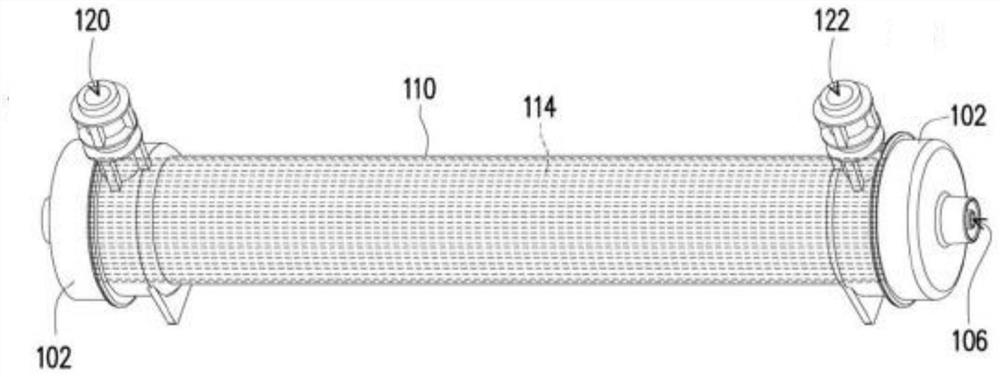

Quality inspection method and assembling method of dialyzer

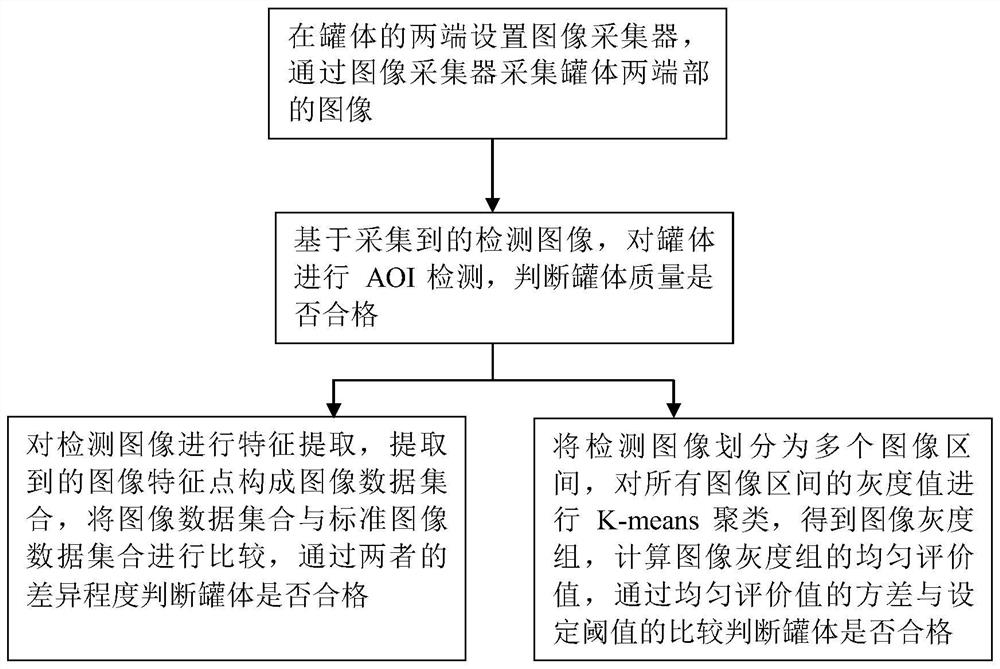

A technology of dialyzer and end cap assembly, which is applied in the field of quality inspection of dialyzers, can solve the problems of affecting the treatment effect, reducing the safety of hemodialysis treatment, and improving the failure rate of products, so as to achieve automatic transmission and automatic transmission. Assembling, reducing manpower and material resources, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0118] As an optional embodiment of the present invention, the quality inspection method further includes checking whether the hollow fiber membranes are blocked, and whether the hollow fiber membranes are blocked is detected before the end cap and the tank body are assembled together. After the tank is injected, centrifuged, cured and cut, the two ends of the hollow fiber bundle will form an opening at the port of the tank. On the detection image, the opening is represented as a circle, such as Figure 4 As shown, the white circle is the opening formed by the hollow fiber membrane, and the area filled with oblique lines is the sealant; under normal circumstances, after the sealant is cut, the two ends of the hollow fiber bundle will be cut to form an opening. If the holes and openings are filled with sealant, the circles in the detection image will be filled with oblique lines, so that which hollow fiber membranes are clogged can be accurately identified. Further, if the numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com