Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Reduce or eliminate defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Turbine blade capable of enhancing impact toughness and production technique thereof

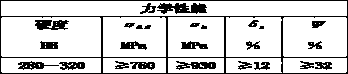

ActiveCN104060191AAvoid formingPrevent early brittle crackingFurnace typesHeat treatment furnacesMischmetalChemical composition

The invention provides a turbine blade capable of enhancing impact toughness, which comprises the following chemical components in percentage by mass: 0.13-0.15% of C, 0.8-0.9% of Si, 0.5-0.8% of Mn, 14-16% of Cr, 0.1-0.3% of Ni, 1.3-1.5% of Cu, 0.6-1.1% of Mo, 0.1-0.15% of W, 0.36-0.45% of V, 0.5-0.8% of Nb, 0.28-0.30% of Al, 0.16-0.18% of Ti, 0.08-0.10% of B, 0.45-0.48% of Na, at most 0.02% of S, at most 0.03% of P, 0.3-0.6% of rare-earth metal and the balance of Fe. The invention also provides a production technique of the turbine blade capable of enhancing impact toughness. The production technique can greatly enhance the impact toughness of the blade and prolong the service life of the blade.

Owner:南京赛达科技有限公司

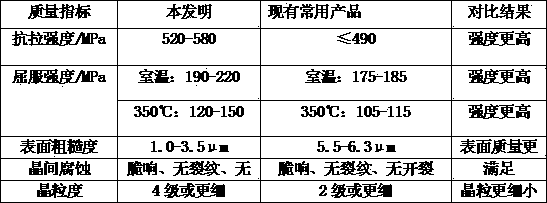

Flange for wind power drum and manufacturing technique thereof

ActiveCN103045960APrevent precipitationGuaranteed corrosion resistanceFlanged jointsTemperingChemical composition

The invention provides a flange for a wind power drum, and a manufacturing technique thereof. The flange comprises the chemical compositions in percentage by weight: 0.15-0.22 percent of C, 0.55-0.65 percent of Si, 0.65-0.75 percent of Mn, 5-8 percent of Ni, 4-6 percent of Cr, 0.65-0.85 percent of Nb, 0.25-0.45 percent of Cu, 0.05-0.07 percent of N, 0.05-0.07 percent of Mo, 0.7-0.9 percent of Al, 0.02-0.03 percent of S, 0.08-0.09 percent of Ti, 0.01-0.04 percent of V, 0.002-0.003 percent of B, 1-2 percent of rare earth lanthanide series and the balance of Fe. According to the invention, with the heating processing procedures of two-time normalization and two-time tempering, the excellent corrosion resistance of the flange is ensured, and meanwhile, high tensile strength and high yield strength are achieved; and the flange is ensured to have smaller surface roughness, more uniform and stable tissue, and less air holes and sand holes.

Owner:WUXI HUAERTAI MACHINERY MFG

Method for improving processing property of FeCrNiAl-based high-entropy alloy

The invention belongs to the fields of metal material processing and heat treatment and relates to a method for improving the processing property of FeCrNiAl-based high-entropy alloy. An optimizing treatment process comprises high-temperature homogenization, forging and annealing, and particularly comprises the following steps: maintaining homogenizing treatment at 1200 to 1300 DEG C for 3 to 20 hours; performing forging with the deformation quantity of 1:9 to 1:5, wherein the forging deformation rate is not more than 10 s<-1>; and performing periodic annealing at the temperature of 1100 to 1250 DEG C and performing furnace cooling to room temperature. After the above optimizing treatment, high-entropy alloy avoids crack and cracking phenomena in cold and hot processing, a stable hot processing area is obviously enlarged and the processing property is significantly improved. Through high-temperature long-time heat insulation, high-temperature forging and periodic annealing process, thedefects of bulky arborescent structure, component segregation and micropores in the cast-state high-entropy alloy are effectively eliminated, so that the plasticity and the toughness of the high-entropy alloy are improved and the processing property can be optimized.

Owner:ANYANG INST OF TECH +1

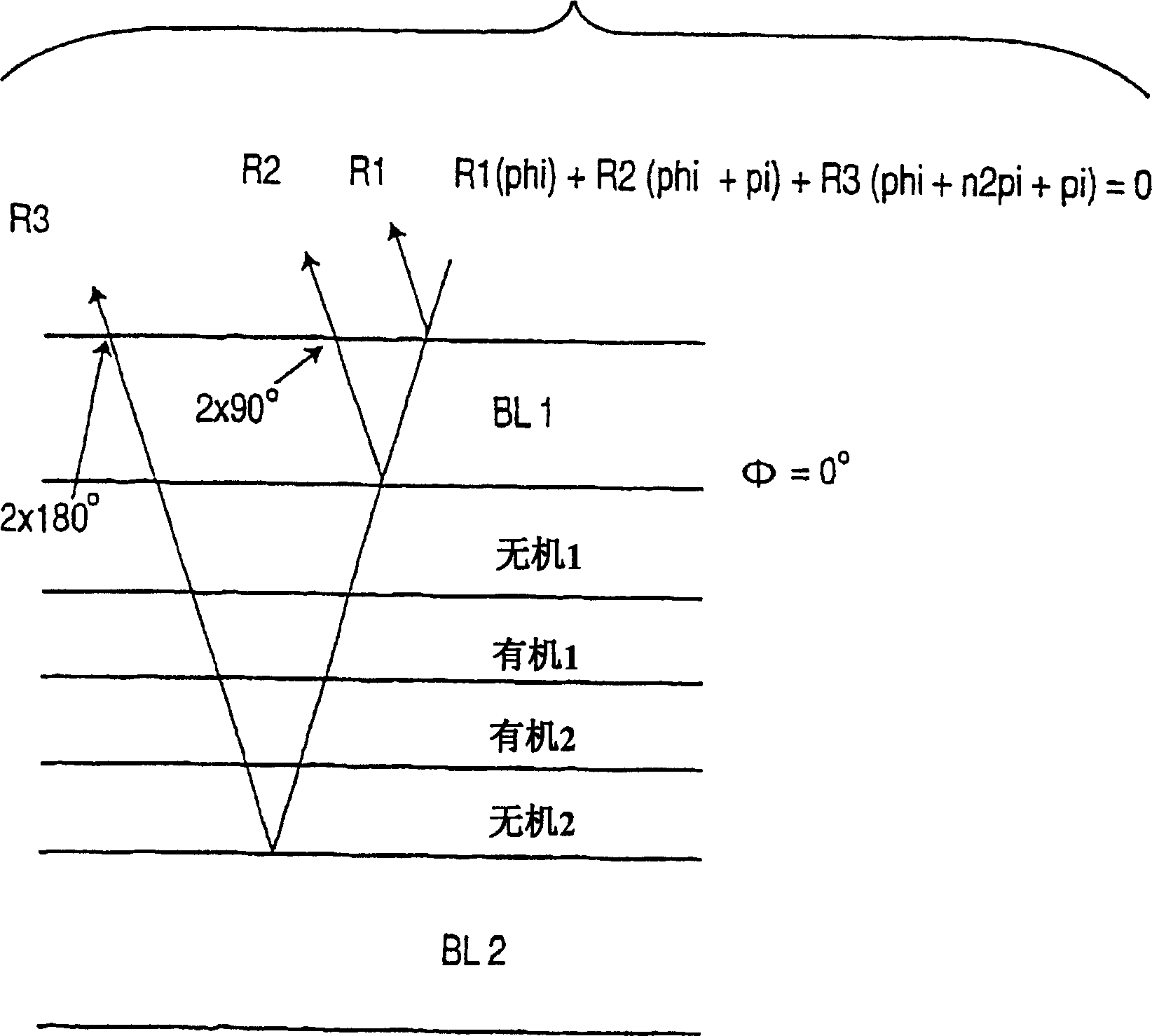

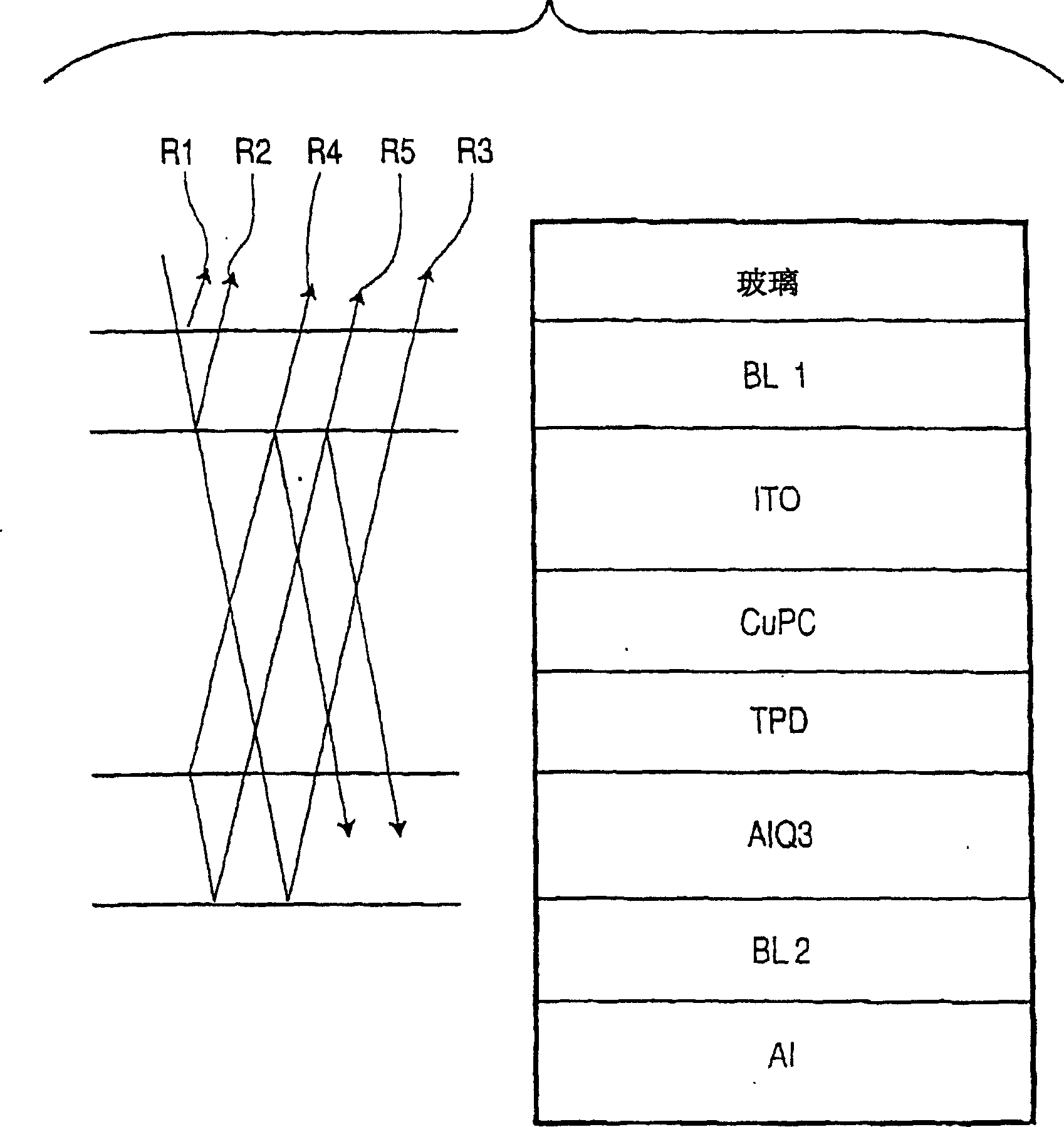

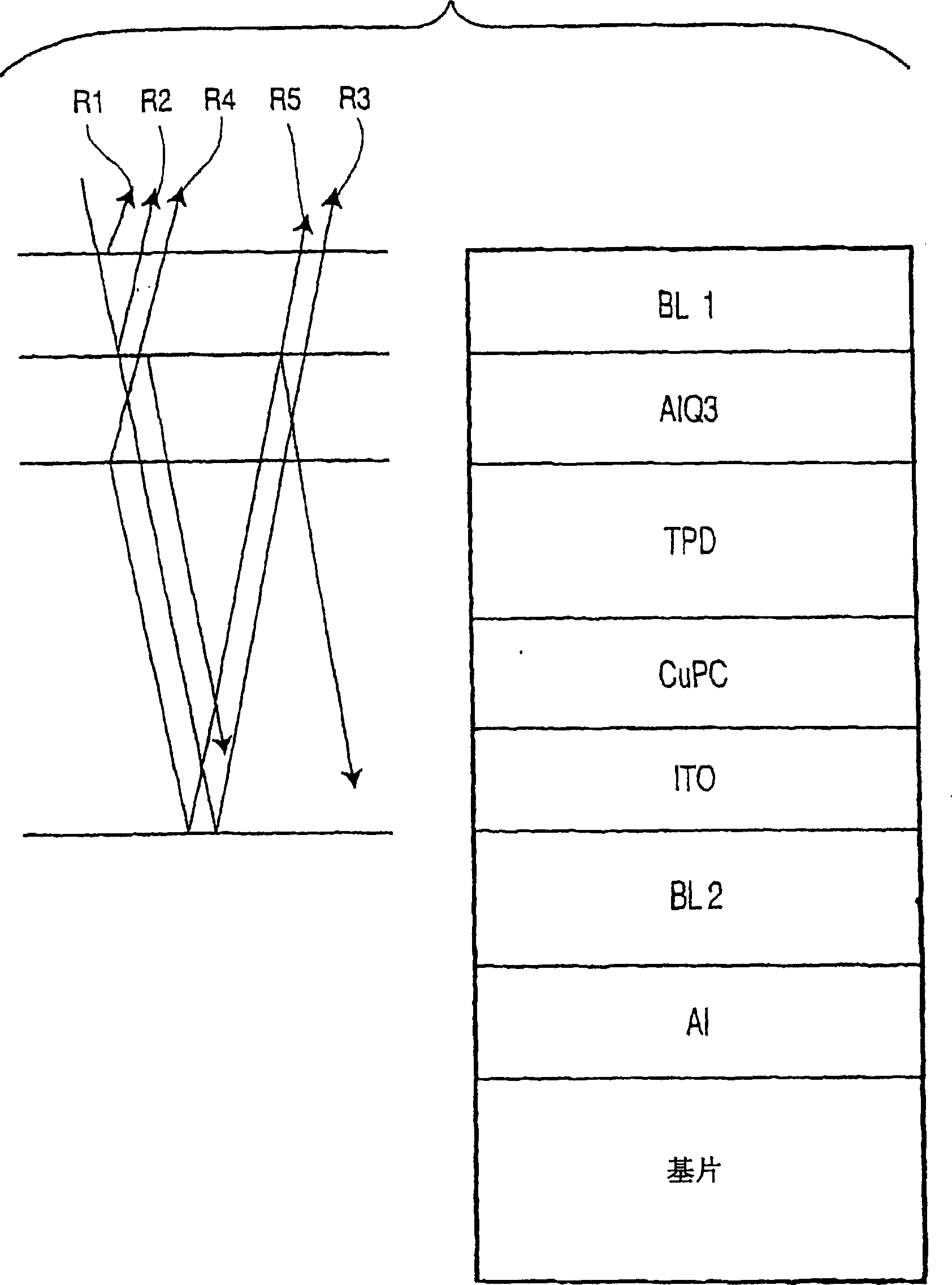

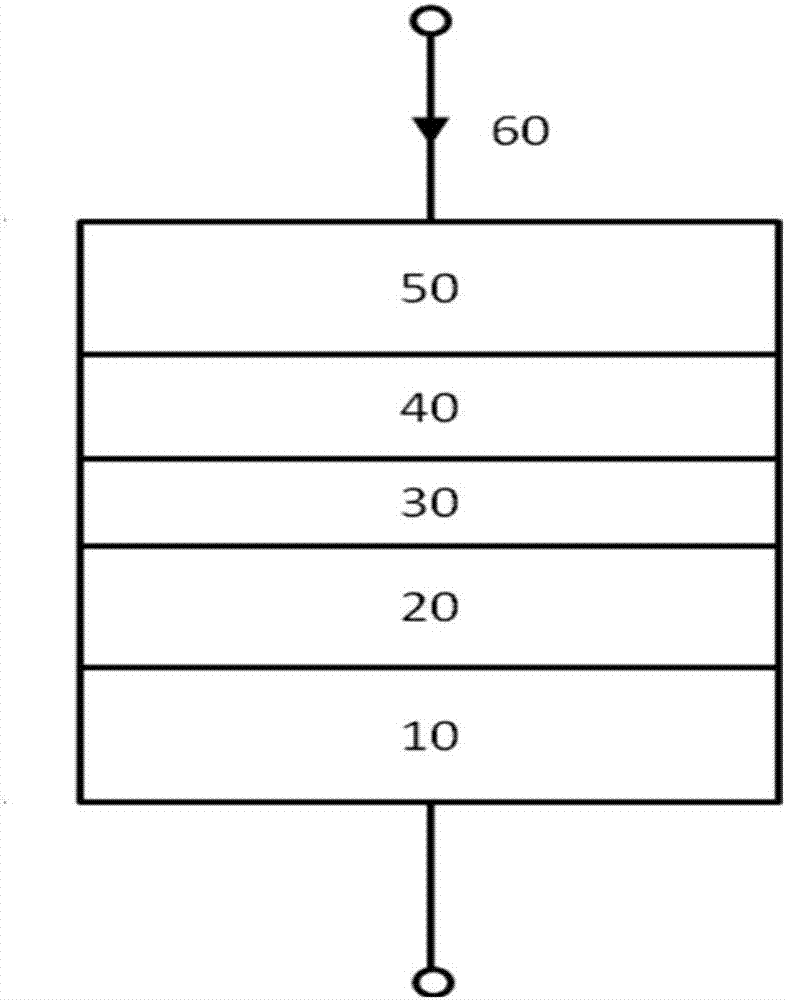

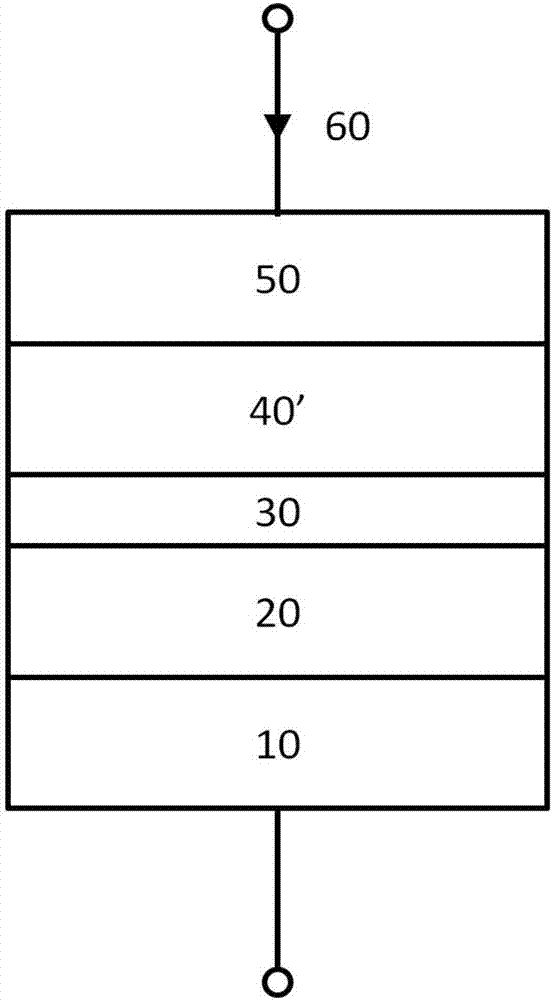

Organic light emitting diode (OLED) with contrast enhancement features

InactiveCN1729584AReduce or eliminate defectsElectroluminescent light sourcesSolid-state devicesContrast enhancementOrganic electroluminescence

An organic electroluminescent device is provided having emitting layers with materials and thicknesses that provide constructive optical interference of emitted light. The device includes additional layers that provide contrast enhancement through destructive optical interference of ambient light entering the device.

Owner:LUXELL技术有限公司

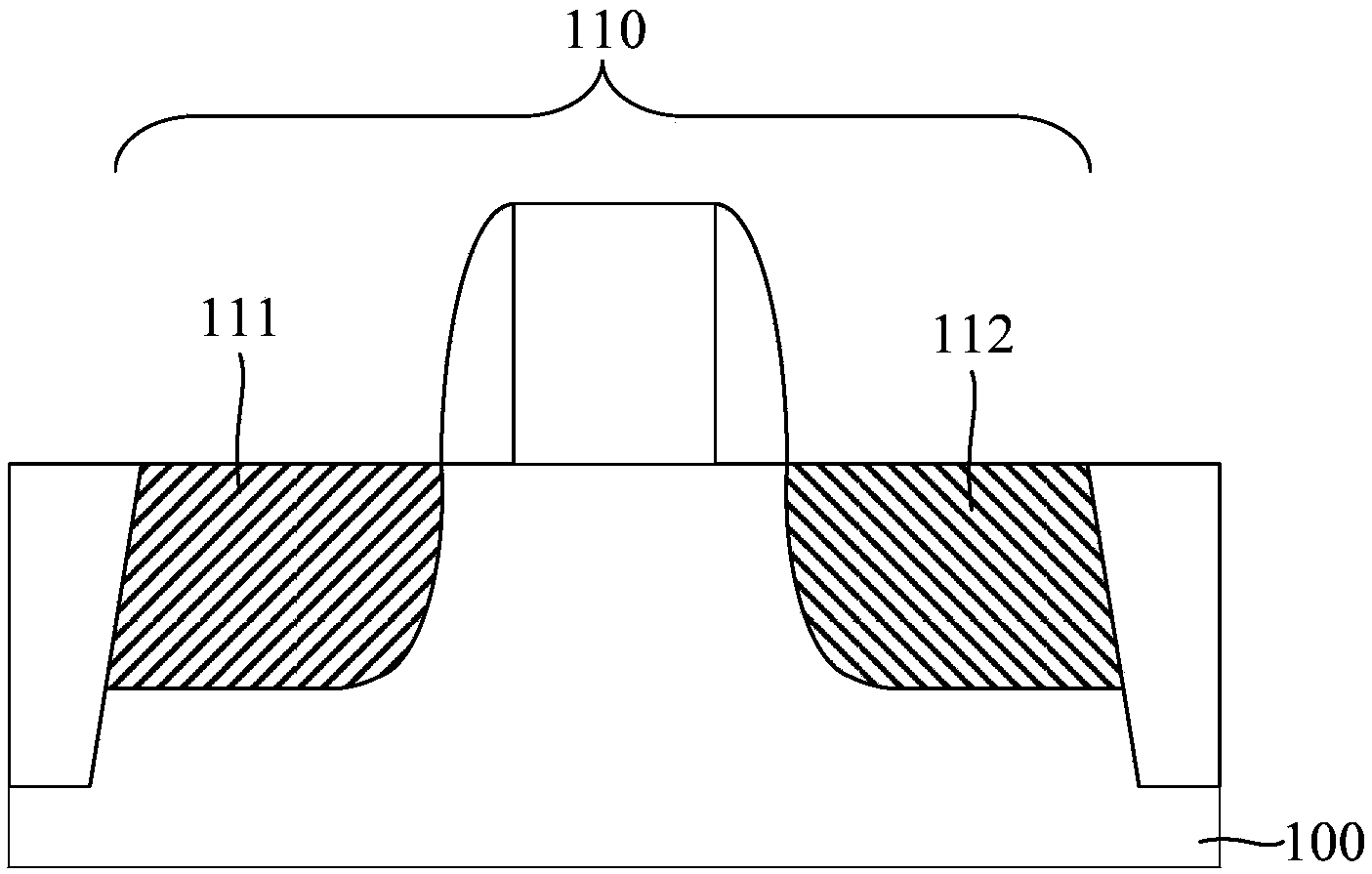

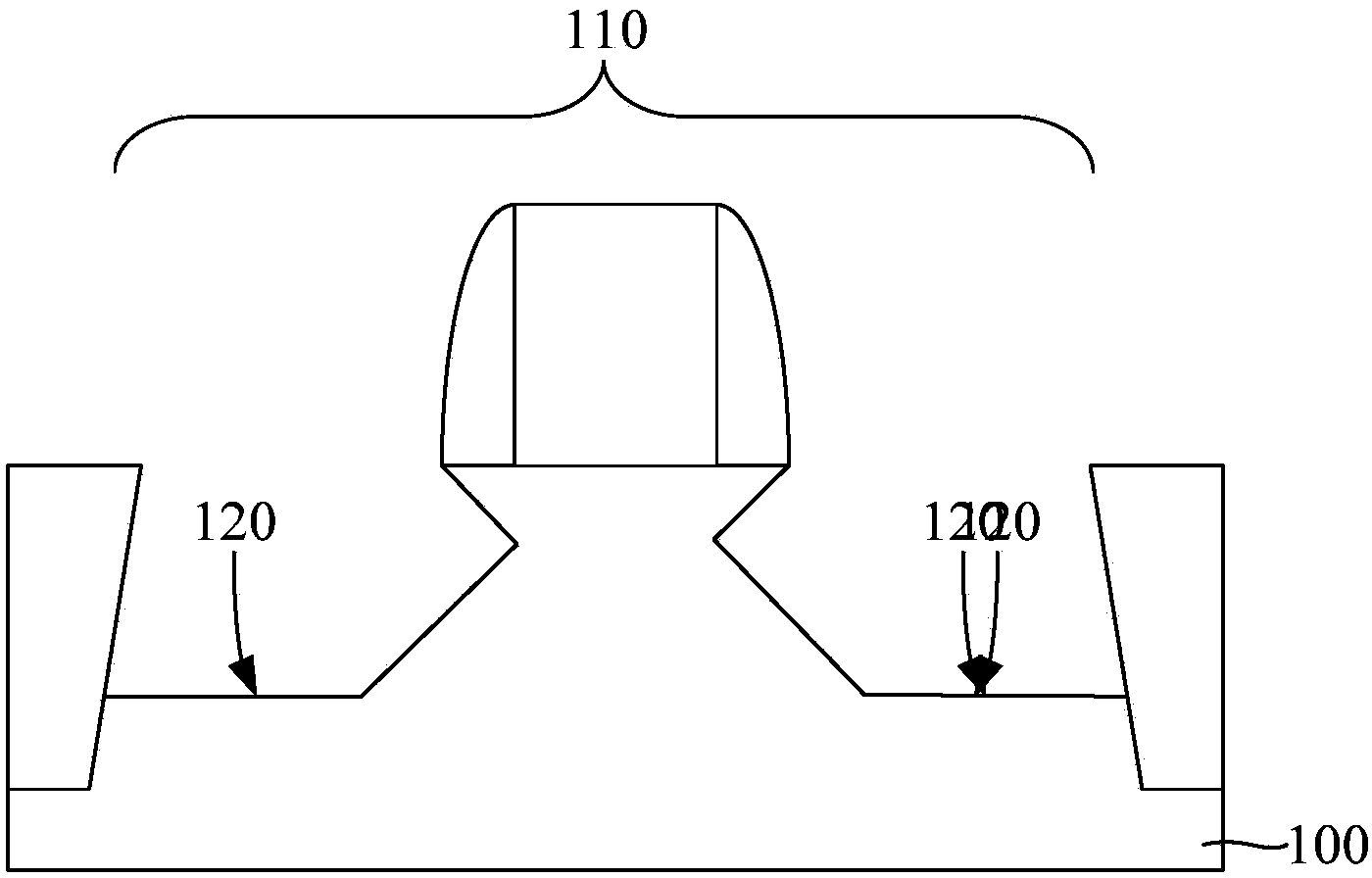

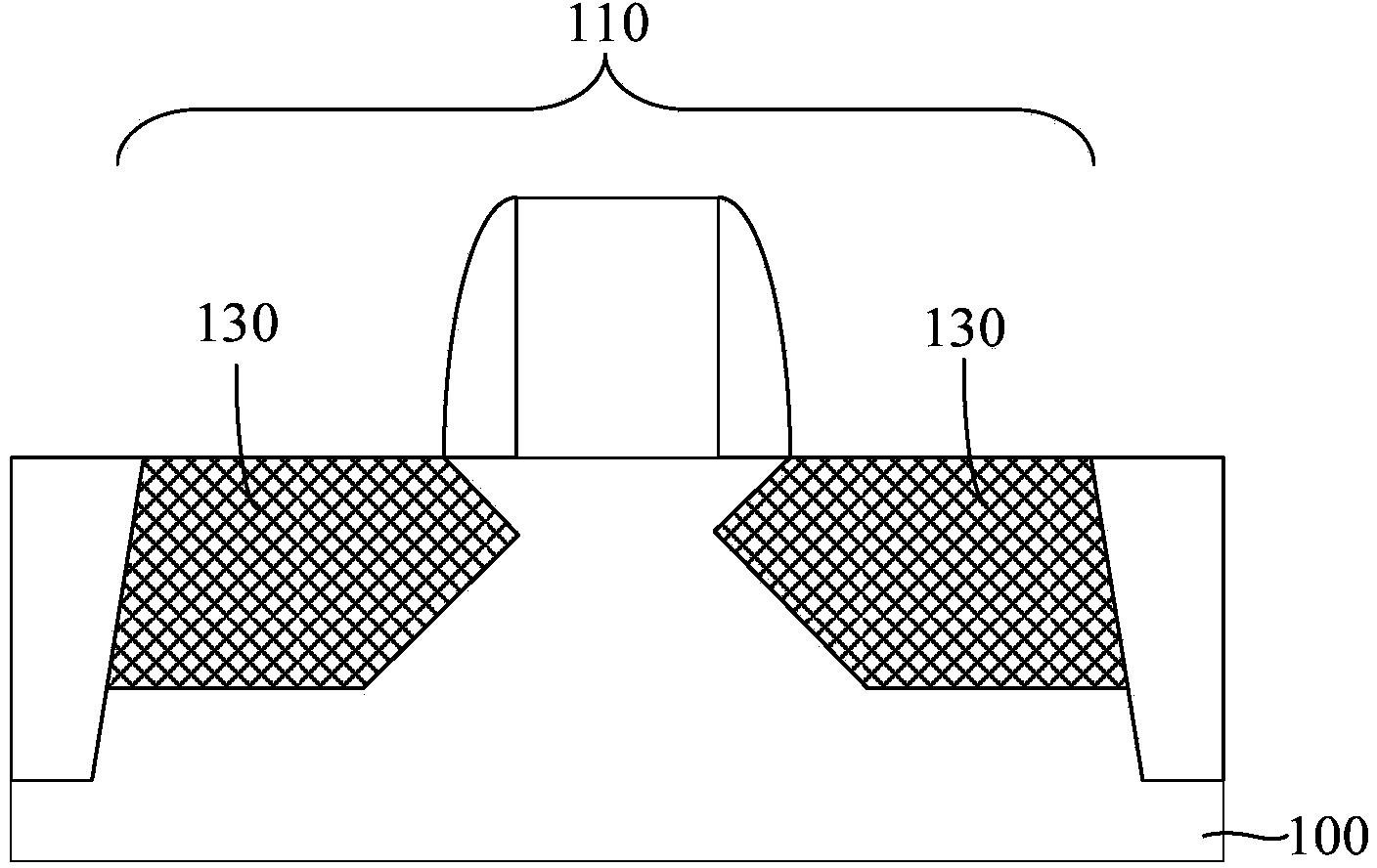

Semiconductor treatment technology and semiconductor device preparation method

InactiveCN103871902AReduce or eliminate defectsTransistorSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention discloses a semiconductor treatment technology. The semiconductor treatment technology includes the step of providing a substrate and carrying out oxidation and oxidation layer removing treatment on the substrate at least once, wherein the oxidation and oxidation layer removing treatment includes the first step of carrying out oxidation treatment on the surface of the substrate and forming an oxidation layer on the surface of the substrate, and the second step of removing the oxidation layer and exposing the substrate. The invention further provides a semiconductor device preparation method through the semiconductor treatment technology so as to improve the performance of an embedded silicon germanium device. Through the oxidation and oxidation layer removing treatment, defects on the surface of the substrate can be reduced or eliminated, so the surface of the substrate is smooth and is beneficial for the next procedure.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Turbine blade capable of improving thermal cracking resistance and production process thereof

ActiveCN104032236AReduced impact toughnessImprove impact toughnessBlade accessoriesMachines/enginesMischmetalChemical composition

The invention discloses a turbine blade capable of improving the thermal cracking resistance. The turbine blade comprises the following chemical components in percentage by mass: 0.31-0.35% of C, 0.10-0.12% of Si, 0.75-0.77% of Mn, 0.63-0.65% of Ni, 11.2-11.7% of Cr, 0.65-0.68% of Mo, 0.16-0.18% of V, 0.85-0.88% of Sr, 0.15-0.17% of Nb, 0.05-0.07% of Cu, 0.27-0.29% of Al, 0.13-0.15% of Ti, 0.06-0.08% of B, less than or equal to 0.02% of S, 0.21-0.35% of rare earth metal and the balance of Fe. By adopting the turbine blade, the impact toughness of a blade is greatly improved, the thermal cracking resistance of the blade is improved, and the service life of the blade is prolonged.

Owner:南京赛达科技有限公司

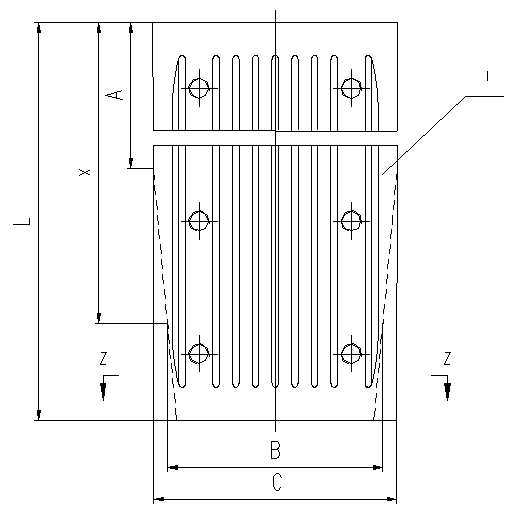

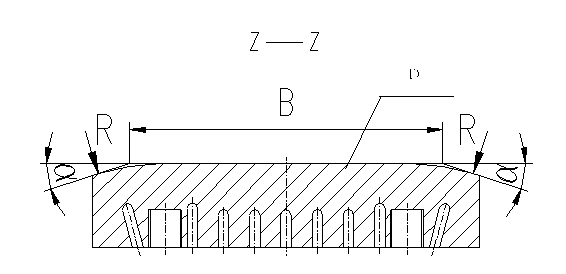

Crystallizer narrow copper plate for solving continuous casting blank corner defects

The invention relates to a crystallizer narrow copper plate for solving continuous casting blank corner defects. The crystallizer narrow copper plate is characterized by comprising a narrow copper plate body (1), the two sides of the middle lower portion of the narrow copper plate are outside chamfered, and k is a coefficient of steel solidification. The crystallizer narrow copper plate has the advantages of guaranteeing slow cooling of continuous casting blank corners, reducing and eliminating the casting blank corner defects, improving casting blank quality, reducing wear of the narrow copper plate, prolonging service life of the narrow copper plate and reducing maintenance of a crystallizer. thermal resistance between the casting blank and the copper plate corners is increased through chamfering, the slow cooling of casting blank corners is guaranteed, defects of the casting blank corners are optimized, and the copper plate corners on the lower portion of the crystallizer contact with the casting blank corners virtually to optimize wear of the copper plate.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Corrosion-resistant turbine blade and production process thereof

ActiveCN104032239AReduced impact toughnessImprove impact toughnessBlade accessoriesFurnace typesTurbine bladeRare earth

The invention discloses a corrosion-resistant turbine blade which comprises the following chemical components in percentage by mass: 0.29-0.31 percent of C, 0.11-0.13 percent of Si, 0.69-0.73 percent of Mn, 0.60-0.62 percent of Ni, 9.5-9.7 percent of Cr, 0.15-0.17 percent of V, 0.16-0.18 percent of Nb, 0.05-0.07 percent of Cu, 0.21-0.23 percent of Al, 0.13-0.15 percent of Ti, 0.75-0.77 percent of Sb, 0.82-0.88 percent of Co, less than or equal to 0.03 percent of S, less than or equal to 0.02 percent of P, 0.09-0.12 percent of rare earth metals and the balance of Fe. The water erosion resistance and corrosion resistance of the blade can be improved, so that the service life of the blade is prolonged.

Owner:南京赛达科技有限公司

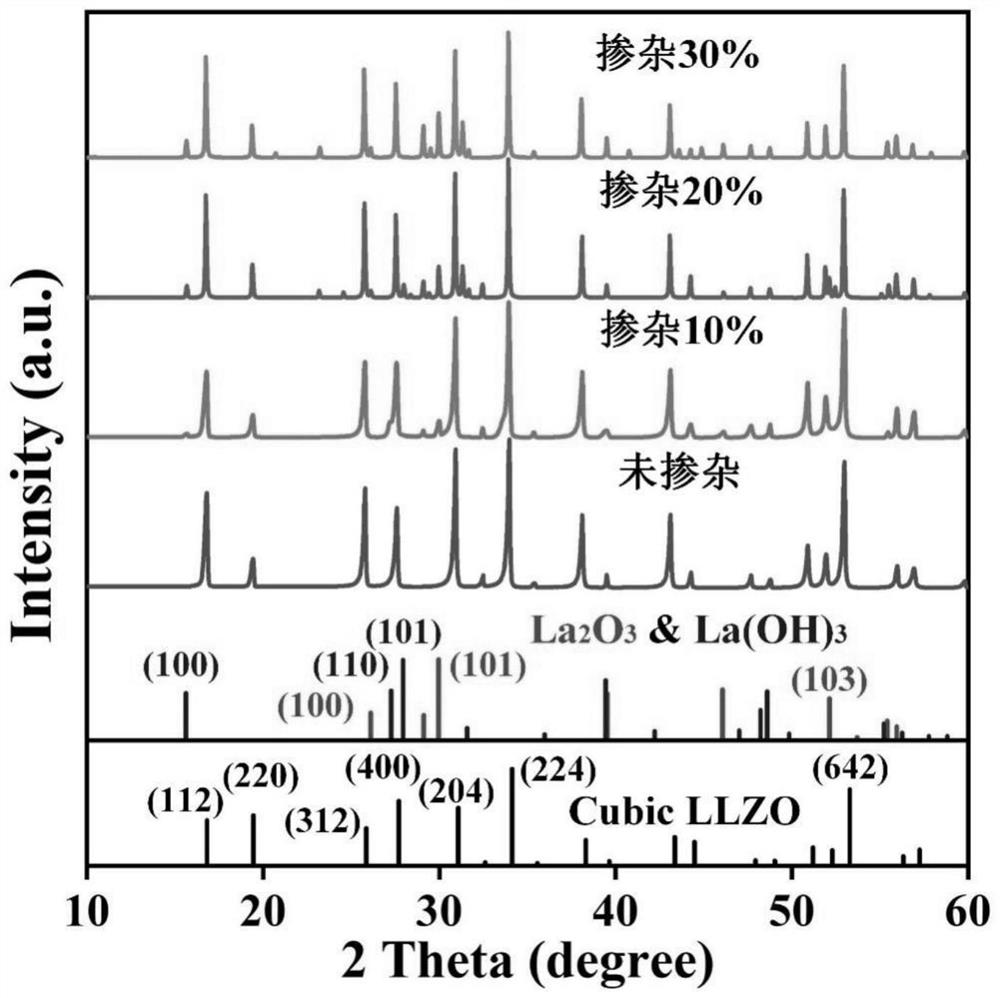

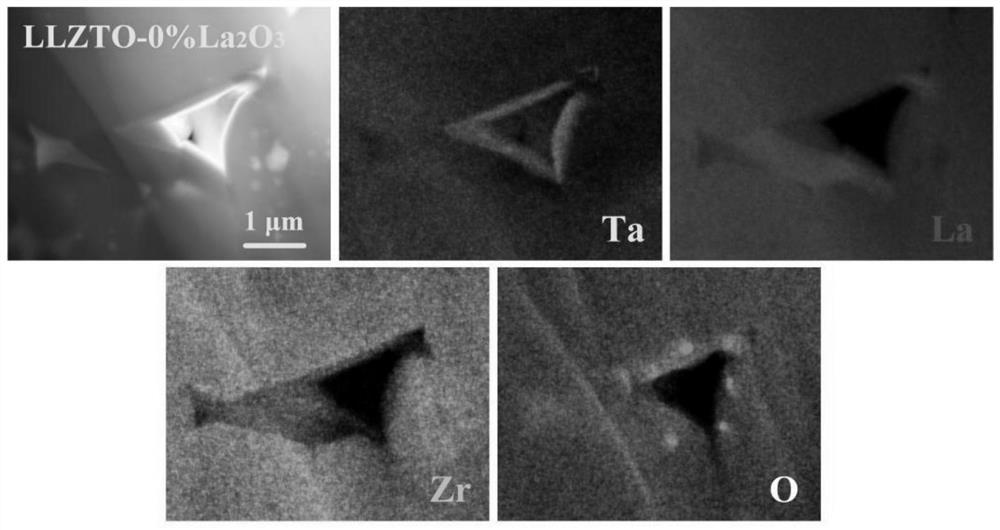

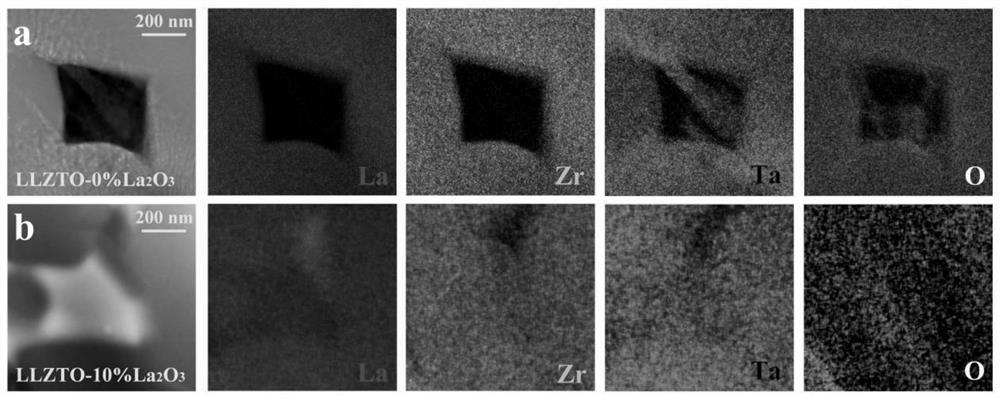

Method for improving compactness and conductivity of tantalum-doped garnet type solid electrolyte

ActiveCN113402271AHigh densityImprove compactnessSecondary cellsElectrolytesSolid state electrolyteAbnormal grain growth

The invention discloses a method for improving compactness and conductivity of tantalum-doped garnet type solid electrolyte, and belongs to the field of electrochemical energy storage. The invention aims to solve the technical problem that the conductivity and compactness of the existing tantalum garnet-doped solid electrolyte are not fully improved. The method comprises the steps of powder mixing, wet ball milling, drying, presintering, wet ball milling, drying, grinding and sieving, glue mixing and tabletting, degumming, and powder burying and sintering. According to the tantalum-doped garnet type solid electrolyte and the preparation method thereof, the element proportion of the La site and the Zr (Ta) site in the tantalum-doped garnet type solid electrolyte LLTZO is adjusted by doping La2O3 nano-particles, then generation of an intermediate phase LaTaO4 is mediated, abnormal grain growth of the LLTZO is effectively inhibited, the sintering homogeneity of the tantalum-doped garnet type solid electrolyte is improved, meanwhile, hole defects are reduced or eliminated to improve the compactness, therefore, the ionic conductivity is improved, and the cycling stability of the solid-state battery is improved. The method is simple, the sintering cost is low, and industrial mass production is easy to realize.

Owner:HARBIN INST OF TECH

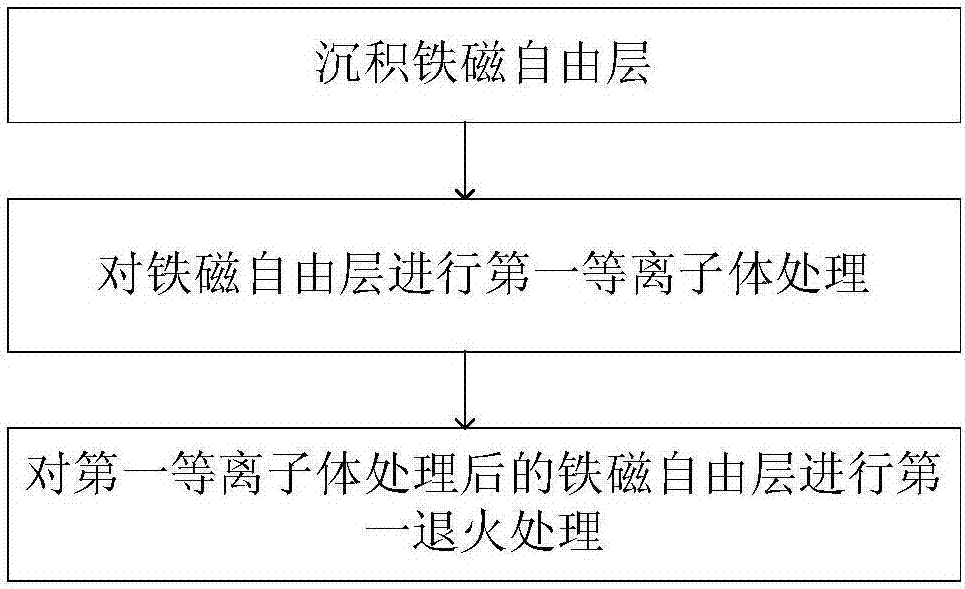

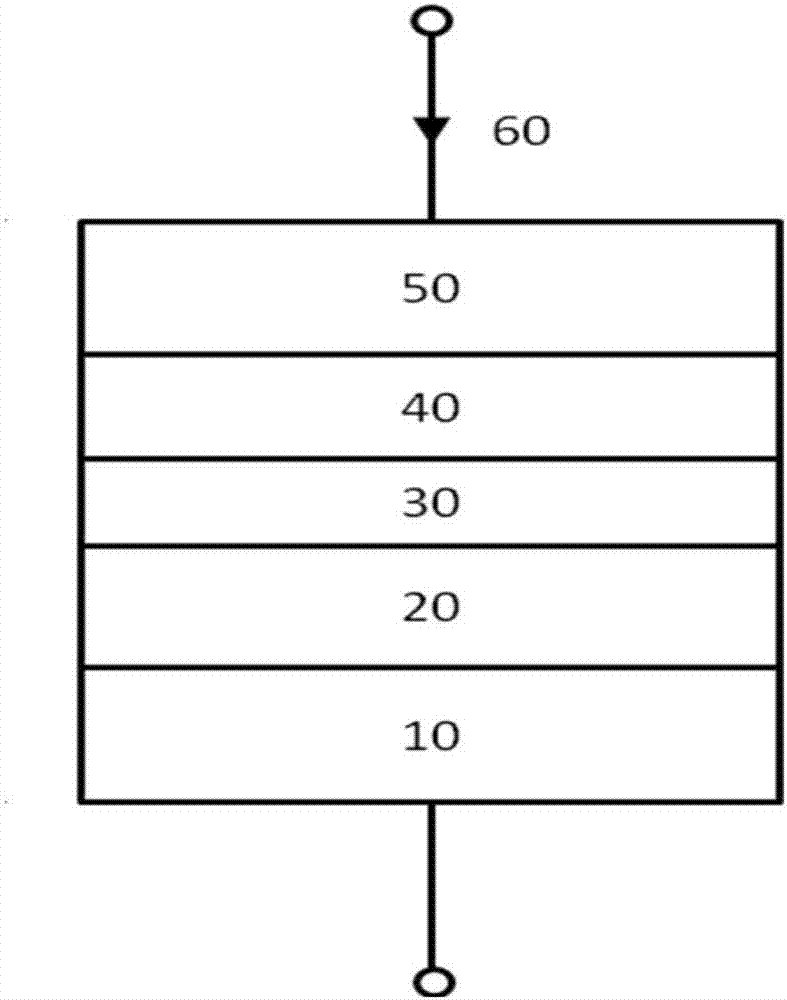

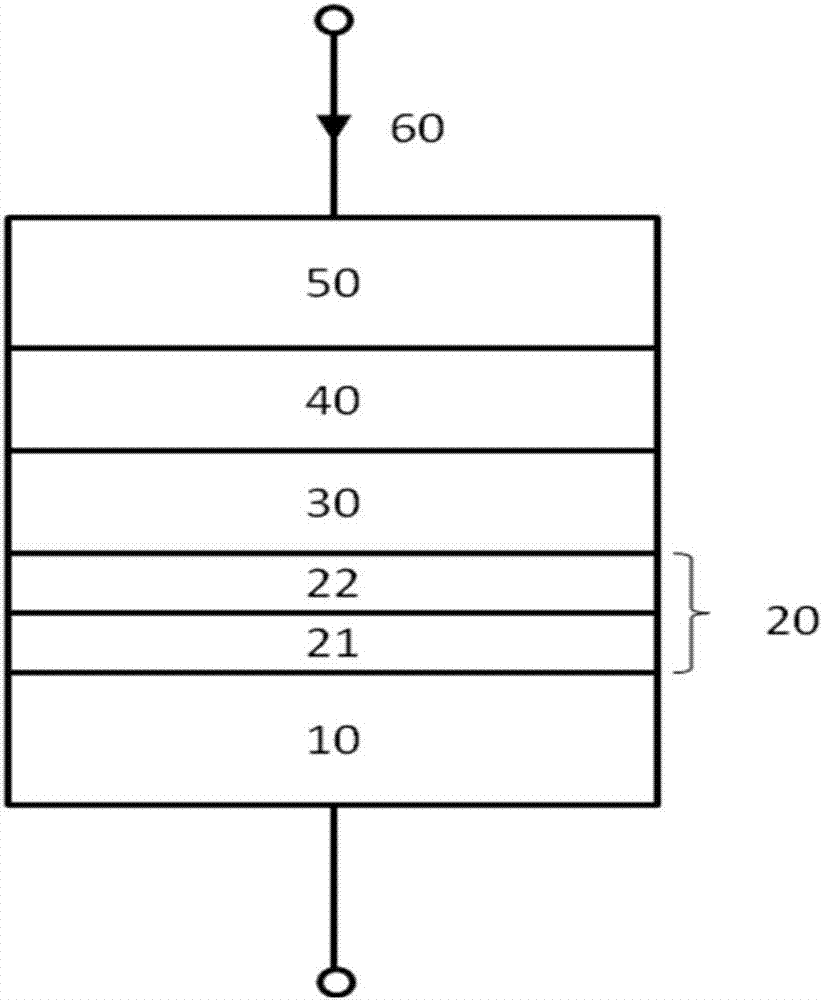

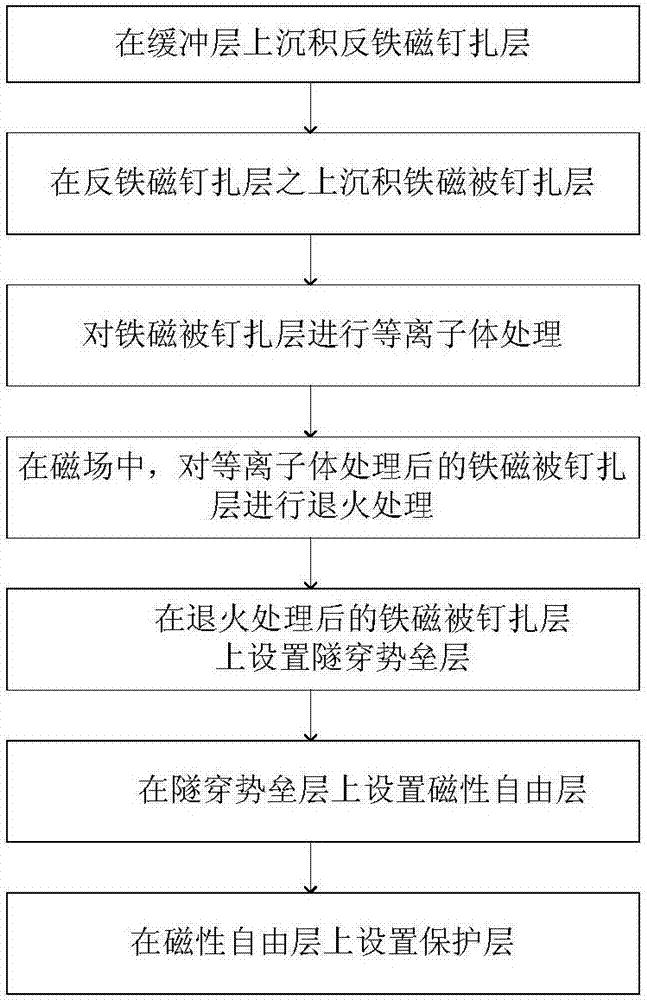

Method for preparing free layer of magnetic tunnel junction and method for preparing magnetic tunnel junction

ActiveCN107958953AImprove surface propertiesImprove performanceGalvano-magnetic device manufacture/treatmentDeposition processTunnel junction

The invention provides a method for preparing a free layer of a magnetic tunnel junction and a method for preparing a magnetic tunnel junction. The method for preparing a free layer of a magnetic tunnel junction includes the steps of setting the films of a free layer through a deposition process, carrying out first plasma treatment on one or more of the films, and carrying out first annealing treatment on the one or more of the films after the first plasma treatment. As in-situ heat treatment is carried out on the one or more films after the first plasma treatment through the first annealing treatment, possible damage or defects caused by the first plasma treatment can be reduced or eliminated, and the surface characteristic of the free layer can be improved. Therefore, the comprehensive performance of a magnetic tunnel junction comprising the free layer can be improved, for example, the TMR value of the magnetic tunnel junction can be improved, and the RA value can be reduced.

Owner:CETHIK GRP +1

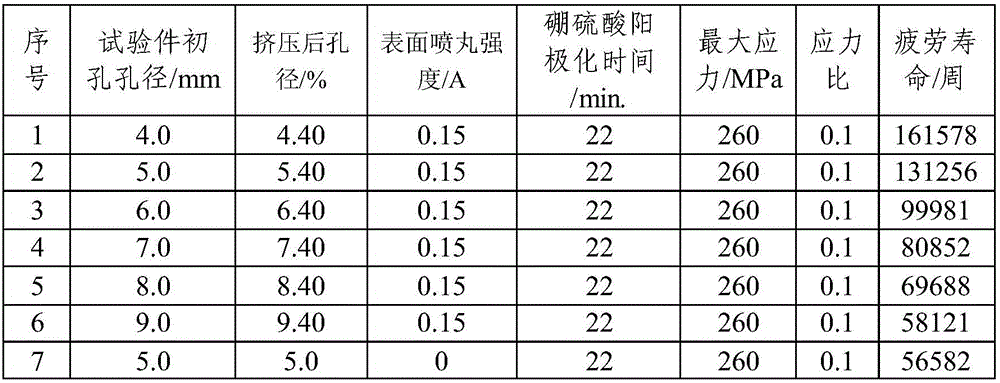

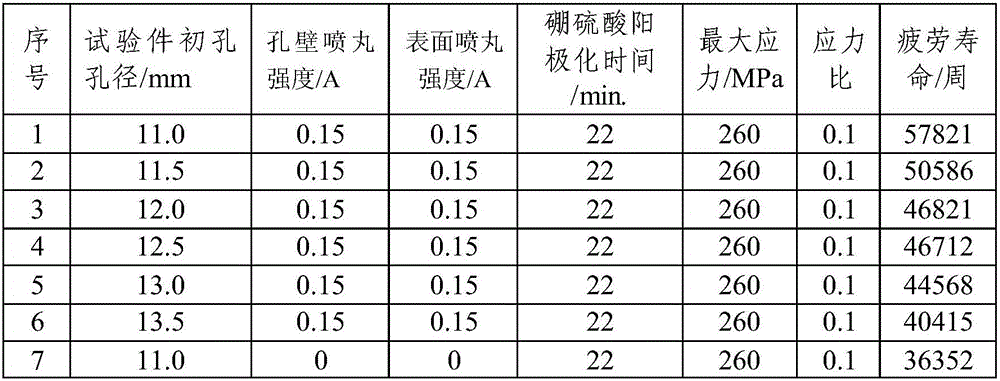

Method for conducting boric sulfuric acid anodization pretreatment on 7A85-T7452 aluminum alloy aeronautical part

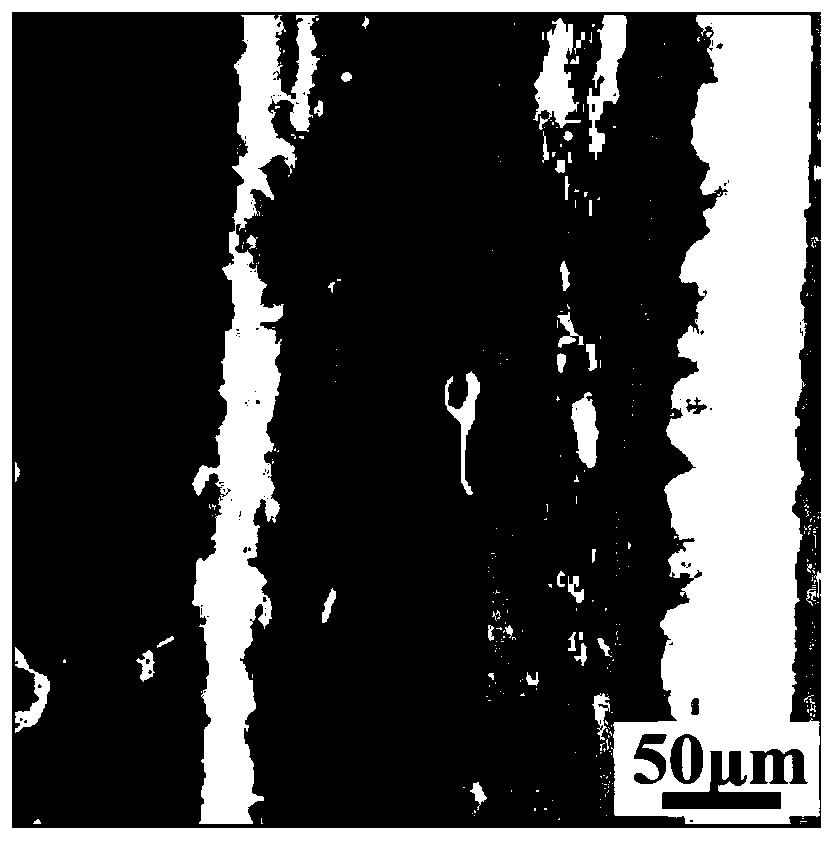

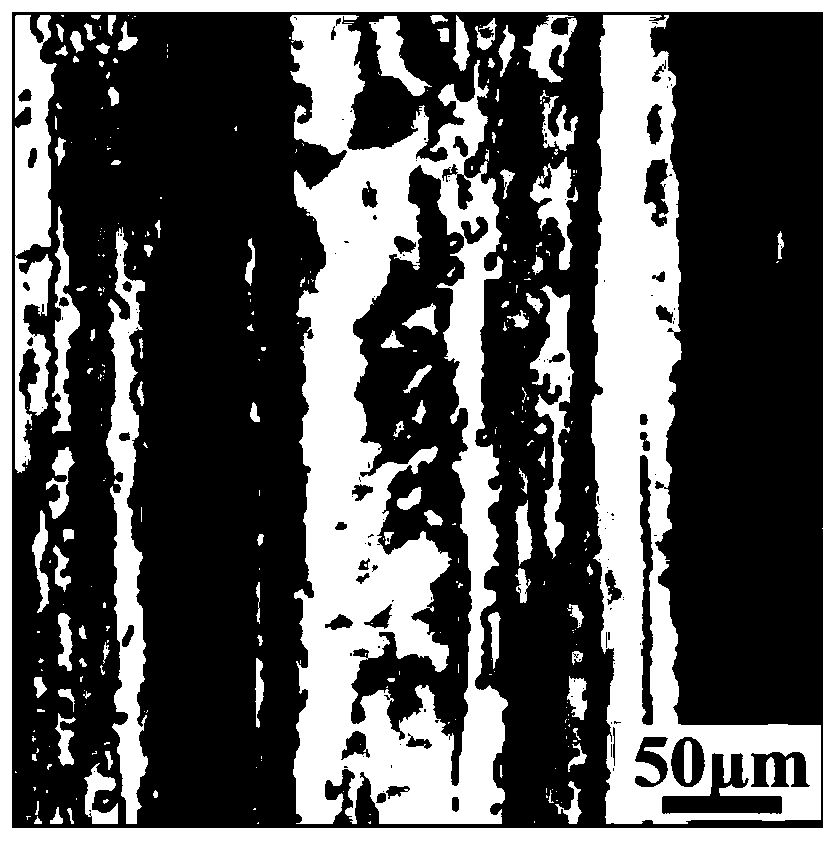

InactiveCN106637344AImprove resistance to damageImprove compactnessAnodisationSurface integrityPeening

The invention belongs to the technical field of aluminum alloy aeronautical part manufacturing and relates to a method for conducting boric sulfuric acid anodization pretreatment on a 7A85-T7452 aluminum alloy aeronautical part. The method comprises the steps of machining of the part, hole treatment, surface treatment, degreasing treatment and surface anodization treatment. The method is targeted at the characteristic that a 7A85-T7452 aluminum alloy has the strong interior sub-grain texture, and the hole treatment process and the surface treatment process for the part are added to the boric sulfuric acid anodization pretreatment phase. By means of hole diameter squeezing or shot blasting treatment conducted on holes and surface shot blasting treatment conducted on the part, surface integrity of the part is effectively restored, and thus compactness and continuity of a boric sulfuric acid anodization oxidation film layer of the part are improved; defects of the oxidation film layer are decreased or eliminated; and damage resistance of the part is improved. By means of the method, corrosion resistance of the part can be improved, and the fatigue life of the part can be prolonged; and in addition, an operation process is easy and convenient to conduct, additional production facilities do not need to be built, and production control can be conducted conveniently.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

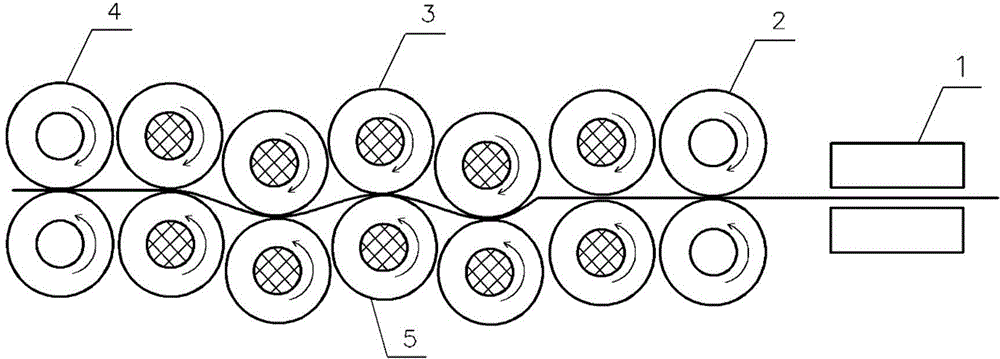

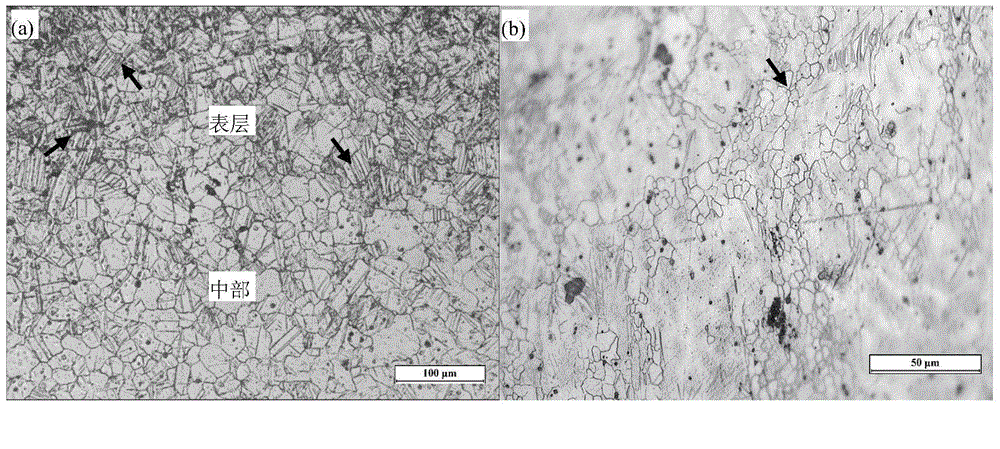

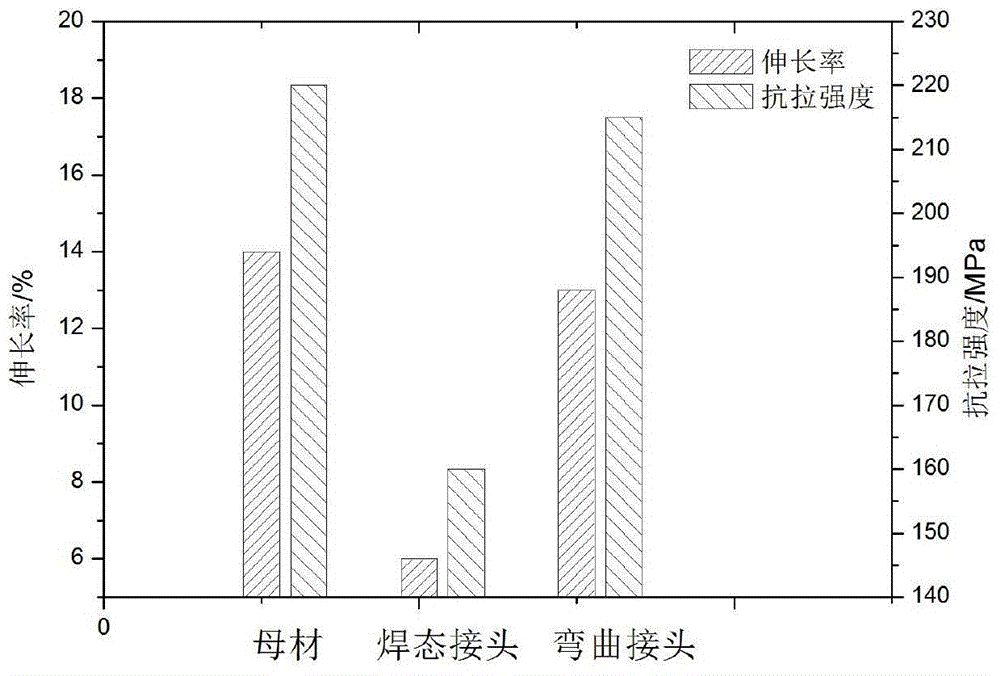

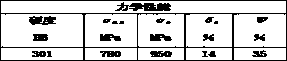

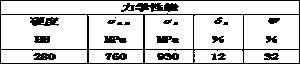

Biaxial bending deformation device and processing method for processing welded joint

ActiveCN104818441AEliminate continuityStress reliefFurnace typesHeat treatment furnacesWeld seamPulp and paper industry

The invention provides a biaxial bending deformation device and a processing method for processing a welded joint. The biaxial bending deformation device comprises a heating heat preservation device, a plate feeding roller group, a plurality of pairs of curved roller groups, a plurality of pairs of rolling roller groups and a passage penetrating through all heat preservation layers, plate feeding roller group, curved roller groups and rolling roller groups, wherein the passage is divided into a horizontal section and a curved section, the heating heat preservation device, the plate feeding roller group and the rolling roller groups are arranged on the horizontal section, the curved roller groups are arranged on the curved section, the curved section comprises a plurality of concave curved surfaces and convex curved surfaces, which are alternately arranged, the curved roller groups include an upper curved roller group and a lower curved roller group, the upper curved roller group is arranged on the convex curved surface, and the lower curved roller group is arranged on the concave curved surface. By adopting the biaxial bending deformation device, a weld seam of the welded joint can be extended to certain extent, so that the residual stress can be reduced, and crystalline grains can be refined; and the biaxial bending deformation device is particularly suitable for the welded joint with relatively low mechanical performance.

Owner:无锡市通瑞电力自动化设备有限公司

Long-life steam turbine blade and production process thereof

ActiveCN104046919AReduced impact toughnessImprove impact toughnessBlade accessoriesFurnace typesMaterials scienceIndustrial engineering

The invention discloses a long-life steam turbine blade. The long-life steam turbine blade consists of the following chemical components in percentage by weight: 0.29-0.31% of C, 0.16-0.19% of Si, 0.75-0.77% of Mn, 0.73-0.85% of Ni, 9.5-10.1% of Cr, 0.55-0.64% of Mo, 0.15-0.17% of Sn, 0.11-0.15% of V, 0.82-0.84% of Sr, 0.15-0.17% of Nb, 0.02%-0.03% of Cu, 0.13%-0.15% of T, 0.06-0.08% of B, not greater than 0.01% of Ca, not greater than 0.03% of S, not greater than 0.03% of P, 0.16%-0.18% of rear-earth metal, and the balance of Fe. The production process disclosed by the invention is carried out by hot-forging, annealing, blade mechanical machining, distressing thermal treatment, tempering thermal treatment, cooling, surface-enhanced thermal treatment, physical and chemical inspecting, ultrasonic-wave flaw detecting, and cleaning-packaging. The production process disclosed by the invention can greatly improve impact toughness of the blade, can improve water erosion resistance and corrosion resistance of the blade, and can prolong the service life of the blade.

Owner:南京赛达科技有限公司

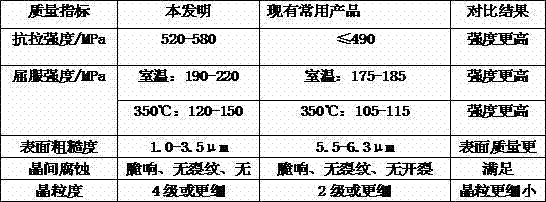

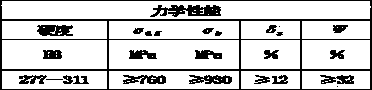

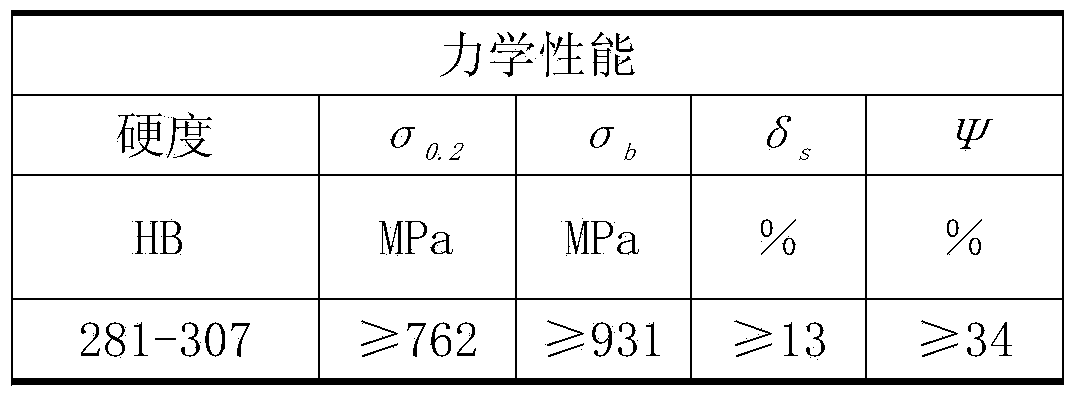

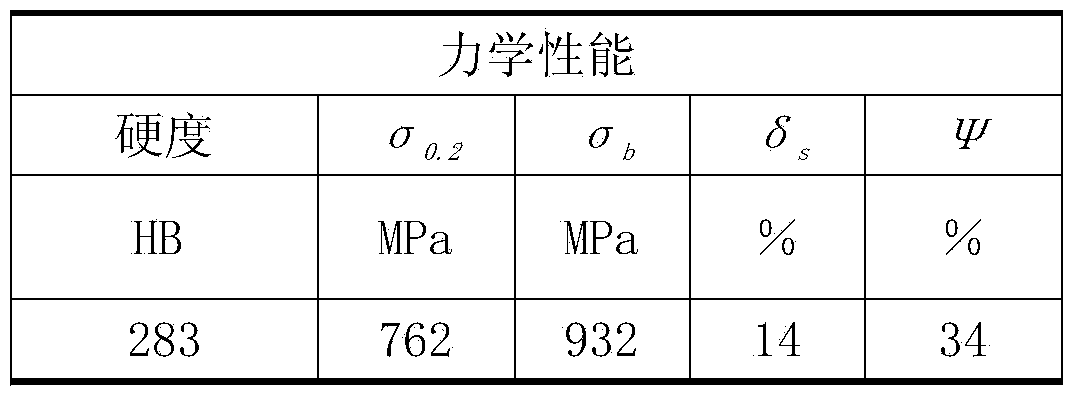

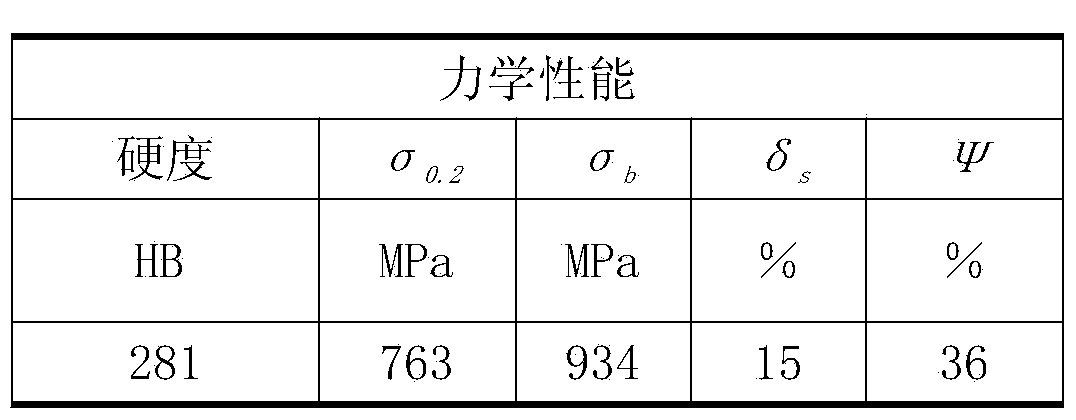

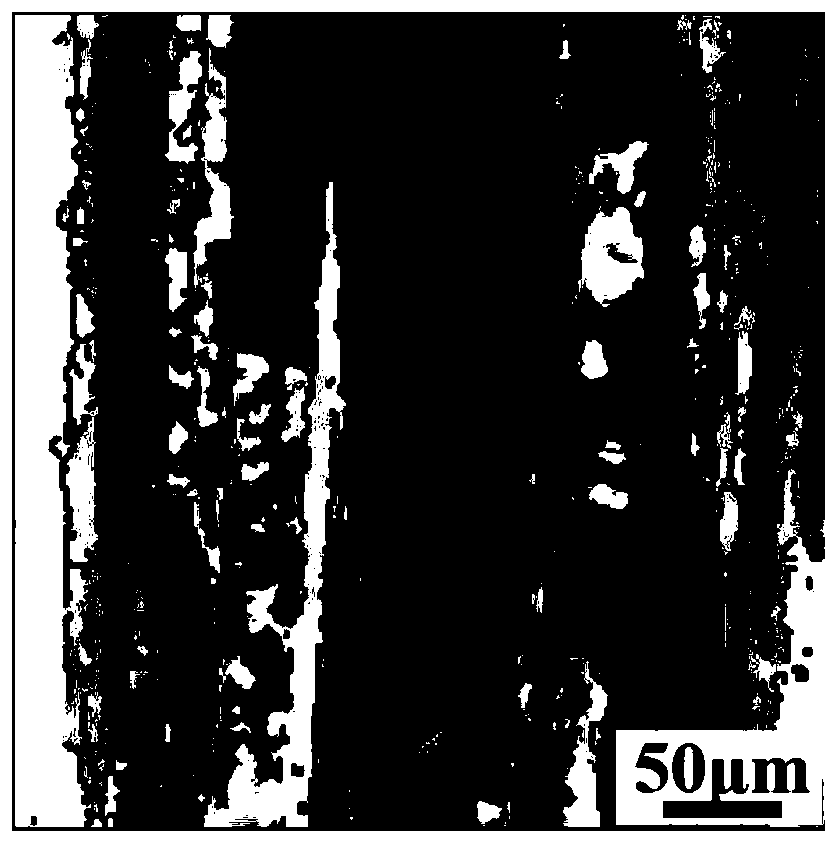

Processing technology of connecting rod shaft

The invention provides a processing technology of a connecting rod shaft. The processing technology comprises the following steps of rough turning, quenching treatment, finish turning, rough grinding, stabilizing treatment, half-finish grinding, secondary stabilizing treatment and finish grinding. The processing technology has the advantages that by adopting the method, the quality of a product is stable, the quality of a bearing is greatly improved, the crystal grains can be fined by the surface strong heat treatment, the roughness of the bearing is improved, the defects of strip structures and the like can be reduced or eliminated, the integral impact property of the bearing is improved, the bearing structure is more uniform and stable, the air holes and sand holes are fewer, and the comprehensive mechanical property and corrosion-resistant property are better; the cycle is shortened, the consumption of a grinding wheel is decreased, the production efficiency is greatly improved, and the comprehensive economic efficiency is greatly improved in comparison with the prior art.

Owner:GUIZHOU HONGXIANG BEARING

Surface modification method of ceramic cutting tool

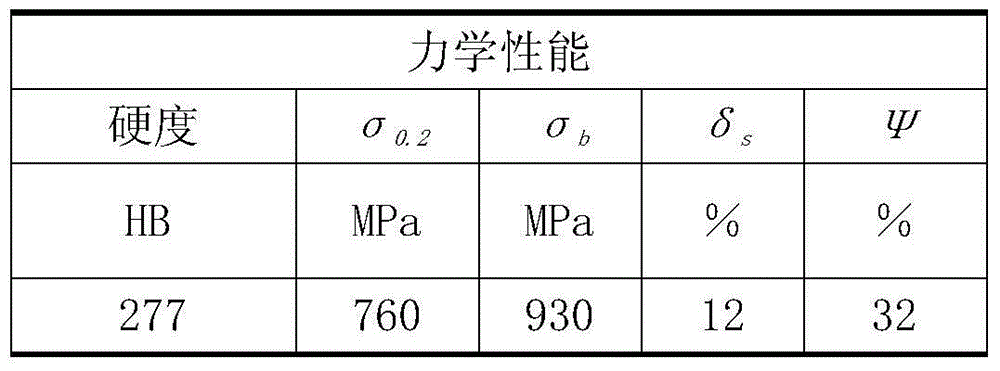

The invention relates to a surface modification method of a ceramic cutting tool. According to the method, an MEVVA implantation technique is adopted to carry out surface modification on a cleaned cutting tool, wherein implanted ions are any three, four or five kinds of titanium, zirconium, chromium, molybdenum and tungsten ions. After ion implanted modification, the mechanical properties of the ceramic cutting tool are remarkably improved, and the life of the ceramic cutting tool is prolonged, so that the ceramic cutting tool is applicable to the machining of high-hardness and high-strength materials.

Owner:WUXI CHENGBO SCI & TECH DEV

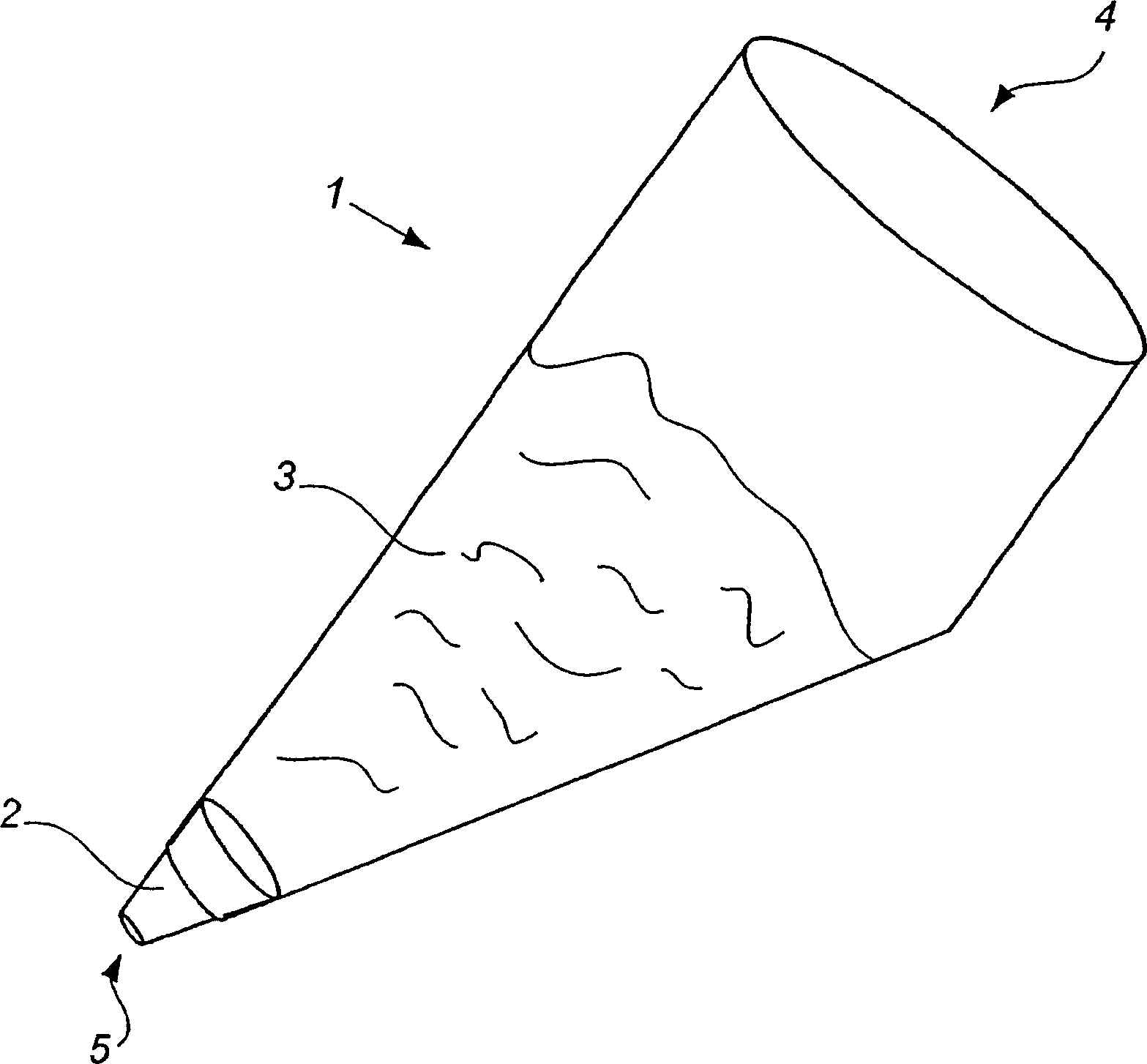

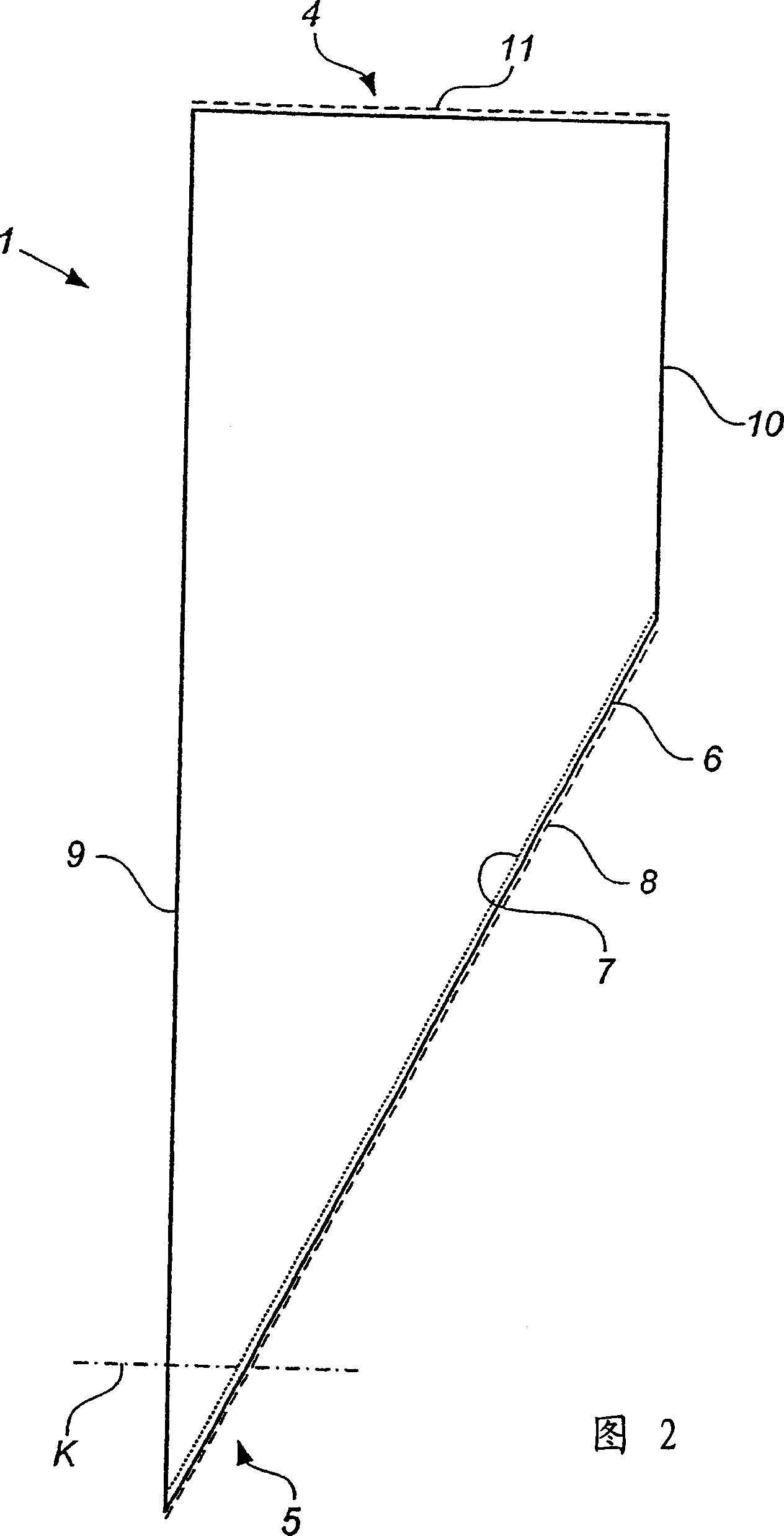

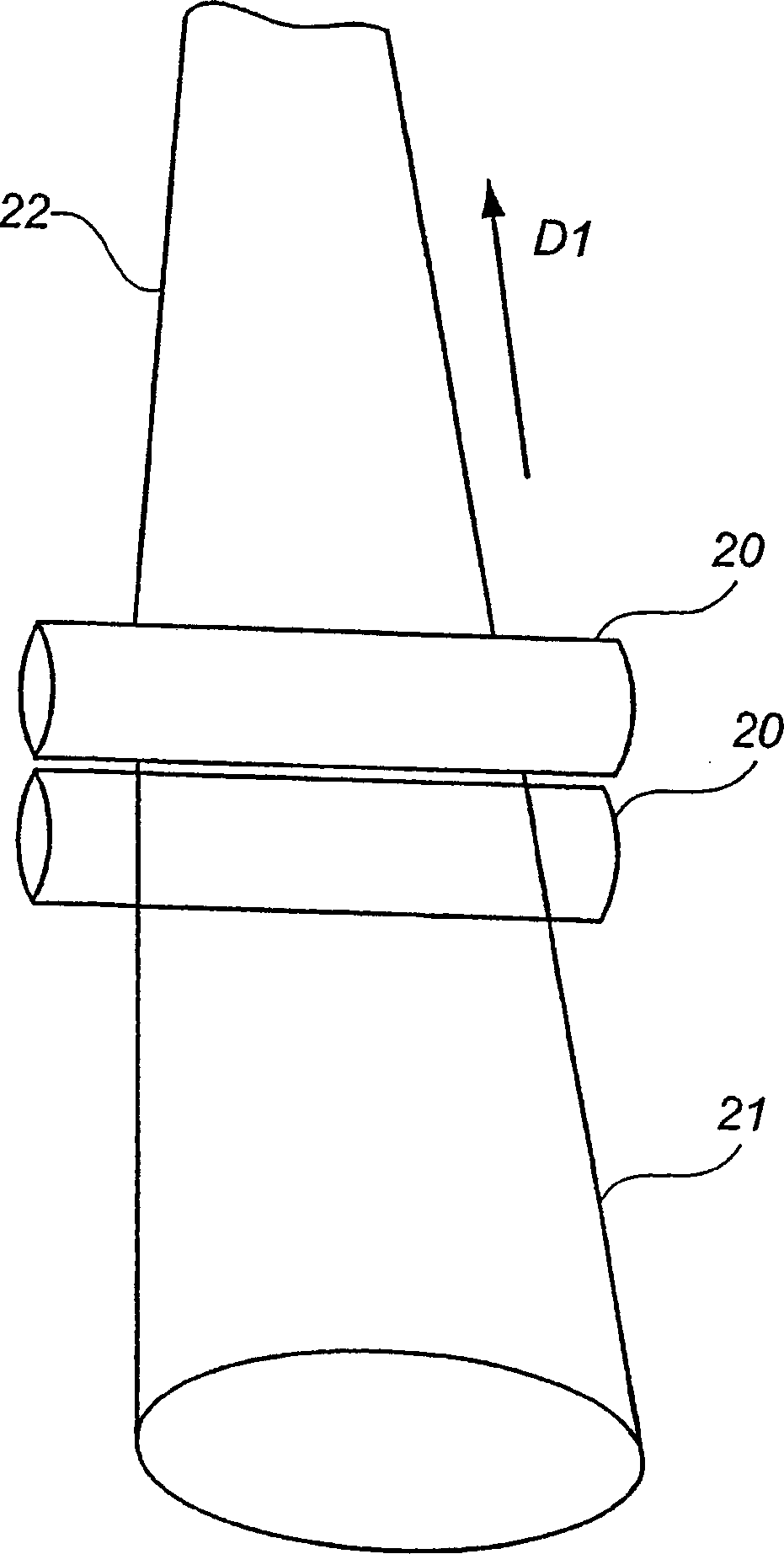

Piping bag, blank for manufacturing a piping bag and method of manufacturing a piping bag

ActiveCN1794919AEasy to holdReduced risk of slippingFlexible coversWrappersEngineeringPolymer thin films

The bag (1) has a container of polymer film, and an outwardly oriented surface to be provided with a rough surface structure to increase friction between user's hand and the bag, where the bag is made essentially from a thin-walled polymer tube. The outwardly oriented surface comprises friction-enhancing agents. The surface structure is formed by adding grains or flakes to polyolefin plastic of which the thin-walled polymer tube is made, pattern-rolling the polymer tube, and applying lacquer to the outwardly oriented surface combined with adding grains or flakes to the lacquer. Independent claims are also included for the following: (1) a blank for manufacturing a disposable piping bag (2) a method for manufacturing a disposable piping bag.

Owner:KEE PLASTICS

Turbine blade capable of enhancing water corrosion resistance and production technique thereof

ActiveCN104060192AThe segregation of alloying elements is weakenedImprove impact toughnessFurnace typesHeat treatment furnacesCorrosionSteam turbine blade

Owner:南京赛达科技有限公司

Special steel and processing technique of high-wear-resistance bearing

ActiveCN104195456AReduce segregationReduced impact toughnessFurnace typesHeat treatment furnacesLutetiumTempering

The invention discloses a special steel of a high-wear-resistance bearing. The blank comprises the following chemical components in percentage by mass: 0.21-0.23% of C, 0.07-0.09% of Si, 0.66-0.68% of Mn, 0.83-0.85% of Ni, 9.1-9.3% of Cr, 0.55-0.57% of Mo, 0.13-0.15% of V, 0.11-0.13% of Nb, 0.01-0.03% of Cu, 0.19-0.21% of Ti, 0.05-0.07% of B, at most 0.025% of S, at most 0.015% of P, 0.12-0.14% of rare-earth metal and the balance of Fe. The rare-earth metal comprises the following chemical components in percentage by mass: 2-4% of cerium, 11-13% of neodymium, 3-5% of gadolinium, 4-6% of lutetium, 5-7% of dysprosium, 1-3% of europium, 8-10% of erbium and the balance of lanthanum. The invention also discloses a processing technique of the high-wear-resistance bearing, which comprises the following steps: forging, annealing, tempering, turning, carburizing and heat treatment. The product has the characteristics of high working size precision, stable inherent quality, excellent properties, long service life and high reliability.

Owner:南京创贝高速传动机械有限公司

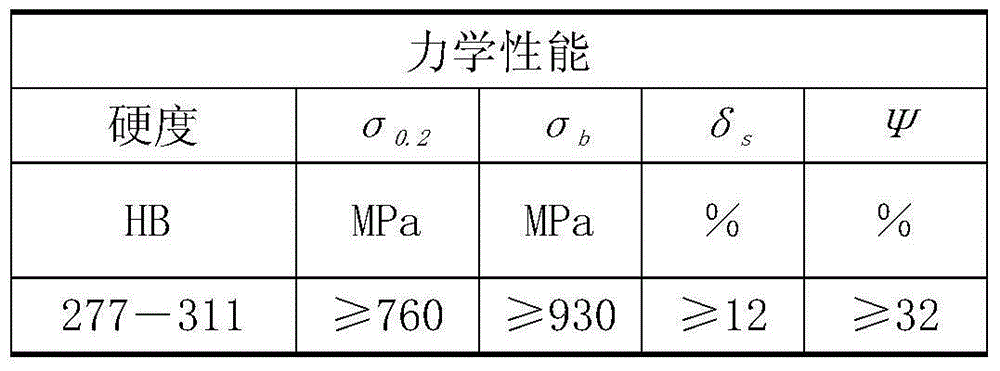

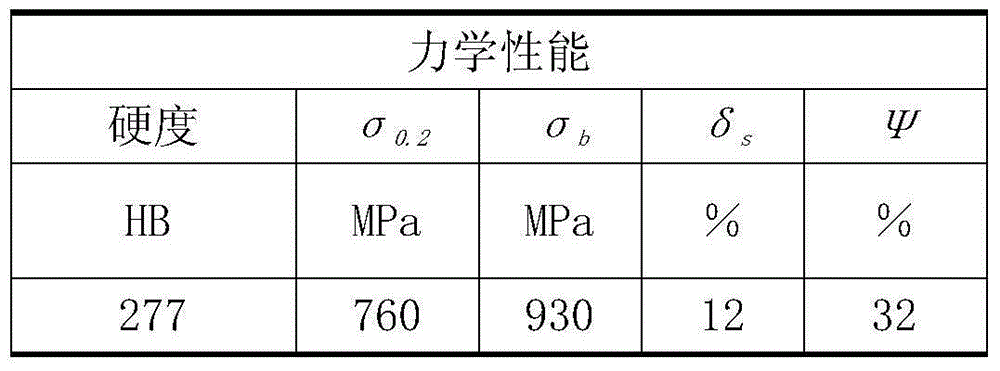

Special steel material for high-strength bearing and machining process of high-strength bearing

ActiveCN104213040AReduce segregationReduced impact toughnessSolid state diffusion coatingMischmetalTempering

The invention discloses a special steel material for a high-strength bearing and a machining process of the high-strength bearing. A blank comprises the following chemical components in percentage by mass: 0.24-0.26% of C, 0.10-0.12% of Si, 0.95-0.97% of Mn, 0.45-0.47% of Ni, 6.3-6.5% of Cr, 0.26-0.28% of Mo, 0.32-0.34% of Sr, 0.08-0.10% of Nb, 0.03-0.05% of Cu, 0.17-0.19% of Al, 0.26-0.28% of Ti, not more than 0.01% of S, not more than 0.02% of P, and 0.15-0.17% of rare earth metals, the balance being Fe, wherein the rare earth metals consist of the following chemical components in percentage by mass: 3-5% of praseodymium, 11-13% of neodymium, 9-11% of promethium, 3-5% of gadolinium, 2-4% of lutecium, 6-8% of europium, 1-3% of terbium and 4-6% of holmium, the balance being erbium. The invention further discloses the machining process of the high-strength bearing; and the machining process comprises the steps of forging, annealing, tempering, turning, carburizing and heat treatment. The produced bearing has the characteristics of high machining size precision, stable inherent quality, excellent performance, long service and high reliability.

Owner:南京创贝高速传动机械有限公司

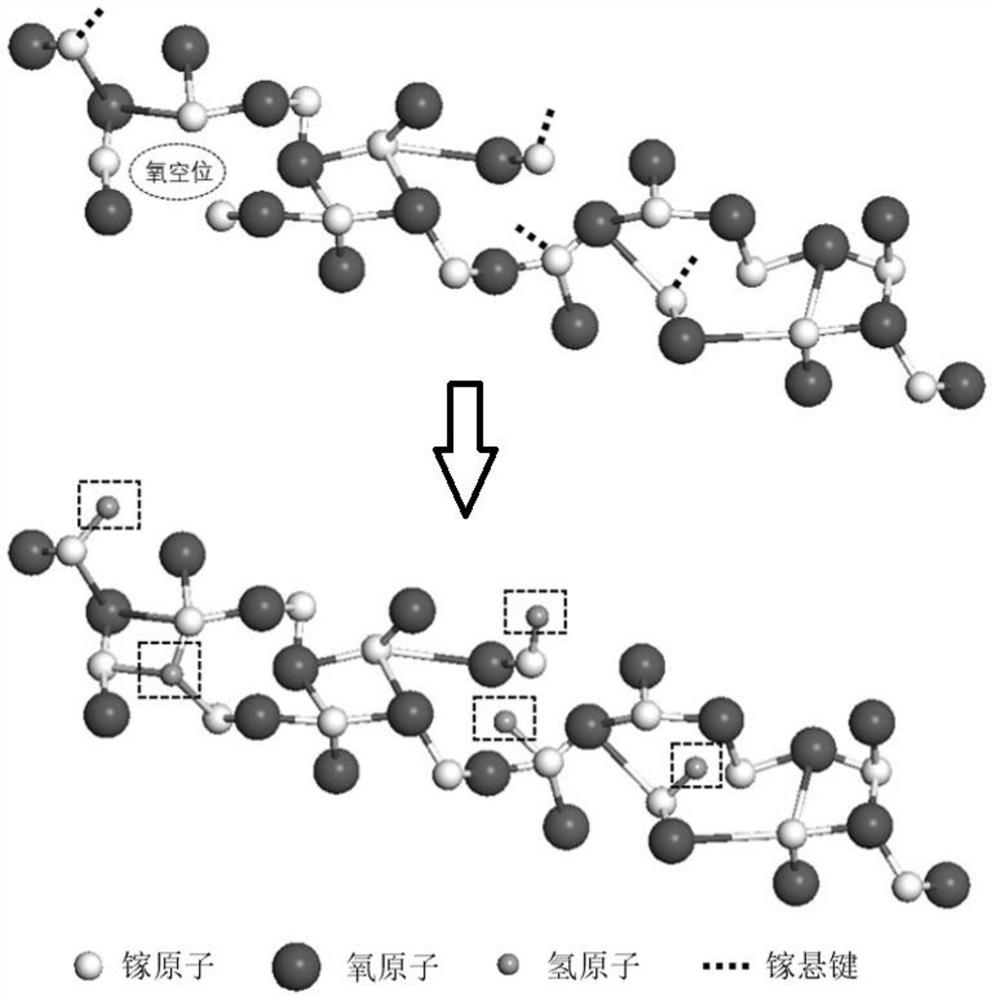

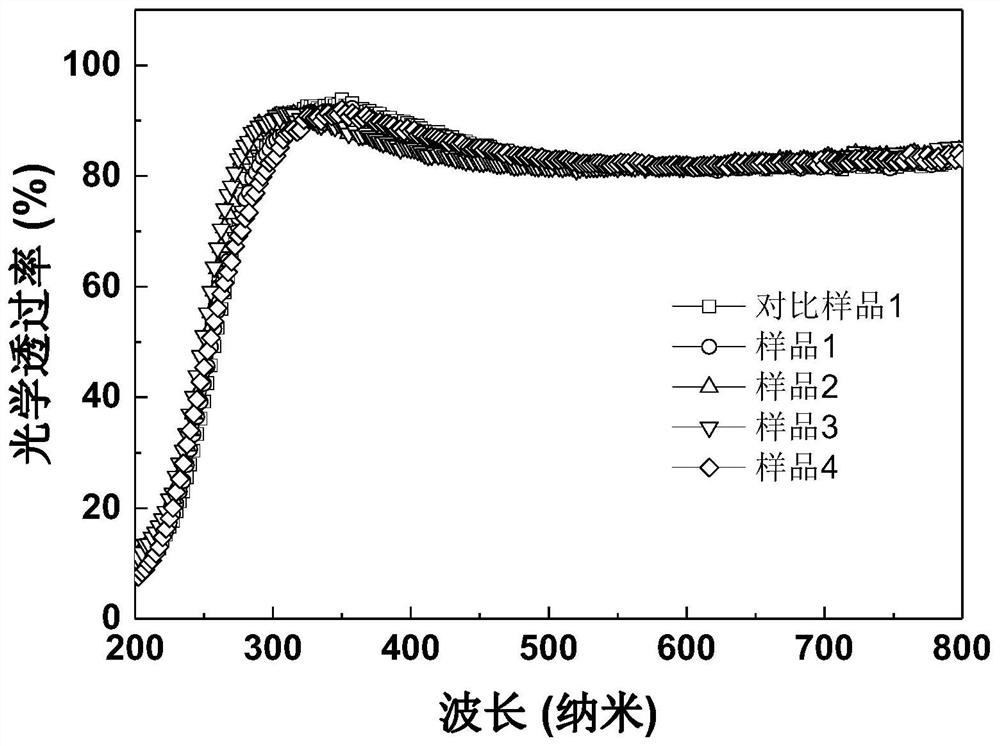

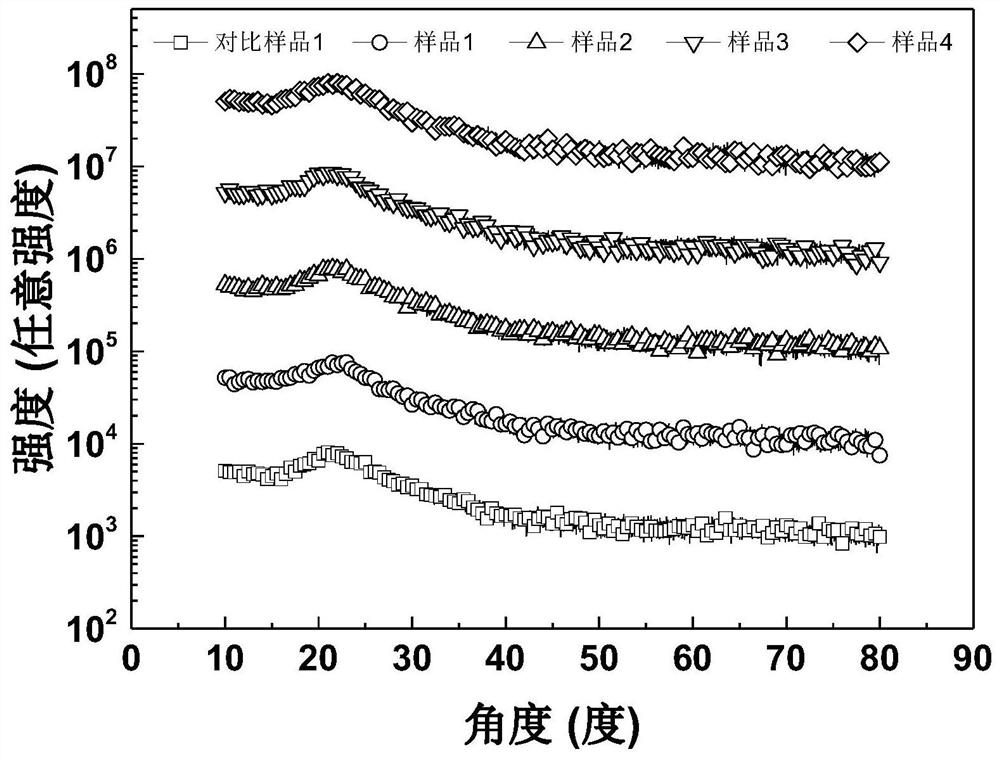

Amorphous Ga2O3 photoelectric detector and preparation method and performance improvement method thereof

ActiveCN111697090AReduce or eliminate defectsIncreased light to dark ratioFinal product manufactureSemiconductor devicesHydrogen atmosphereChemical vapor deposition

The invention discloses an amorphous Ga2O3 photoelectric detector and a preparation method and a performance improvement method thereof. The amorphous Ga2O3 photoelectric detector comprises a substrate, a hydrogen-doped amorphous Ga2O3 thin film active layer deposited on the surface of the substrate and an electrode arranged on the hydrogen-doped amorphous Ga2O3 thin film active layer, wherein thehydrogen-doped amorphous Ga2O3 thin film active layer is an amorphous thin film prepared by adopting a vacuum deposition method in a hydrogen-containing atmosphere at the temperature of 20-400 DEG C;the vacuum deposition method comprises any one of magnetron sputtering, pulse laser deposition, electron beam deposition and chemical vapor deposition.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Large-diameter flange and preparation process thereof

ActiveCN103031500BGrain refinementUniform grain refinementFurnace typesHeat treatment furnacesChemical compositionTempering

The invention discloses a large-diameter flange and a preparation process thereof. The large-diameter flange comprises the following chemical components by weight percent: 0.45 to 0.65% of C, 0.25 to 0.30% of Si, 0.85 to 0.95% of Mn, 9 to 11% of Ni, 2 to 3 % of Cr, 0.15 to 0.20% of Nb, 0.85 to 0.95% of Cu, 0.02 to 0.04% of N, 0.13 to 0.15% of Mo, 0.2 to 0.3% of Al, 0.07 to 0.09% of S, 0.03 to 0.04% of Ti, 0.02 to 0.03% of V, 0.002 to 0.004% of B, 6 to 8% of lanthanide rare earth, and the balance of Fe. The processes of twice normalizing and twice tempering and the cooling thermal treatment process are adopted, the flange is guaranteed to have high tensile strength, high yield strength and smaller surface roughness, the structure is more stable and more uniform, and air holes and sand holes are little.

Owner:WUXI HUAERTAI MACHINERY MFG

Method for preparing reference layer of magnetic tunnel junction and method for preparing magnetic tunnel junction

ActiveCN107958954AImprove surface propertiesImprove performanceMagnetic-field-controlled resistorsGalvano-magnetic device manufacture/treatmentDeposition processTunnel junction

The invention provides a method for preparing a reference layer of a magnetic tunnel junction and a method for preparing a magnetic tunnel junction. The method for preparing a reference layer of a magnetic tunnel junction includes the steps of setting the films of a reference layer through a deposition process, carrying out plasma treatment on one or more of the films, and carrying out annealing treatment on the one or more of the films after the plasma treatment. As in-situ heat treatment is carried out on the one or more films after the plasma treatment through the annealing treatment, possible damage or defects caused by the plasma treatment can be reduced or eliminated, and the surface characteristic of the reference layer can be improved. Therefore, the comprehensive performance of amagnetic tunnel junction comprising the reference layer can be improved, for example, the TMR value of the magnetic tunnel junction can be improved, and the RA value can be reduced.

Owner:CETHIK GRP +1

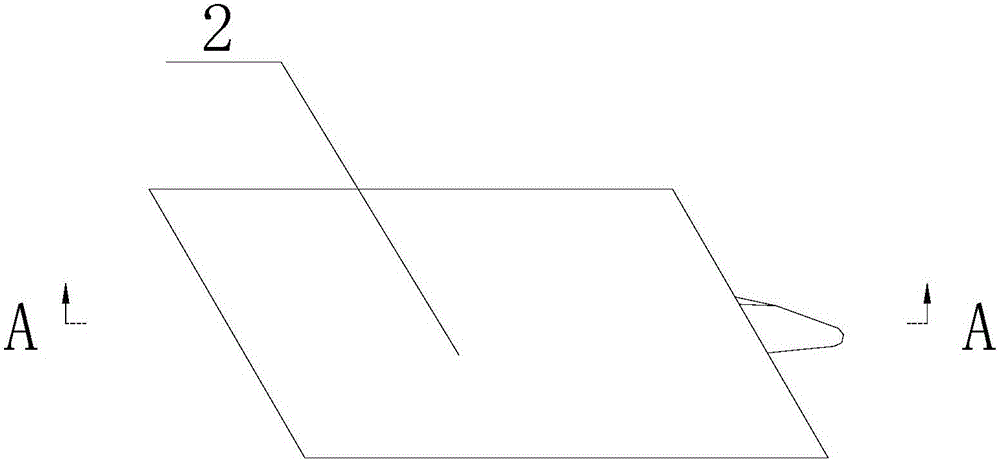

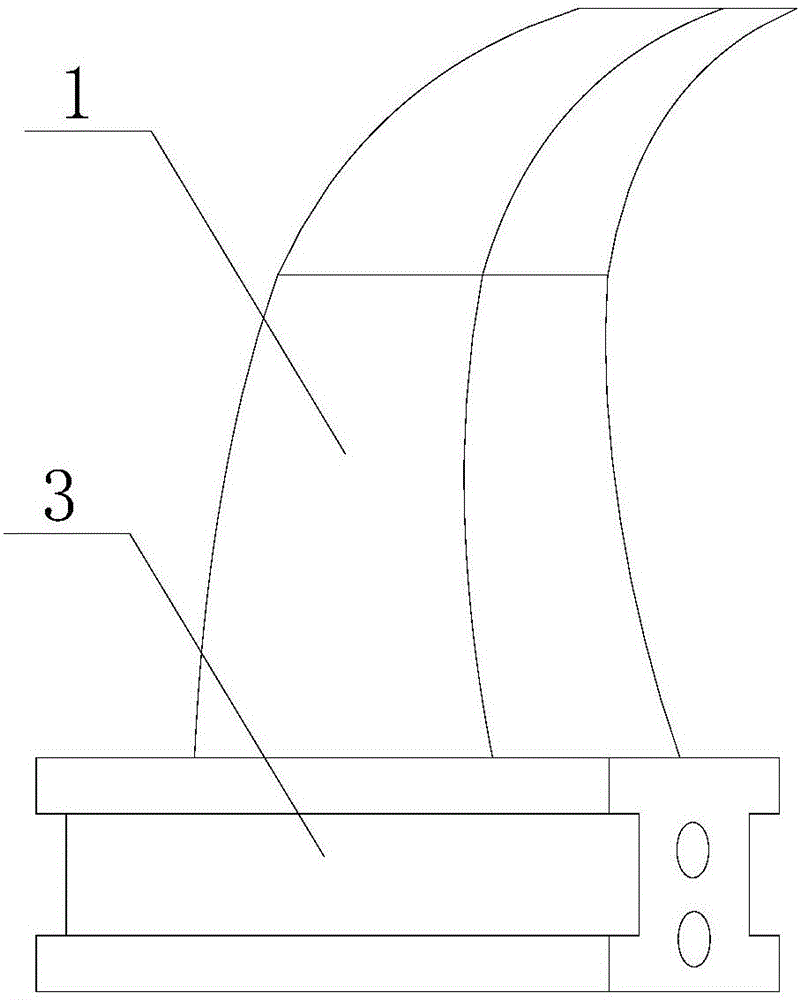

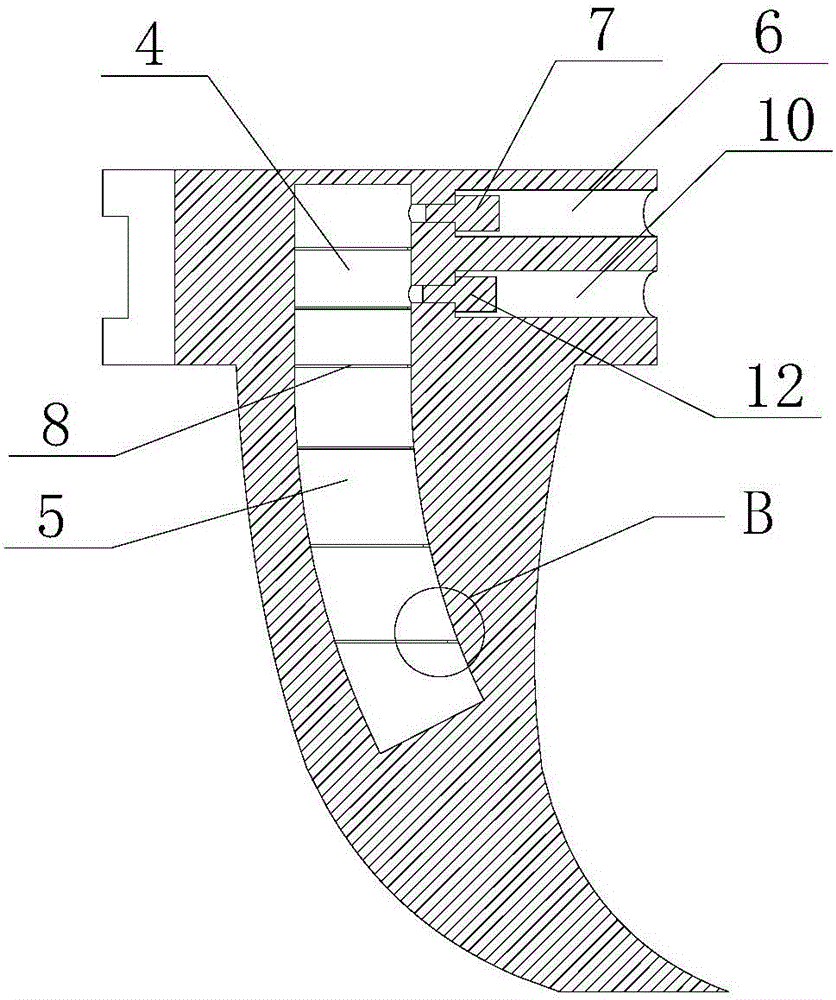

Water-cooled type steam turbine vane

InactiveCN106435355AImprove water erosion resistanceUniform and stable tissueMolten spray coatingBlade accessoriesSteam turbine bladeImpact toughness

The invention relates to a water-cooled type steam turbine vane comprising a vane body and a vane root. The vane root is in a parallelogram shape. Vane root grooves are formed in the upper side and the lower side of the vane root correspondingly. A first cavity and a second cavity which communicate with each other are formed in the vane body and the vane root correspondingly. A groove is formed in the side, in the length direction, of the vane root. A plug is arranged at the bottom of the groove. The groove communicates with the second cavity. Cooling water is contained in the first cavity and the second cavity. A high-temperature-resistant metal coating is arranged on the surface of the vane body. By means of the water-cooled type steam turbine vane, the impact toughness of the vane can be substantially improved, the service life of the vane is prolonged, and the cooling performance of the vane is improved.

Owner:南京赛达科技有限公司

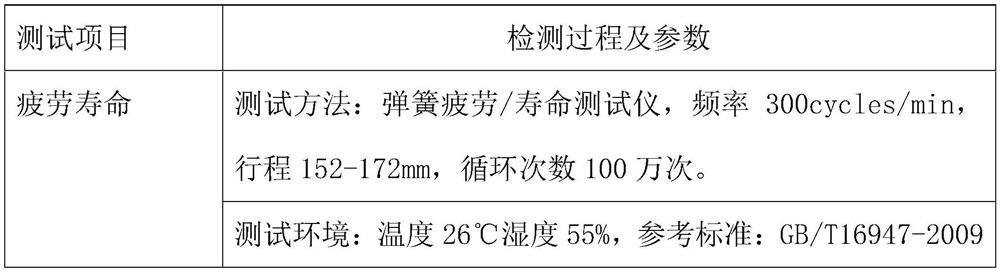

Production technique for suspension springs

InactiveCN106734779AShorten winding timeExcellent stress relaxation resistanceAnalysing solids using sonic/ultrasonic/infrasonic wavesWire springsSand blastingStress relief

The invention discloses a production technique for suspension springs. The production technique for the suspension springs comprises the following steps of winding, specifically, winding of suspension spring main bodies is conducted according to the preset heights, outer diameters and turn numbers of the springs, one-time drawing formation of hook rings at the two ends and the suspension spring main bodies is conducted at the same time, and thus primary finished suspension springs are obtained; tempering stress relief, specifically, the primary finished suspension springs are placed in a tempering furnace for tempering stress relief; flaw detection, specifically, flaw detection is conducted on the primary finished suspension springs subject to tempering stress relief; surface treatment, specifically, primary sand blasting is conducted on the primary finished suspension springs subjected to flaw detection, and secondary sand blasting is conducted on the primary finished suspension springs subjected to primary sand blasting; sorting, specifically, machined finished suspension springs are conveyed one by one through spring conveying equipment, and stacking and sorting of the finished suspension springs are achieved; and packaging, specifically, the sorted suspension springs are placed in storage bags so as to be packaged. In this way, by adoption of the production technique for the suspension springs, the winding time of the suspension springs can be shortened, the stress relaxation resistance of the suspension springs is effectively improved, and the fatigue life of the springs is prolonged.

Owner:WUXI FENGLI SPRING

Aluminum alloy for petroleum drill rod, manufacturing method of pipe thereof and pipe for petroleum drill rod

The invention relates to an aluminum alloy for a petroleum drill rod, a manufacturing method of a pipe thereof and the pipe for the petroleum drill rod, which belong to the technical field of aluminumalloy materials. The aluminum alloy is composed of the following components in percentages by mass: 5.9-6.3% of Zn, 1.6-2.0% of Mg, 1.1-1.5% of Cu, 0.3-0.35% of Mn, 0.14-0.16% of Cr, 0.03-0.13% of Er, 0.06-0.08% of Zr, 0.05% of Ti, less than or equal to 0.1% of inevitable impurities, and the balance Al. The aluminum alloy is used as a raw material and cooperates with a preparation process combining two-stage homogenization, two-stage solid solution and three-stage aging system, the pipe for the petroleum drill rod with high strength, corrosion resistance and high heat resistance can be prepared, and the manufacturing method of the pipe is simple and easy to operate, low in equipment requirement and suitable for expanded production.

Owner:CHONGQING UNIV

High-pressure-resistant turbine blade and production process thereof

ActiveCN105239021AReduce segregationReduced impact toughnessFurnace typesHeat treatment furnacesTurbine bladeRare earth

The invention relates to a high-pressure-resistant turbine blade. The chemical components of the high-pressure-resistant turbine blade include 0.019-0.021% of C, 0.09-0.11% of Si, 0.83-0.85% of Mn, 0.55-0.57% of Ni, 1.7-1.9% of Cr, 0.11-0.13% of Mo, 3.9-4.1% Co, 4.26-4.28% of V, 0.01-0.03% of Nb, 0.03-0.05% of Cu, 6.21-6.23% of Al, 0.007-0.009% of N, 0.23-0.25% of Ti, 0.08-0.10% of rare earth metal and the balance Fe. The invention further provides a production process for the high-pressure-resistant turbine blade. The impact toughness of the blade is greatly improved, the anti-water-erosion capacity and the corrosion resistance of the blade are improved, and the service life of the blade is prolonged.

Owner:南京赛达科技有限公司

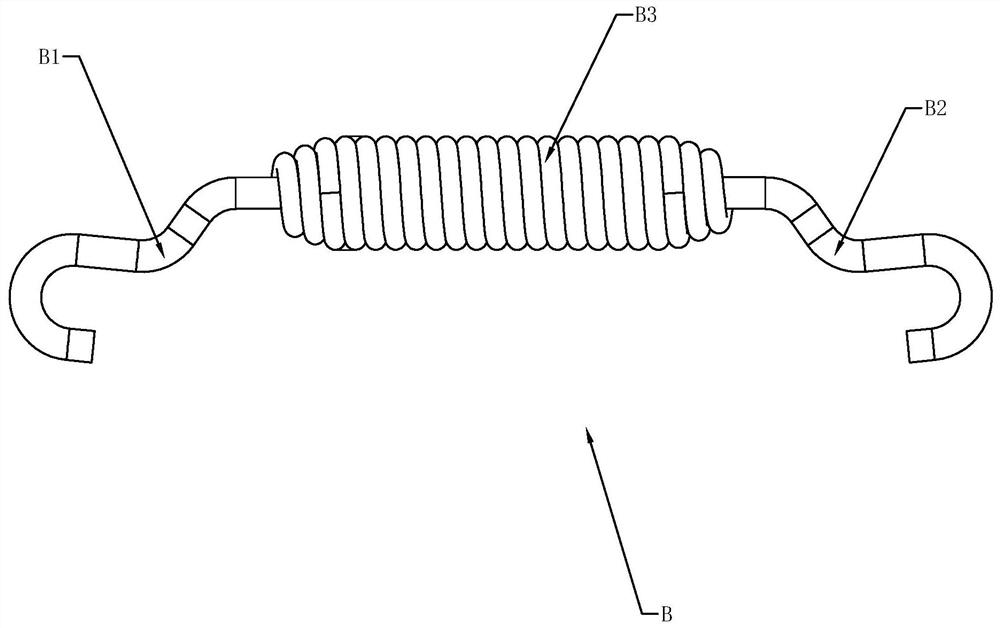

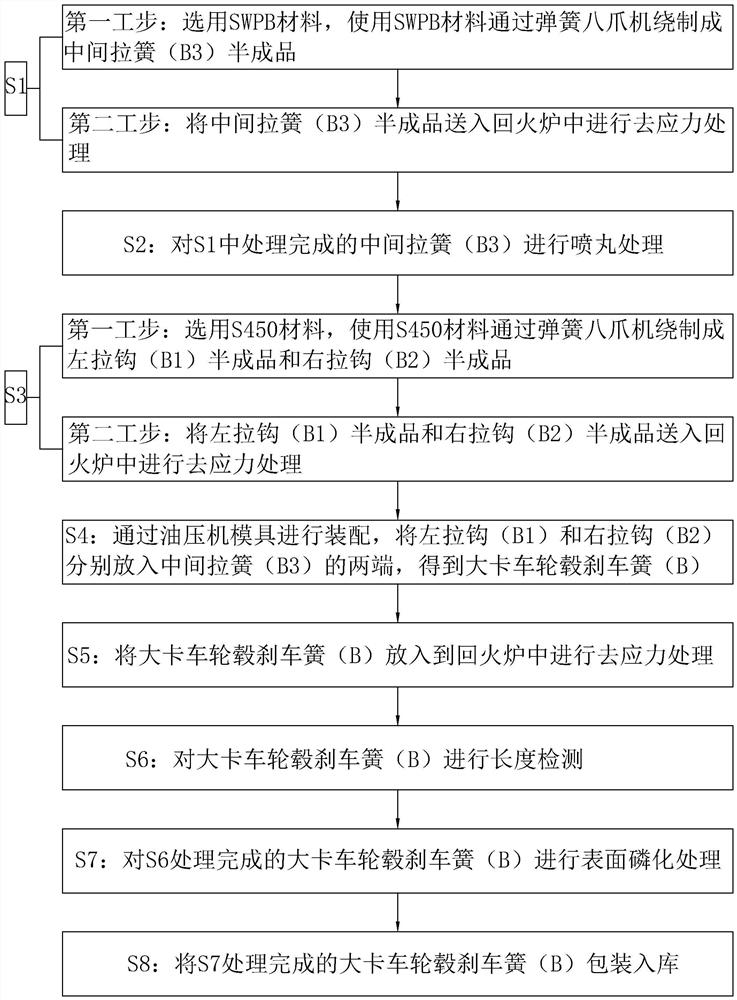

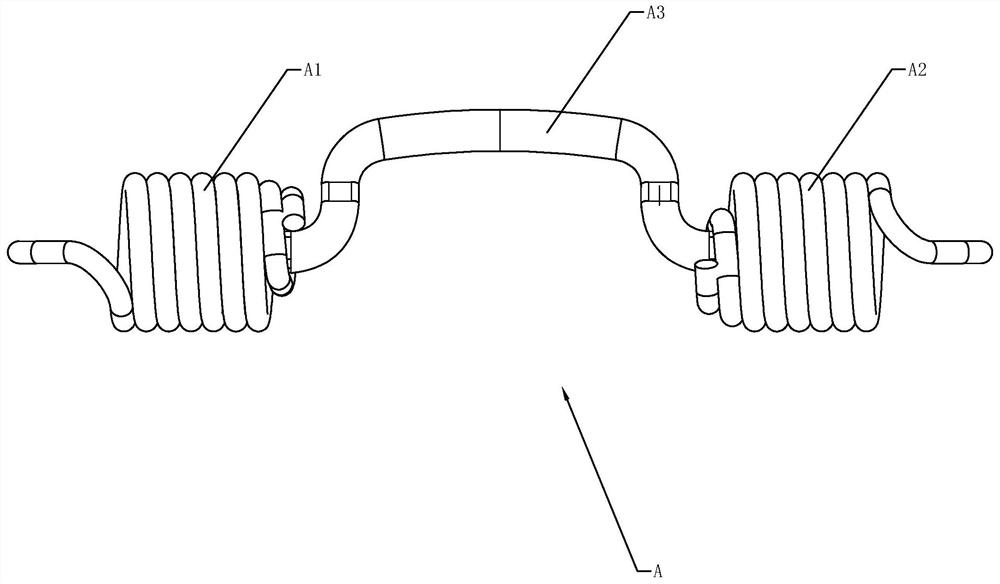

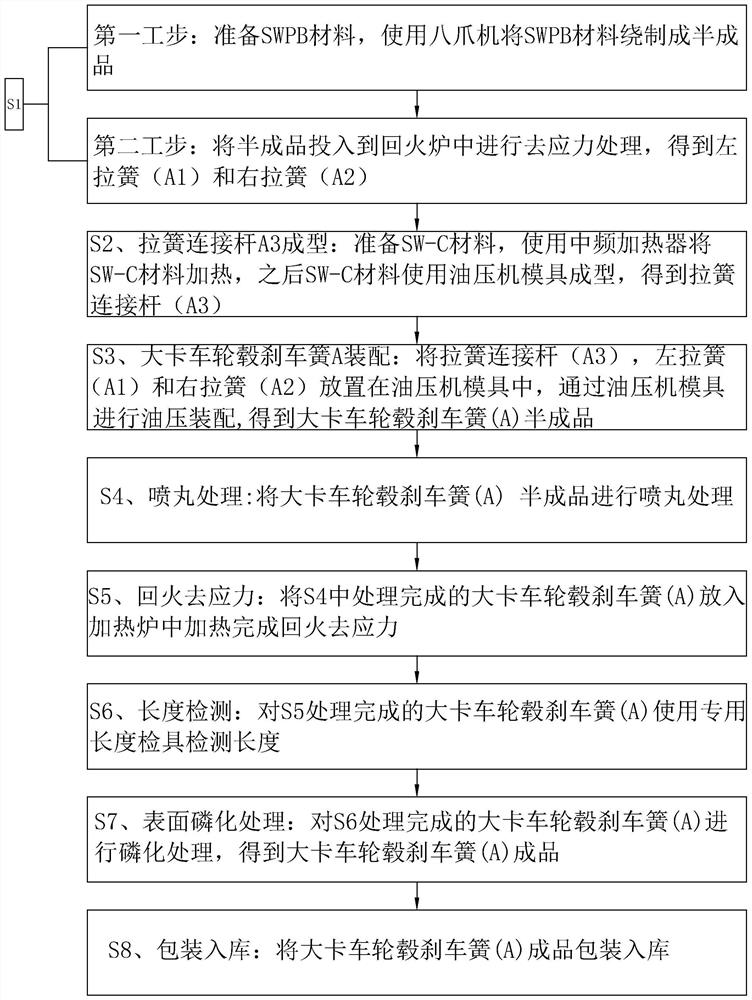

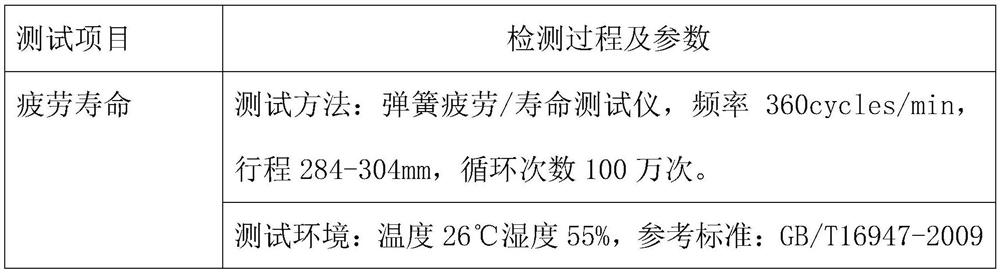

Production technology of big truck hub brake spring B

InactiveCN111702109AExtended service lifeReduce stress concentrationFurnace typesWire springsBrakeMachine

The invention discloses a production technology of a big truck hub brake spring B, and belongs to the field of the production technology of the brake spring. The technical scheme of the production technology is characterized by comprising following steps: S1, a first process step: a middle tension spring semi-finished product is manufactured by a spring eight-claw machine through winding; and a second process step: the middle tension spring semi-finished product is subjected to destressing treatment; S2, the middle tension spring is subjected to shot blasting treatment; S3, a first process step: a left drag hook semi-finished product and a right drag hook semi-finished product are manufactured by the spring eight-claw machine through winding; and a second process step: the left drag hook semi-finished product and the right drag hook semi-finished product are subjected to destressing treatment; S4, stamping assembly is carried out by an oil press die; S5, the big truck brake hub springis placed in a tempering furnace and subjected to destressing treatment; S6, the big truck hub brake spring is subjected to length direction; S7, the big truck hub brake spring processed by S6 is subjected to alramenting treatment; and S8, the big truck hub brake spring is packaged and put in storage. The production technology has the advantage of improving comprehensive performance of the big truck hub brake spring B.

Owner:无锡市金新阳科技有限公司

A steam turbine blade capable of improving impact toughness and its production process

ActiveCN104060191BReduced impact toughnessImprove impact toughnessFurnace typesHeat treatment furnacesMischmetalChemical composition

The invention is a steam turbine blade which can improve the impact toughness. The mass percentage of its chemical composition is: C: 0.13-0.15%, Si: 0.8-0.9%, Mn: 0.5-0.8%, Cr: 14-16%, Ni: 0.1-0.3%, Cu: 1.3-1.5%, Mo: 0.6-1.1%, W: 0.1-0.15%, V: 0.36-0.45%, Nb: 0.5-0.8%, Al: 0.28-0.30%, Ti : 0.16-0.18%, B: 0.08-0.10%, Na: 0.45-0.48%, S≤0.02%, P≤0.03%, rare earth metal: 0.3-0.6%, the balance is Fe; the invention also provides The production process of the steam turbine blade with high toughness, the invention can greatly improve the impact toughness of the blade and improve the service life of the blade.

Owner:南京赛达科技有限公司

Production process of large truck hub brake spring A

InactiveCN111702108AImprove fatigue lifeReduce stress concentrationFurnace typesWire springsBrakeTruck

The invention discloses a production process of a large truck hub brake spring A, and belongs to the field of brake spring production processes. The production process is technically characterized bycomprising the following steps that S1, a left tension spring A1 and a right tension spring A2 are formed; S2, a tension spring connecting rod A3 is formed; S3, the large truck hub brake spring A is assembled, wherein the tension spring connecting rod (A3), the left tension spring (A1) and the right tension spring (A2) are placed in an oil press mold, and oil pressure assembly is carried out through the oil press mold to obtain a semi-finished product of the large truck hub brake spring (A); S4, shot blasting treatment is conducted, and specifically, shot blasting treatment is conducted on thesemi-finished product of the large truck hub brake spring (A); S5, tempering and destressing are conducted, and specifically, the large truck hub brake spring (A) treated in the S4 is put into a tempering furnace to be heated to complete tempering and destressing; S6, length detection is carried out; S7, surface phosphating treatment is carried out; and S8, packaging and warehousing are carried out, and specifically the finished product of the large truck hub brake spring (A) is packaged and warehoused. The production process has the advantage of improving the usability of the large truck hubbrake spring A.

Owner:无锡市金新阳科技有限公司

A steam turbine blade capable of improving water erosion resistance and its production process

ActiveCN104060192BReduced impact toughnessImprove impact toughnessFurnace typesHeat treatment furnacesChemical compositionSteam turbine blade

The invention provides a turbine blade capable of enhancing water corrosion resistance, which comprises the following chemical components: 0.26-0.28% of C, 0.13-0.15% of Si, 0.75-0.77% of Mn, 0.63-0.65% of Ni, 10.5-10.7% of Cr, 0.65-0.67% of Mo, 0.16-0.18% of V, 0.82-0.84% of Sr, 0.15-0.17% of Nb, 0.05-0.07% of Cu, 0.24-0.26% of Al, 0.13-0.15% of Ti, 0.06-0.08% of B, at most 0.03% of S, at most 0.03% of P, 0.12-0.15% of rare-earth metal and the balance of Fe. The production technique can greatly enhance the impact toughness of the blade, enhance the water corrosion resistance and corrosion resistance of the blade and prolong the service life of the blade.

Owner:南京赛达科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com