Multi-bin cotton feed roller flaw preventing device

A cotton feeding roller and defect prevention technology, which is applied in the field of multi-silo cotton feeding roller defect prevention devices, can solve the problems affecting the service performance and life of the bearing, the loss of normal production and economic benefits, and affecting the heat dissipation of the bearing, so as to reduce the number of unqualified products. efficiency, simple structure, and the effect of increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

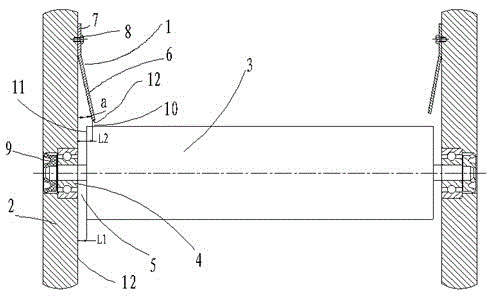

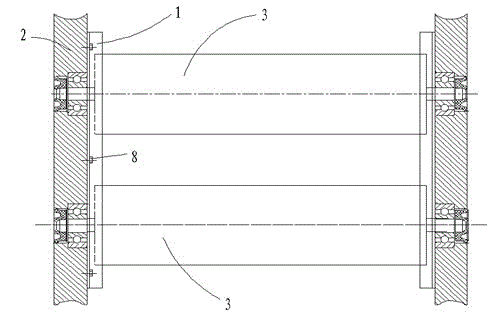

[0017] like figure 1 As shown, a multi-compartment cotton feeding roller defect prevention device includes a warehouse plate 2 and two matching cotton feeding rollers 3, and the two ends of the cotton feeding roller 3 are supported by bearings 4 in the bearing holes of the two warehouse plates. Inside, an anti-winding baffle 1 is provided on the inner side of the bin plate 2 on the upper part of the roller 3, and the baffle is a bent plate, including an upper connecting plate 7 and a lower baffle surface 6, and the baffle surface 6 is connected to the warehouse. The included angle between the plates 2 is an acute angle α, and the axial gap 5 between the working outer end surface 11 of the roller and the inner surface 12 of the silo plate, that is, the vertical distance L1 is smaller tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com