Ink for surface of finish paint and preparation method thereof

A technology of ink and topcoat, which is applied in the field of ink, can solve the problems of poor wear resistance and chemical resistance, unstable adhesion of UV/PU topcoat substrates, etc., and achieve simplified decoration processing technology, excellent adhesion, The effect of reducing the rate of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1 Take 20 parts (weight) of a ketone solvent, 35 parts (weight) of a modified acrylic resin, and 20 parts (weight) of a modified polyester resin under normal temperature and pressure, and stir at 600-1200r / min for 15-30 minutes to make After it is completely dissolved, add 1.5 parts (weight) of dispersant, 18 parts (weight) of pigment, stir evenly, pass through a three-roll machine and grind to below 10цm, then add 1.5 parts (weight) of defoamer, stir and disperse evenly, that is Get the finished product.

Embodiment 2

[0057] Take 20 parts (weight) of ketone solvent, 30.5 parts (weight) of modified acrylic resin and 20 parts (weight) of modified polyester resin under normal temperature and pressure, and stir at 600-1200r / min for 15-30 minutes to dissolve completely Finally, add 1.5 parts (weight) of dispersant, 18 parts (weight) of pigment, stir evenly, pass through three-roll machine and grind to below 10цm, then add 1.5 parts (weight) of defoamer, 5 parts (weight) of alcohol ether solvent After stirring and dispersing evenly, the finished product is obtained.

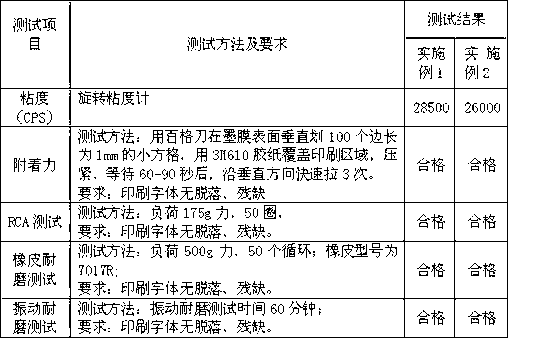

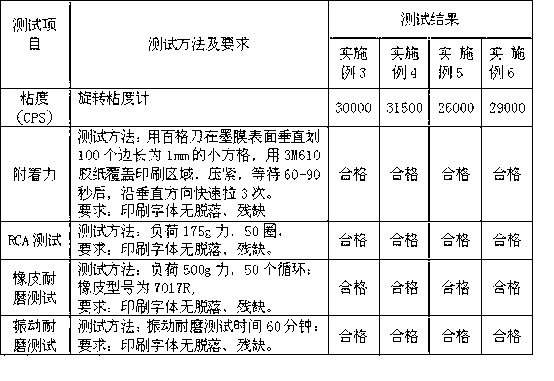

[0058] When the ink used for the surface of the topcoat obtained in the above examples is on the surface of the PU topcoat product, when the pad printing thickness is 10μm, the printing effect and physical and chemical index status of the ink on the material are shown in Table 1.

[0059] Table 1

[0060]

Embodiment 3

[0062] Under normal temperature and pressure, take 25 parts (weight) of alcohol ether solvent, 42 parts (weight) of modified acrylic resin, 12 parts (weight) of modified polyester resin, stir at 600-1200r / min for 15-30 minutes to dissolve After completion, add 1.5 parts (weight) of dispersant, 18 parts (weight) of pigment, stir evenly, pass through a three-roll machine and grind to below 10цm, then add 1.5 parts (weight) of defoamer, stir and disperse evenly, and the finished product is obtained .

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com