Roll-like polyelectrolyte film packaging body, and manufacturing method thereof, and packed object

A polymer electrolyte and membrane packaging technology, applied in the field of packaging, can solve problems such as damage, polymer electrolyte membrane damage, and inability to use fuel cells, and achieve the effect of reducing the rate of defective products and suppressing wrinkles or damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

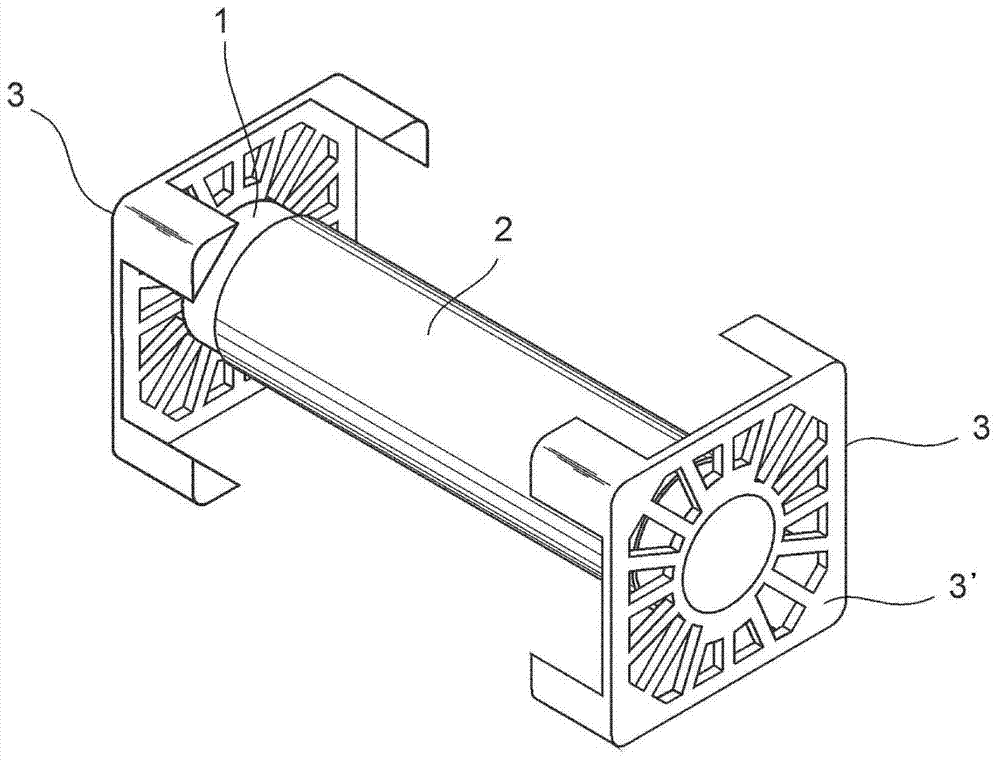

Image

Examples

Embodiment 1

[0138] As a polymer electrolyte membrane, it is manufactured as follows [CF 2 CF 2 ] 0 . 812 -[CF 2 -CF(-O-(CF 2 ) 2 -SO 3 H)] 0 . 188 An electrolyte membrane composed of the indicated perfluorocarbon sulfonic acid polymer (hereinafter referred to as "PFSA") was used as a polymer electrolyte membrane.

[0139] (Preparation of Polymer Electrolyte Solution)

[0140] First, precursor particles of the above polymer electrolyte (proton exchange capacity after hydrolysis and acid treatment: 1.4 meq / g) were prepared. Next, the precursor particles were brought into contact with an aqueous solution in which potassium hydroxide (15% by mass) and methanol (50% by mass) were dissolved at 80° C. for 20 hours to perform a hydrolysis treatment. After that, the pellets were immersed in water at 60° C. for 5 hours. Next, the particles immersed in water were immersed in 60° C. 2N hydrochloric acid aqueous solution for 1 hour, and the above treatment was repeated 5 times, and the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com