Preparation process for plate roller for printing

A technology for preparation process and version roller, which is applied in the field of preparation process of printing version roller, can solve the problems of reducing surface smoothness difference and large surface smoothness difference, and achieves small surface roughness, small difference, and reduced times The effect of defective product rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

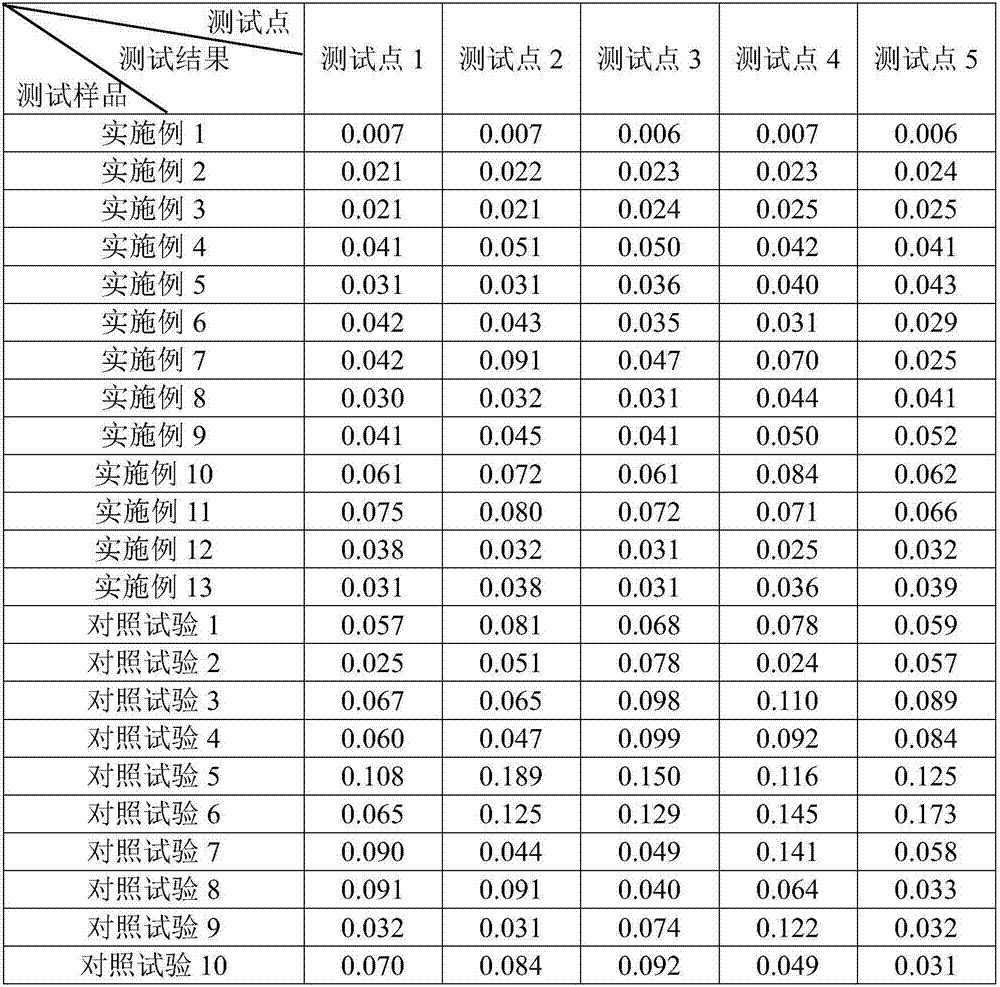

Examples

Embodiment 1

[0023] Embodiment 1: a kind of preparation technology of plate roller for printing comprises the following steps:

[0024] (1) Production of plate roller base: it is processed by seamless steel pipe;

[0025] Among them, in terms of mass percentage, the formula of seamless steel pipe is: C: 0.01%; Si: 0.35%; Mn: 0.02%; S: 0.005%; P: 0.005%; Cr: 15.50%; : 0.48%; N: 0.01%; Ti: 0.02%; the balance is Fe and unavoidable impurities;

[0026] (2) Copper plating treatment on the base of the version roller: place the base of the version roller in an electroplating tank equipped with a copper plating solution for copper plating, and the thickness of the copper layer plated is 15-18 μm;

[0027] Among them, the copper plating solution includes 5g / l of CuSO 4 , 0.4g / l Na 2 SO 3 , 0.3g / l complexing agent, 0.2g / l NaCl and 0.02g / l PVA, and the pH of the copper plating solution is 12.0-13.0;

[0028] (3) Surface treatment of plate roller after copper plating: grinding the copper surface;...

Embodiment 2

[0034] Example 2: A preparation process of a printing plate roller, the difference from Example 1 is that the formula of the seamless steel pipe is: C: 0.01wt%; Si: 0.40wt%; Mn: 0.02wt%; S P: 0.005wt%; Cr: 15.00wt%; Ni: 8.50wt%; Cu: 0.45wt%; N: 0.01wt%; Ti: 0.03wt%; the balance is Fe and unavoidable impurities .

Embodiment 3

[0035] Example 3: A preparation process of a printing plate roller, the difference from Example 1 is that the formula of the seamless steel pipe is: C: 0.02wt%; Si: 0.45wt%; Mn: 0.03wt%; S P: 0.01wt%; Cr: 16.00wt%; Ni: 9.00wt%; Cu: 0.50wt%; N: 0.02wt%; Ti: 0.04wt%; the balance is Fe and unavoidable impurities .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com