Automatic assembling machine of invisible zipper head

A technology of automatic assembly machine and invisible zipper puller, which is applied in the direction of sliding fastener components, clothing, fasteners, etc., can solve the problems of unguaranteed product quality, low degree of automation, and low production efficiency, so as to improve assembly efficiency and quality, The effect of high degree of automation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

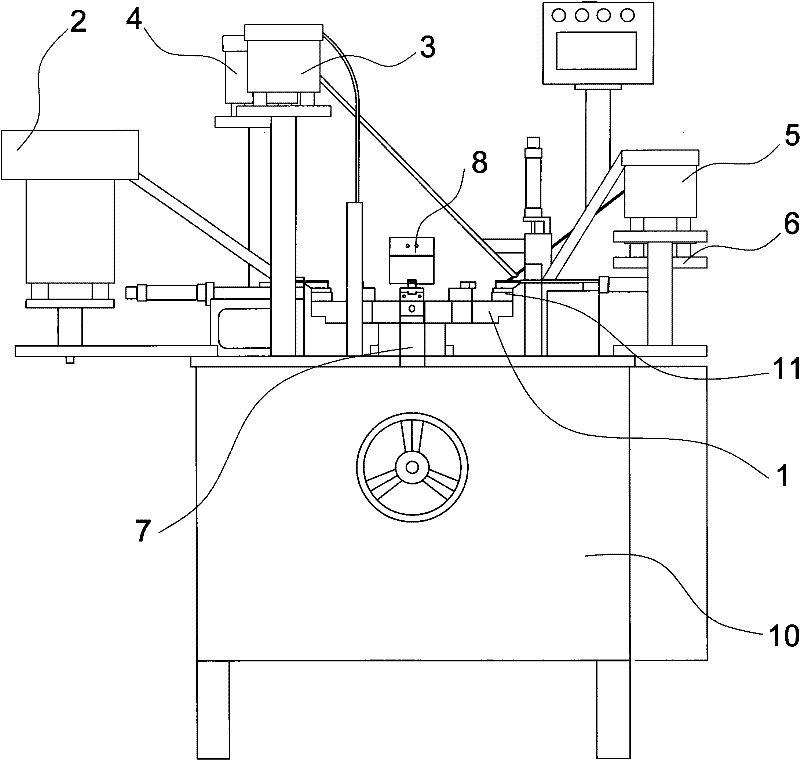

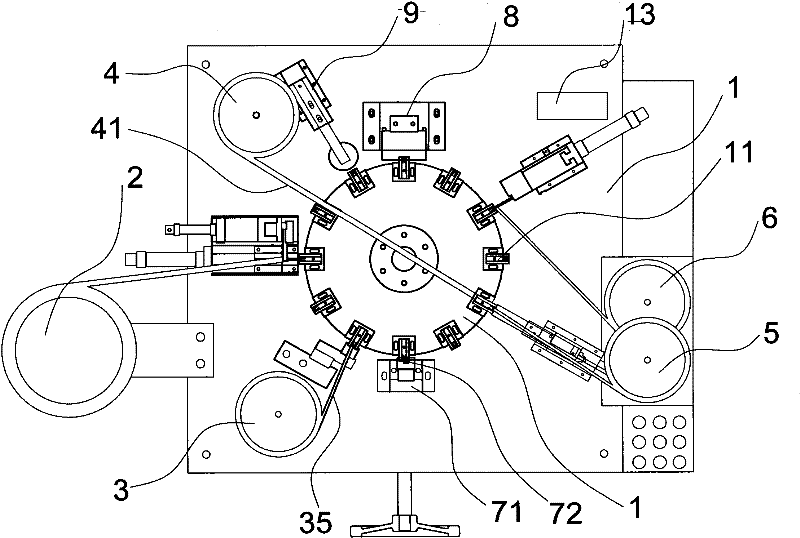

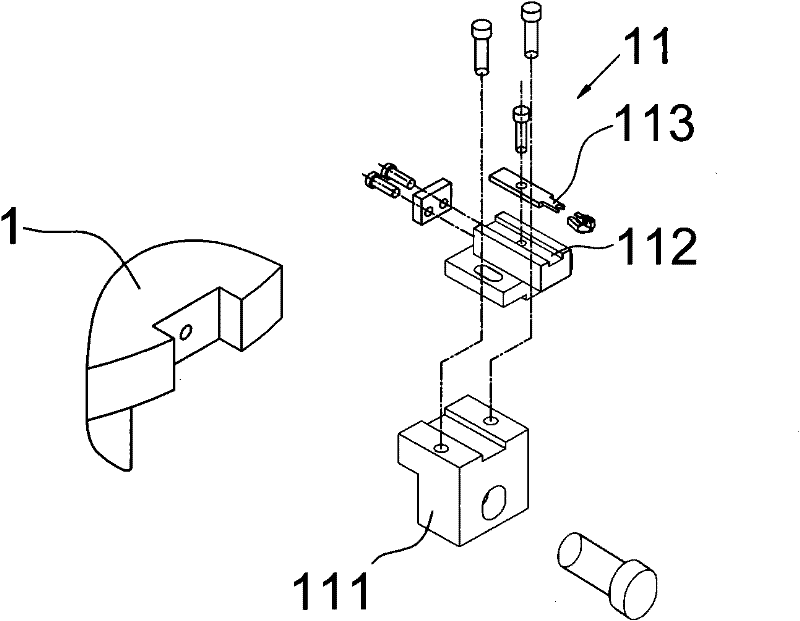

[0027] like figure 1 and figure 2 Shown, a kind of automatic assembling machine of invisible zipper slider of the present invention comprises the disc-shaped assembly dish 1 that can rotate around central axis, is equipped with 12 assembly molds 11 on the disc shape, and the assembly mold 11 is in the disc-shaped The circumference of the edge is evenly distributed, and the slider feeding mechanism 2 and the spring feeding mechanism 3 are sequentially installed on the base 10 around the assembly tray 1 in the counterclockwise direction, which are used to detect the parts on the assembly mold 11 and control the detection of the operation of the assembly machine. Control mechanism 7, horse hook feeding mechanism 5, copper pin feeding mechanism 6, riveting mechanism 8, discharging mechanism 9 and triangle feeding mechanism 4. Each feeding mechanism is connected to the vibrating plate through one end of the material guide groove, and the other end is corresponding to the assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com