Preparation method of hyperbranched polyphenylene sulfide

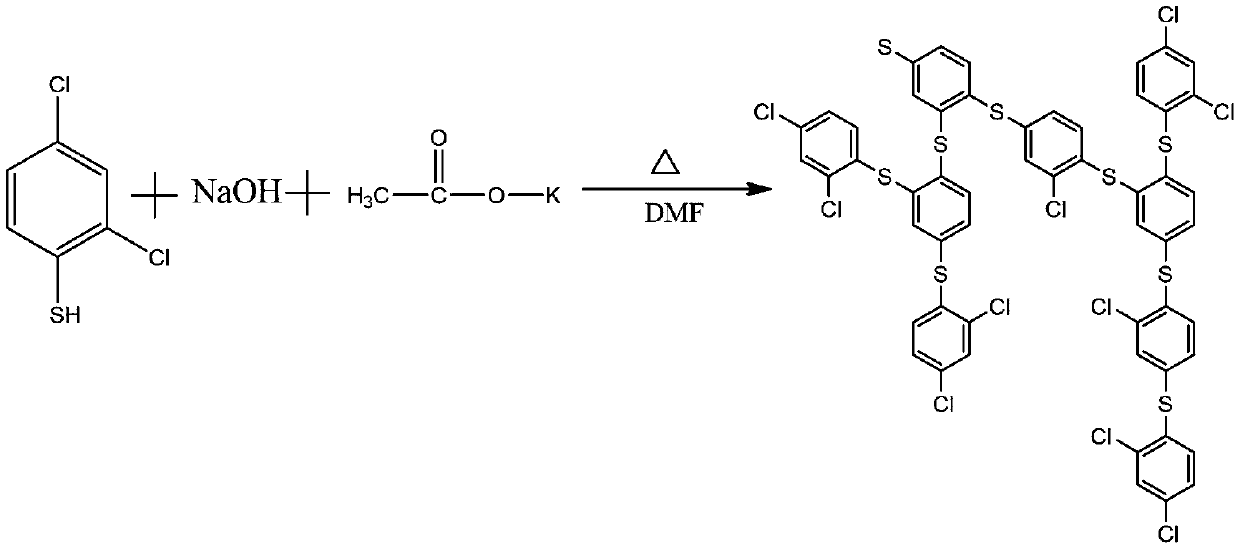

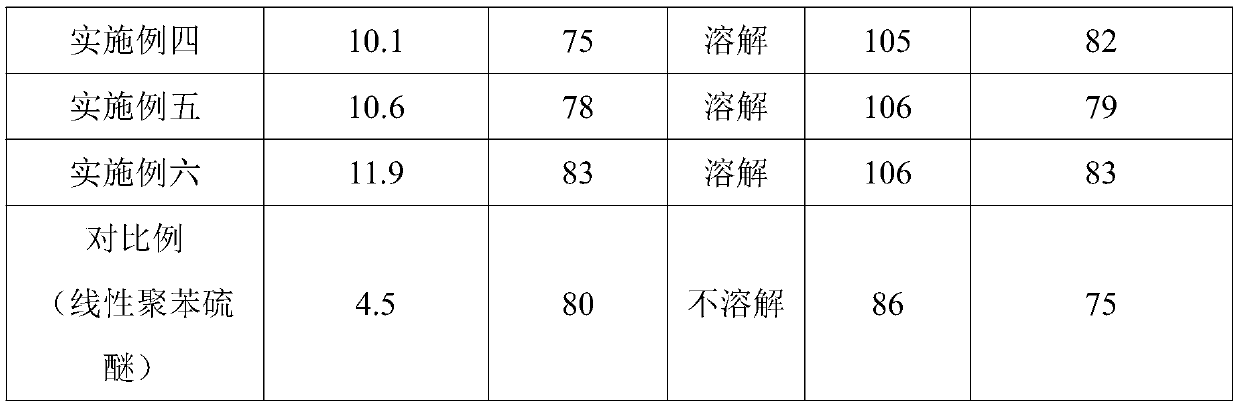

A technology of polyphenylene sulfide and dichlorothiophenol, which is applied in the field of preparation of hyperbranched polyphenylene sulfide, can solve the problems of severe end group decomposition, single end-capping end group, and increased viscosity, and achieve short reaction time , good thermal stability, high molecular weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of hyperbranched polyphenylene sulfide includes the following steps:

[0033] 1. Put 2,4-dichlorothiophenol (1 part), sodium hydroxide (1.5 parts), potassium acetate (0.9 parts) into the solvent of N,N-dimethylformamide (8 parts), Put it into a three-necked flask and heat it in an oil bath under the protection of high-purity nitrogen (99.999%);

[0034] 2. Raise the temperature of the system in step 1 to 275°C for 180 minutes;

[0035] 3. Cool the system of step 2 to 80°C, add 8 parts of distilled water, and continue to stir for 60 minutes;

[0036] 4. Put the system of step 3 into 40 parts by mass of 8% hydrochloric acid solution, and continue to stir for 240 minutes;

[0037] 5. After filtering the system of step 4, take the filtrate, put it into 16 parts of acetone solution for elution, and repeat the elution 8 times;

[0038] 6. After filtering the system of step 5, take the filtrate and put it into 20 parts of distilled water for elution, and repeat the ...

Embodiment 2

[0041] A preparation method of hyperbranched polyphenylene sulfide includes the following steps:

[0042] 1. Put 2,4-dichlorothiophenol (1.1 parts), sodium hydroxide (1.6 parts), potassium acetate (1 part) into the solvent of N,N-dimethylformamide (8 parts), Put it into a three-necked flask and heat it in an oil bath under the protection of high-purity nitrogen (99.999%);

[0043] 2. Raise the temperature of the system in step 1 to 270°C for 180 minutes;

[0044] 3. Cool the system of step 2 to 85°C, add 8 parts of distilled water, and continue to stir for 60 minutes;

[0045] 4. Put the system of step 3 into 40 parts by mass of 8% hydrochloric acid solution, and continue to stir for 240 minutes;

[0046] 5. After filtering the system of step 4, take the filtrate, put it into 17 parts of acetone solution for elution, and repeat the elution 8 times;

[0047] 6. After filtering the system of step 5, take the filtrate and put it into 19 parts of distilled water for elution, and the elution...

Embodiment 3

[0050] A preparation method of hyperbranched polyphenylene sulfide includes the following steps:

[0051] 1. Put 2,4-dichlorothiophenol (1.2 parts), sodium hydroxide (1.7 parts), potassium acetate (1.1 parts) into the solvent of N,N-dimethylformamide (8 parts), Put it into a three-necked flask and heat it in an oil bath under the protection of high-purity nitrogen (99.999%);

[0052] 2. Raise the temperature of the system in step 1 to 268°C for 180 minutes;

[0053] 3. Cool the system of step 2 to 80°C, add 8 parts of distilled water, and continue to stir for 60 minutes;

[0054] 4. Put the system of step 3 into 40 parts by mass of 8% hydrochloric acid solution, and continue to stir for 240 minutes;

[0055] 5. After filtering the system of step 4, take the filtrate, put it into 18 parts of acetone solution for elution, and repeat the elution 8 times;

[0056] 6. After filtering the system of step 5, take the filtrate and put it into 18 parts of distilled water for elution, and repeat t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com