A Probe for On-Line Monitoring of High Temperature Pipeline Wall Thickness

A technology for monitoring probes and pipeline walls, applied in measuring devices and instruments, using ultrasonic/sonic/infrasonic waves, etc., can solve the problems of reducing ultrasonic signal intensity, corrosion of oil refining equipment, and inability to contact high-temperature pipelines for a long time, to improve stability. performance and accuracy, avoid safety hazards, and reduce production costs

Active Publication Date: 2018-07-06

SHENYANG ZKWELL CORROSION CONTROL TECH

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, with the processing of a large amount of high-sulfur crude oil, the corrosion of refinery equipment is becoming more and more serious, especially in high-temperature environments, the sulfur in crude oil is prone to severe high-temperature sulfur corrosion, which will cause great safety hazards to production

For high temperature corrosion monitoring, existing methods have certain limitations. For example, the working temperature of the resistance probe method cannot be higher than 240°C. Although the temperature of the inductance probe method can reach 430°C, the measurement accuracy and sensitivity are also very good. , but it needs to be installed on the pipeline, and it is relatively troublesome to disassemble and install the probe

High-temperature artificial fixed-point ultrasonic thickness measurement has certain flexibility and accuracy, but it also has certain shortcomings. First, it requires people to enter the device for detection, and human safety needs to be considered; second, the continuous temperature resistance of the thickness measurement probe Poor, can not contact high-temperature pipes for a long time, and the high-temperature couplant will evaporate instantly, so the measurement must be completed within a few seconds, which will bring inconvenience to manual measurement operations in high-temperature areas

Furthermore, due to differences in the operation of the instrument by different surveyors, the continuity of the thickness measurement data at the same point is poor, which cannot well reflect the change trend of the pitting corrosion

Thickness measurement can also be carried out with the thin and long waveguide method, but the echo signal is weak, the distortion is serious, and there are many clutters, which makes the follow-up measurement processing relatively complicated, and it is difficult to achieve high-precision thickness measurement

In addition, the slender tape waveguide is not good for high temperature heat dissipation, and the effect of high temperature is simply extended by extending its physical length. The increase in length will further reduce the ultrasonic signal strength, which directly affects the accuracy and stability of thickness measurement.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0031] This example is to measure the pipe wall of a 430°C high-temperature pipeline, the thickness is 10mm, and the thickness measurement used is

[0032] The frequency of the probe is 2-10MHz, and the diameter of the probe chip is 13mm. The experiment was carried out for 4 weeks.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

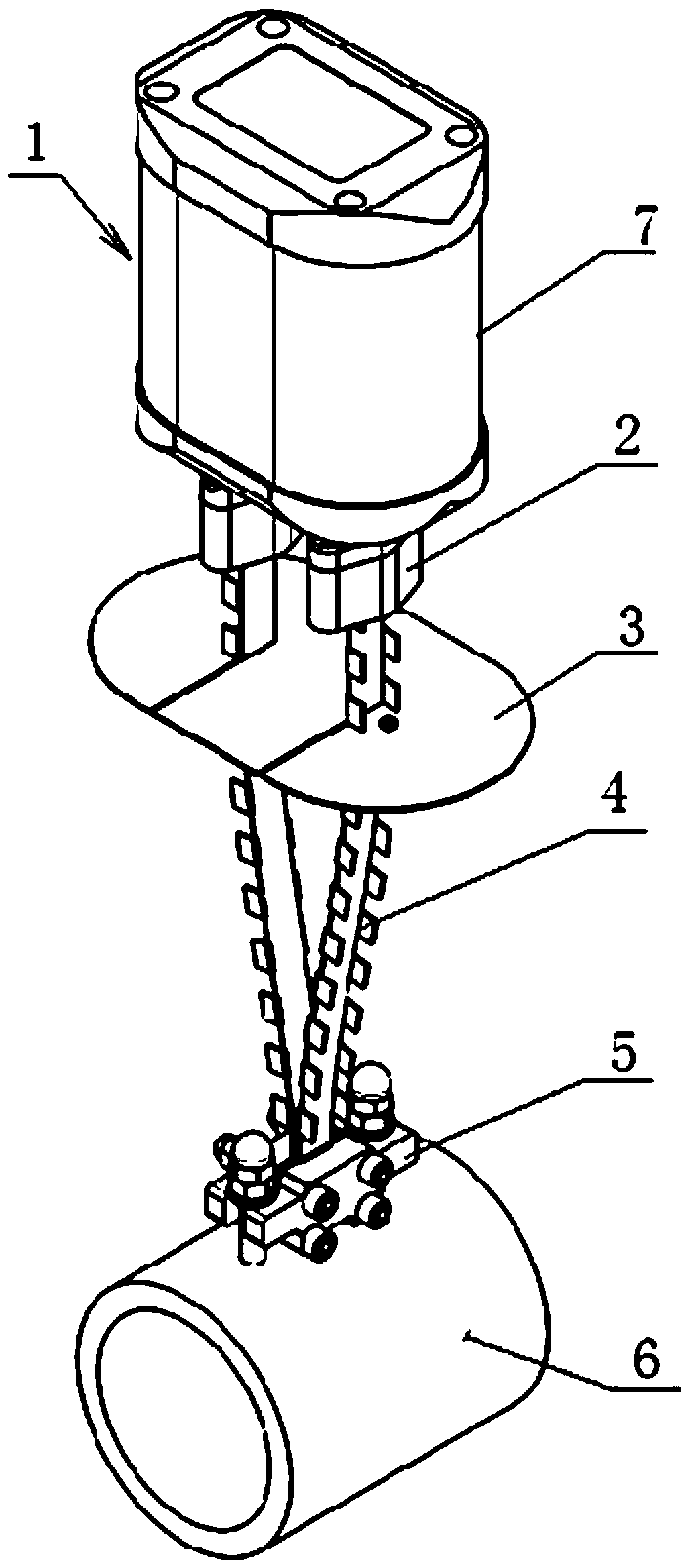

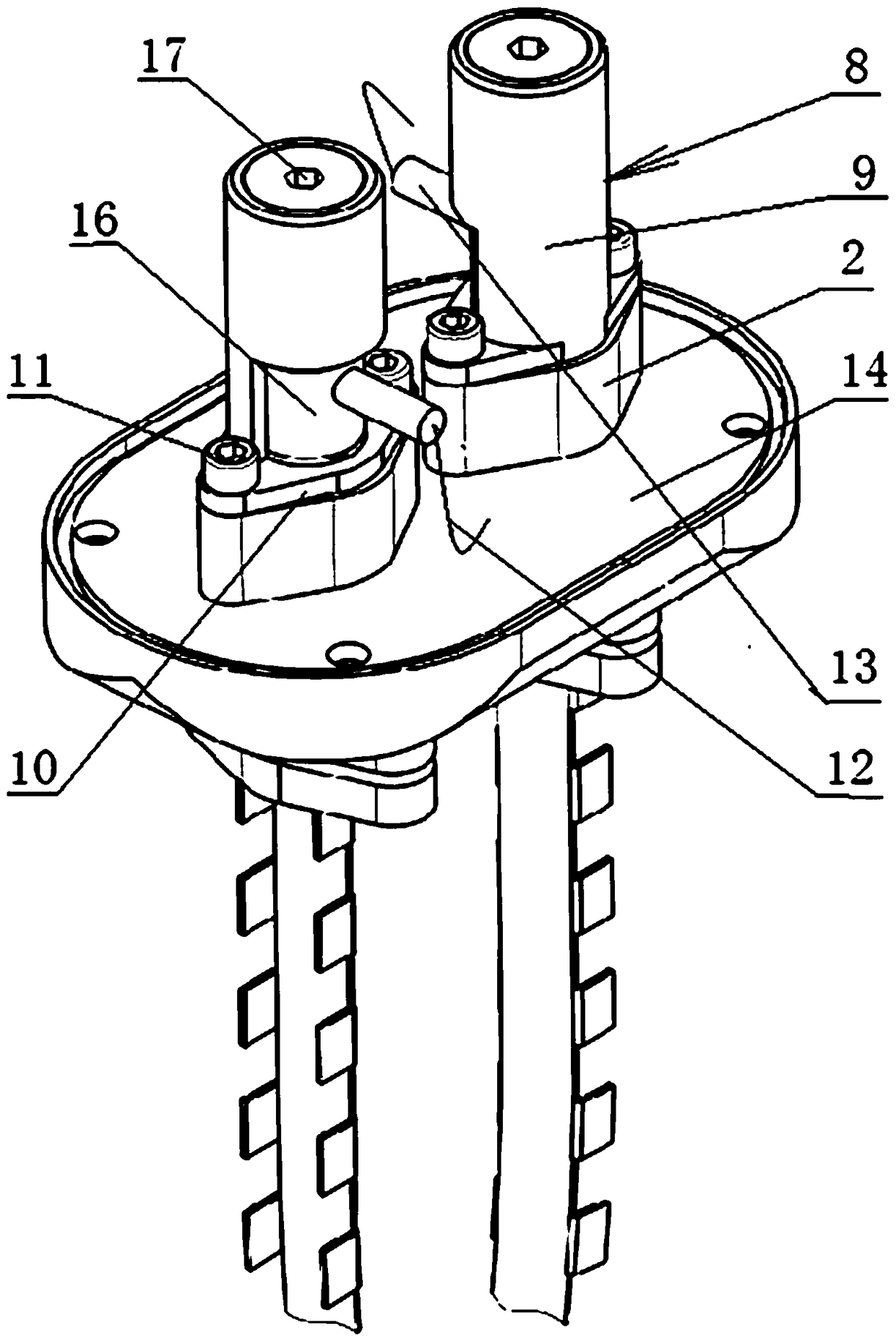

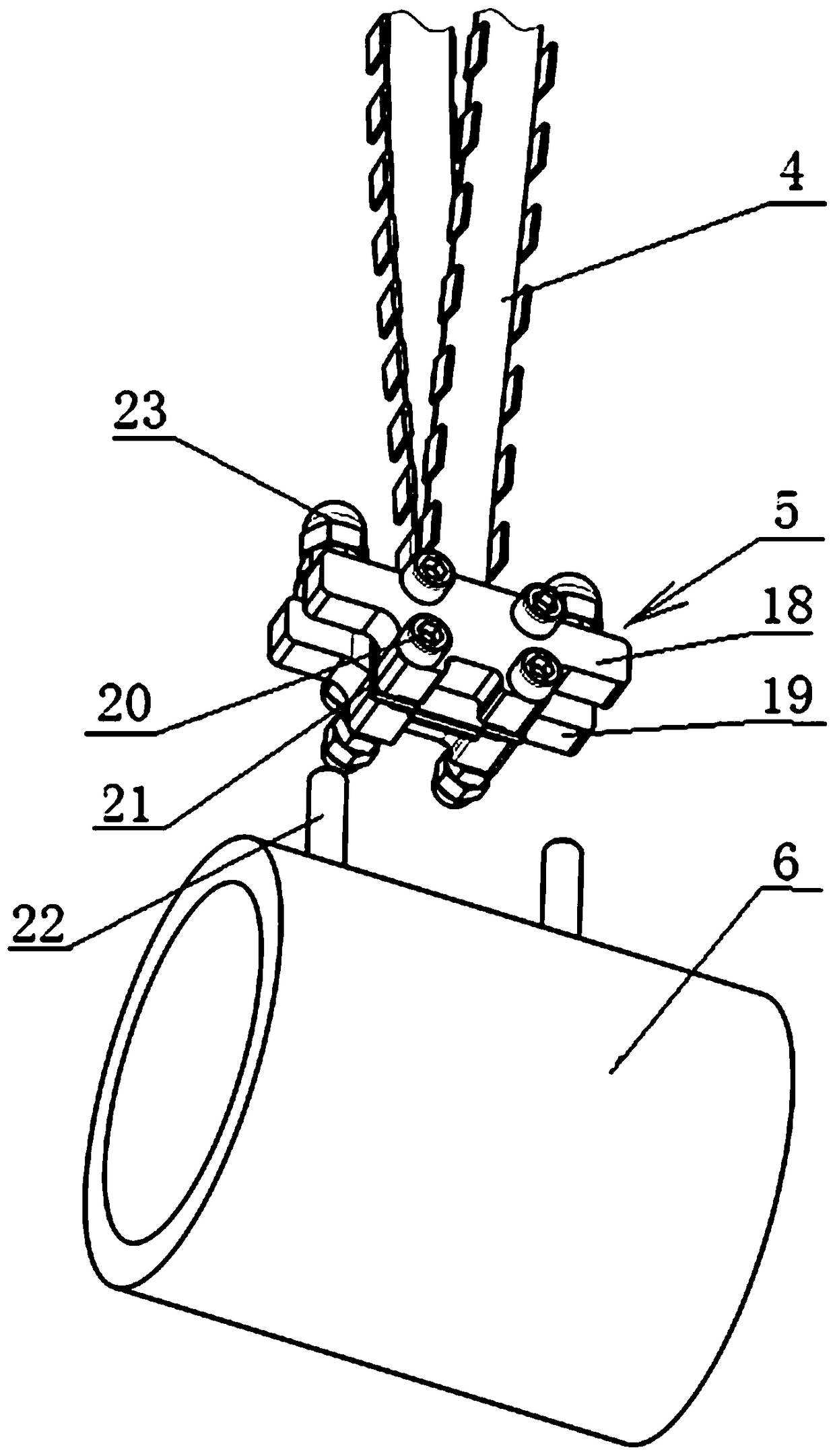

The invention discloses an online high temperature-resisting pipeline wall thickness monitoring probe, which comprises an ultrasonic thickness monitoring host, embedded fixtures, a heat insulation baffle, dentate waveguide plates, a dentate waveguide fixture, and a high temperature pipeline, wherein the dentate waveguide fixture is composed of a front fixture plate and a rear fixture plate; bottom ends of the two dentate waveguide plates are respectively embedded in dentate waveguide plate clamping grooves of the front fixture plate and the rear fixture plate, and the dentate waveguide plates are firmly clamped and fixed via four bolts distributed; fixed stud passing openings are arranged at two end sides of the dentate waveguide fixture, fixed studs are correspondingly welded on the high temperature pipeline, and thus the dentate waveguide fixture is fixed on the high temperature pipeline via the fixed studs and nuts; upper ends of the two dentate waveguide plates pass through the heat insulation baffle respectively and are then embedded on the two embedded fixtures; and the two dentate waveguide plates are connected with two ultrasonic probes of the ultrasonic thickness monitoring host via the two embedded fixtures. No hole drilling needs to be carried out on the pipeline, assembly and disassembly are convenient, the operation is safe and reliable, and particularly, measurement stability and precision are improved.

Description

technical field [0001] The invention relates to nondestructive on-line monitoring equipment, in particular to an on-line monitoring probe for high-temperature-resistant pipeline wall thickness used in oil refinery equipment and high-temperature pipelines in oil refineries. Background technique [0002] At present, with the processing of a large amount of high-sulfur crude oil, the corrosion of refinery equipment is becoming more and more serious. Especially in high-temperature environments, the sulfur in crude oil is prone to severe high-temperature sulfur corrosion, which will cause great safety hazards to production. For high-temperature corrosion monitoring, existing methods have certain limitations. For example, the working temperature of the resistance probe method cannot be higher than 240°C. Although the temperature of the inductance probe method can reach 430°C, the measurement accuracy and sensitivity are also very good. , but it needs to be installed on the pipelin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01B17/02

CPCG01B17/02

Inventor 郑丽群周光森呼立红

Owner SHENYANG ZKWELL CORROSION CONTROL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com