Desktop-level polyether ether ketone high-temperature 3D printing device

A polyetheretherketone, 3D printing technology, applied in the field of 3D printing, can solve the problems of large cutting allowance, untimely heating and melting, and large influence of environmental temperature, reducing the rate of unqualified products, satisfying diversified printing, and facilitating the effect of observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

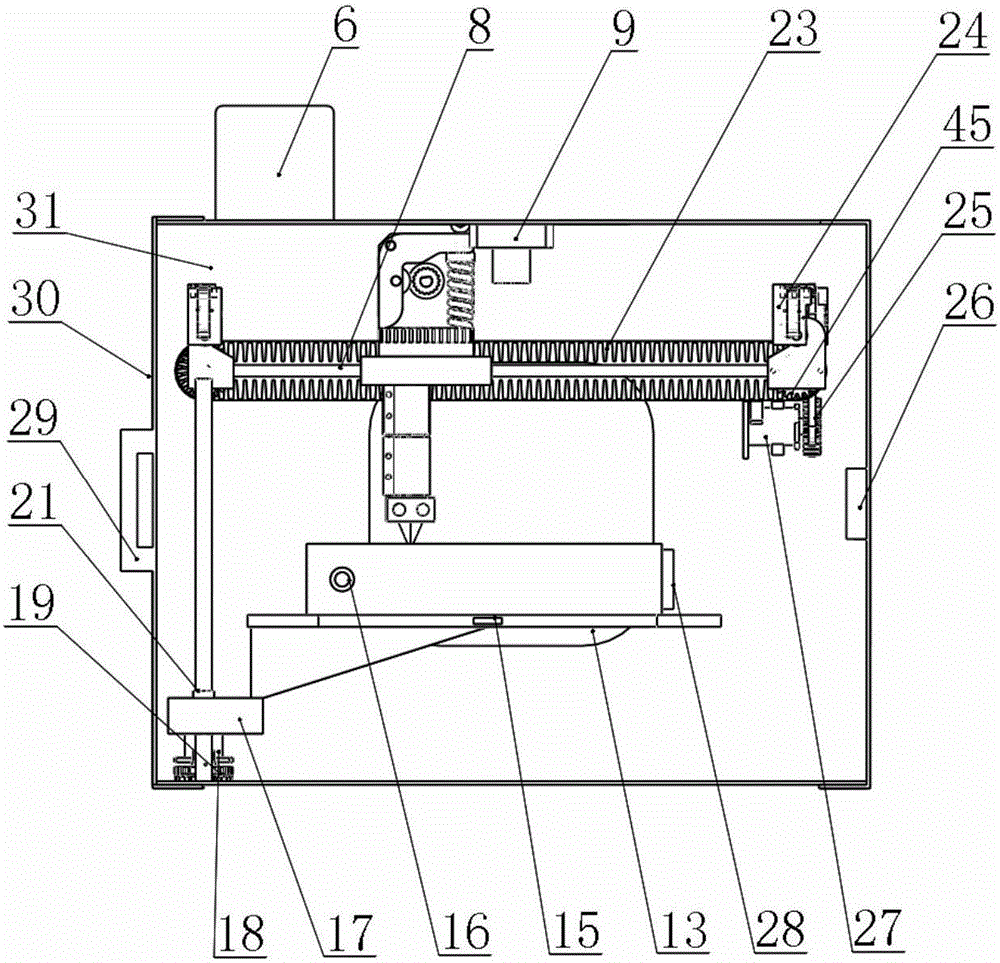

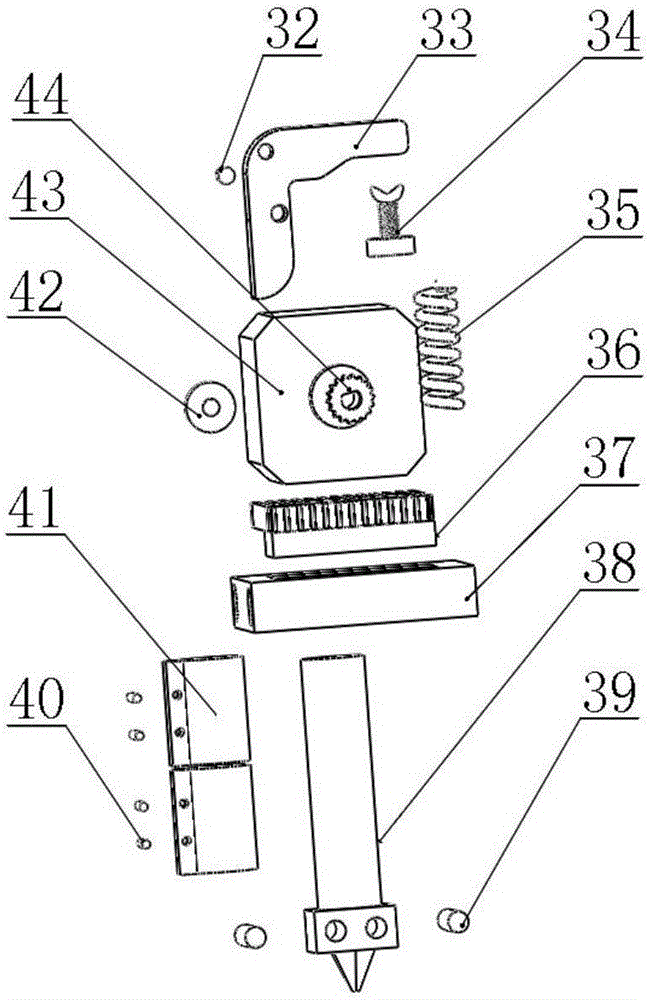

[0022] The objects and effects of the present invention will become more apparent when the present invention is described in detail below with reference to the accompanying drawings.

[0023] like figure 1 As shown, a desktop-grade polyether ether ketone high-temperature 3D printing device provided by the present invention includes: a box body, a moving mechanism, a print head, a driving mechanism and a temperature control mechanism, and the moving mechanism includes an X-axis moving mechanism, a Z-axis moving mechanism mechanism and two Y-axis moving mechanisms, the two Y-axis moving mechanisms are fixed in the box, the X-axis moving mechanism is installed on the two Y-axis moving mechanisms, the print head is installed on the X-axis moving mechanism, and the temperature control mechanism Fixed on the Z-axis moving mechanism.

[0024] Described casing is made up of left plate 30, cover plate 11, right plate 12, base plate 14, front plate 22, rear plate 31, described left pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com