Experimental method for corrosion resistance of steel bar used in concrete structure in tropical marine atmospheric environment

A concrete structure and experimental method technology, applied in the direction of weather resistance/light resistance/corrosion resistance, test sample preparation, sampling, etc., can solve the problems of deviation, long field exposure test cycle, low scientific research efficiency, etc., to reduce errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

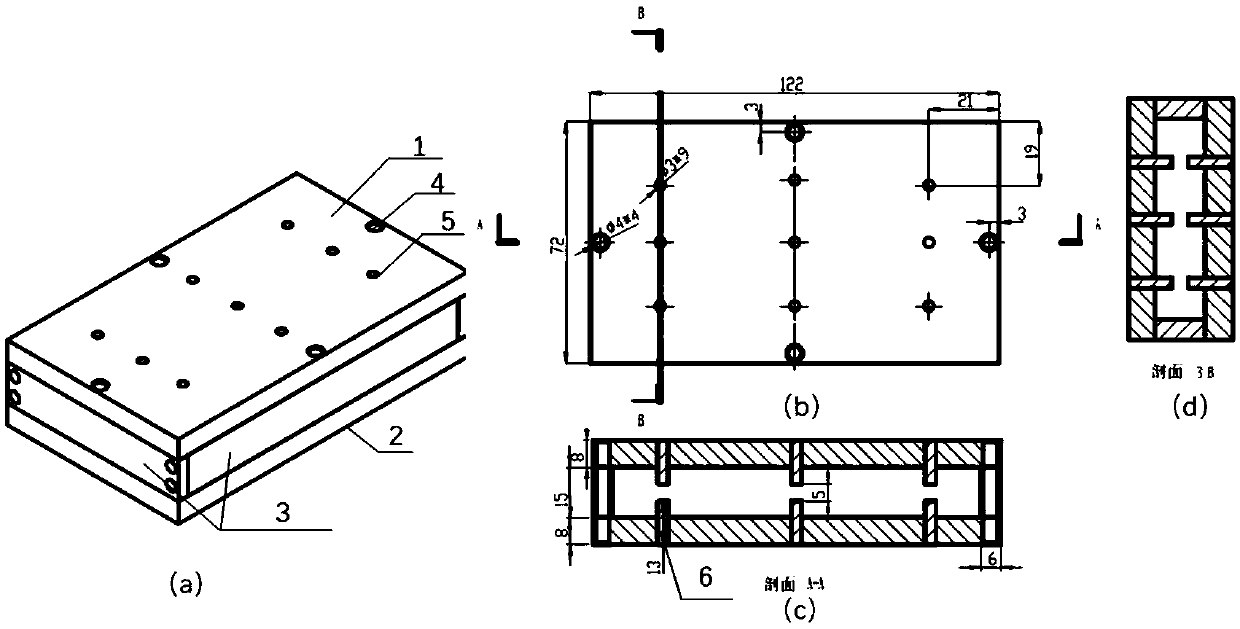

Method used

Image

Examples

Embodiment 1

[0056] Example 1 Thailand Coastal A Experimental Station

[0057] The prepared two reinforced concrete samples were subjected to the on-site atmospheric exposure test with reference to the standard GB11112-89, and the test site was the A experimental station in the coastal area of Thailand. The annual average temperature of the area where the experimental station is located is 29-31°C, the relative humidity is 80-90%RH, the rainfall is 1500-2000mm, and the radiation is 96-120mW / m 2 . The test time was 7 months. After the test, the reinforced concrete samples were taken back, and the surface concrete was removed to observe the macroscopic corrosion morphology. Then, the corrosion products were removed from the samples according to GB / T16545-1996, and the corrosion rate and average corrosion depth were obtained.

[0058] The results of corrosion rate and average corrosion depth of the two steel bar samples are shown in Table 2. The macroscopic corrosion morphology of the oth...

Embodiment 2

[0061] Example 2 Thailand coastal B experimental station

[0062] The prepared reinforced concrete samples were subjected to the on-site atmospheric exposure test with reference to the standard GB11112-89, and the test site was the B experimental station along the coast of Thailand. The annual average temperature of the area where the experimental station B is located is 28-30°C, the relative humidity is 75-85%RH, the rainfall is 1200-1500mm, and the radiation is 90-115mW / m 2 . The test time was 7 months. After the test, the reinforced concrete samples were taken back, and the surface concrete was removed to observe the macroscopic corrosion morphology. Then, the corrosion products were removed from the samples according to GB / T16545-1996, and the corrosion rate and average corrosion depth were obtained.

[0063] The results of corrosion rate and average corrosion depth of the two steel bar samples are shown in Table 3. The macroscopic corrosion morphology of the other two s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com