Online evaluation device and evaluation method for mountainous area gas collecting pipeline corrosion inhibitor coating effect

A technology for gas-gathering pipelines and evaluation devices, which is applied to measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., and can solve the problem that the corrosion inhibitor coating film effect of gas-gathering pipelines in mountainous areas cannot be regularly evaluated, and corrosion inhibitors cannot be evaluated Concentration distribution, effective migration distance of corrosion inhibitor, adjustment of corrosion inhibitor operation plan, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

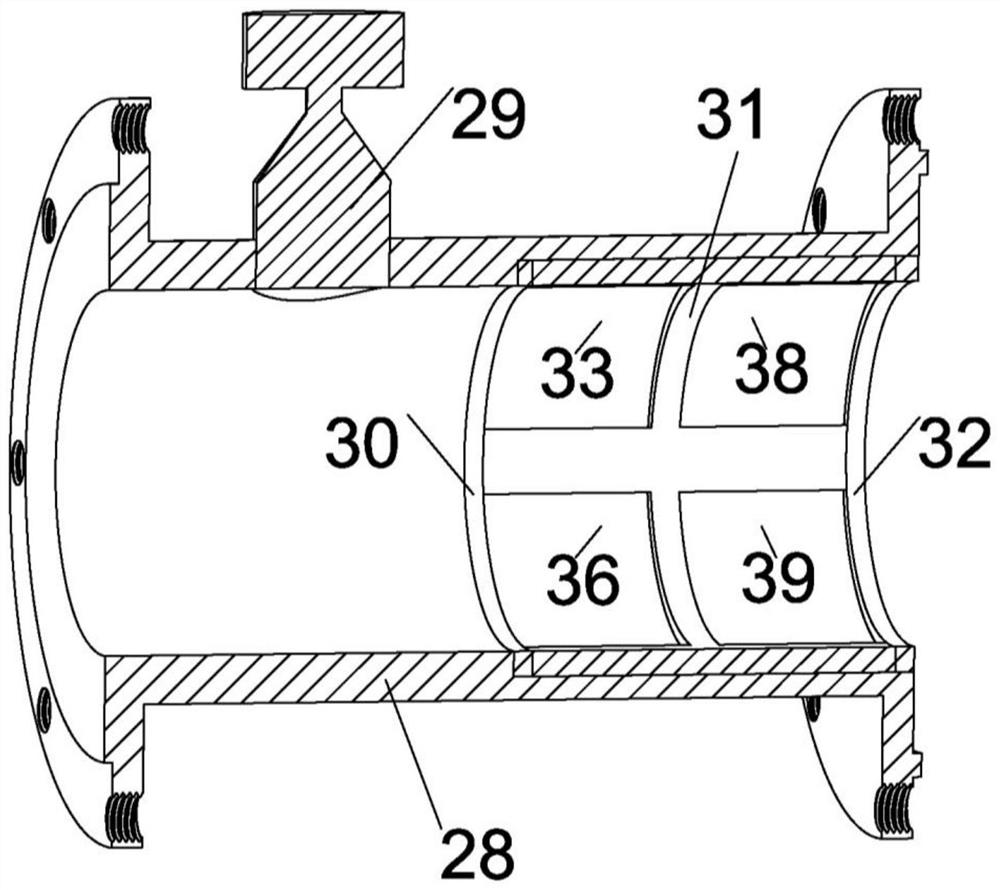

[0040] An online evaluation device for the coating effect of corrosion inhibitors for gas-gathering pipelines in mountainous areas, such as figure 1 As shown, it includes a serving tube (4), an uphill elbow front pipeline (8), a mountainous uphill pipeline (9), a mountainous downhill pipeline (10), a downhill elbow rear pipeline (11), a ball receiving cylinder ( 5), purge valve, vent valve, sewage valve, sewage buffer tank (53); the pipeline (8) before the uphill elbow is provided with a 1# monitoring pipe section (28) and a bypass pipeline is provided at the corresponding position, The mountainous uphill pipeline (9) is provided with a 2# monitoring pipe section (49) and a bypass pipeline at the corresponding position, and the mountainous downhill pipeline (10) is provided with a 3# monitoring pipe section (50) and a bypass pipeline is provided at the corresponding position Pipeline, after the downhill bend, the pipeline (11) is provided with a 4# monitoring pipe section (51)...

Embodiment 2

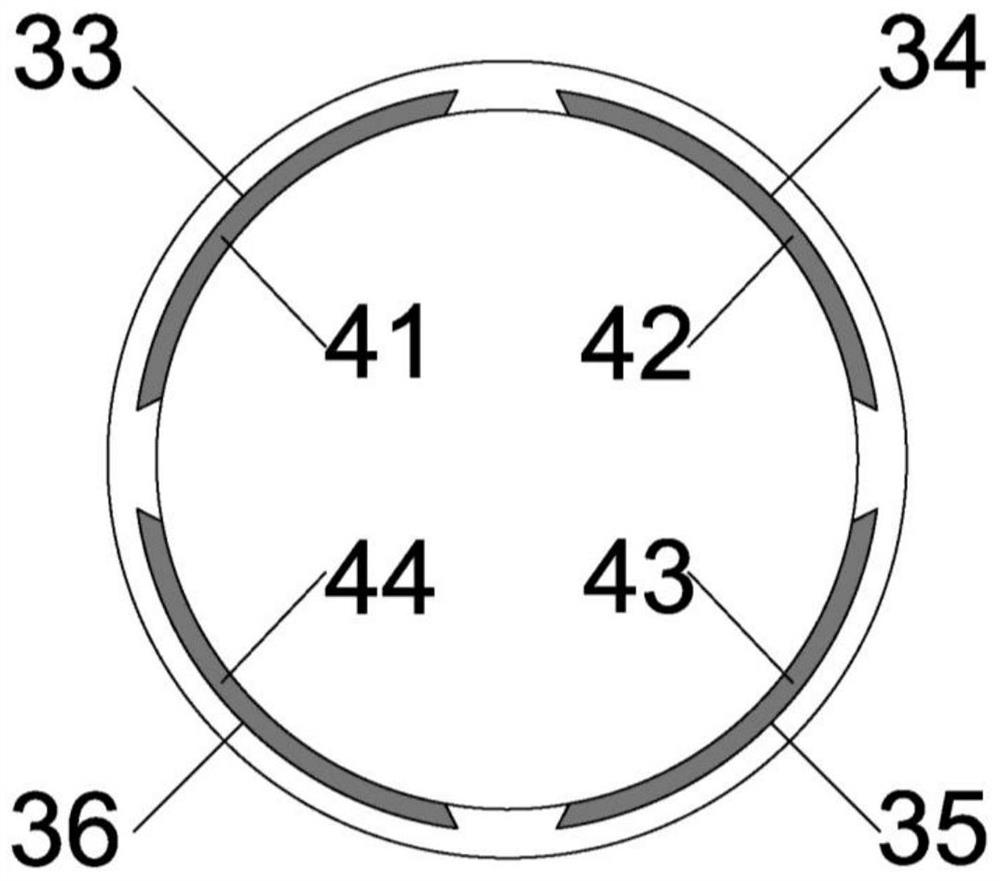

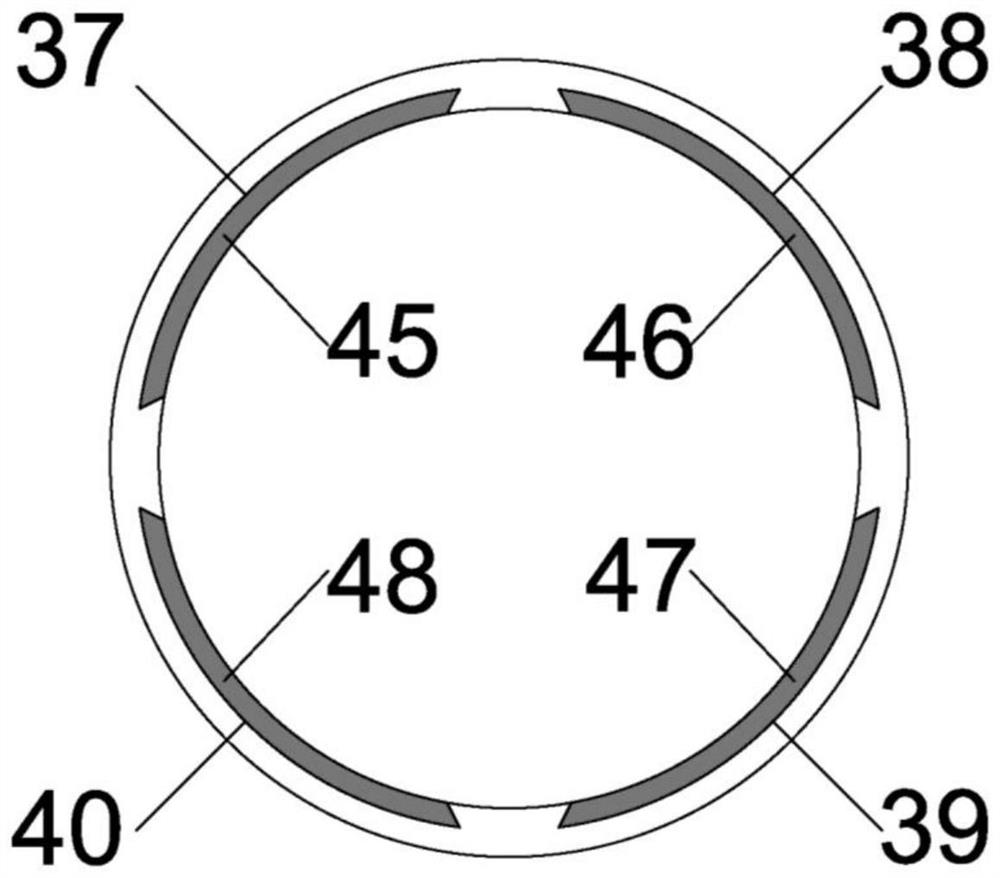

[0058] An online evaluation device for the coating effect of corrosion inhibitors in gas-gathering pipelines in mountainous areas is basically the same as in Example 1, except that 1# monitoring pipe section (28), 2# monitoring pipe section (49), and 3# monitoring pipe section The internal diameter d of the first half of the pipe section (50) and the 4# monitoring pipe section (51) 1 is 311.1mm, and the inner diameter of the second half is d 2 It is 317.5mm, and the inner diameter difference between the two is equal to the wall thickness δ of the cage test piece fixture (31) and is 6.4mm. The test piece clamp (24) is seamlessly inserted into the second half of the monitoring pipe section. A resistance probe (29) is arranged on the top of the first half of the monitoring pipe section (28), and the monitoring surface of the resistance probe (29) is flush with the inner wall of the pipe.

[0059] The two ends of the cage-shaped test piece fixture (31) are provided with a left g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Uniform corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com