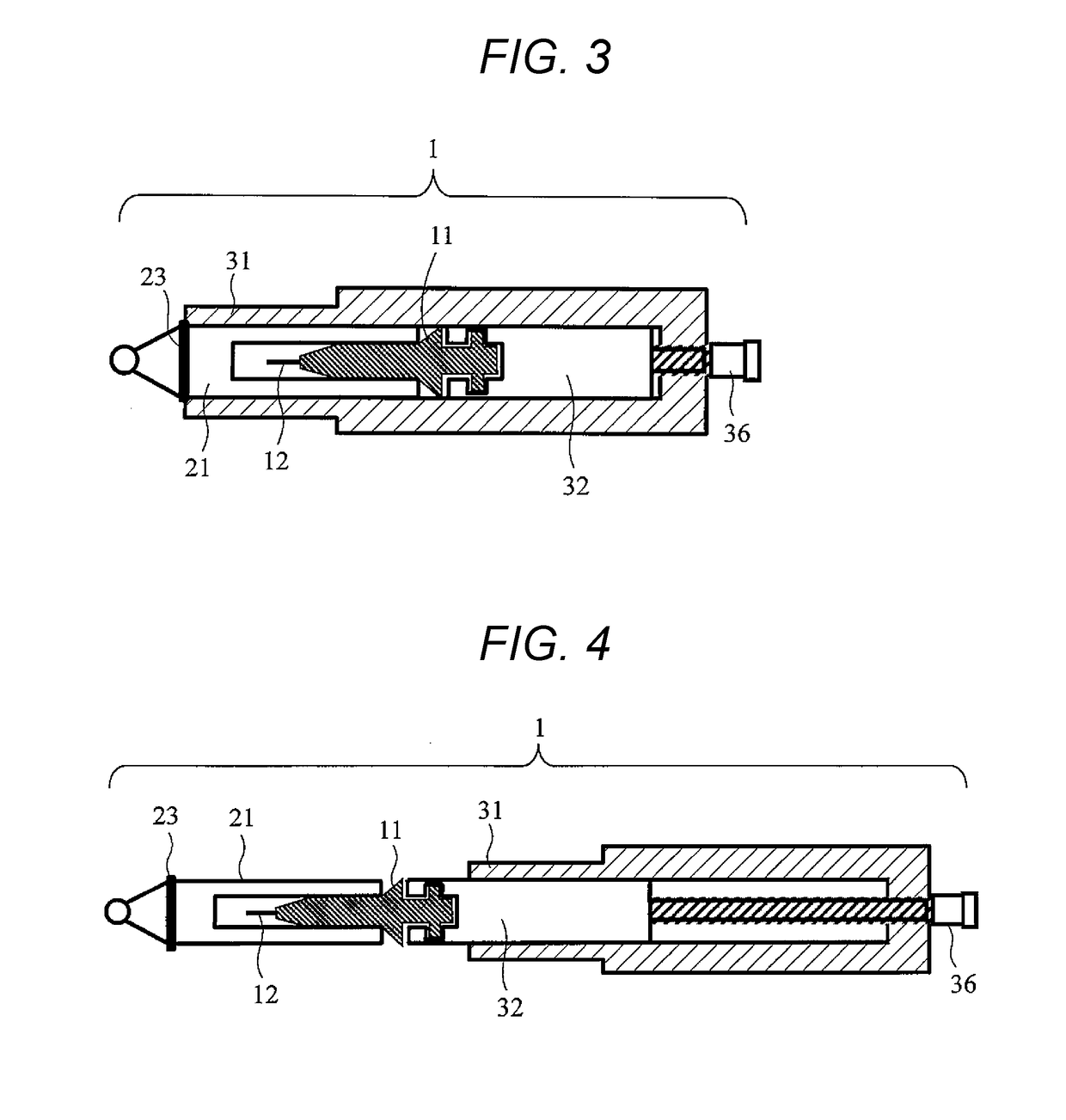

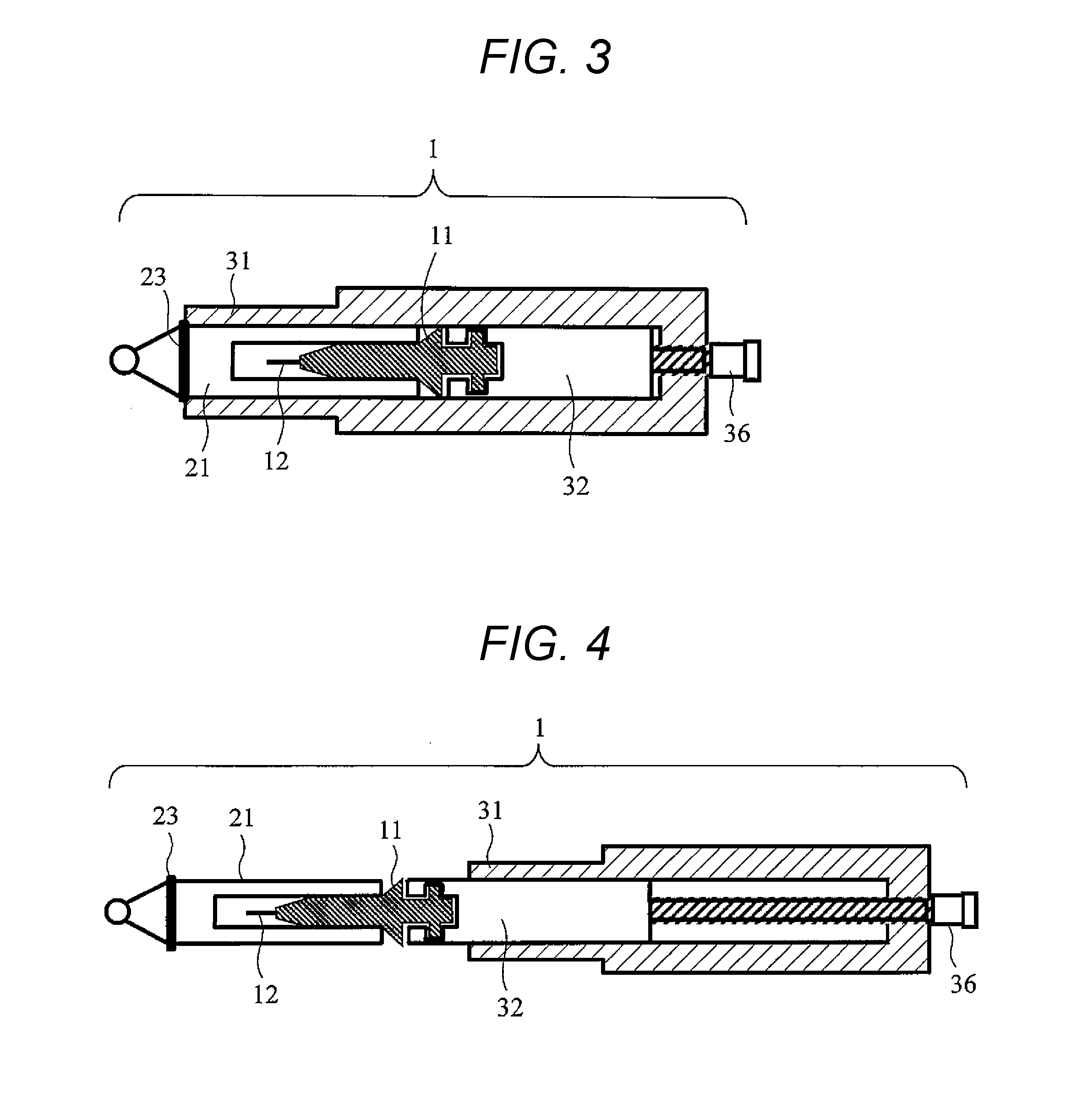

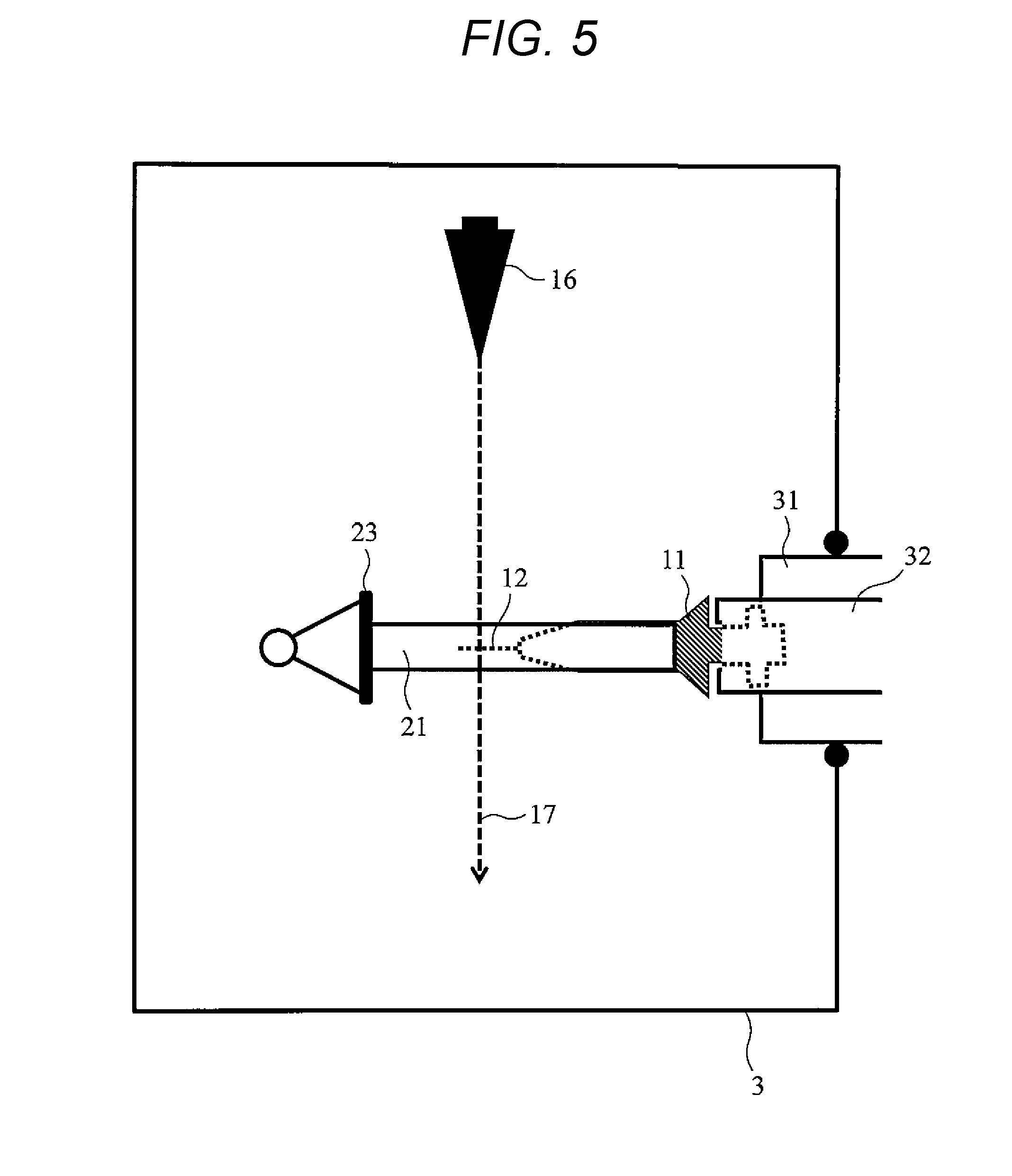

Sample holder and analytical vacuum device

ActiveUS9875878B2Sample transferringSecure and easyElectric discharge tubesMaterial analysis by measuring secondary emissionElectron microscopeAtom probe

Sample transferring can be securely and easily performed between an FIB device, an electron microscope, and an atom probe device, and atom probe analysis can be performed to a material that easily alters due to atmospheric exposure. A sample holder that holds a sample (12) is provided with an atmosphere-isolation mechanism that prevents the sample from altering due to the atmospheric exposure upon the sample transferring between the devices. There is provided a structure enabling of attaching and detaching a housing (21) of a sample holder leading end of a part of the atmosphere-isolation mechanism in an analytical vacuum device, such as the atom probe device.

Owner:HITACHI LTD

Sample holder and analytical vacuum device

ActiveUS20170004952A1Easy to changeSample transferringMaterial analysis using wave/particle radiationElectric discharge tubesElectron microscopeAtom probe

Sample transferring can be securely and easily performed between an FIB device, an electron microscope, and an atom probe device, and atom probe analysis can be performed to a material that easily alters due to atmospheric exposure. A sample holder that holds a sample (12) is provided with an atmosphere-isolation mechanism that prevents the sample from altering due to the atmospheric exposure upon the sample transferring between the devices. There is provided a structure enabling of attaching and detaching a housing (21) of a sample holder leading end of a part of the atmosphere-isolation mechanism in an analytical vacuum device, such as the atom probe device.

Owner:HITACHI LTD

CMOS Transistor Junction Regions Formed By A CVD Etching And Deposition Sequence

The invention adds to the art of replacement source-drain CMOS transistors. Processes may involve etching a recess in the substrate material using one equipment set, then performing deposition in another. Disclosed is a method to perform the etch and subsequent deposition in the same reactor without atmospheric exposure. In-situ etching of the source-drain recess for replacement source-drain applications provides several advantages over state of the art ex-situ etching. Transistor drive current is improved by: (1) Eliminating contamination of the silicon-epilayer interface when the as-etched surface is exposed to atmosphere and (2) Precise control over the shape of the etch recess. Deposition may be done by a variety of techniques including selective and non-selective methods. In the case of blanket deposition, a measure to avoid amorphous deposition in performance critical regions is also presented.

Owner:INTEL CORP

Endoscope cleaning/disinfecting apparatus

Endoscope connection portions, a fluid feeding duct, a liquid supply duct, a pump, a first atmospheric exposure duct including one end connected to the fluid feeding duct and the other end exposed to atmosphere, a relief valve disposed at an intermediate position of the first atmospheric exposure duct, a first stop section disposed at an intermediate position of the first atmospheric exposure duct, and a control section that performs control to supply a liquid to ducts of endoscopes and controls at least opening / closing operation of the first stop section are included.

Owner:OLYMPUS CORP

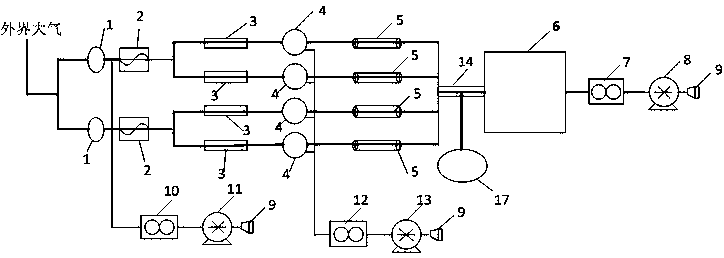

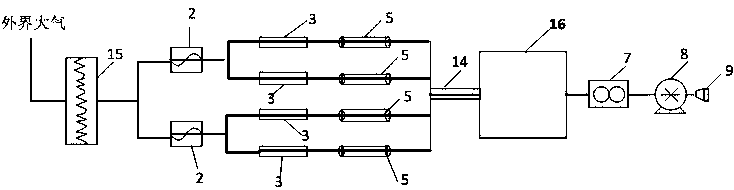

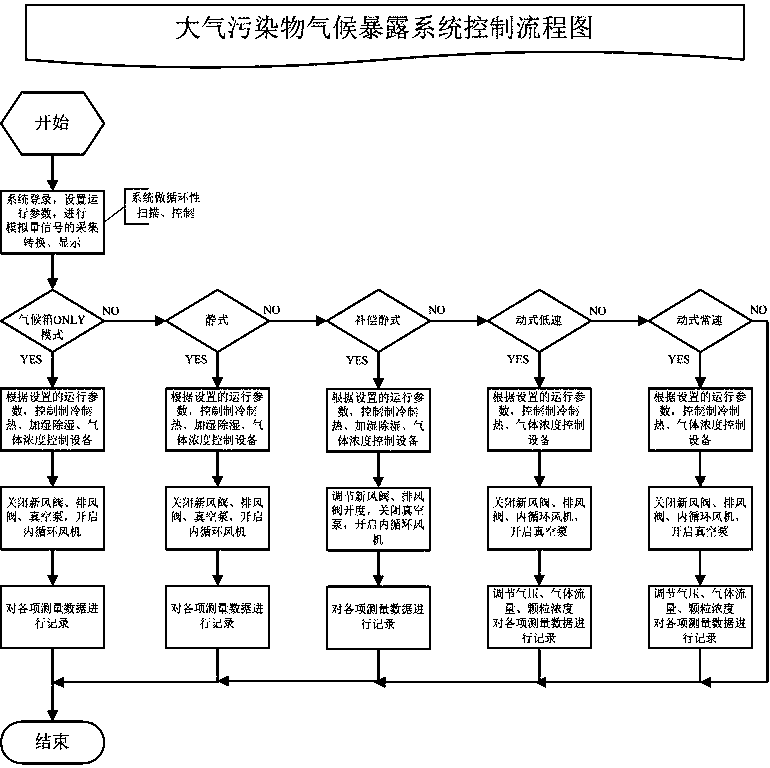

A kind of artificial climate environment exposure system and application method

ActiveCN105136619BDifferent densityConcentration fold changeMaterial analysisSuspended particlesSystems design

The invention discloses an artificial climate environment exposure system and an application method. The system includes aerosol collection and concentration, harmful gas mixing, temperature and humidity adjustment, exposure box and control box and various auxiliary equipment, providing an efficient and cumulative animal experiment suitable for aerosol particles and harmful gas exposure The environmental control system combines the collection of aerosol particles with multi-factor control of the warehouse-style artificial climate environment. The system is designed with a combination of various environmental factors, and has a variety of experimental functions to achieve the effect of one machine with multiple functions. It can be used not only to study the exposure of atmospheric suspended particles to animals, but also to study harmful gases and environmental climate factors. For the exposure effect of animals, the synergistic exposure effect of the three can also be studied.

Owner:长三角环境气象预报预警中心 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com